Technical Contents

Engineering Guide: Laser Cutting Parts

Engineering Insight: The Critical Role of Precision in Laser Cutting Parts

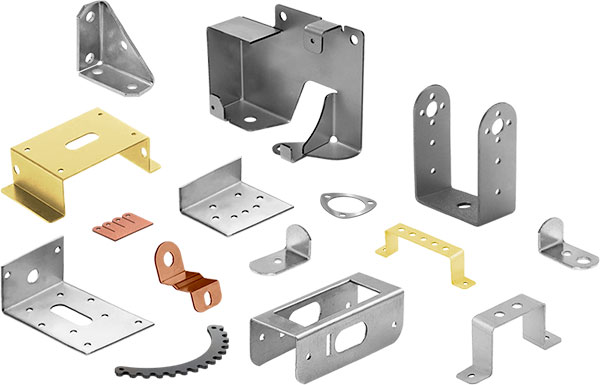

In the realm of high-end sheet metal fabrication, precision is not merely a performance metric—it is the foundation of reliability, functionality, and long-term value. At Wuxi Lead Precision Machinery, we understand that laser cutting parts must meet exacting dimensional tolerances and edge quality standards, especially when deployed in mission-critical applications such as aerospace, defense, and large-scale infrastructure. The accuracy of a laser cut directly influences downstream processes including bending, welding, and assembly. Even minor deviations can cascade into costly rework, delays, or system failure in the field.

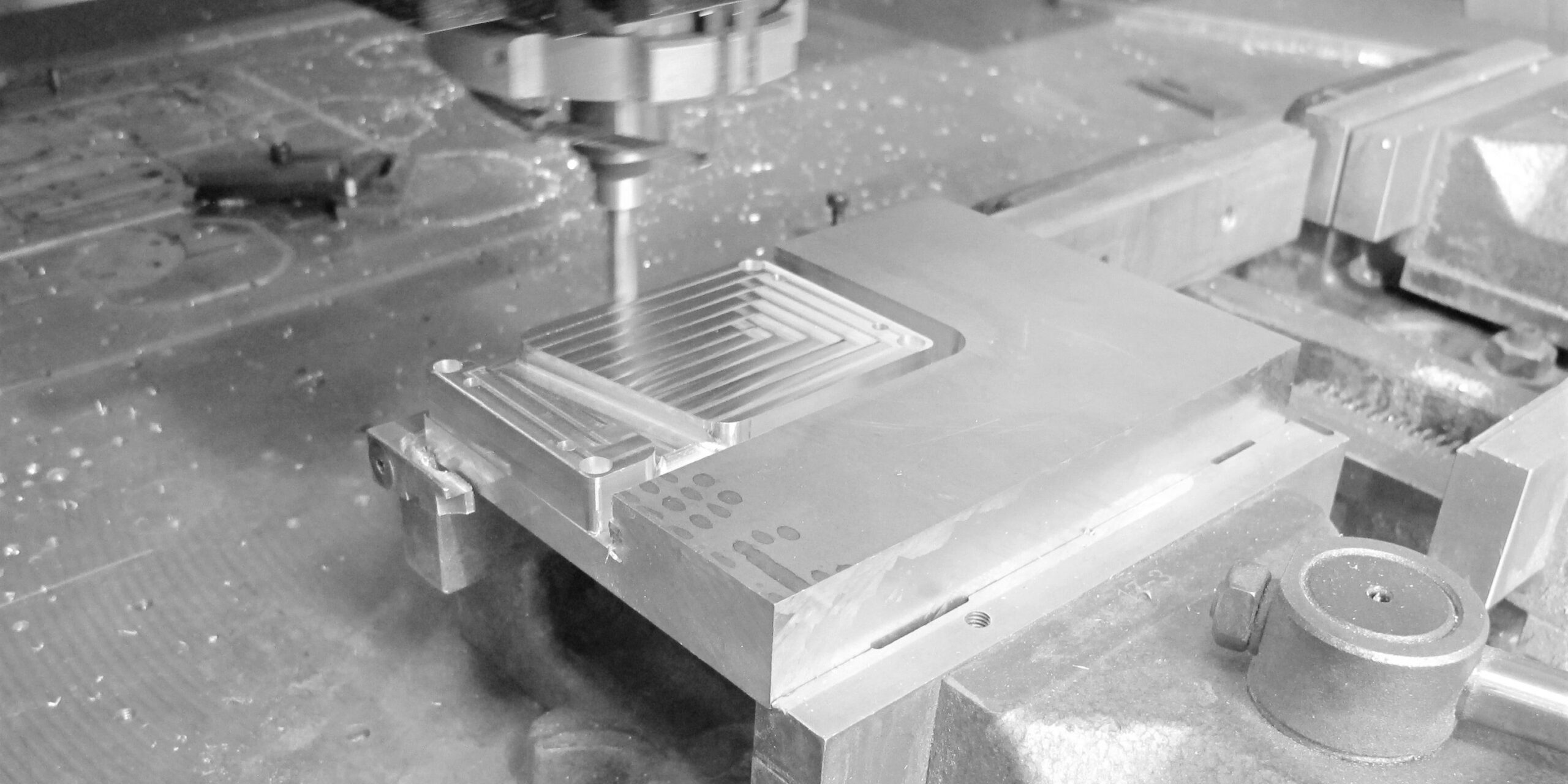

Our engineering philosophy centers on achieving micron-level consistency across every production run. This begins with the selection of high-performance fiber laser systems capable of maintaining beam stability under continuous operation. Coupled with advanced CNC motion control and real-time monitoring, our equipment ensures that each cut adheres to the specified geometry without thermal distortion or taper. We further enhance precision through optimized nesting algorithms that minimize heat accumulation and material warping during high-density cutting sequences.

Material selection and preparation are equally vital. We source certified alloys with consistent mechanical properties and conduct rigorous incoming inspections to verify flatness and surface integrity. Contaminants such as oil, scale, or oxidation are removed prior to processing, ensuring clean, spatter-free cuts. Our technicians calibrate assist gases—nitrogen for stainless steel, oxygen for mild steel, and compressed air for non-ferrous metals—based on thickness and application requirements, maximizing edge quality and minimizing post-processing.

Wuxi Lead Precision Machinery brings over a decade of specialized experience in producing laser-cut components for projects of national and international significance. Our portfolio includes structural and enclosure elements for Olympic-grade sports facilities, where dimensional accuracy ensures seamless integration across vast architectural assemblies. We have also supplied precision-cut panels and chassis components for military communication systems, meeting stringent MIL-STD compliance for durability and electromagnetic shielding. These projects demand not only technical excellence but also full traceability, documentation, and repeatable quality across batches.

Our commitment to precision is validated through continuous investment in metrology. Every critical feature is verified using coordinate measuring machines (CMM) and optical profilometers, with data logged for quality assurance. This disciplined approach enables us to deliver parts that fit, function, and perform as intended—every time.

Below are key technical specifications reflecting our laser cutting capabilities:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser (IPG Photonics) |

| Maximum Power | 12 kW |

| Cutting Thickness Range | 0.5 mm – 25 mm (steel) |

| Positioning Accuracy | ±0.03 mm/m |

| Repeatability | ±0.02 mm |

| Minimum Feature Size | 0.8 mm (holes, slots) |

| Edge Roughness (Ra) | < 6.3 µm (for t ≤ 6 mm) |

| Lead Time (Prototype) | 3–5 working days |

| Materials Supported | Carbon steel, stainless steel, aluminum, brass, copper |

Precision in laser cutting is not an accident—it is engineered. At Wuxi Lead Precision Machinery, we combine advanced technology, rigorous process control, and proven experience to deliver components that meet the highest standards of performance and reliability.

Precision Specs & Tolerances

Advanced Laser Cutting Capabilities for Mission-Critical Applications

Wuxi Lead Precision Machinery delivers exceptional precision and versatility in laser cutting for demanding sheet metal fabrication projects. Our integrated manufacturing ecosystem centers on state-of-the-art 5-axis CNC laser systems, enabling us to tackle complex geometries and stringent tolerances that conventional 2D or 3D platforms cannot achieve. This advanced capability is fundamental for producing high-integrity components used in aerospace, medical devices, semiconductor equipment, and advanced robotics, where part functionality and assembly integrity are non-negotiable. The 5-axis functionality allows for simultaneous cutting and beveling at precise angles directly within a single setup. This eliminates the need for secondary operations, significantly reduces part handling, minimizes cumulative error, and ensures superior edge quality and dimensional consistency across intricate features. Material utilization is optimized through intelligent nesting software, reducing waste on high-value alloys like titanium, Inconel, and specialized stainless steels without compromising cut speed or edge finish.

Rigorous quality control is embedded at every process stage, with Coordinate Measuring Machine (CMM) inspection serving as the cornerstone of our verification protocol. Every critical dimension, hole location, contour, and angular feature on finished laser-cut parts undergoes non-contact or tactile probing against the original CAD model. Our calibrated Zeiss and Hexagon CMMs provide micron-level measurement accuracy, generating comprehensive inspection reports traceable to international standards. This data-driven approach ensures absolute conformance to your engineering specifications and provides auditable proof of quality for regulated industries. We do not rely solely on machine capability; we validate every shipment against your unique requirements.

The achievable precision for laser-cut components is demonstrable through our controlled process parameters and stringent QC. The following table outlines typical tolerance capabilities for common materials under optimal processing conditions. Actual tolerances for your specific project will be confirmed during engineering review based on material grade, thickness, part complexity, and your functional requirements.

| Material Thickness Range | Linear Dimension Tolerance | Hole Diameter Tolerance | Angular Tolerance | Edge Squareness Tolerance |

|---|---|---|---|---|

| 0.5 mm – 3.0 mm | ±0.05 mm | +0.05 mm / -0.00 mm | ±0.25° | 0.05 mm per 25 mm |

| 3.1 mm – 6.0 mm | ±0.08 mm | +0.08 mm / -0.00 mm | ±0.30° | 0.10 mm per 25 mm |

| 6.1 mm – 12.0 mm | ±0.10 mm | +0.10 mm / -0.00 mm | ±0.40° | 0.15 mm per 25 mm |

These specifications represent our standard high-precision capability for production runs. Wuxi Lead Precision Machinery combines cutting-edge 5-axis laser technology with uncompromising metrology to transform complex sheet metal designs into reality. We partner with engineering teams to optimize designs for manufacturability while guaranteeing the dimensional accuracy and surface integrity demanded by next-generation applications. Contact our technical sales team to discuss how our laser cutting capabilities can ensure the success of your most challenging fabrication requirements.

Material & Finish Options

Material selection is a critical factor in precision laser cutting, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-accuracy sheet metal fabrication, offering expert guidance in choosing the optimal materials and surface treatments for demanding industrial applications. Aluminum, steel, and titanium represent the core materials used in laser-cut components, each offering distinct mechanical and thermal properties suited to specific engineering requirements.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and high thermal and electrical conductivity. It is ideal for aerospace, electronics, and transportation applications where lightweight yet rigid structures are essential. Grade 6061-T6 is commonly selected for its weldability and machinability, while 5052-H32 offers superior corrosion resistance in marine environments. Aluminum’s reflectivity requires precise laser parameters to avoid beam scattering, a challenge our fiber laser systems are specifically calibrated to manage.

Steel remains the most versatile material in sheet metal fabrication. Mild steel (A36) provides high tensile strength and affordability, making it suitable for structural components and industrial enclosures. For enhanced durability, stainless steel grades such as 304 and 316 offer superior resistance to oxidation and chemical exposure, with 316 being particularly effective in saline or high-moisture environments. Our laser cutting systems achieve clean, burr-free edges on steel up to 25 mm in thickness, ensuring dimensional accuracy and minimal post-processing.

Titanium, though more costly, delivers exceptional performance in extreme conditions. Known for its outstanding strength-to-density ratio and resistance to high temperatures and corrosion, Grade 5 (Ti-6Al-4V) is commonly used in aerospace, medical, and defense applications. Its low thermal conductivity demands precise thermal control during laser cutting to prevent localized hardening or oxidation, a capability our advanced CNC-controlled lasers provide with consistent repeatability.

Surface finishing further enhances part functionality and longevity. Anodizing, particularly for aluminum, creates a durable, non-conductive oxide layer that improves wear and corrosion resistance while allowing for color coding. Type II (sulfuric acid anodizing) is standard for decorative and protective finishes, while Type III (hardcoat anodizing) delivers thicker, engineered coatings for high-wear components.

Below is a comparison of key material specifications relevant to laser cutting performance.

| Material | Typical Grades | Max Thickness (mm) | Tensile Strength (MPa) | Key Applications |

|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 20 | 290–320 | Aerospace, Electronics |

| Mild Steel | A36, Q235 | 25 | 400–550 | Industrial Frames, Enclosures |

| Stainless Steel | 304, 316 | 25 | 515–620 | Medical, Food Processing |

| Titanium | Gr2, Gr5 (Ti-6Al-4V) | 15 | 860–1000 | Aerospace, Defense, Medical |

At Wuxi Lead Precision Machinery, we combine material expertise with state-of-the-art laser technology to deliver precision-cut components tailored to your operational demands.

Manufacturing Process & QC

Laser Cutting Production Process: Ensuring Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, our laser cutting production process is engineered for uncompromising quality, transforming client specifications into flawless sheet metal components. We integrate advanced technology with rigorous quality management across three critical phases: Design, Prototyping, and Mass Production. This structured approach, governed by our Zero Defects philosophy, eliminates errors before they occur, ensuring guaranteed conformance to your exacting standards and minimizing total project risk.

Design Phase Precision Engineering

Our process begins with meticulous design validation. Engineers utilize CAD/CAM software to optimize part geometry, nesting efficiency, and material utilization while strictly adhering to your dimensional tolerances and material specifications. Finite Element Analysis (FEA) predicts potential thermal distortion during cutting, allowing preemptive adjustments to kerf width and cutting paths. Material grain direction and mechanical properties are factored in to prevent warpage. This phase includes comprehensive Design for Manufacturability (DFM) reviews, where our team collaborates with your engineers to resolve ambiguities and refine features that could compromise precision or yield. Every design file undergoes automated and manual verification against ISO 2768-mK geometric tolerancing standards before release.

Prototyping Phase Validation & Refinement

A physical prototype is manufactured using the exact production laser system and parameters planned for volume run. This critical step validates the digital design against real-world material behavior and machine capabilities. We conduct rigorous first-article inspection (FAI) using coordinate measuring machines (CMM) and optical comparators, measuring all critical dimensions, edge quality, and burr levels against your blueprint. Any deviation triggers immediate root cause analysis and process correction. Material certification and traceability documentation are verified. Only after the prototype achieves 100% conformance and receives client sign-off does the process advance. This phase ensures mass production parameters are perfected, eliminating costly errors downstream.

Mass Production Phase Zero Defects Execution

Volume production leverages the validated parameters within a closed-loop quality system. Our fiber laser systems operate under Statistical Process Control (SPC), with real-time monitoring of laser power, gas pressure, and positional accuracy. Automated in-process inspections at defined intervals verify critical features, while 100% visual inspection checks for surface defects. Material batches are quarantined until full certification is confirmed. Final inspection employs calibrated metrology equipment against the original FAI report. Every component is traceable via serialized lot numbering, linking material certs, machine logs, and inspection data. This disciplined execution, combined with our certified ISO 9001:2015 quality management system, guarantees consistent output where defects are statistically impossible, not merely minimized.

Our core laser cutting capabilities support this precision workflow, as detailed in the specifications below.

| Parameter | Specification | Capability Impact |

|---|---|---|

| Laser Type | IPG Photonics Fiber Lasers | Superior edge quality, minimal dross |

| Max. Thickness | Carbon Steel: 25mm; Stainless: 20mm | Broad material applicability |

| Positioning Accuracy | ±0.05mm per meter | Critical for tight-tolerance assemblies |

| Repeatability | ±0.02mm | Ensures batch-to-batch consistency |

| Kerf Width | As low as 0.1mm | Enables intricate geometries |

| Edge Quality | ISO 9013 Class I | Eliminates secondary finishing needs |

This integrated process delivers laser cut parts that meet the most stringent aerospace, medical, and industrial requirements, proving that Zero Defects is an achievable standard, not an aspiration. Wuxi Lead guarantees conformance, on time, every time.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Expertise in Laser Cutting Parts

When it comes to precision sheet metal fabrication, the quality of your laser cutting parts directly impacts the performance, reliability, and longevity of your end products. At Wuxi Lead Precision Machinery, we combine decades of engineering excellence with state-of-the-art laser technology to deliver components that meet the most demanding industrial standards. Our advanced manufacturing capabilities, strict quality control systems, and commitment to on-time delivery make us the preferred partner for global OEMs, automation integrators, and high-tech equipment manufacturers.

Our laser cutting process is built on a foundation of precision, repeatability, and material integrity. Utilizing high-power fiber laser systems, we achieve clean, burr-free edges with minimal heat distortion—critical for applications in aerospace, medical devices, robotics, and industrial automation. Every component is cut with micron-level accuracy, ensuring tight tolerances and seamless integration into complex assemblies. Our team of experienced engineers works closely with clients during the design phase to optimize part geometry, material selection, and nesting efficiency—reducing waste and lowering overall production costs.

We support a wide range of materials, including stainless steel, carbon steel, aluminum, brass, and copper, with thicknesses ranging from 0.5 mm to 25 mm. Whether you require low-volume prototypes or high-volume production runs, our scalable manufacturing model ensures consistent quality across batches. All processes are performed in a controlled, ISO 9001-certified environment, with full traceability and comprehensive inspection reports available upon request.

Below are the key technical specifications of our laser cutting capabilities:

| Parameter | Specification |

|---|---|

| Laser Type | High-Power Fiber Laser |

| Maximum Cutting Thickness | 25 mm (mild steel), 20 mm (stainless/aluminum) |

| Material Compatibility | Stainless Steel, Carbon Steel, Aluminum, Brass, Copper |

| Cutting Area | Up to 3000 mm × 15000 mm |

| Positioning Accuracy | ±0.05 mm |

| Repeatability | ±0.03 mm |

| Edge Quality | Burr-free, minimal dross, smooth finish |

| Tolerance Range | ±0.1 mm (standard), tighter upon request |

| Supported File Formats | DXF, DWG, STEP, IGES, PDF |

| Lead Times | Prototype: 3–5 days; Production: 7–15 days |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we deliver engineering solutions. Our customer-first approach means responsive communication, technical collaboration, and a dedication to exceeding expectations on every project.

For inquiries, technical support, or to request a quote, contact us today at [email protected]. Let us help you achieve precision, efficiency, and reliability in every cut.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.