Technical Contents

Engineering Guide: Laser Cutting Machine Sheet Metal

Engineering Insight Precision in Laser Cutting for Sheet Metal Fabrication

Precision in laser cutting is not merely a desirable attribute; it is the absolute foundation of reliable, high-performance sheet metal fabrication. In critical applications spanning aerospace components, medical device enclosures, and advanced defense systems, dimensional inaccuracies measured in microns can cascade into catastrophic assembly failures, compromised structural integrity, or non-compliance with stringent regulatory standards. The laser cutting process must consistently deliver edges within specified tolerances, maintain perfect geometric fidelity across complex contours, and ensure minimal thermal distortion to preserve material properties. This level of control demands far more than a powerful laser source; it requires integrated engineering excellence encompassing motion control stability, beam quality management, adaptive process monitoring, and rigorous environmental calibration. At Wuxi Lead Precision Machinery, we understand that true precision is systemic, born from the seamless convergence of machine architecture, intelligent software, and unwavering process discipline.

Our commitment to micron-level accuracy is validated through demanding real-world applications. We have successfully delivered components meeting the exacting tolerances required for Olympic-grade sporting infrastructure, where structural perfection ensures athlete safety and event integrity under immense dynamic loads. Furthermore, our laser cutting systems consistently produce parts adhering to stringent military specifications (MIL-STD), where failure is not an option. This experience underscores our capability to handle materials ranging from ultra-thin stainless steel for electronics to high-strength alloys for defense platforms, always maintaining the dimensional stability and edge quality essential for downstream welding, bending, and assembly. Precision here translates directly to reduced scrap rates, accelerated production cycles, and ultimate product reliability for our clients.

The technical specifications of a laser cutting machine are the tangible expression of its precision capability. The following table details the critical performance parameters achievable with Wuxi Lead Precision Machinery systems designed for high-end sheet metal fabrication:

| Parameter | Specification | Significance for Precision |

|---|---|---|

| Positioning Accuracy | ±0.02 mm | Ensures correct feature location across entire work envelope |

| Repeatability | ±0.01 mm | Guarantees consistent part-to-part dimensional fidelity |

| Maximum Cutting Thickness | 25 mm (Mild Steel) | Maintains precision integrity even at material limits |

| Cutting Speed (1mm SS) | 45 m/min | High speed without sacrificing edge squareness or kerf width |

| Control System | Siemens 840D SL | Advanced motion control and real-time process compensation |

Achieving this level of performance requires continuous investment in machine rigidity, linear drive technology, and closed-loop feedback systems that actively correct for thermal drift and mechanical variance. It is this holistic engineering approach, proven in mission-critical projects, that allows Wuxi Lead Precision Machinery to deliver laser cutting solutions where absolute dimensional certainty is non-negotiable. Precision is the metric by which our machines, and our clients’ success, are ultimately measured.

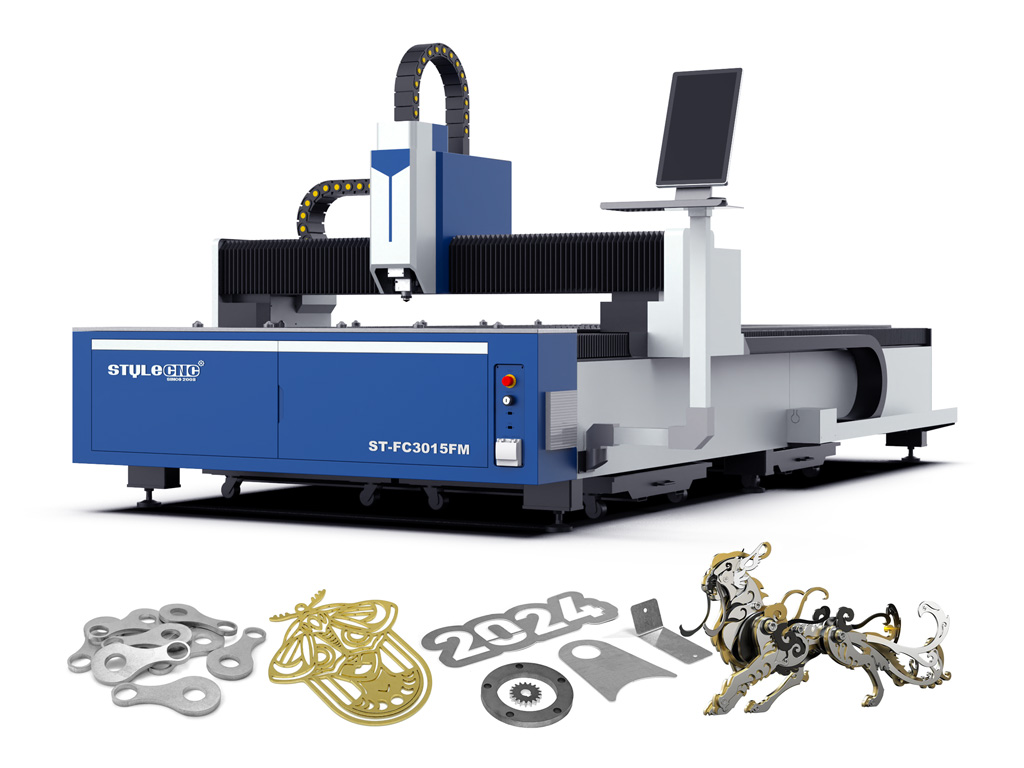

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in sheet metal fabrication, anchored by state-of-the-art 5-axis CNC laser cutting technology. Our integrated manufacturing platform enables precise, efficient, and repeatable processing of complex geometries across a broad range of conductive and non-conductive sheet materials. By combining high-power fiber laser sources with multi-axis motion control, we achieve intricate cuts, beveled edges, and three-dimensional contouring that traditional 2D systems cannot replicate. This level of precision supports demanding applications in aerospace, medical device manufacturing, and high-end industrial equipment.

Our 5-axis laser systems operate with dynamic beam control and intelligent path optimization, allowing for variable focus positioning and adaptive cutting parameters in real time. This ensures consistent edge quality across material thicknesses ranging from 0.5 mm to 25 mm, including stainless steel, aluminum, carbon steel, and specialty alloys. The simultaneous five-axis movement enables access to undercuts and angled features without secondary fixturing, reducing setup time and eliminating cumulative alignment errors. Each machine is maintained to OEM specifications and monitored through predictive maintenance protocols to ensure sustained peak performance.

Quality assurance is embedded throughout the production workflow. Every critical component undergoes post-processing inspection using a Zeiss DuraMax and GLOBAL S coordinate measuring machine (CMM), providing micron-level verification of dimensional accuracy and geometric conformity. Our inspection regime follows ISO 10360 standards, with full first-article reporting and batch traceability. Data from CMM inspections is integrated into our digital quality management system, enabling real-time feedback loops for process correction and continuous improvement.

To ensure consistency and meet client engineering requirements, we adhere to strict tolerance standards across all laser-cut features. These tolerances are validated through routine calibration and in-process measurement, ensuring compliance with ISO 2768 and customer-specific specifications.

| Feature | Standard Tolerance | Precision Tolerance (Optional) | Notes |

|---|---|---|---|

| Linear Dimensions (up to 100 mm) | ±0.1 mm | ±0.05 mm | Verified with CMM |

| Linear Dimensions (100–500 mm) | ±0.15 mm | ±0.08 mm | Per ISO 2768-m |

| Hole Diameter | +0.1 / –0.05 mm | +0.05 / –0.02 mm | Depends on material thickness |

| Angular Cuts (Bevels) | ±0.5° | ±0.2° | 5-axis controlled |

| Edge Perpendicularity | ±0.15 mm/m | ±0.08 mm/m | For plates >10 mm |

| Feature-to-Feature Positioning | ±0.1 mm | ±0.05 mm | Critical for assembly |

Wuxi Lead Precision Machinery maintains full technical documentation for every production run, including laser parameter logs, inspection reports, and material certifications. This comprehensive approach to technical execution ensures that every laser-cut component meets the highest standards of precision, repeatability, and functional performance in real-world applications.

Material & Finish Options

Material Selection for Precision Laser Cutting in Sheet Metal Fabrication

Selecting the correct material is critical for optimizing laser cutting performance, part quality, and cost efficiency. At Wuxi Lead Precision Machinery, we emphasize that material properties directly influence laser parameters, edge quality, and secondary processing requirements. This section details key considerations for aluminum, steel, and titanium, alongside anodizing compatibility for high-end applications.

Aluminum alloys dominate aerospace and electronics due to their strength-to-weight ratio and conductivity. However, aluminum’s high reflectivity and thermal conductivity demand precise laser control to prevent back-reflection damage to optics and inconsistent cuts. We recommend 5052 or 6061 alloys for optimal laser cut quality, as they minimize dross formation compared to high-silicon variants like 4043. Maximum thickness for clean cuts typically reaches 25mm with fiber lasers, though thinner sheets (under 6mm) yield superior edge smoothness. Avoid uncoated aluminum for intricate geometries without specialized anti-reflective coatings on the laser system.

Carbon steel and stainless steel remain industry staples for structural components. Mild steel (A36, SPCC) cuts efficiently with oxygen assist gas, producing oxidized edges suitable for welding or painting. For stainless steel (304, 316), nitrogen assist is essential to maintain corrosion resistance by preventing oxide layer formation. Stainless steel’s chromium content increases reflectivity and thermal resistance, requiring higher power density. Note that thickness capabilities vary: carbon steel cuts cleanly up to 30mm, while stainless steel is optimal under 20mm for fine-feature work. Exceeding these limits risks taper and slag adhesion.

Titanium alloys (Grade 2, 5) are reserved for critical aerospace and medical applications where strength and biocompatibility are paramount. Titanium’s low thermal conductivity necessitates high-purity nitrogen or argon shielding to prevent oxygen embrittlement during cutting. Thickness is generally limited to 12mm; beyond this, heat accumulation causes microcracking. Always verify material certification, as trace elements like iron can compromise cut integrity.

Material compatibility with post-processing finishes is equally vital. Anodizing, a common aluminum surface treatment, cannot be applied before laser cutting. The anodized layer interferes with laser absorption, causing uneven cuts and coating damage. Anodize only after cutting, deburring, and cleaning to ensure uniform electrolyte penetration and adhesion.

Key material specifications for laser cutting are summarized below. Parameters assume fiber laser systems (1–6 kW) with optimized assist gas and focus settings.

| Material | Max Recommended Thickness | Laser Type | Key Consideration |

|---|---|---|---|

| Aluminum Alloys | 25 mm | Fiber | High reflectivity; use anti-reflective optics |

| Carbon Steel | 30 mm | Fiber/CO₂ | Oxygen assist for speed; edge oxidation |

| Stainless Steel | 20 mm | Fiber | Nitrogen assist required; avoid oxygen |

| Titanium Alloys | 12 mm | Fiber (high-power) | Inert gas shielding mandatory |

Material choice directly impacts your project’s cost, lead time, and functional performance. Wuxi Lead Precision Machinery’s engineering team conducts material-specific parameter validation to eliminate trial-and-error waste. For complex projects involving titanium or tight-tolerance aluminum, consult our application specialists to refine your material and process strategy. We ensure your sheet metal fabrication achieves aerospace-grade repeatability while maximizing yield.

Manufacturing Process & QC

Design Phase: Precision Engineering for Optimal Fabrication

The foundation of flawless sheet metal production begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we integrate advanced CAD/CAM software to translate conceptual blueprints into manufacturable designs. Our engineering team evaluates material selection, thickness compatibility, and geometric complexity to ensure laser cut parts meet both functional and aesthetic requirements. Design for Manufacturability (DFM) principles are applied rigorously, minimizing stress points, optimizing kerf width, and accounting for thermal distortion during laser processing. This phase includes comprehensive simulation using CNC nesting software to maximize material utilization and reduce waste. Every design undergoes cross-functional review to verify dimensional accuracy, tolerance adherence (±0.1 mm standard), and alignment with international standards such as ISO 2768.

Prototyping: Validating Accuracy Before Scale

Once the design is finalized, a high-precision prototype is produced using our fiber laser cutting systems. This stage serves as a physical validation of the digital model, allowing for real-world assessment of fit, form, and function. Prototyping at Wuxi Lead leverages the same industrial-grade equipment used in mass production—ensuring consistency across stages. The prototype undergoes rigorous inspection via coordinate measuring machines (CMM) and optical comparators to verify edge quality, hole alignment, and overall geometry. Any deviations are traced back to the design or process parameters and corrected before progression. Customer feedback is incorporated at this stage, enabling iterative refinement without impacting production timelines. This closed-loop validation process ensures that only error-free designs advance to full-scale manufacturing.

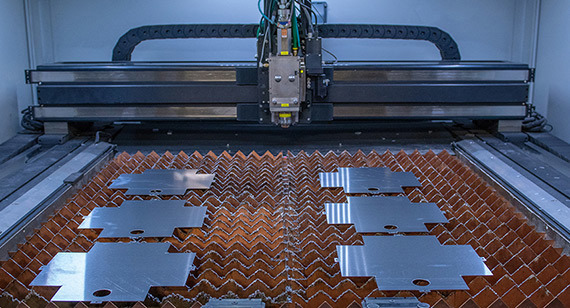

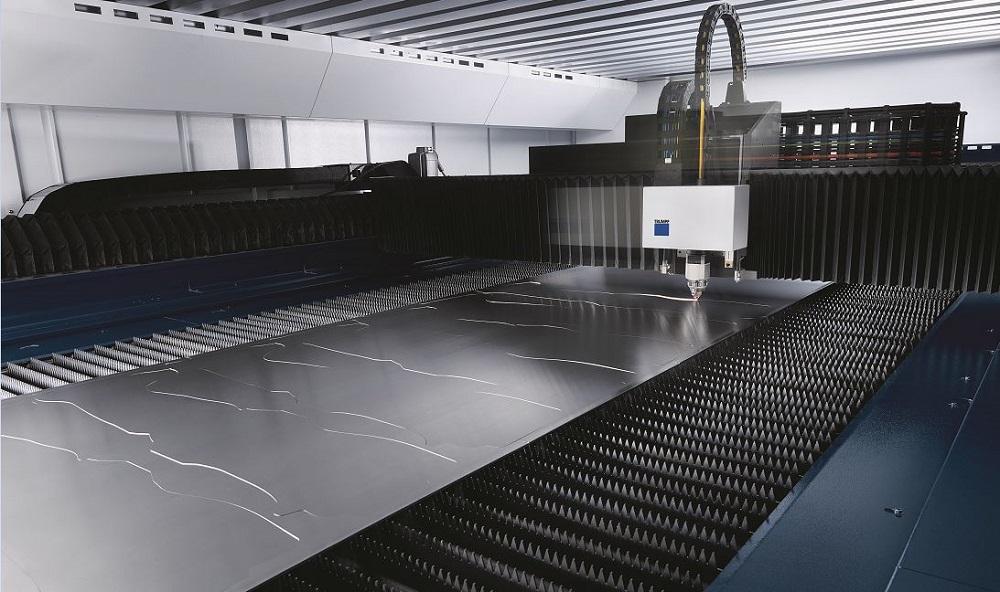

Mass Production: Zero-Defect Execution at Scale

With prototype approval, the project transitions into mass production, where Wuxi Lead’s automated laser cutting cells deliver high-speed, high-accuracy output with uncompromised consistency. Our fiber laser machines operate at peak performance, supported by real-time monitoring systems that detect anomalies in power delivery, gas pressure, or beam focus. Each sheet is processed with automated material handling, reducing human intervention and minimizing contamination or handling errors. In-process quality checks occur at defined intervals, including first-article inspection and statistical process control (SPC) sampling. All parts are deburred and cleaned post-cutting, followed by 100% visual and dimensional inspection for critical components. Traceability is maintained through batch coding and digital logs, enabling full auditability.

Laser Cutting Machine Specifications

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser (IPG or Raycus Source) |

| Cutting Thickness Range | 0.5 – 25 mm (mild steel) |

| Positioning Accuracy | ±0.03 mm/m |

| Repeatability | ±0.02 mm |

| Maximum Cutting Speed | Up to 100 m/min (thin sheet) |

| Supported Materials | Mild Steel, Stainless Steel, Aluminum, Galvanized Sheet |

| Control System | Siemens, Fanuc, or PA8000 |

| Nesting Software | Lantek, SigmaNEST, or Hypertherm ProNest |

| Power Consumption (Avg.) | 8 – 15 kW depending on laser power |

Through integrated design validation, precision prototyping, and disciplined mass production protocols, Wuxi Lead ensures zero-defect delivery in every sheet metal component we manufacture.

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Fabrication Through Strategic Partnership

In the competitive landscape of precision sheet metal manufacturing, your laser cutting machine represents far more than a production tool—it is the cornerstone of quality, efficiency, and profitability. Wuxi Lead Precision Machinery understands that selecting a partner requires confidence in engineering excellence, unwavering reliability, and responsive technical collaboration. We deliver not merely equipment, but a comprehensive solution engineered to integrate seamlessly into your operational workflow, minimize downtime, and maximize yield across diverse materials including stainless steel, aluminum, and carbon steel up to 30mm thickness.

Our commitment begins with precision-engineered laser cutting systems built to international standards, featuring advanced motion control and intelligent nesting software that optimizes material utilization while maintaining micron-level accuracy. The table below outlines core specifications defining our industrial-grade platforms:

| Specification | Lead Precision LP Series Standard | Lead Precision LP Series High-Power |

|---|---|---|

| Cutting Area (mm) | 1500 x 3000 | 2000 x 4000 |

| Max. Material Thickness | 25mm Carbon Steel / 20mm Stainless | 30mm Carbon Steel / 25mm Stainless |

| Positioning Accuracy | ±0.03mm | ±0.03mm |

| Repeatability | ±0.02mm | ±0.02mm |

| Laser Source Options | IPG/ Raycus Fiber (6kW, 8kW, 12kW) | IPG Fiber (12kW, 20kW) |

| Control System | Siemens 840D SL / Cypcut Pro | Siemens 840D SL with AI Optimization |

Beyond specifications, our partnership model provides tangible operational advantages. We deploy factory-certified engineers for installation and operator training, ensuring rapid commissioning and immediate productivity gains. Our global service network guarantees 24/7 technical support with remote diagnostics capabilities, reducing mean time to repair by up to 70% compared to industry averages. Crucially, we collaborate proactively—analyzing your specific part geometries, volume requirements, and material challenges to configure a system that delivers measurable ROI from day one. This consultative approach prevents costly over-specification while future-proofing your investment through modular upgrade paths.

Wuxi Lead Precision Machinery operates under ISO 9001 and CE certifications, with stringent in-house testing protocols exceeding IEC 60204-1 safety standards. Every machine undergoes 72-hour continuous burn-in cycles and laser calibration verification before shipment, eliminating field adjustment delays. We recognize that your reputation hinges on consistent part quality; our systems incorporate real-time monitoring of beam focus, gas pressure, and thermal compensation to maintain dimensional integrity across extended production runs.

Initiate your precision transformation by contacting our engineering team directly. Forward your current fabrication challenges, material specifications, and target throughput to [email protected]. Within 24 business hours, a dedicated applications engineer will provide a customized capability assessment and ROI analysis tailored to your facility. Do not compromise on the foundation of your sheet metal operations—partner with a manufacturer committed to your long-term competitive advantage through precision, partnership, and proven performance. Your next-generation fabrication capability begins with a single, decisive connection.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.