Technical Contents

Engineering Guide: Lathe Cnc Parts

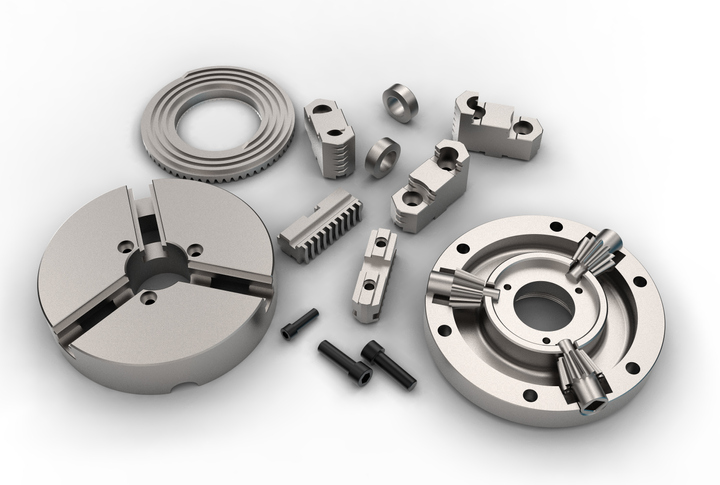

Engineering Insight: The Critical Role of Precision in CNC Lathe Parts

In high-performance manufacturing, the integrity and functionality of CNC lathe parts directly influence the reliability of the final product. Whether integrated into aerospace propulsion systems, medical diagnostics equipment, or advanced defense mechanisms, these components must adhere to exacting standards where even micron-level deviations can lead to catastrophic failure. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a quality metric—it is the foundation of engineering excellence.

CNC lathe parts are characterized by rotational symmetry and are often subjected to high stress, thermal cycling, and dynamic loads. Achieving dimensional accuracy, tight tolerances, and superior surface finishes is paramount. Our advanced CNC turning centers, equipped with real-time tool monitoring and closed-loop feedback systems, ensure consistent repeatability down to ±0.002 mm. This level of control is maintained through rigorous environmental regulation, precision calibration protocols, and continuous in-process inspection using coordinate measuring machines (CMM) and optical comparators.

Our experience extends to mission-critical applications where failure is not an option. Wuxi Lead has successfully delivered precision-turned components for Olympic-grade timing systems, where nanosecond accuracy in mechanical response is essential. Additionally, we have supported select military programs requiring ISO 27001 compliance and full traceability across every production batch. These projects demand more than technical capability—they require a culture of precision that permeates every stage of design, machining, and quality assurance.

Material selection further underscores our engineering approach. We routinely process high-strength alloys such as titanium Grade 5 (Ti-6Al-4V), Inconel 718, and hardened stainless steels, as well as engineered polymers like PEEK and PTFE. Each material presents unique challenges in chip control, thermal expansion, and tool wear, necessitating customized cutting strategies and specialized tooling. Our engineers employ finite element analysis (FEA) and machinability simulations to optimize toolpaths and minimize residual stress in the final part.

Below are representative specifications achievable across our CNC lathe operations:

| Specification | Capability |

|---|---|

| Maximum Turning Diameter | 420 mm |

| Maximum Turning Length | 1000 mm |

| Spindle Speed | Up to 6,000 RPM |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Surface Finish (Ra) | As low as 0.4 μm |

| Tolerances | IT6 to IT7 (ISO 286) |

| Materials Processed | Steel, Stainless Steel, Aluminum, Titanium, Brass, PEEK, PTFE |

At Wuxi Lead Precision Machinery, we combine state-of-the-art equipment with decades of applied engineering knowledge to deliver CNC lathe parts that meet the most stringent performance requirements. Precision is not accidental—it is engineered, verified, and guaranteed.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision CNC Lathe Components

Wuxi Lead Precision Machinery delivers uncompromising accuracy and complexity in CNC lathe part manufacturing through integrated advanced technologies and rigorous quality protocols. Our core strength lies in mastering intricate geometries and tight tolerances demanded by aerospace, medical, and high-performance industrial sectors. We specialize in transforming challenging designs into fully functional, mission-critical components where dimensional stability and surface integrity are non-negotiable.

Our multi-axis CNC turning centers form the foundation of this capability. Equipped with state-of-the-art 5-axis milling and turning functionality, these machines enable simultaneous multi-surface machining of complex cylindrical and asymmetrical features within a single setup. This eliminates cumulative errors from multiple handling stages, significantly enhancing part accuracy and repeatability. The integrated live tooling and Y-axis capabilities allow for sophisticated milling, drilling, tapping, and contouring operations directly on turned parts, producing complete components without secondary operations. This streamlined process reduces lead times, minimizes work-in-process inventory, and ensures superior feature-to-feature relationships critical for high-precision assemblies.

Quality assurance is systematically embedded throughout production, not merely a final checkpoint. Every critical dimension and geometric feature undergoes comprehensive verification using calibrated Coordinate Measuring Machines (CMMs). Our CMM inspection routines, developed per ASME Y14.5 standards, provide full 3D metrology data traceable to international standards. This data-driven approach guarantees conformance to the most stringent engineering specifications and provides documented evidence for customer audits and regulatory compliance. Statistical Process Control (SPC) methodologies are actively employed to monitor process capability and drive continuous improvement, ensuring consistent output batch after batch.

The precision achievable across our CNC lathe machining operations is quantifiable and consistently met. Below are our standard achievable tolerance specifications for reference:

| Specification Category | Typical Capability | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.001 mm |

| Geometric Tolerances | ±0.008 mm | ±0.002 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Concentricity | 0.010 mm | 0.003 mm |

| True Position | 0.015 mm | 0.005 mm |

This technical proficiency translates directly into reduced assembly scrap, enhanced product performance, and extended component lifespan for our clients. Wuxi Lead Precision Machinery operates at the intersection of engineering excellence and manufacturing execution. We understand that your CNC lathe parts are not merely components but integral elements of your final product’s success. Partnering with us means securing a supplier whose technical capabilities, quality infrastructure, and commitment to precision align with the highest demands of advanced manufacturing. Contact our engineering team to discuss how our specific capabilities can address your most challenging lathe part requirements.

Material & Finish Options

Material selection is a critical phase in the production of high-performance CNC lathe parts, directly influencing mechanical behavior, service life, and overall component reliability. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining of engineered components, with extensive expertise in processing aluminum, steel, and titanium—each offering distinct advantages depending on application requirements.

Aluminum is widely favored in aerospace, automotive, and electronics industries due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grades such as 6061-T6 and 7075-T6 are commonly used for structural and lightweight components. Aluminum’s natural corrosion resistance is further enhanced through surface treatments like anodizing, which forms a durable oxide layer. This makes it ideal for parts exposed to environmental stress or requiring electrical insulation.

Steel remains the backbone of industrial machinery, offering superior strength, wear resistance, and dimensional stability. Alloy steels like 4140 and 4340 are frequently selected for high-stress applications such as shafts, gears, and hydraulic components. Stainless steels, particularly 303, 304, and 17-4 PH, provide excellent corrosion resistance and are widely used in medical, food processing, and marine environments. While steel is more challenging to machine than aluminum, advanced CNC tooling and process optimization ensure tight tolerances and excellent surface finishes.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice in extreme environments such as aerospace, defense, and high-performance automotive systems. Its outstanding strength-to-density ratio, resistance to high temperatures, and immunity to corrosion in harsh conditions make it indispensable. However, titanium’s low thermal conductivity and high chemical reactivity demand specialized cutting strategies and tooling to prevent work hardening and tool wear. At Wuxi Lead, our CNC lathes are equipped with high-rigidity spindles and optimized coolant delivery systems to ensure consistent titanium machining.

Surface finishing, especially anodizing, plays a vital role in enhancing part performance. Anodizing is primarily applied to aluminum, increasing surface hardness up to 60 HRC and improving wear and corrosion resistance. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly used, with Type III offering thicker, more durable coatings for industrial applications. Anodized layers are also electrically insulating and can be dyed for identification or aesthetic purposes.

The following table summarizes key mechanical and machining characteristics of commonly used materials:

| Material | Tensile Strength (MPa) | Hardness (HB) | Machinability Rating | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 95 | Excellent | Anodizing, Bead Blast | Enclosures, Brackets, Heat Sinks |

| Steel 4140 | 655 | 190 | Good | Zinc Plating, Passivation | Shafts, Tooling, Fasteners |

| Stainless 304 | 515 | 180 | Moderate | Electropolishing | Medical, Food Processing |

| Titanium Ti-6Al-4V | 950 | 360 | Fair | Anodizing, Passivation | Aerospace, Defense, Marine |

Selecting the right material and finish requires a comprehensive understanding of operational demands. Wuxi Lead Precision Machinery supports clients in making informed decisions, ensuring every CNC-turned component meets the highest standards of performance and reliability.

Manufacturing Process & QC

Precision Lathe CNC Parts Production: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our lathe CNC parts production process is engineered for uncompromising quality and repeatability. We integrate advanced technology with rigorous quality management to ensure every component meets exacting industrial standards. The journey begins with collaborative design engineering. Our team works with client CAD models to perform detailed manufacturability analysis, optimizing toolpaths and material selection for efficiency and precision. Critical tolerances are validated through simulation software, ensuring geometric accuracy down to ±0.001mm before any metal is cut. This phase eliminates theoretical errors, reducing downstream rework and accelerating time-to-market.

Prototyping follows stringent first-article inspection protocols. Using high-precision Swiss-type and multi-axis lathes, we produce initial units under full production conditions. Each prototype undergoes comprehensive metrology: CMM verification, surface roughness testing, and material composition analysis. We measure critical dimensions against ASME Y14.5 standards, documenting deviations and refining processes until Cpk ≥1.67 is achieved. Client approval requires 100% specification compliance—not just dimensional accuracy but functional performance under simulated operational loads. This validation phase ensures scalability while preventing mass-production defects.

Mass production leverages our zero-defect framework. Automated in-process gauging with Renishaw probes monitors critical features during machining, triggering immediate corrections for drift. Each part batch includes embedded traceability codes linking to machine parameters, tool wear data, and operator logs. Final inspection employs multi-sensor metrology systems for 100% verification of geometric tolerances, concentricity, and surface integrity. We enforce a closed-loop corrective action system: any anomaly triggers root-cause analysis within 24 hours, with process adjustments implemented before subsequent batches. This methodology achieves <50 PPM defect rates across industries from aerospace to medical devices.

Our technical capabilities are anchored in measurable precision, as demonstrated below:

| Specification | Capability | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm | Zeiss CONTURA CMM |

| Surface Roughness | Ra 0.2 µm (max) | Mitutoyo SJ-410 Profilometer |

| Material Range | Stainless Steel, Titanium, Inconel, Brass | Spectrographic Analysis |

| Max Part Diameter | 320 mm | Laser Scanning |

| Geometric Tolerance | ≤0.002 mm (concentricity) | Coordinate Measuring Machine |

| Production Capacity | 50,000+ units/month | Real-time OEE Monitoring |

Wuxi Lead’s production ecosystem transforms design intent into flawless physical components. By embedding quality at every phase—from virtual simulation to final packaging—we eliminate scrap costs and guarantee on-time delivery of mission-critical lathe CNC parts. Partner with us to convert your precision requirements into defect-free reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Lathe Component Excellence

At Wuxi Lead Precision Machinery, we understand that in high-performance industries such as aerospace, medical devices, automotive, and industrial automation, precision is not a luxury—it is a necessity. When sourcing lathe CNC parts, your choice of manufacturing partner directly impacts product reliability, production timelines, and overall operational efficiency. As a leading provider of precision CNC machining services in China, Lead Precision combines advanced technology, rigorous quality control, and engineering expertise to deliver components that meet the most demanding specifications.

Our state-of-the-art facility is equipped with multi-axis CNC lathes, Swiss-type machines, and live tooling centers, enabling us to produce complex geometries with tolerances as tight as ±0.001 mm. Whether you require high-volume production runs or low-volume prototypes, our agile manufacturing processes ensure consistent quality, rapid turnaround, and full traceability. We specialize in machining a wide range of materials, including stainless steel, aluminum, titanium, brass, and engineering plastics, ensuring compatibility with your application requirements.

What sets Lead Precision apart is our engineering-first approach. From initial design review to final inspection, our team of experienced CNC engineers collaborates closely with clients to optimize manufacturability, reduce costs, and enhance performance. We support full documentation packages, including CAD/CAM files, First Article Inspection (FAI) reports, and PPAP submissions, ensuring seamless integration into your supply chain.

Our commitment to quality is reinforced by ISO 9001:2015 certification and a comprehensive in-house metrology lab equipped with CMMs, optical comparators, and surface finish testers. Every lathe CNC part we produce undergoes rigorous inspection to guarantee compliance with international standards and customer-specific requirements.

We serve global clients across North America, Europe, and Asia, offering competitive pricing without compromising on precision or service. With streamlined logistics and responsive project management, we ensure on-time delivery and continuous communication throughout the production cycle.

Below are key capabilities that define our CNC lathe machining services:

| Specification | Detail |

|---|---|

| Maximum Turning Diameter | 300 mm |

| Maximum Turning Length | 600 mm |

| Spindle Speed | Up to 8,000 RPM |

| Tolerance | ±0.001 mm (±0.00004″) |

| Materials | Stainless Steel, Aluminum, Titanium, Brass, PEEK, Delrin |

| Secondary Operations | Milling, Drilling, Tapping, Threading, Knurling, Heat Treatment, Plating |

| Quality Standards | ISO 9001:2015, RoHS Compliant, Full FAI & PPAP Support |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally dedicated to your success. For inquiries, technical collaboration, or to request a quote, contact us today at [email protected]. Let us help you achieve perfection in every rotation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.