Technical Contents

Engineering Guide: Liquid Plastic For Molds

Engineering Insight: Liquid Plastic for Molds – The Critical Role of Precision in High-End Manufacturing

In high-performance manufacturing, the use of liquid plastic for molds demands an uncompromising commitment to precision. While the material itself offers flexibility, rapid prototyping advantages, and cost-effective production for complex geometries, its successful application hinges on the accuracy of the mold’s underlying metal structure. At Wuxi Lead Precision Machinery, we understand that even the most advanced liquid plastic formulations cannot compensate for dimensional inaccuracies, surface imperfections, or thermal inconsistencies in the mold base. Our decades of experience in custom metal manufacturing—backed by projects for Olympic-standard equipment and military-grade components—underscore the non-negotiable role of precision engineering in mold performance.

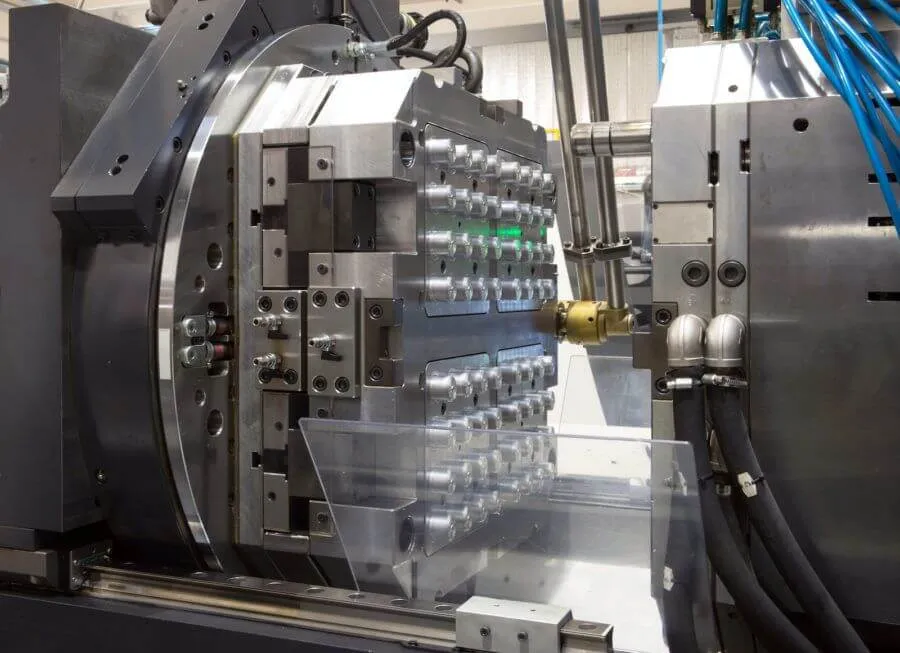

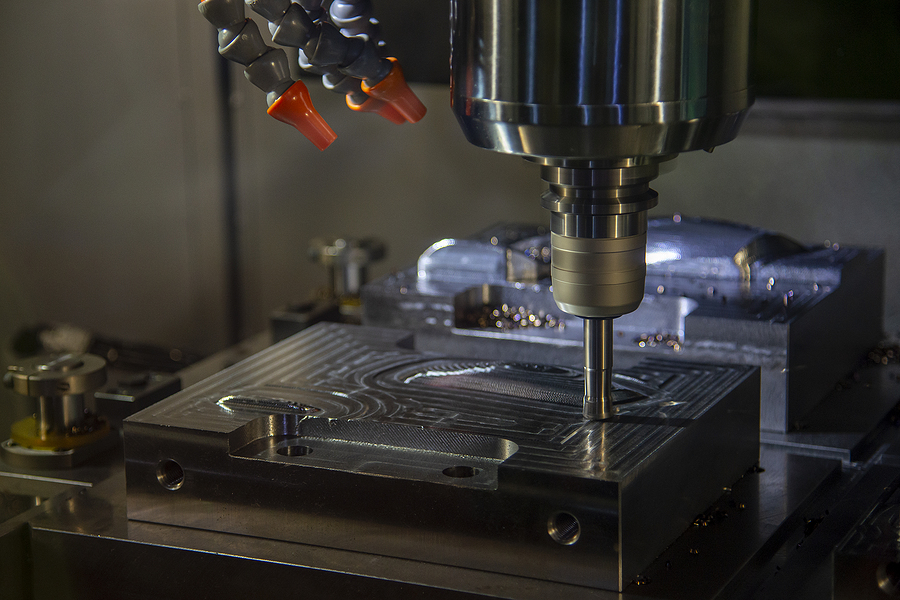

Liquid plastic, typically introduced via injection or casting, conforms exactly to the mold cavity. Any deviation in cavity geometry, surface finish, or thermal regulation directly translates into defects in the final part: warping, flash, incomplete filling, or inconsistent wall thickness. These flaws are unacceptable in industries where performance, safety, and reliability are paramount. Our engineering approach begins with high-tolerance CNC machining of mold cores and cavities, ensuring dimensional accuracy within ±0.002 mm. This level of control is achieved through state-of-the-art 5-axis machining centers, real-time tool monitoring, and rigorous post-process inspection using coordinate measuring machines (CMM).

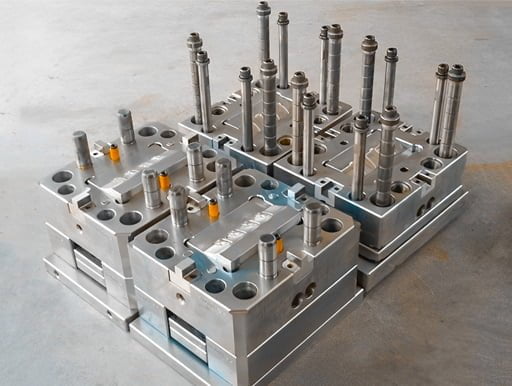

Beyond dimensional accuracy, thermal management is critical. Liquid plastics undergo phase changes during curing, and uneven heat distribution can lead to internal stresses and part failure. We integrate precision-machined cooling channels and use thermal simulation software to optimize heat dissipation, ensuring uniform solidification. This capability has been validated in mission-critical applications, including the production of components used in high-altitude aerospace systems and precision-guided defense mechanisms.

Our experience with Olympic-level projects has further refined our standards. For example, in manufacturing molds for lightweight composite components used in competitive sports equipment, even micrometer-level deviations could affect aerodynamics or structural integrity. These applications demanded not only precision but also repeatability across production runs—a hallmark of our quality control protocols.

Wuxi Lead Precision Machinery combines advanced metallurgy, precision machining, and deep process understanding to deliver molds that ensure flawless replication with liquid plastics. Whether for medical devices, automotive sensors, or defense electronics, our molds are engineered to perform under the most demanding specifications.

Typical Mold Specifications for Liquid Plastic Applications

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish (Ra) | 0.1 – 0.4 µm |

| Material Options | H13, S136, 420 Stainless, P20 |

| Hardness Range | 48 – 54 HRC |

| Cooling Channel Precision | ±0.01 mm positional accuracy |

| Machining Method | 5-Axis CNC, Wire EDM |

| Inspection Standard | ISO 2768-m, ASME Y14.5 |

| Thermal Simulation | ANSYS & Moldflow Integration |

Precision is not a feature—it is the foundation. At Wuxi Lead, we build that foundation to last.

Precision Specs & Tolerances

Technical Capabilities: Precision Mold Manufacturing for Liquid Plastic Processes

Wuxi Lead Precision Machinery delivers mission-critical metal components for liquid plastic molding applications, where dimensional stability and surface integrity directly impact final part quality and production efficiency. Our expertise centers on machining high-performance molds for injection, casting, and rotational molding of liquid plastics, requiring micron-level accuracy to prevent flash, sink marks, or warpage in end products. Leveraging advanced 5-axis CNC milling and turning centers, we achieve complex geometries—internal cooling channels, undercuts, and organic contours—that standard 3-axis systems cannot replicate. This capability ensures optimal thermal management and part ejection in high-cycle plastic molding operations, directly extending mold service life and reducing downtime for global OEMs.

Our 5-axis platform integrates DMG MORI and Makino equipment with high-torque spindles (up to 30,000 RPM) and sub-micron linear encoders. This enables single-setup machining of multi-faceted mold bases, cavities, and cores in hardened tool steels (P20, H13, S136) and aluminum alloys. Simultaneous 5-axis interpolation eliminates manual repositioning errors, critical for maintaining alignment in multi-cavity molds producing identical plastic parts. All machining employs adaptive toolpath strategies that minimize tool deflection during deep cavity milling, preserving surface finish integrity essential for glossy or textured plastic surfaces.

Quality assurance is anchored in Zeiss CONTURA CMM systems with 0.5μm volumetric accuracy, performing full-surface scanning against CAD models per ISO 10360-2 standards. Every mold undergoes first-article inspection, including GD&T validation of critical features like parting lines, ejector pin bores, and gate locations. We verify thermal performance through coordinate-based cooling channel mapping, ensuring uniform heat dissipation to prevent plastic viscosity variations during injection. This closed-loop process guarantees molds meet ASTM D999 or ISO 294 requirements for dimensional repeatability across 100,000+ cycles.

Tolerances reflect our commitment to molding excellence under production conditions:

| Feature Type | Material | Dimensional Tolerance | Surface Finish (Ra) | Application Context |

|---|---|---|---|---|

| Core/Cavity Geometry | Hardened Steel | ±0.005 mm | 0.4–0.8 μm | High-volume optical/medical molds |

| Parting Line Interface | Pre-hard Steel | ±0.003 mm | 0.2–0.4 μm | Zero-flash cosmetic surfaces |

| Cooling Channels | Copper Alloys | ±0.010 mm | 1.6–3.2 μm | Conformal cooling efficiency |

| Ejector Pin Bores | All Tool Steels | H6 (0/-0.006 mm) | 0.8–1.6 μm | Wear-resistant alignment |

These specifications are validated under thermal load simulations replicating 180–350°C plastic processing environments. By controlling tolerances at the micron level, we eliminate costly trial-and-error during mold commissioning, accelerating time-to-market for liquid plastic components in automotive, medical, and consumer electronics sectors. Our process ensures molds consistently produce plastic parts within ±0.05% of nominal dimensions—meeting the stringent demands of automated assembly lines where even minor deviations cause downstream failures. Partner with Wuxi Lead to transform complex liquid plastic molding challenges into reliable, high-yield production.

Material & Finish Options

Material selection is a critical phase in custom metal manufacturing, particularly when producing molds for liquid plastic applications. The performance, durability, and surface quality of a mold directly influence the final plastic part’s dimensional accuracy, surface finish, and production cycle efficiency. At Wuxi Lead Precision Machinery, we specialize in high-precision mold fabrication using premium-grade aluminum, steel, and titanium, each offering distinct advantages depending on production volume, plastic type, and operational demands.

Aluminum alloys are widely used for prototype molds and low-to-medium volume production runs. Their excellent thermal conductivity allows for faster cooling cycles, reducing part ejection time and increasing throughput. Aluminum is also easier to machine, enabling complex geometries with tight tolerances. However, its lower hardness compared to steel makes it less suitable for abrasive plastics or long production runs. For enhanced wear resistance and corrosion protection, we recommend hard anodizing, which creates a durable ceramic-like surface layer while maintaining dimensional stability.

Steel, particularly tool steels such as P20, H13, and S136, is the standard for high-volume liquid plastic molding. These steels offer superior hardness, wear resistance, and longevity, capable of withstanding thousands to millions of cycles. Stainless variants like S136 are ideal for applications requiring high corrosion resistance, especially when processing PVC or other corrosive resins. While steel molds have longer lead times and higher machining costs, their extended service life and dimensional stability deliver lower cost-per-part in large-scale manufacturing.

Titanium, though less common in mold construction, is gaining traction in specialized applications requiring extreme strength-to-weight ratios and exceptional corrosion resistance. It is particularly beneficial in aerospace and medical molding where weight reduction and biocompatibility are critical. Titanium’s high cost and challenging machinability limit its use to niche, high-performance molds, but its resistance to thermal deformation and aggressive chemical environments offers unique advantages in demanding conditions.

Surface finishing plays a vital role in mold performance. Anodizing, primarily applied to aluminum, enhances surface hardness and wear resistance while allowing for decorative or functional color coding. Different anodizing grades—standard, hard, and precision hard—anodizing—offer varying coating thicknesses and properties. For steel molds, alternatives such as chrome plating, polishing, or PVD coatings are typically used to improve release properties and prevent corrosion.

Below is a comparative overview of key material properties for mold applications:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Common Finishes | Best Use Case |

|---|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | 10,000 – 100,000 | Hard Anodizing, Polishing | Prototypes, low-volume production |

| P20 Steel | 28–32 | 30 | 100,000 – 500,000 | Chrome Plating, Polishing | Medium to high-volume production |

| H13 Steel | 48–52 | 35 | 500,000 – 1,000,000 | Nitriding, PVD Coating | High-stress, high-temp molding |

| S136 Steel | 50–54 | 25 | 1,000,000+ | Mirror Polish, Coating | Corrosive environments |

| Titanium Gr5 | 35–40 (surface) | 7 | 50,000 – 200,000 | PVD, Anodizing (limited) | Aerospace, medical applications |

Selecting the optimal material and finish requires a thorough understanding of your production goals, resin characteristics, and quality requirements. Wuxi Lead Precision Machinery provides expert consultation and precision manufacturing to ensure your molds meet the highest industrial standards.

Manufacturing Process & QC

Integrated Production Process: From Digital Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our production process for custom metal components leverages liquid plastic molding solely within the prototyping phase to de-risk final tooling. This strategic approach ensures seamless transition from concept to flawless mass production. The journey begins with rigorous digital design engineering. Our team utilizes advanced CAD/CAM software to develop 3D models, incorporating critical manufacturability analysis (DFM) to optimize wall thickness, draft angles, and material flow. Finite element analysis (FEA) simulates thermal and structural behavior under operational loads, preemptively resolving potential weaknesses. Client collaboration is embedded at this stage, ensuring alignment with functional requirements and regulatory standards before physical work commences.

Prototyping employs liquid plastic—typically silicone or polyurethane—to create rapid, cost-effective molds for initial part validation. These molds replicate the geometry of final steel tooling but allow swift iteration. We pour liquid resin into the prototype mold, cure under controlled conditions, and extract functional samples within 72 hours. This phase validates form, fit, and function, identifies design flaws, and permits material testing without committing to expensive metal tooling. Crucially, dimensional inspection against CAD data using coordinate measuring machines (CMM) confirms accuracy to ±0.05 mm, ensuring prototype fidelity directly informs mass production readiness.

Mass production shifts exclusively to precision CNC-machined steel molds, manufactured in-house on our HAAS and DMG MORI systems. Multi-axis machining achieves micron-level tolerances, while hardened tool steel ensures longevity exceeding 500,000 cycles. Every production run undergoes real-time statistical process control (SPC), with automated in-line vision systems and CMM spot checks monitoring critical dimensions. Our zero-defect protocol mandates 100% first-article inspection and continuous process validation against the specifications below. This closed-loop system—rooted in ISO 9001-certified workflows—eliminates deviations before parts reach your assembly line, guaranteeing yield rates above 99.8%.

Key production specifications underpinning zero-defect outcomes:

| Parameter | Specification | Validation Method |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (critical features) | CMM, Optical Comparator |

| Surface Finish | Ra 0.2–0.8 µm (as-machined) | Profilometer, Visual Inspection |

| Material Hardness | HRC 48–52 (P20 tool steel) | Rockwell Hardness Tester |

| Production Yield | ≥99.8% | SPC Charts, Real-Time Monitoring |

| Cycle Time Accuracy | ±0.5 seconds | PLC Data Logging |

This integrated methodology—where liquid plastic prototyping de-risks design, and CNC metal manufacturing delivers uncompromising precision—ensures your components perform flawlessly in mission-critical applications. Wuxi Lead transforms complex requirements into defect-free reality, accelerating your time-to-market while eliminating costly rework.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Liquid Plastic Mold Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, custom-engineered metal components designed to meet the exacting demands of modern manufacturing. As a trusted leader in precision CNC machining and mold fabrication, we extend our expertise to advanced applications involving liquid plastic molding processes. Our engineering team collaborates closely with clients to develop robust, durable, and dimensionally accurate metal molds that ensure consistent replication, thermal stability, and extended service life when used with liquid plastic materials.

Liquid plastic molding requires molds with exceptional surface finish, tight tolerances, and resistance to thermal cycling. At Lead Precision, we manufacture molds from premium-grade tool steels and specialty alloys, precision-machined using 5-axis CNC technology and finished with advanced surface treatments. Our molds are engineered to support injection, compression, and transfer molding techniques, accommodating a wide range of liquid silicone rubbers (LSR), polyurethanes, and epoxy resins. Whether you’re producing medical devices, automotive seals, consumer electronics components, or industrial gaskets, our molds deliver repeatable accuracy and superior part quality.

We understand that every application is unique. That’s why we offer fully customized mold design and fabrication services, integrating your material specifications, part geometry, and production volume requirements into a tailored manufacturing solution. Our in-house design validation process includes mold flow analysis, thermal simulation, and prototype testing to ensure optimal performance before full-scale production begins.

Our commitment to quality is reinforced by ISO 9001:2015 certification, state-of-the-art metrology equipment, and rigorous process controls throughout manufacturing. From initial concept to final delivery, we maintain clear communication and full transparency, ensuring your project stays on time, within budget, and to the highest technical standards.

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally with deep expertise in high-precision metal components for advanced molding applications. We combine engineering excellence, cutting-edge technology, and responsive customer service to support your innovation and growth.

For technical inquiries or to discuss your liquid plastic mold requirements, contact us today at [email protected]. Let our team help you achieve superior mold performance and production efficiency.

| Specification | Detail |

|---|---|

| Material Options | P20, 718H, NAK80, S136, H13, Stainless Steel, Aluminum Alloys |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished, EDM, or coated) |

| Maximum Mold Size | 1200 x 800 x 600 mm |

| Machining Technology | 3-axis, 4-axis, 5-axis CNC, Wire EDM, High-Speed Milling |

| Applications | Liquid Silicone Rubber (LSR), Polyurethane, Epoxy Molding |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Report (FAIR) |

| Lead Time | 15–30 days (based on complexity and size) |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.