Technical Contents

Engineering Guide: Lighthouse Molding

Engineering Insight: lighthouse molding and the Imperative of Precision

In the realm of high-performance manufacturing, lighthouse molding represents a benchmark in engineering excellence—where form, function, and reliability converge under extreme conditions. Unlike conventional molding processes, lighthouse molding demands micron-level precision, material integrity under thermal and mechanical stress, and repeatable consistency across production cycles. These requirements are non-negotiable in sectors such as defense, aerospace, and elite infrastructure, where failure is not an option.

At Wuxi Lead Precision Machinery, we approach lighthouse molding not merely as a production technique but as a discipline rooted in advanced metrology, finite element analysis, and decades of applied engineering. Our involvement in mission-critical projects—including components for Olympic-standard timing systems and military-grade communication enclosures—has reinforced a singular truth: precision is not an outcome, it is the foundation.

The challenge in lighthouse molding lies in maintaining dimensional stability across complex geometries, often involving thin-walled structures, integrated sealing surfaces, and multi-axis alignment features. Even minor deviations—measured in microns—can compromise optical alignment, electromagnetic shielding, or environmental sealing. This is where our in-house expertise in mold flow simulation, cavity pressure monitoring, and real-time process control becomes decisive. By integrating high-resolution sensors and closed-loop feedback systems into our molding platforms, we ensure that every cavity fill, pack, and cooling phase adheres to the original engineering intent.

Material selection further amplifies the complexity. We routinely work with reinforced thermoplastics such as PEEK, ULTEM, and LCP—materials chosen for their thermal stability, chemical resistance, and mechanical strength. However, their processing windows are narrow, requiring exact control of melt temperature, injection speed, and mold surface conditions. Our engineers leverage decades of empirical data and DOE (Design of Experiments) protocols to optimize these parameters for each unique part.

Wuxi Lead Precision Machinery’s track record in delivering components for high-stakes applications is a direct result of our commitment to precision at every level—from initial CAD modeling to final inspection. Our facility operates under ISO 9001 and IATF 16949 standards, with full traceability and 100% in-process dimensional verification for critical features.

The following table outlines key performance specifications achievable through our lighthouse molding process:

| Specification | Capability | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ISO 2768-mK |

| Surface Roughness (Ra) | 0.05 – 0.8 µm | ISO 4287 |

| Mold Accuracy | ±0.002 mm | VDI 2005 |

| Cavity Repeatability (CPK) | ≥1.67 | ISO 21747 |

| Material Compatibility | PEEK, ULTEM, LCP, PPS | UL 94 V-0 rated |

| Cleanroom Molding | Class 10,000 (ISO 7) | ISO 14644-1 |

Our experience with Olympic and military programs has instilled a culture of zero-defect manufacturing, where every component is engineered to perform flawlessly in the field. In lighthouse molding, as in all precision disciplines, excellence is not accidental—it is engineered.

Precision Specs & Tolerances

Technical Capabilities for Precision Lighthouse Molding Components

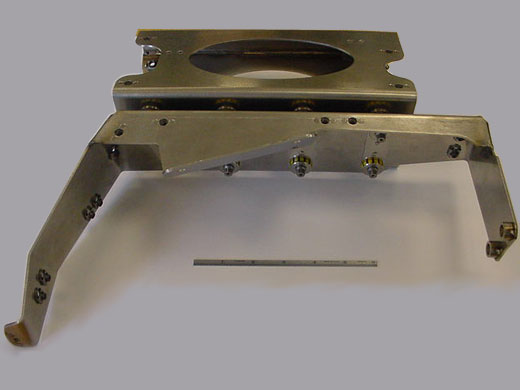

Wuxi Lead Precision Machinery defines lighthouse molding components as critical, high-precision metal elements serving as primary reference datums within complex assemblies. These parts demand exceptional dimensional stability and geometric accuracy to ensure seamless integration and function of the entire system. Our technical capabilities are specifically engineered to meet and exceed the stringent requirements inherent in lighthouse molding applications across aerospace, medical device, and advanced optics sectors.

Our core manufacturing strength resides in advanced 5-axis CNC machining centers. These systems enable the simultaneous, continuous machining of complex geometries from a single setup, eliminating cumulative errors inherent in multi-setup processes. This capability is non-negotiable for lighthouse components where critical datums, intricate sealing surfaces, and tight-tolerance bores must maintain absolute positional relationships. We utilize high-rigidity machines with sub-micron linear scale feedback and thermal compensation systems, ensuring dimensional integrity during extended production runs. Material expertise spans challenging alloys including Inconel 718, titanium Ti-6Al-4V, and hardened tool steels, processed with optimized toolpaths and cutting strategies to minimize residual stress and distortion.

Precision is meaningless without rigorous verification. Every lighthouse molding component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMMs, operating within a certified ISO 17025 metrology lab, provide full 3D geometric dimensioning and tolerancing (GD&T) validation. Inspection protocols are developed during the engineering phase, focusing explicitly on the critical-to-function datums and interfaces specified for the lighthouse role. Reports include detailed deviation maps against nominal CAD models, surface profile analysis, and comprehensive roundness/cylindricity data for critical bores. Full traceability from raw material certification through final inspection is maintained, providing complete confidence in part conformance.

The following table represents our standard and premium capability ranges for key geometric features common in lighthouse molding components. These values reflect achievable results under controlled process conditions using our integrated 5-axis machining and CMM verification systems, consistently meeting or surpassing ISO 2768-mK and ISO 286-2 standards.

| Feature Type | Standard Capability (mm) | Premium Capability (mm) |

|---|---|---|

| Linear Dimensions | ± 0.010 | ± 0.005 |

| Hole Diameter (Ø) | +0.010 / -0.000 | +0.005 / -0.000 |

| Positional Tolerance | Ø 0.015 | Ø 0.008 |

| Flatness | 0.010 | 0.005 |

| Roundness (Circularity) | 0.005 | 0.002 |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

Achieving lighthouse-level precision requires more than just equipment; it demands an integrated process where machining strategy, material science, and metrology are in constant dialogue. Wuxi Lead Precision Machinery provides this closed-loop capability, ensuring your critical reference components perform flawlessly as the foundation for your most demanding assemblies. We partner with clients from initial design for manufacturability through final validation, guaranteeing components that eliminate assembly drift and ensure ultimate system performance.

Material & Finish Options

Material selection is a critical step in the development of high-performance molds used in lighthouse molding applications. At Wuxi Lead Precision Machinery, we prioritize precision, durability, and thermal efficiency to ensure optimal mold performance under demanding production cycles. The choice between aluminum, steel, and titanium directly impacts mold life, cycle time, surface finish quality, and overall manufacturing cost. Each material offers distinct mechanical and thermal properties suited to specific molding requirements.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype molds and low-to-medium volume production. Their high thermal conductivity enables rapid heat dissipation, reducing cycle times significantly. Aluminum is also easier to machine, allowing for complex geometries and faster lead times. However, its lower hardness and wear resistance make it less suitable for long production runs or abrasive materials. For applications requiring frequent design changes or fast turnaround, aluminum remains a cost-effective and efficient solution.

Steel, especially tool steels like P20, H13, and S136, is the preferred choice for high-volume molding operations. These alloys offer superior hardness, wear resistance, and longevity, withstanding thousands of cycles without significant degradation. While steel has lower thermal conductivity than aluminum, its dimensional stability and resistance to deformation under pressure make it ideal for precision molds producing high-tolerance components. Proper heat treatment and surface finishing further enhance steel’s performance, ensuring consistent part quality over extended use.

Titanium alloys, though less common due to cost and machining complexity, offer exceptional strength-to-density ratios and corrosion resistance. They are typically reserved for specialized applications where weight reduction, extreme durability, or resistance to aggressive environments is paramount. Titanium molds are challenging to machine and require advanced CNC capabilities, but they deliver unmatched performance in niche aerospace and medical molding applications.

Surface finishing, particularly anodizing, plays a vital role in enhancing mold performance—especially with aluminum. Anodizing increases surface hardness, improves wear resistance, and provides a protective oxide layer that reduces galling and eases part ejection. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with the latter offering thicker, more durable coatings suitable for high-stress environments. Anodized surfaces can also be colored for identification or aesthetic purposes without compromising functionality.

The following table summarizes key material properties relevant to mold manufacturing:

| Material | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Hardness (HB) | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075 | 570 | 130 | 150 | Prototypes, low-volume molds |

| P20 Steel | 980 | 30 | 280 | High-volume production molds |

| H13 Steel | 1550 | 35 | 230 | Hot-runner, high-temperature molds |

| Titanium Ti-6Al-4V | 900 | 7 | 360 | Aerospace, medical, corrosive environments |

Selecting the right material and finish requires a detailed understanding of production volume, part complexity, and environmental conditions. At Wuxi Lead Precision Machinery, we collaborate closely with clients to match material properties with application demands, ensuring molds that deliver precision, efficiency, and long-term reliability.

Manufacturing Process & QC

Precision Metal Manufacturing Process: Achieving Zero Defects in Lighthouse Molding

At Wuxi Lead Precision Machinery, our lighthouse molding process defines the pinnacle of custom metal component production. This integrated workflow—spanning Design, Prototyping, and Mass Production—is engineered for absolute precision and zero-defect delivery. We treat every project as a critical-path operation, where tolerances are non-negotiable and consistency is quantifiable. Our methodology ensures components meet the exacting demands of aerospace, medical, and semiconductor applications, where failure is not an option.

The Design phase begins with rigorous collaboration. Our engineering team utilizes advanced CAD/CAE software to model components, incorporating material science analysis and mold flow simulation. Critical factors like thermal expansion, stress distribution, and microstructure integrity are validated before any metal is cut. Client specifications are cross-referenced against ISO 2768 and ASME Y14.5 standards, with design for manufacturability (DFM) reviews eliminating potential production risks upfront. This phase establishes the geometric and material blueprint for zero-defect execution.

Prototyping transforms validated designs into tangible validation. Using 5-axis CNC milling and wire EDM, we produce functional prototypes within 72 hours. Each prototype undergoes comprehensive metrology via Zeiss CMM and optical comparators, measuring against the original CAD model at micron-level resolution. Dimensional reports highlight deviations exceeding ±0.001mm, triggering immediate design or process adjustments. This rapid iteration loop—typically 2-3 cycles—proves the process capability before scaling, ensuring mass production starts with proven parameters.

Mass Production deploys our zero-defect framework through closed-loop control systems. Components are machined on Makino and DMG MORI platforms with real-time SPC monitoring of critical dimensions. Every 15 minutes, automated gauging checks feature tolerances, feeding data to our central quality dashboard. Statistical process control charts trigger automatic machine recalibration if trends approach specification limits. Full batch traceability links each part to its material certificate, machine log, and inspection record. Final validation includes 100% visual inspection under ISO 14644 Class 7 cleanroom conditions and destructive testing on sacrificial samples per ASTM E8.

Our process capability is anchored in measurable precision. The following table details the core specifications achievable across our production ecosystem:

| Parameter | Specification | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm to ±0.005 mm | ISO 286-2 (IT01-IT2) |

| Surface Roughness | Ra 0.05 µm to Ra 0.4 µm | ISO 1302 |

| Geometric Accuracy | ±0.002 mm (flatness) | ASME Y14.5 GD&T |

| Material Integrity | Zero porosity/inclusions | ASTM E45 (Microscopy) |

This disciplined progression—from simulation-validated design through metrology-driven prototyping to SPC-governed mass production—eliminates variability at every touchpoint. Wuxi Lead’s lighthouse molding process doesn’t merely meet specifications; it redefines reliability in custom metal manufacturing. Your zero-defect mandate is our operational reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

When your manufacturing operation demands precision, consistency, and innovation, partnering with Wuxi Lead Precision Machinery ensures you achieve lighthouse molding excellence. As a leading provider of custom metal manufacturing solutions based in China, we specialize in delivering engineered components that meet the most stringent industry standards. Our commitment to quality, advanced CNC capabilities, and deep understanding of complex molding applications make us the strategic partner of choice for global manufacturers striving for operational leadership.

At Lead Precision, we recognize that lighthouse molding is not just about producing parts—it’s about enabling smart, scalable, and sustainable production systems. Our engineering team works collaboratively with clients to design, prototype, and manufacture high-precision metal components tailored to the exact thermal, mechanical, and dimensional requirements of advanced molding processes. From mold bases and inserts to cooling systems and hot runner components, every product we deliver is built to enhance performance, reduce cycle times, and extend tool life.

Our state-of-the-art facility is equipped with multi-axis CNC machining centers, wire EDM, surface grinding, and CMM inspection systems, enabling us to maintain tolerances as tight as ±0.002 mm. With full in-house capabilities, we control every stage of production, ensuring traceability, faster turnaround, and consistent quality. We serve industries including automotive, medical devices, consumer electronics, and industrial automation—sectors where reliability and repeatability are non-negotiable.

What sets us apart is our engineering-first approach. We don’t just manufacture parts—we solve manufacturing challenges. Whether you’re scaling a new mold design, optimizing for high-cavity production, or integrating Industry 4.0 sensors into your tooling, our team provides technical insights that drive real operational gains. Our clients benefit from reduced downtime, improved part quality, and faster time-to-market.

We understand that every project is unique. That’s why we offer fully customized solutions—from material selection (including hardened steels, aluminum alloys, and specialty tool steels) to surface treatments such as nitriding, PVD coating, and laser texturing. Our quality management system is ISO 9001-certified, and we adhere to international standards including DIN, ANSI, and JIS.

Below are key technical capabilities that define our manufacturing excellence.

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (CNC), 400 x 300 x 150 mm (EDM) |

| Materials Processed | P20, 718H, H13, S136, Aluminum 7075, Titanium Grade 5, Copper Alloys |

| Surface Finish | Ra 0.05 µm to Ra 1.6 µm (polished, ground, machined) |

| Quality Standards | ISO 9001, ISO 14001, Full First Article Inspection Reports |

| Lead Time (Typical) | 15–25 days, based on complexity and volume |

To begin your partnership with a team that combines precision engineering with responsive, client-focused service, contact us today. Send your inquiries, RFQs, or design files to [email protected]. Our engineers are ready to support your next breakthrough in lighthouse molding.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.