Technical Contents

Engineering Guide: Liquid Moulding Rubber

Engineering Insight: Liquid Moulding Rubber and the Imperative of Precision in Custom Metal Manufacturing

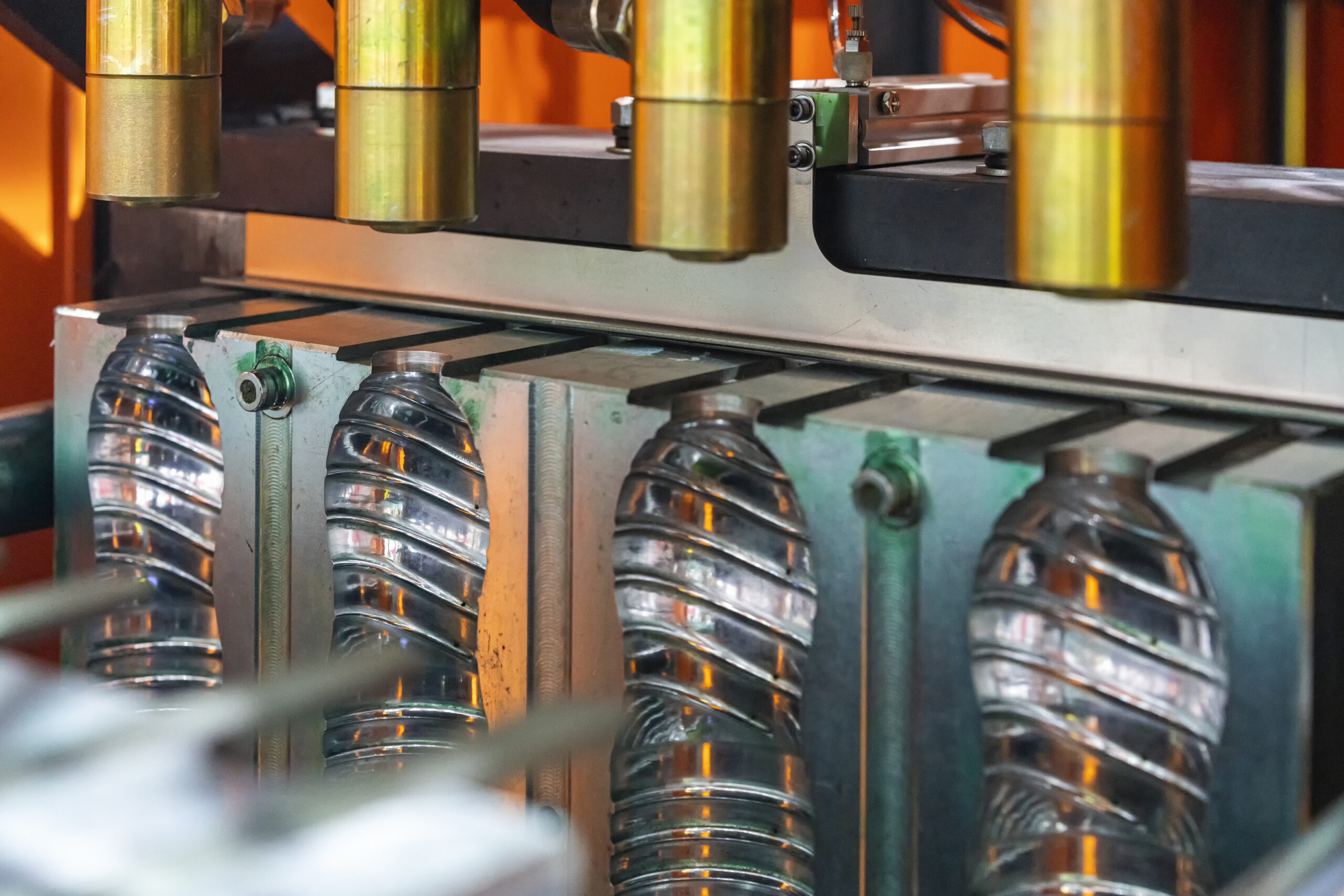

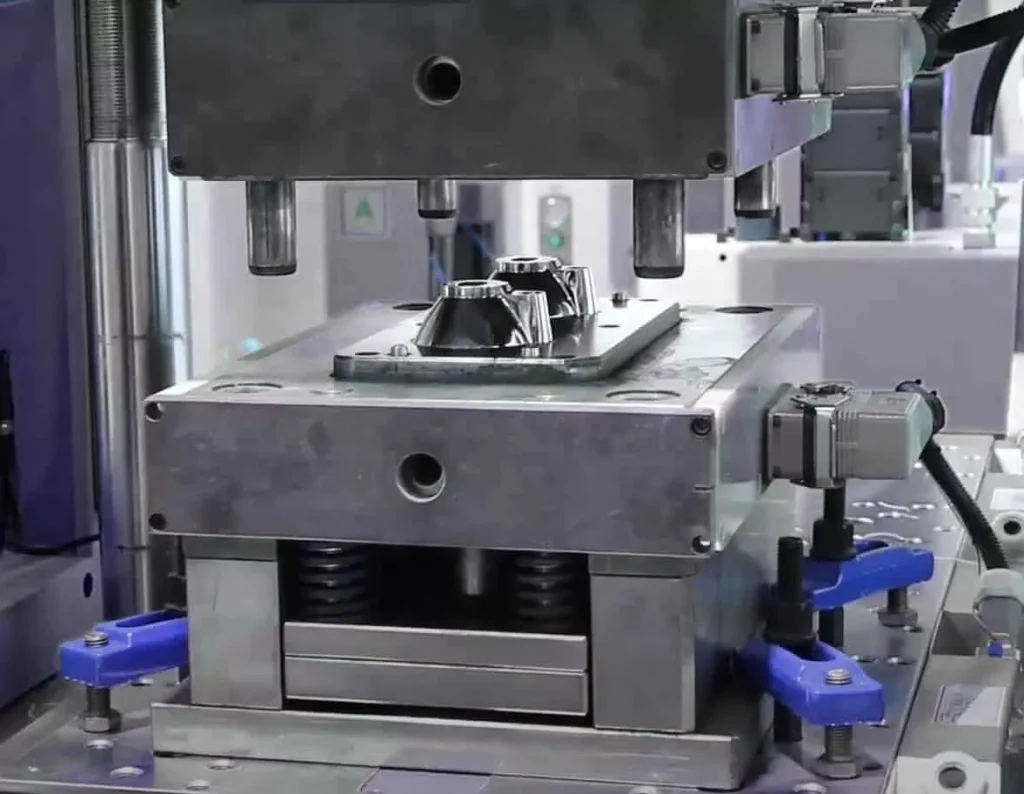

In the realm of advanced elastomer processing, liquid moulding rubber (LMR) stands as a cornerstone technology for producing high-integrity, dimensionally stable components across aerospace, defense, medical, and high-performance automotive sectors. Unlike traditional rubber injection methods, LMR leverages low-viscosity silicone or synthetic compounds that cure rapidly under heat and pressure, enabling intricate part geometries with minimal flash and exceptional repeatability. However, the success of any LMR operation is fundamentally contingent upon the precision of the metal tooling that shapes it.

At Wuxi Lead Precision Machinery, we recognize that the performance of liquid moulding rubber is only as reliable as the tooling that contains it. Even micron-level deviations in cavity dimensions, surface finish, or thermal management can result in part warpage, incomplete fills, or inconsistent cross-linking—defects that are unacceptable in mission-critical applications. This is why our engineering approach integrates metrology-grade design, CNC-machined steel or aluminum tooling, and rigorous thermal simulation to ensure uniform curing and zero tolerance drift across production cycles.

Our expertise in precision metal manufacturing is not theoretical. We have engineered and produced tooling systems deployed in Olympic-grade sporting equipment and certified components for military-grade sealing applications, where failure is not an option. These projects demanded not only compliance with ISO 9001 and AS9100 standards but also the ability to maintain tolerances within ±0.005 mm under repeated thermal cycling. Our experience in such high-stakes environments has refined our understanding of material behavior, thermal expansion compensation, and cavity balance—factors that directly influence LMR part integrity.

Precision extends beyond the tool’s geometry. Surface finish, gate design, venting strategy, and cooling channel placement are all engineered with the same rigor as the core cavity. A polished Ra < 0.2 µm finish, for example, ensures clean demolding and prevents surface adhesion, while optimized runner systems minimize material waste and maximize flow consistency. At Lead Precision, every LMR tool undergoes in-house validation using coordinate measuring machines (CMM) and mold-flow analysis software to simulate performance before the first shot is cast.

The following table outlines key specifications and capabilities relevant to our liquid moulding rubber tooling solutions:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.005 mm |

| Surface Finish (Ra) | 0.05 – 0.4 µm (polished to mirror grade) |

| Tooling Materials | H13, P20, 718H, Stainless Steel, Aluminum |

| Maximum Mold Size | 1200 x 800 x 700 mm |

| Thermal Control | Integrated conformal cooling channels |

| Production Lifespan | Up to 1 million cycles (material dependent) |

| Standards Compliance | ISO 9001, AS9100, GD&T certified |

At Wuxi Lead Precision Machinery, we do not manufacture molds—we engineer performance. Our legacy in supporting Olympic and military-grade applications is a testament to our unwavering commitment to precision, reliability, and technical excellence in every custom metal solution we deliver.

Precision Specs & Tolerances

Technical Capabilities for Liquid Moulding Rubber Tooling

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal components essential for high-performance liquid moulding rubber (LMR) applications. Our core strength lies in advanced 5-axis CNC machining centers, specifically configured to produce complex, high-integrity molds, inserts, and fixtures required for demanding LMR processes. These machines utilize simultaneous multi-axis interpolation to achieve intricate geometries, seamless undercuts, and superior surface finishes critical for preventing flash and ensuring clean part release in rubber molding. We machine a wide spectrum of tooling alloys, including pre-hardened P20, H13, and specialized stainless steels, with meticulous attention to thermal stability and wear resistance—factors paramount for maintaining dimensional consistency across thousands of molding cycles under heat and pressure.

Rigorous quality control is embedded at every stage. All critical features undergo comprehensive verification using state-of-the-art Coordinate Measuring Machines (CMM). Our CMM inspection protocols follow ISO 10360 standards, providing full 3D geometric dimensioning and tolerancing (GD&T) validation against client CAD models. This data-driven approach ensures absolute conformity to specifications before mold release, eliminating costly trial-and-error during client production ramp-up. First-article inspection reports are standard, offering complete traceability and confidence in part integrity. Our engineers collaborate closely with clients during the design-for-manufacturability phase, leveraging CNC capabilities to optimize mold flow paths, venting systems, and cooling channels specifically for LMR material behavior and cycle time efficiency.

The table below outlines our standard and achievable tolerance capabilities for LMR tooling components, reflecting the precision delivered through our integrated CNC and QC systems. These values represent typical production capabilities for features machined in tool steel under controlled environmental conditions.

| Feature Type | Standard Production Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) | CMM |

| Geometric Form (Flatness, Roundness) | 0.015 mm (0.0006″) | 0.008 mm (0.0003″) | CMM / Optical Comparator |

| Positional Tolerance | ±0.012 mm (±0.0005″) | ±0.006 mm (±0.00025″) | CMM |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 0.4 µm (16 µin) | Profilometer |

| Critical Mold Interfaces | ±0.008 mm (±0.0003″) | ±0.003 mm (±0.0001″) | CMM / Air Gaging |

This precision foundation directly translates to superior mold performance in the LMR press. Tighter tolerances minimize flash generation, reduce material waste, extend mold life by preventing galling, and ensure consistent part geometry critical for sealing surfaces and functional components. Wuxi Lead’s combination of 5-axis CNC mastery, systematic CMM validation, and deep understanding of LMR process demands guarantees tooling that meets the exacting standards of aerospace, medical, and automotive sectors. We engineer for zero-defect delivery, enabling our clients’ production efficiency and product reliability from the first shot. Partner with us for tooling where micron-level accuracy is non-negotiable.

Material & Finish Options

Material Selection for Liquid Moulding Rubber Tooling: Aluminum, Steel, and Titanium

In high-precision liquid moulding rubber applications, the selection of tooling material is critical to ensuring dimensional stability, thermal performance, and production longevity. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the exacting demands of rubber molding processes. The choice between aluminum, steel, and titanium depends on production volume, cycle time, part complexity, and required surface finish. Each material offers distinct mechanical and thermal properties that influence mold performance and final product quality.

Aluminum is widely used for prototyping and low-to-medium volume production due to its excellent thermal conductivity and machinability. Its lightweight nature allows for faster heating and cooling cycles, which enhances productivity in liquid silicone rubber (LSR) and other rubber molding operations. However, aluminum is less wear-resistant than steel and may not be suitable for extended production runs exceeding 100,000 cycles. When properly treated with hard anodizing, aluminum molds can achieve improved surface hardness and corrosion resistance, extending service life and maintaining dimensional accuracy.

Steel, particularly tool steel grades such as H13 and P20, is the preferred choice for high-volume production. It offers superior hardness, wear resistance, and thermal stability, making it ideal for molds subjected to repeated thermal cycling and mechanical stress. While steel has lower thermal conductivity than aluminum, its durability ensures consistent part quality over millions of cycles. Steel molds are often used in automotive, medical, and industrial rubber component manufacturing where tight tolerances and long service life are paramount.

Titanium is less common but offers a unique combination of high strength-to-density ratio and excellent corrosion resistance. Though more expensive and challenging to machine, titanium is suitable for specialized applications requiring extreme durability in corrosive environments or where weight reduction is critical. Its use in standard rubber molding tooling is limited but growing in niche aerospace and defense sectors.

Surface finish, particularly anodizing, plays a vital role in mold performance. Hard anodizing aluminum increases surface hardness up to 60 HRC, reduces friction, and improves release characteristics—critical for clean demolding of rubber parts. The anodized layer is electrically insulating and highly resistant to wear and chemical attack, enhancing both part quality and maintenance intervals.

Below is a comparative overview of key material properties relevant to liquid moulding rubber tooling:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (Cycles) | Corrosion Resistance | Recommended Use Case |

|---|---|---|---|---|---|

| Aluminum (6061-T6) | 15–20 (up to 60 with hard anodizing) | 167 | 10,000–100,000 | Moderate (improved with anodizing) | Prototyping, medium-volume LSR |

| H13 Steel | 48–52 | 36 | 500,000–1,000,000+ | Good | High-volume production, complex molds |

| P20 Steel | 28–32 | 28 | 300,000–500,000 | Moderate | Medium-to-high volume, pre-hardened molds |

| Titanium (Grade 5) | 35–40 | 7 | 1,000,000+ | Excellent | Specialized, corrosive environments |

Selecting the appropriate material and finish ensures optimal performance, cost-efficiency, and reliability in liquid moulding rubber applications. Wuxi Lead Precision Machinery provides expert consultation and precision manufacturing to match your production needs with the ideal tooling solution.

Manufacturing Process & QC

Precision Metal Tooling for Liquid Moulding Rubber: The Zero Defects Production Pathway

At Wuxi Lead Precision Machinery, we engineer metal tooling systems that form the critical foundation for high-integrity liquid moulding rubber (LMR) components. Our process transcends standard manufacturing by embedding Zero Defects methodology from initial concept through serial production. This ensures your rubber parts achieve exacting dimensional stability, material consistency, and functional reliability—non-negotiables in aerospace, medical, and automotive applications.

The journey begins with collaborative Design Engineering. Our team integrates your LMR material specifications with finite element analysis (FEA) to simulate flow dynamics, curing behavior, and thermal management within the metal cavity. Critical to Zero Defects is preemptive failure mode analysis (FMEA), identifying potential flash lines, knit marks, or shrinkage zones. We optimize gate locations, venting, and cooling channel geometry in the metal tool using 3D CAD/CAM, ensuring uniform pressure distribution and eliminating cure inconsistencies before metal cutting commences.

Prototyping transforms validated designs into physical proof. Utilizing CNC-machined aluminum or steel prototype tools, we produce initial rubber batches under production-equivalent conditions. Each prototype undergoes rigorous metrology-grade CMM validation against CAD nominal data, with emphasis on critical-to-function dimensions and surface finish. Material cross-sections are analyzed for porosity and adhesion. This phase is iterative; deviations trigger immediate tool geometry corrections, not rubber formulation adjustments. Only when dimensional repeatability (Cpk >1.67) and material integrity are confirmed does the tool advance.

Mass Production leverages hardened steel production tools manufactured to micron-level tolerances on our multi-axis machining centers. Real-time process control is non-optional. In-mold pressure and temperature sensors feed data to our SPC system, automatically adjusting injection parameters to maintain ±0.5°C thermal stability and ±0.1MPa pressure consistency. Every cavity is individually monitored, with automated vision inspection scanning for surface defects at line speed. Full traceability links each rubber part to its specific tool cavity, machine parameters, and raw material lot. Statistical process control charts are audited hourly, ensuring process capability (Ppk >1.5) is sustained. Defective units are physically isolated before exiting the cell—zero escapes.

Our commitment to Zero Defects is quantifiable through the precision of the metal tooling we deliver. The table below details the baseline specifications achievable for LMR production tools:

| Specification Category | Performance Standard | Validation Method |

|---|---|---|

| Dimensional Tolerance | ±0.02 mm | CMM with 0.002 mm uncertainty |

| Surface Finish (Cavity) | Ra 0.2 µm | Profilometer measurement |

| Thermal Uniformity | ΔT ≤ ±1.0°C across cavity | Infrared thermal mapping |

| Process Capability (Cpk) | ≥1.67 during validation | SPC analysis of 30 consecutive shots |

| Tool Life Expectancy | 500,000+ cycles | Accelerated life testing per ISO 2819 |

This disciplined convergence of precision metal manufacturing and embedded quality systems guarantees LMR components that perform flawlessly in your assembly. Wuxi Lead does not merely supply tooling—we deliver defect-proof production capability. Contact our engineering team to initiate a Zero Defects pathway for your next liquid moulding rubber application.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision Metal Components in Liquid Moulding Rubber Applications

When engineering demands flawless integration of metal and high-performance elastomers, Wuxi Lead Precision Machinery stands as your trusted manufacturing partner. Specializing in custom metal components designed for liquid moulding rubber (LMR) systems, we deliver engineered solutions that meet the exacting standards of automotive, medical, industrial automation, and advanced electronics sectors. Our expertise lies in producing precision-turned, milled, and stamped metal inserts, cores, and housings that serve as critical structural elements within rubber overmoulding processes.

Liquid moulding rubber requires metal components with exceptional dimensional accuracy, surface finish, and material compatibility to ensure adhesion, sealing integrity, and long-term performance. At Lead Precision, we understand the interplay between metal substrate geometry and rubber flow dynamics. Our engineering team collaborates closely with clients during the design phase to optimize part geometry, draft angles, undercuts, and surface textures—ensuring seamless integration into LMR tooling and consistent production outcomes.

Backed by ISO 9001-certified manufacturing processes and state-of-the-art CNC machining centers, we produce components from a wide range of materials including stainless steel, aluminum, brass, and specialty alloys. Our in-house capabilities span from prototyping to high-volume production, supported by rigorous quality control protocols including CMM inspection, surface roughness testing, and first-article reporting. Whether you require tight-tolerance metal inserts for medical-grade silicone moulding or robust housings for automotive sealing systems, we deliver reliability at scale.

We pride ourselves on being more than a supplier—we are a technical partner committed to your product’s success. From material selection guidance to design-for-manufacturability feedback, our team ensures your components are not only manufacturable but optimized for performance, cost-efficiency, and repeatability.

Explore how Wuxi Lead Precision Machinery can support your liquid moulding rubber projects with precision, consistency, and engineering excellence.

| Specification | Details |

|---|---|

| Material Options | Stainless Steel (303, 304, 316), Aluminum (6061, 7075), Brass (C3604), Titanium, Inconel |

| Tolerances | ±0.005 mm (precision grinding), ±0.02 mm (standard CNC) |

| Surface Finish | Ra 0.2–3.2 μm (custom finishes available) |

| Max Part Size | Ø300 mm x 400 mm (turning/milling) |

| Production Capacity | Low-volume prototyping to high-volume series (up to 500,000 pcs/month) |

| Secondary Operations | Passivation, anodizing, plating, laser marking, heat treatment |

| Quality Standards | ISO 9001:2015, RoHS compliant, full traceability, FAI reports |

Contact us today at [email protected] to discuss your liquid moulding rubber application requirements. Let Wuxi Lead Precision Machinery be the foundation of your next high-performance component.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.