Technical Contents

Engineering Guide: Laser Marking Plastic Parts

Engineering Insight: Laser Marking Plastic Parts with Precision

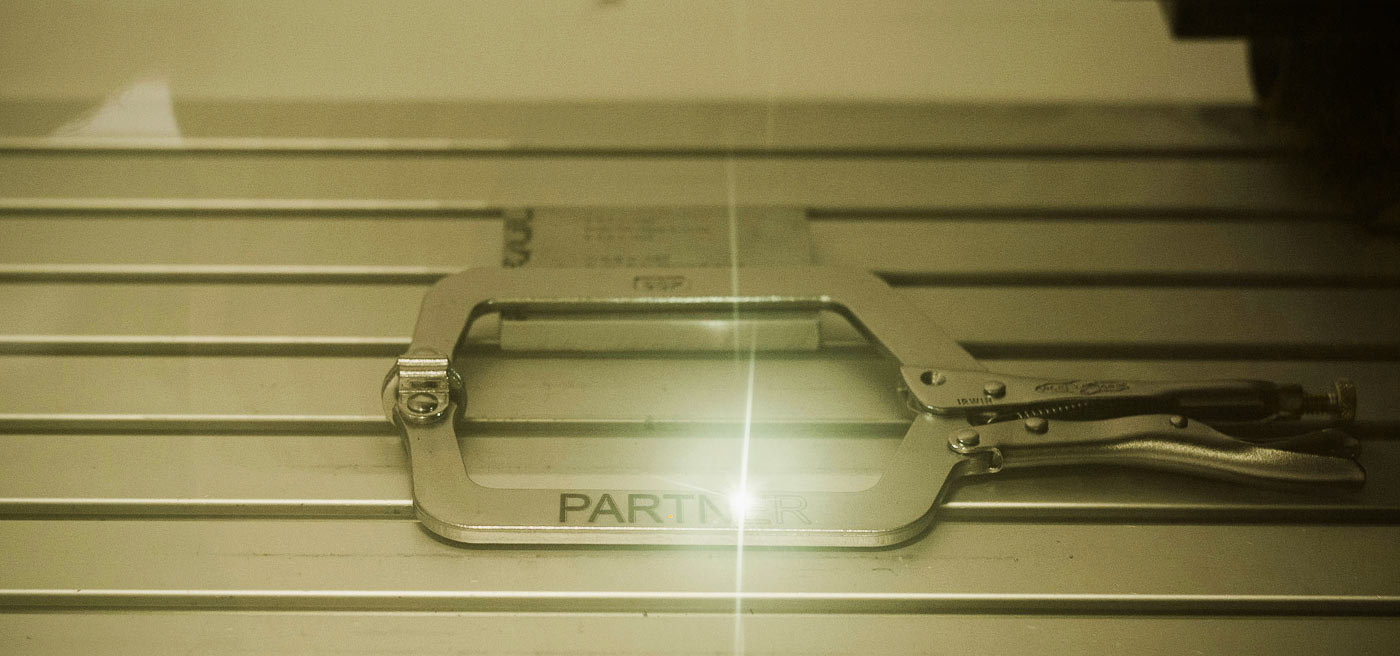

In high-end manufacturing, particularly within sheet metal fabrication and integrated component assembly, the marking of plastic parts is far more than a labeling step—it is a critical engineering process. Laser marking plastic parts demands exceptional precision, material understanding, and system stability to ensure permanent, high-contrast, and contamination-free identification. At Wuxi Lead Precision Machinery, we integrate this capability into our end-to-end production workflow, ensuring traceability, compliance, and brand integrity across aerospace, medical, defense, and industrial applications.

Precision in laser marking is not merely about achieving legible text or barcodes. It involves controlling laser energy distribution, focal accuracy, pulse duration, and beam positioning to interact optimally with diverse polymer substrates. Plastics such as polycarbonate, ABS, PEEK, and polyamide respond differently to laser wavelengths. Overexposure can lead to melting or carbonization; underexposure results in faint or non-durable marks. Our engineering team leverages fiber and UV laser systems calibrated to micron-level accuracy, ensuring consistent results without structural compromise to the part.

Material compatibility is another cornerstone of successful laser marking. Unlike ink-based methods, laser marking alters the surface chemistry or topography of the plastic to create contrast. This process, known as coloration, engraving, or foaming, must be tailored to the polymer’s thermal and optical properties. Wuxi Lead employs pre-production material testing and parameter optimization, ensuring that every mark meets ISO 9001 and RoHS standards while maintaining part functionality.

Our experience in delivering precision solutions for Olympic-standard equipment and military-grade enclosures underscores our commitment to excellence. In these applications, traceability and durability are non-negotiable. Components must withstand extreme environments—UV exposure, chemical sterilization, mechanical abrasion—without degradation of the mark. Our laser systems are integrated with CNC-guided positioning and vision alignment, enabling batch consistency and 2D data matrix coding with read rates exceeding 99.9%.

Beyond technical capability, Wuxi Lead emphasizes process integration. Laser marking is synchronized with upstream fabrication—cutting, bending, welding—and downstream assembly, minimizing handling and reducing cycle time. This holistic approach ensures that marking is not a bottleneck but a seamless, value-added step in production.

The following table outlines key specifications of our laser marking systems for plastic components:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber, UV, and MOPA |

| Wavelength Range | 355 nm (UV), 1064 nm (Fiber) |

| Marking Field Size | Up to 300 × 300 mm (adjustable optics) |

| Positioning Accuracy | ±0.005 mm |

| Minimum Line Width | 0.01 mm |

| Supported Plastics | PC, ABS, PEEK, PA, PMMA, PBT, PET |

| Marking Speed | Up to 7000 mm/s |

| Data Integration | PLC, MES, barcode/QR code generation |

| Compliance Standards | ISO 9001, CE, RoHS, FDA (for medical grades) |

At Wuxi Lead Precision Machinery, we treat laser marking not as an afterthought but as a precision engineering discipline. Our systems reflect years of applied research and mission-critical deployment, ensuring that every marked plastic part meets the highest standards of performance and reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Laser Marking for Plastic Components

Wuxi Lead Precision Machinery delivers advanced laser marking solutions for plastic parts, engineered to meet stringent aerospace, medical, and automotive sector requirements. Our integrated approach leverages 5-axis CNC motion control systems to execute complex marking geometries on contoured and multi-faceted plastic surfaces. This capability eliminates the need for secondary fixturing, ensuring consistent mark placement across intricate 3D forms. The system utilizes fiber and CO₂ laser sources optimized for polymer interaction, enabling permanent, high-contrast markings—including Data Matrix codes, serial numbers, and logos—without surface ablation or structural compromise. Critical to plastic applications is our proprietary thermal management protocol, which dynamically adjusts pulse duration and peak power to prevent melting, charring, or micro-cracking in sensitive materials like polycarbonate, ABS, and PEEK.

All marking processes are developed through rigorous material-specific parameter optimization. Our engineering team conducts substrate compatibility testing to define optimal laser wavelength, power density, and scan speed for each polymer formulation. This methodology ensures mark readability per ISO/IEC 15415 standards while maintaining part integrity. For applications demanding traceability, we implement closed-loop verification where camera systems validate code legibility in real-time, rejecting non-conforming parts before downstream assembly. While our primary quality control infrastructure—featuring Zeiss CMMs and optical comparators—is calibrated for metal fabrication tolerances, plastic marking validation employs dedicated vision inspection systems with micron-level resolution to assess mark depth, contrast, and positional accuracy against client specifications.

The following table details achievable marking specifications for common engineering plastics under controlled production conditions:

| Material Type | Positional Tolerance | Minimum Feature Size | Mark Depth Range | Surface Roughness (Ra) |

|---|---|---|---|---|

| Polycarbonate (PC) | ±0.05 mm | 0.15 mm | 10–50 μm | < 0.8 μm |

| Acrylic (PMMA) | ±0.08 mm | 0.20 mm | 15–60 μm | < 1.2 μm |

| ABS | ±0.10 mm | 0.25 mm | 20–70 μm | < 1.5 μm |

| Polyamide (Nylon) | ±0.12 mm | 0.30 mm | 25–80 μm | < 2.0 μm |

| PEEK | ±0.07 mm | 0.18 mm | 12–55 μm | < 1.0 μm |

Process validation includes accelerated environmental testing per ASTM D4329, simulating UV exposure, thermal cycling, and chemical resistance to guarantee mark permanence throughout the product lifecycle. Our facility maintains ISO Class 8 cleanroom conditions for medical-grade components, preventing particulate contamination during marking. By integrating laser processing within our broader precision manufacturing ecosystem—including CNC milling, bending, and finishing—we provide end-to-end traceability from raw material to marked component. This holistic capability ensures plastic parts meet both functional performance criteria and regulatory marking mandates without supply chain fragmentation. Clients receive comprehensive process documentation, including laser parameter logs and first-article inspection reports, enabling seamless audit compliance for critical applications.

Material & Finish Options

Material Selection for Laser Marking Plastic Parts in High-Precision Sheet Metal Fabrication

When integrating laser marking into the production of plastic parts within sheet metal fabrication systems, material selection is critical to ensure durability, readability, and aesthetic consistency. While the primary structure may involve metals such as aluminum, steel, or titanium, the plastic components—often used for labels, housings, or insulative elements—must be compatible with laser marking processes. The interaction between laser energy and plastic composition determines mark contrast, permanence, and surface integrity.

Aluminum is frequently used as a structural base in sheet metal applications due to its lightweight and excellent thermal conductivity. When plastic parts are mounted on or near aluminum components, thermal management becomes essential during laser marking. High laser power or prolonged exposure may cause heat transfer that deforms sensitive plastics. Therefore, low-power fiber or UV lasers are recommended for marking plastics in such assemblies. Additionally, anodized aluminum surfaces can reflect laser energy unpredictably, requiring precise beam control to avoid interference with adjacent plastic elements.

Steel, particularly stainless steel, offers superior strength and corrosion resistance, making it ideal for industrial enclosures and mounting frames. However, steel absorbs laser energy more readily than aluminum, reducing stray reflections. This property allows for tighter control when marking nearby plastic components. When designing systems with steel and plastic integration, it is advisable to use plastics with high laser absorption rates at common wavelengths (1064 nm for fiber lasers). Materials like ABS, polycarbonate, and PEEK respond well under controlled parameters, producing high-contrast, permanent marks without cracking or charring.

Titanium, though less common due to cost, is employed in aerospace and medical-grade enclosures where strength-to-density ratios are critical. Its biocompatibility and resistance to extreme environments make it a preferred choice for high-end applications. Titanium’s low thermal conductivity requires careful thermal isolation from plastic parts during laser processing. UV lasers are especially effective in these scenarios, offering cold marking capabilities that minimize heat-affected zones.

Anodizing, commonly applied to aluminum parts, enhances surface hardness and corrosion resistance. However, the anodized layer can influence laser marking outcomes on adjacent plastics due to altered reflectivity. Darker anodized finishes absorb more laser energy, reducing back-reflection risks. For optimal results, system designers should consider the finish type and its optical properties when planning laser paths near plastic components.

The following table outlines key material and process parameters for laser marking plastic parts in conjunction with common sheet metal substrates:

| Material | Laser Type | Wavelength (nm) | Marking Speed (mm/s) | Typical Plastic Response | Thermal Risk to Plastic |

|---|---|---|---|---|---|

| Aluminum | Fiber | 1064 | 500–1000 | Moderate reflection | High |

| Anodized Al | Fiber / UV | 1064 / 355 | 400–800 | Low reflection (dark coat) | Medium |

| Stainless Steel | Fiber | 1064 | 600–1200 | Low reflection | Low to Medium |

| Titanium | UV | 355 | 300–700 | Minimal reflection | Low |

Selecting the appropriate combination of base metal, finish, and laser parameters ensures clean, durable markings on plastic parts without compromising structural integrity. Wuxi Lead Precision Machinery recommends comprehensive material testing during prototyping to optimize marking quality in final production.

Manufacturing Process & QC

Laser Marking Plastic Parts: Precision Traceability for Critical Applications

Achieving flawless laser marking on plastic components demands rigorous process control from initial design through high-volume production. At Wuxi Lead Precision Machinery, we integrate material science expertise with advanced laser technology to deliver permanent, high-contrast identifiers meeting stringent medical, automotive, and electronics traceability requirements. Our Zero Defects methodology ensures every mark complies with ISO 13485 and IATF 16949 standards, eliminating surface damage, readability failures, or material degradation.

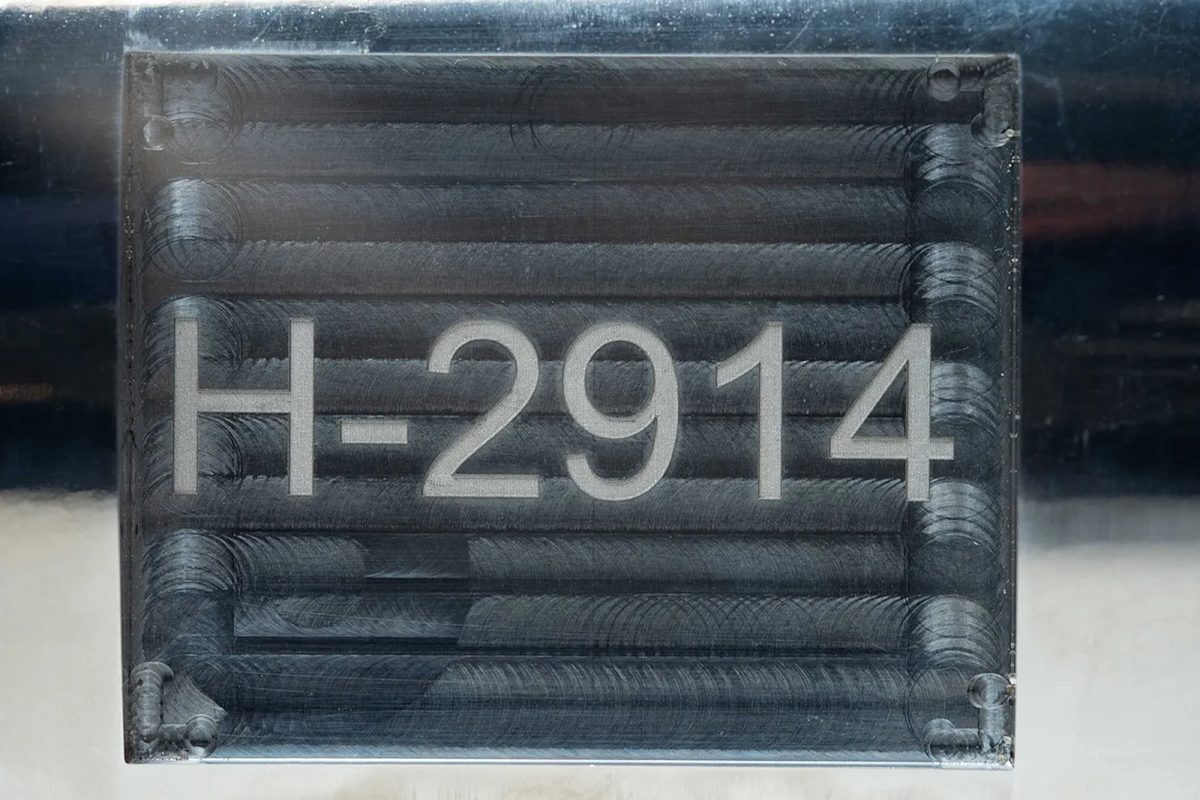

The process begins with collaborative design engineering. Material composition—whether ABS, polycarbonate, or engineered polymers—dictates optimal laser parameters. We analyze thermal properties, filler content, and pigment stability to prevent carbonization or delamination. CAD-integrated simulations predict beam interaction, defining critical zones for mark placement relative to structural features. This phase establishes baseline parameters for wavelength, pulse duration, and power density, ensuring the mark penetrates only the intended surface layer without compromising part integrity or function.

Prototyping employs Design of Experiments (DOE) to validate parameters. A statistically significant sample set undergoes iterative marking trials under controlled environmental conditions. Each iteration is subjected to accelerated aging, chemical resistance testing, and 100% automated vision inspection for contrast, edge definition, and dimensional accuracy against the design file. Only parameters yielding consistent, defect-free results across all test conditions advance to mass production. This empirical validation phase reduces process variation to under 2% before scaling.

Mass production execution leverages our fiber and UV laser platforms with real-time closed-loop monitoring. In-line cameras perform 100% inspection against pre-approved digital templates, rejecting non-conforming parts via automated sorting. Statistical Process Control (SPC) charts track key variables—laser power stability, focal point deviation, and conveyor speed—with automatic parameter correction if trends approach tolerance limits. Environmental controls maintain humidity below 45% RH and temperature at 22±1°C to prevent moisture-related marking inconsistencies. All process data is logged for full traceability, enabling rapid root-cause analysis should anomalies occur.

Critical laser marking specifications for plastic substrates are maintained within these operational boundaries:

| Parameter | Fiber Laser Range | UV Laser Range | Tolerance Control |

|---|---|---|---|

| Wavelength | 1064 nm | 355 nm | ±2 nm |

| Power Range | 20-50 W | 3-10 W | ±0.5 W |

| Marking Speed | 500-2000 mm/s | 300-1500 mm/s | ±15 mm/s |

| Spot Size | 20-50 μm | 15-30 μm | ±2 μm |

| Positional Accuracy | ±0.03 mm | ±0.02 mm | Verified per batch |

This structured approach—from material-aware design through statistically validated prototyping to SPC-driven mass production—ensures every marked plastic component meets the highest reliability standards. Wuxi Lead’s integrated process control delivers regulatory-compliant traceability without secondary operations, minimizing waste and maximizing uptime for your production line.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery to achieve unmatched precision and consistency in laser marking plastic parts for your sheet metal fabrication applications. As a trusted leader in advanced manufacturing solutions based in China, we specialize in integrating high-performance laser marking systems tailored to the demanding requirements of modern industrial environments. Our expertise ensures that every plastic component—whether used in control panels, enclosures, or embedded assemblies—is marked with permanent clarity, traceability, and brand integrity.

At Wuxi Lead Precision Machinery, we understand that laser marking is more than just aesthetic labeling—it’s a critical step in product identification, compliance, and lifecycle management. Our engineering team works closely with global OEMs and tier-one suppliers to develop customized marking solutions that meet ISO standards, resist environmental degradation, and support automated production workflows. From serial numbers and barcodes to logos and QR codes, our systems deliver crisp, high-contrast marks on a wide range of engineering-grade plastics including ABS, polycarbonate, acrylic, and polyamide.

We utilize fiber and UV laser technologies optimized for thermal sensitivity and material compatibility, ensuring clean marks without warping, melting, or surface damage. Our integrated systems are designed for seamless operation within existing production lines, supporting real-time data input and traceability through Industry 4.0 protocols. Whether you require batch coding, date stamping, or dynamic data marking, our solutions enhance efficiency while reducing operational downtime.

Our commitment extends beyond equipment supply. We provide full technical support, from initial material testing and sample validation to on-site installation and operator training. Every system is backed by rigorous quality control and long-term service agreements to ensure peak performance across years of continuous use.

Below are key specifications of our standard laser marking systems for plastic components:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser (MOPA), UV Laser (355 nm) |

| Marking Area | Up to 300 × 300 mm (customizable) |

| Marking Speed | Up to 7,000 mm/s |

| Minimum Line Width | 0.01 mm |

| Repeatability | ±0.003 mm |

| Supported Materials | ABS, PC, PMMA, PBT, PET, PE, PP, PVC |

| Marking Content | Text, QR Codes, Data Matrix, Logos, Serial Numbers |

| Software Interface | User-friendly PC-based control with PLC integration |

| Power Supply | 220 V ±10%, 50/60 Hz |

| Cooling System | Air-cooled (standard), Water-cooled (optional) |

| Compliance | CE, ISO 9001, RoHS |

Partnering with Wuxi Lead Precision Machinery means investing in precision, reliability, and long-term manufacturing excellence. Contact us today at [email protected] to discuss your laser marking requirements or request a sample test. Let our engineers help you optimize your sheet metal fabrication line with intelligent marking solutions built for global industry standards.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.