Technical Contents

Engineering Guide: Laser Cutting Of Technical Elastomers

Engineering Insight: Laser Cutting of Technical Elastomers

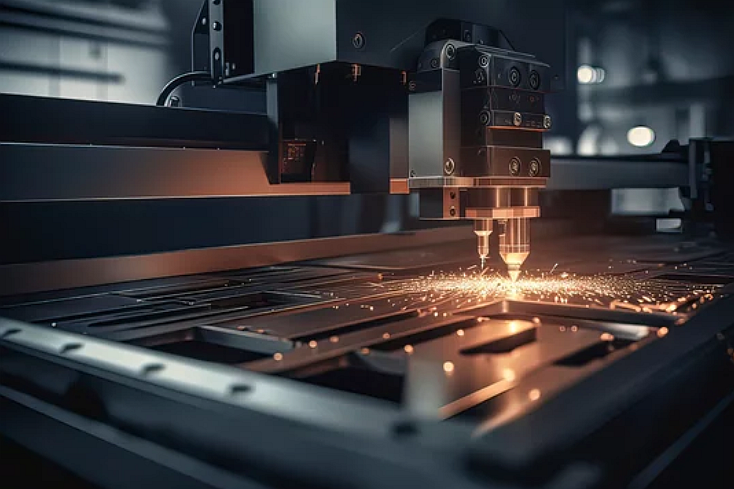

Precision in the laser cutting of technical elastomers is not merely a performance metric—it is a foundational requirement for mission-critical applications across aerospace, defense, medical devices, and high-performance automotive systems. Unlike conventional polymers or metals, technical elastomers such as Viton®, EPDM, silicone, and fluorosilicone present unique thermal and mechanical behaviors under laser exposure. Their viscoelastic nature, combined with low thermal conductivity and high carbon content in certain formulations, demands an exacting balance of laser parameters to achieve clean, burr-free, and dimensionally stable cuts.

At Wuxi Lead Precision Machinery, our engineering team has refined laser processing protocols through years of applied research and real-world validation in projects supporting Olympic-grade athletic equipment and military-grade sealing components. These applications leave no margin for error. In sealing systems used in extreme environments—whether cryogenic, high-pressure, or chemically aggressive—even a 10-micron deviation can compromise system integrity. Our approach integrates closed-loop CNC control with high-resolution galvanometric scanning systems, enabling micron-level positioning accuracy and consistent kerf width control across complex 2D profiles.

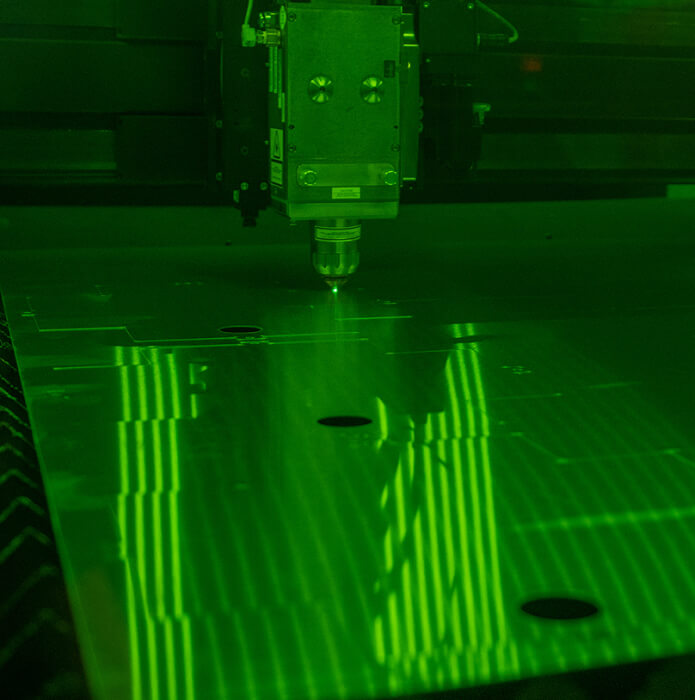

One of the critical challenges in elastomer laser cutting is managing heat-affected zones (HAZ). Excessive thermal input leads to charring, micro-cracking, and post-cut deformation—failures that are unacceptable in precision assemblies. To mitigate this, Lead Precision employs pulsed-wave CO₂ lasers with adjustable pulse duration and frequency modulation. This allows selective energy deposition, minimizing thermal diffusion while maintaining cutting speed. Coupled with optimized assist gas dynamics—typically nitrogen or dry air—we ensure clean edge quality without oxidation or residue.

Material consistency is another pillar of precision. We source technical elastomers from certified global suppliers and conduct in-house material characterization before processing. Batch-specific laser parameters are then calibrated using proprietary algorithms developed through thousands of test cuts under controlled environmental conditions. This data-driven methodology ensures repeatability across production runs, a capability proven in long-term contracts for defense contractors requiring ITAR-compliant documentation and traceability.

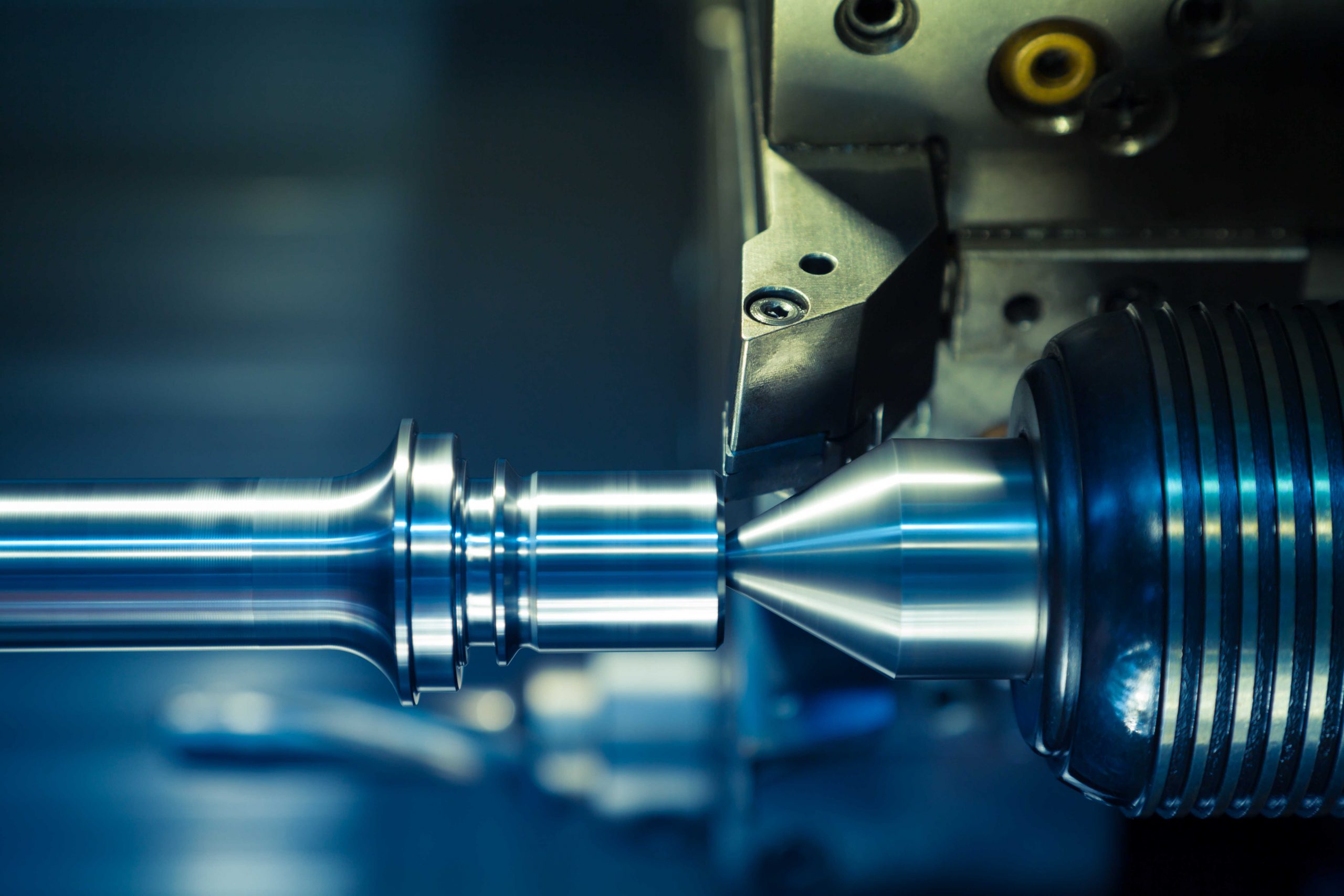

Our CNC laser platforms are built with rigid cast-iron frames and temperature-stabilized linear encoders, reducing positional drift to less than ±3 µm/m. Combined with real-time beam diagnostics and automated focus tracking, this enables stable processing of elastomer sheets from 0.5 mm to 6.0 mm thickness with tight tolerance retention.

Below are key performance specifications achieved on our standard production systems for technical elastomer cutting:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±2 µm |

| Repeatability | ±1 µm |

| Minimum Feature Size | 0.3 mm diameter |

| Edge Roughness (Ra) | ≤ 6.3 µm |

| Kerf Width Tolerance | ±0.05 mm |

| Max Cutting Speed (2mm Viton®) | 120 mm/s |

| HAZ Width | < 0.1 mm |

Wuxi Lead Precision Machinery continues to set benchmarks in the laser processing of advanced elastomers by merging precision engineering with deep application expertise. Our work in elite performance sectors underscores a simple truth: when failure is not an option, precision must be engineered into every micron.

Precision Specs & Tolerances

Technical Capabilities: Precision Laser Cutting of Technical Elastomers

Wuxi Lead Precision Machinery delivers advanced laser cutting solutions specifically engineered for the demanding requirements of technical elastomers. Materials such as silicone, fluorosilicone, EPDM, nitrile, and specialized thermoplastic elastomers present unique challenges including thermal sensitivity, elastic recovery, and potential for edge degradation during processing. Our dedicated approach overcomes these obstacles through integrated 5-axis CNC laser technology and rigorous process control, ensuring dimensional accuracy and clean, functional edges critical for high-performance applications in aerospace, medical devices, and semiconductor manufacturing.

Our core capability centers on high-precision CO2 and fiber laser systems integrated with 5-axis CNC motion control. This configuration provides unparalleled flexibility for cutting complex 3D contours, intricate profiles, and tight internal features within elastomeric sheets and molded preforms. Precise beam parameter modulation—adjusting power density, pulse frequency, and assist gas dynamics—is essential. We utilize optimized nitrogen or specialized gas mixtures as assist media to minimize thermal impact, prevent carbonization, eliminate melt adhesion, and achieve burr-free edges without secondary finishing. The 5-axis capability allows for optimal beam angle orientation relative to the material surface, critical for maintaining consistent cut quality through varying section thicknesses and complex geometries, significantly reducing part handling and secondary operations.

Achieving reliable results with elastomers demands more than advanced hardware; it requires deep material science understanding and closed-loop process validation. Every cutting program undergoes meticulous parameter development tailored to the specific elastomer compound, durometer, and part geometry. Critical factors such as beam focus position, traverse speed, and thermal management strategies are calibrated to counteract material memory and minimize post-cut dimensional shift. This scientific approach ensures cuts meet stringent functional requirements while preserving the elastomer’s inherent physical properties.

Verification is non-negotiable. All critical dimensions undergo comprehensive post-process inspection using calibrated Coordinate Measuring Machines (CMM). Our CMM protocols are designed specifically for elastomeric components, accounting for material handling and environmental stabilization to provide true dimensional representation. This data validates process capability and provides traceable quality assurance for our clients. The following table details achievable tolerance benchmarks for common elastomer cutting scenarios under controlled conditions.

| Feature Type | Material Thickness Range | Typical Tolerance (±) |

|---|---|---|

| Linear Dimensions | 0.5 mm – 3.0 mm | 0.05 mm |

| Linear Dimensions | 3.1 mm – 6.0 mm | 0.08 mm |

| Angular Features | All Thicknesses | 0.25° |

| Hole Diameter | 1.0 mm – 5.0 mm | 0.07 mm |

| Contour Complexity | All Thicknesses | 0.10 mm (Profile) |

| Inter-feature Spacing | All Thicknesses | 0.08 mm |

Wuxi Lead Precision Machinery combines specialized laser technology, material-specific process expertise, and metrology-grade verification to transform technically challenging elastomer components from design concept to high-integrity production reality. Our capabilities enable the fabrication of precision seals, gaskets, diaphragms, and custom elastomeric elements where conventional methods fail, ensuring reliability in the most demanding operational environments. Partner with us for solutions where material behavior and micron-level precision are equally critical.

Material & Finish Options

Material Selection for Laser Cutting of Technical Elastomers in High-Precision Sheet Metal Fabrication

When integrating technical elastomers into precision sheet metal assemblies, the selection of compatible structural materials is critical to ensuring long-term reliability, dimensional stability, and performance under dynamic loads. At Wuxi Lead Precision Machinery, we emphasize a systems-level approach to material pairing, particularly when laser cutting elastomeric components that interface with metals such as aluminum, steel, and titanium. These metals not only provide structural support but also influence thermal management, sealing integrity, and resistance to environmental degradation.

Aluminum is frequently chosen for its lightweight properties and excellent thermal conductivity. It is particularly suitable in applications where weight reduction is essential, such as in aerospace and electric vehicle battery enclosures. When laser cutting elastomers that will be mounted or bonded to aluminum, it is imperative to consider the coefficient of thermal expansion (CTE) mismatch. Anodizing aluminum enhances surface hardness and corrosion resistance, creating a more durable interface for elastomeric seals. Type II (sulfuric acid) and Type III (hard coat) anodizing are commonly applied, with the latter offering superior wear resistance for high-stress environments.

Stainless steel remains the preferred choice in high-corrosion or high-temperature environments. Its mechanical strength and dimensional stability make it ideal for industrial fluid handling systems where elastomeric gaskets are exposed to aggressive media. Laser cutting elastomers for use with stainless steel components requires tight control over edge quality to prevent micro-tearing, which can initiate premature failure. Passivation of stainless steel surfaces further improves compatibility by removing free iron and enhancing the natural oxide layer.

Titanium, while more costly, delivers exceptional strength-to-density ratios and outstanding resistance to saltwater and chemical exposure. It is often used in marine, medical, and aerospace applications where both performance and longevity are paramount. When pairing elastomers with titanium, plasma or chemical surface treatments can improve adhesion and sealing performance. Laser cutting parameters must be finely tuned to accommodate the high reflectivity and thermal conductivity of titanium substrates during hybrid assembly processes.

Surface finishes play a pivotal role in the functional lifespan of elastomer-metal systems. Anodizing not only protects aluminum but also provides a porous layer that can be sealed with fluoropolymers to enhance chemical resistance and reduce friction. For all metal-elastomer interfaces, surface roughness should be controlled within 0.8–1.6 μm Ra to ensure optimal sealing without excessive compression set.

Below is a comparative overview of key material properties relevant to laser cutting and elastomer integration:

| Material | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | CTE (10⁻⁶/K) | Common Surface Finish | Compatibility with Elastomers |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 167 | 23.6 | Anodizing (Type II/III) | High – with proper sealing |

| Stainless Steel 316 | 570 | 16 | 16.0 | Passivation | Very High |

| Titanium Grade 5 | 900 | 7.2 | 8.6 | Plasma Treatment | Excellent – in harsh environments |

At Wuxi Lead Precision Machinery, we combine advanced fiber laser technology with material science expertise to ensure clean, precise cuts in technical elastomers, tailored to the specific metal substrate and operational environment. Proper material and finish selection directly influences the performance and service life of the final assembly.

Manufacturing Process & QC

Precision Laser Cutting of Technical Elastomers: A Zero-Defect Production Framework

Achieving flawless laser cutting of technical elastomers demands a rigorously controlled process chain where design integrity, validated prototyping, and statistically monitored mass production converge. At Wuxi Lead Precision Machinery, we treat Zero Defects not as an aspiration but as the fundamental requirement for components in demanding sectors like medical devices, aerospace seals, and high-performance gaskets. This necessitates moving beyond basic cutting parameters to integrate material science, thermal dynamics, and real-time process verification from the earliest design phase.

The process begins with meticulous design engineering. Technical elastomers—silicones, FKM, EPDM, and specialized polyurethanes—exhibit unique thermal degradation thresholds and melt behaviors under laser exposure. Our engineers collaborate closely with clients during CAD development, embedding critical process knowledge directly into the part geometry. This includes optimizing kerf compensation for specific durometer ratings, designing strategic micro-vents to manage outgassing, and establishing precise thermal barrier zones to prevent edge charring or recast layer formation. Material batch certification data is cross-referenced against our laser parameter database to pre-validate feasibility, eliminating downstream surprises. Design sign-off requires confirmation that all features exceed the elastomer’s minimum resolvable feature size under laser processing.

Prototyping transitions theory into actionable data. We employ Design of Experiments (DOE) methodology, systematically varying laser power, pulse frequency, assist gas composition (often nitrogen or argon for oxidation-sensitive elastomers), and focal position across representative material batches. Each prototype undergoes non-destructive testing in our metrology lab: optical profilometry quantifies edge squareness and taper, FTIR spectroscopy verifies absence of chemical degradation, and tensile testing confirms unaffected bulk material properties. Only when dimensional accuracy consistently meets ±0.02mm tolerance and edge quality achieves Ra < 3.2µm without micro-cracking do we approve the final parameter set. This phase generates the validated recipe locked into our production control system.

Mass production executes with embedded quality assurance. Our fiber laser systems integrate real-time monitoring of beam power stability, gas pressure, and plume emission spectra. Statistical Process Control (SPC) charts track critical outputs per batch, with automatic machine hold if any parameter drifts beyond ±1.5σ. Every part undergoes 100% automated vision inspection for edge defects, dimensional conformity, and foreign material adherence before laser marking traceability codes. Material traceability links each component to its specific elastomer lot and process log. This closed-loop system ensures the Zero Defects standard is maintained across 10,000+ part runs, not merely targeted.

Critical Laser Cutting Parameters for Technical Elastomers

| Parameter | Typical Range | Critical Impact on Quality | Zero Defects Control Method |

|---|---|---|---|

| Laser Type | Pulsed Fiber | Minimizes HAZ, prevents melting | Fixed per material class |

| Power | 20W – 150W | Edge charring vs. incomplete cut | DOE-optimized per thickness/durometer |

| Pulse Frequency | 50 kHz – 500 kHz | Surface smoothness, dross formation | Real-time SPC monitoring |

| Assist Gas | N₂ / Ar (99.999%) | Oxidation prevention, debris ejection | Pressure/flow sensors with auto-cut |

| Edge Quality (Ra) | < 3.2 µm | Seal integrity, particle generation | 100% inline vision inspection |

This integrated approach—where design foresight, empirical prototyping validation, and production-grade process control operate as a single continuum—forms the bedrock of Wuxi Lead’s capability to deliver technically complex elastomer components with uncompromised reliability. Zero Defects is engineered in, not inspected in.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Laser Cutting of Technical Elastomers

In the demanding world of high-precision manufacturing, the ability to process technical elastomers with accuracy, consistency, and repeatability is critical. At Wuxi Lead Precision Machinery, we specialize in delivering state-of-the-art laser cutting solutions tailored specifically for advanced materials used in aerospace, medical devices, automotive sealing systems, and industrial automation. Our expertise in sheet metal fabrication extends beyond metals into the complex domain of technical elastomers—materials such as fluorocarbon rubber (FKM), ethylene propylene diene monomer (EPDM), silicone, and polyurethane—where thermal sensitivity, dimensional stability, and edge quality are paramount.

Our CO₂ and fiber laser systems are engineered with precision motion control, optimized beam delivery, and closed-loop monitoring to ensure clean, burr-free cuts without melting, charring, or deformation. We understand that elastomers present unique challenges due to their viscoelastic properties and low thermal conductivity. That’s why our processes are developed through rigorous material testing and parameter optimization, enabling us to achieve tight tolerances down to ±0.1 mm and kerf widths as narrow as 0.15 mm.

Wuxi Lead Precision Machinery combines German-level engineering standards with scalable production capabilities, serving global OEMs and Tier-1 suppliers who demand reliability and compliance. Whether you’re prototyping a new sealing component or scaling up for high-volume production, our team provides full technical support—from material evaluation and CAD/CAM programming to final inspection and process documentation.

We adhere to ISO 9001:2015 quality management protocols and maintain controlled environments to prevent material degradation during processing. Our facility is equipped with inline camera monitoring and automated material handling systems to ensure consistent part quality across batches.

Below are key technical specifications for our laser cutting platform when processing technical elastomers:

| Parameter | Specification |

|---|---|

| Laser Type | Sealed CO₂ (9.3 μm & 10.6 μm wavelength) |

| Maximum Power | 150 W (adjustable for material thickness) |

| Cutting Speed Range | 10–100 mm/s (material-dependent) |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Minimum Feature Size | 0.3 mm (holes), 0.5 mm (slots) |

| Edge Quality (Ra) | < 15 μm (no secondary finishing required) |

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Supported File Formats | DXF, DWG, STEP, IGES |

| Work Envelope | 600 × 400 mm (customizable up to 1200 × 800 mm) |

Every project begins with a collaborative engineering review to assess material behavior, part geometry, and performance requirements. We offer sample cutting runs and feasibility studies to validate results before full-scale production.

To elevate your elastomer component manufacturing, contact us today at [email protected]. Let Wuxi Lead Precision Machinery become your trusted partner in precision laser processing—where advanced technology meets industrial reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.