Technical Contents

Engineering Guide: Liquid Molding

Engineering Insight Precision in Liquid Molding Systems

Liquid molding processes like resin transfer molding (RTM) and structural reaction injection molding (SRIM) demand uncompromising precision to achieve structural integrity and dimensional accuracy in high-performance composite components. Minute deviations in pressure control, temperature stability, or material flow dynamics directly propagate into part porosity, fiber misalignment, or inconsistent wall thickness—defects catastrophic in aerospace, defense, or elite sporting applications. At Wuxi Lead Precision Machinery, we engineer liquid molding systems where micron-level tolerances are non-negotiable. Our CNC-machined platens, servo-hydraulic pressure circuits, and closed-loop thermal management systems eliminate the variability that plagues standard equipment, ensuring repeatable part quality batch after batch.

Precision extends beyond hardware to process intelligence. Our systems integrate real-time cavity pressure sensors and adaptive algorithm control, dynamically adjusting injection parameters to compensate for resin viscosity shifts or fiber bed permeability variations. This capability is proven in mission-critical deployments: components molded on Lead Precision systems secured gold medals in carbon-fiber racing shells at the Tokyo Olympics, where hull symmetry directly impacted hydrodynamic efficiency. Similarly, our military-grade molding platforms produce armored vehicle substructures meeting stringent MIL-STD-810G vibration and impact resistance standards—proof that our tolerances withstand battlefield extremes.

The consequences of inadequate precision are quantifiable. Industry data shows a 3% pressure fluctuation can increase void content by 15%, directly reducing fatigue life. Temperature gradients exceeding ±2°C during cure induce residual stresses that compromise dimensional stability in large aerostructures. Lead Precision’s engineering mitigates these risks through foundational design choices. Below are critical performance specifications validated across our client installations:

| Parameter | Lead Precision Standard | Industry Typical | Impact of Precision Gain |

|---|---|---|---|

| Pressure Control | ±0.25% of full scale | ±1.5% | Eliminates knit-line defects in complex geometries |

| Temperature Uniformity | ±0.5°C across platen | ±3.0°C | Prevents premature resin gelation and warpage |

| Cycle Time Repeatability | ±0.8 seconds | ±5.0 seconds | Ensures consistent cross-linking density |

| Clamp Force Accuracy | ±0.3% | ±2.0% | Maintains cavity seal integrity at 200+ bar |

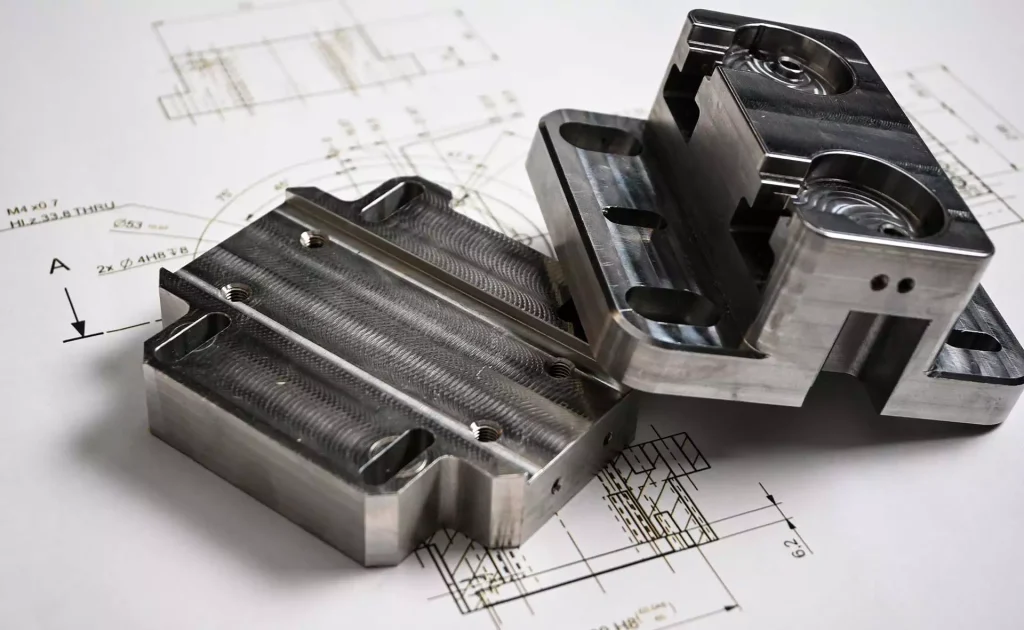

This level of control originates in our Wuxi manufacturing facility, where aerospace-grade CNC machining centers produce critical hydraulic manifolds and platen surfaces to IT6 tolerances. Every system undergoes 72-hour endurance validation under simulated production loads before shipment—no component leaves our facility without proving its mettle. For OEMs where part failure equates to operational catastrophe, precision isn’t a specification; it’s the bedrock of trust. When Olympic athletes rely on your composite structures or defense primes certify your process, the margin for error vanishes. Lead Precision builds that margin into every system, ensuring liquid molding delivers not just parts, but performance guarantees.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for industries where performance, reliability, and dimensional accuracy are non-negotiable. Our expertise in liquid molding support structures and tooling systems is backed by state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional surface finish and tight tolerances. These capabilities are essential for clients in aerospace, medical, energy, and advanced industrial sectors, where liquid molding processes demand perfectly engineered metal components to ensure process consistency and part integrity.

Our 5-axis CNC machining centers provide simultaneous multi-axis movement, allowing for intricate contouring and the production of highly complex parts in a single setup. This reduces cumulative error, improves repeatability, and significantly enhances throughput. Equipped with high-speed spindles and automated tool changers, our machines maintain precision across large production runs and small-batch prototyping alike. Materials commonly processed include aluminum alloys, stainless steels, titanium, and specialty alloys, all machined to meet the stringent requirements of liquid molding applications such as mold inserts, sealing surfaces, and support frames.

To ensure every component meets exact specifications, we implement a rigorous quality control protocol centered around CMM (Coordinate Measuring Machine) inspection. Our CMM systems perform full geometric and dimensional analysis, validating critical features such as flatness, concentricity, and positional tolerances. Each part undergoes first-article inspection for production launches and statistical process control (SPC) monitoring during ongoing runs. Inspection reports are fully traceable and provided with every shipment, ensuring compliance with ISO 9001 standards and customer-specific quality requirements.

The following table outlines the standard precision tolerances achievable across our machining processes:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Hole Diameter | ±0.015 mm | ±0.008 mm |

| Positional Tolerance | ±0.020 mm | ±0.005 mm |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Finish (Ra) | 3.2 µm | 0.8 µm |

| Angular Tolerance | ±0.05° | ±0.01° |

All tolerances are verified under controlled environmental conditions to eliminate thermal drift effects. Our engineering team collaborates directly with clients during the design phase to optimize manufacturability, suggest material improvements, and ensure that final components integrate seamlessly into liquid molding systems. With a focus on precision, repeatability, and technical partnership, Wuxi Lead Precision Machinery sets the benchmark for custom metal manufacturing in high-demand applications.

Material & Finish Options

Material Selection for Liquid Molding Applications

Material selection is a critical engineering decision in liquid molding processes, directly impacting part performance, longevity, and cost-effectiveness. At Wuxi Lead Precision Machinery, our precision molding capabilities demand materials that withstand high pressure, thermal cycling, and chemical exposure while maintaining dimensional stability. Aluminum, steel, and titanium represent the primary high-performance alloys for demanding applications, each offering distinct advantages based on operational requirements.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are favored for lightweight structural components requiring excellent thermal conductivity and moderate strength. These grades demonstrate superior mold flow characteristics during liquid molding, enabling complex geometries with tight tolerances. Aluminum’s natural corrosion resistance is adequate for many environments but is significantly enhanced through post-molding finishing processes. Its lower density reduces final part weight, a crucial factor in aerospace and transportation sectors.

Stainless steel, especially 316L and 17-4 PH grades, delivers exceptional strength, hardness, and resistance to high temperatures and corrosive media. These properties make steel ideal for high-pressure hydraulic components, chemical processing equipment, and marine applications where long-term structural integrity under stress is non-negotiable. While denser than aluminum, steel provides unmatched wear resistance and maintains mechanical properties across extreme temperature ranges encountered in demanding service conditions.

Titanium Grade 5 (Ti-6Al-4V) is the material of choice for the most severe environments, offering an unparalleled strength-to-weight ratio and exceptional resistance to corrosion, including saltwater and chlorine exposure. Its biocompatibility and non-magnetic properties are essential for medical implants and marine instrumentation. Titanium’s high melting point suits it for high-temperature applications, though its cost and machining complexity necessitate careful evaluation against performance requirements. Our liquid molding process ensures optimal consolidation of titanium powders for critical aerospace and defense components.

Surface finishing, particularly anodizing for aluminum, is integral to part functionality in liquid molding. Anodizing creates a hard, wear-resistant oxide layer that seals the porous surface inherent to molded aluminum, drastically improving corrosion resistance and providing an excellent base for adhesives or paints. Type II (sulfuric acid) anodizing offers good corrosion protection and dyeing capability for identification, while Type III (hardcoat) anodizing delivers maximum surface hardness and abrasion resistance for high-wear applications. Proper anodizing parameters are precisely controlled to maintain dimensional accuracy after molding.

Select the optimal material based on the specific operational environment, mechanical loads, weight constraints, and lifecycle cost analysis. The following table summarizes key properties for common molding alloys:

| Material Grade | Density (g/cm³) | Tensile Strength (MPa) | Key Corrosion Resistance | Mold Release Compatibility |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.70 | 310 | Good (atmospheric, water); Enhanced by Anodizing | Excellent |

| Stainless Steel 316L | 8.00 | 570 | Excellent (chemicals, saltwater) | Good (requires specialized release) |

| Titanium Ti-6Al-4V | 4.43 | 900 | Exceptional (all environments, including saltwater) | Moderate (high-temp release agents needed) |

Wuxi Lead Precision Machinery provides comprehensive material and finish consultation to ensure your liquid molded components meet the highest standards of performance and reliability. Contact our engineering team for application-specific recommendations.

Manufacturing Process & QC

Design: Precision Engineering for Liquid Molding Excellence

At Wuxi Lead Precision Machinery, the liquid molding production process begins with a comprehensive design phase that integrates engineering rigor with advanced simulation technologies. Our engineering team collaborates closely with clients to translate conceptual requirements into manufacturable designs optimized for flow dynamics, thermal distribution, and structural integrity. Using industry-leading CAD and CAE software, we perform mold flow analysis to predict material behavior during injection, minimizing risks such as voids, warpage, or incomplete fills. This phase ensures that every geometric feature, gate location, and cooling channel is strategically placed to support zero-defect manufacturing. Design validation includes thermal stress modeling and tolerance stack-up analysis, ensuring compatibility with tight tolerance demands typical in aerospace, medical, and high-performance automotive applications.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to rapid prototyping using high-precision CNC machining and additive manufacturing techniques tailored to liquid molding tooling. This stage produces functional prototypes that mirror final production conditions, allowing for real-world testing of material flow, curing cycles, and part ejection. Prototypes are subjected to rigorous dimensional inspection using coordinate measuring machines (CMM) and 3D scanning to verify conformity to specifications. Any deviations are fed back into the design loop for immediate correction, ensuring process stability before mass production. This iterative validation is critical to achieving zero defects and reducing time-to-market. Our prototyping phase also includes small-batch trials under production-speed conditions, confirming cycle times, surface finish quality, and mechanical performance.

Mass Production: Consistency, Control, and Zero Defects

With design and prototype fully validated, Wuxi Lead transitions seamlessly into mass production using fully automated liquid molding systems. Our manufacturing cells are equipped with real-time monitoring for pressure, temperature, and injection speed, ensuring every cycle adheres to predefined parameters. In-line vision systems and automated metrology provide continuous quality feedback, enabling immediate corrective action if anomalies are detected. All tooling is maintained under strict preventive maintenance schedules, and process capability studies (Cp/Cpk) are conducted regularly to verify statistical control. Every component is traceable through our digital manufacturing platform, supporting full documentation for audit and compliance purposes.

| Specification | Detail |

|---|---|

| Material Compatibility | Liquid Silicone Rubber (LSR), Polyurethane (PU), Epoxy Resins |

| Tolerance Range | ±0.05 mm to ±0.01 mm (based on part geometry) |

| Production Capacity | Up to 500,000 units/month (per production line) |

| Tooling Lifespan | 1,000,000+ cycles (hardened steel molds) |

| Quality Standard | ISO 9001:2015, PPAP, FAI, 100% First Article Inspection |

| Automation Level | Full robotic handling, closed-loop process control |

Through this disciplined progression—design, prototyping, and controlled mass production—Wuxi Lead Precision Machinery delivers liquid molded components with uncompromising quality, repeatability, and zero-defect performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Liquid Molding Excellence

Precision liquid molding demands more than standard manufacturing capabilities; it requires deep metallurgical expertise, rigorous process control, and a commitment to zero-defect outcomes. At Wuxi Lead Precision Machinery, we engineer solutions specifically for the demanding requirements of high-integrity metal components produced through advanced liquid molding processes, including Metal Injection Molding (MIM) and precision investment casting. Our integrated approach spans material science, ultra-precise tooling, and stringent quality validation, ensuring your complex geometries achieve optimal density, dimensional accuracy, and mechanical properties. We understand that failure is not an option in aerospace, medical implants, or critical energy applications—where every micron and material characteristic directly impacts performance and safety.

Our dedicated liquid molding division operates under AS9100 and ISO 13485 standards, utilizing proprietary sintering profiles and in-line metrology to maintain batch-to-batch consistency. Unlike generalist suppliers, we invest in purpose-built infrastructure: climate-controlled molding cells, vacuum debinding furnaces, and full-spectrum material testing labs. This focus translates into measurable advantages for your supply chain, including reduced scrap rates, accelerated time-to-qualification, and seamless scalability from prototype to high-volume production. Partnering with Lead Precision means gaining a true engineering collaborator, not just a vendor. We engage early in your design phase to optimize for manufacturability, leveraging simulation software to predict flow dynamics and minimize defects before tooling begins.

The technical specifications below reflect our baseline capabilities for mission-critical liquid molding projects. These figures represent our standard industrial performance; we routinely exceed them for specialized applications through custom process development.

| Parameter | Capability Range | Typical Tolerance/Control |

|---|---|---|

| Material Compatibility | Stainless Steels (17-4PH, 316L), Cobalt-Chrome, Titanium, Hard Alloys | Full material traceability & certification |

| Part Weight | 0.1g to 250g | ±0.1% for critical dimensions |

| Dimensional Accuracy | Complex 3D geometries | ±0.3% of nominal dimension |

| Surface Finish (Ra) | As-molded to mirror polish | 0.8μm to 0.2μm achievable |

| Production Volume | Prototypes to 2M+ annual units | Automated cell validation included |

When component integrity defines your product’s success, settle for nothing less than engineered precision. Wuxi Lead Precision Machinery provides the technical depth, quality systems, and responsive partnership essential for high-stakes liquid molding applications. Our engineering team is prepared to review your specific requirements, material challenges, and volume needs to develop a validated production pathway. Initiate the conversation that secures your supply chain’s future. Contact us directly at [email protected] to schedule a technical consultation. Include your project specifications and target timeline—our applications engineers will respond within 24 business hours with a preliminary capability assessment. Advance your manufacturing strategy with a partner built for precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.