Technical Contents

Engineering Guide: Laser Cutting Fabrication

Engineering Insight: Precision in Laser Cutting Fabrication

In the realm of advanced sheet metal fabrication, precision is not merely a performance metric—it is the foundation of reliability, functionality, and long-term value. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations can compromise the integrity of critical components used in aerospace, defense, and high-performance industrial systems. This understanding drives our engineering philosophy: precision must be engineered into every stage of the laser cutting process, from material handling to final inspection.

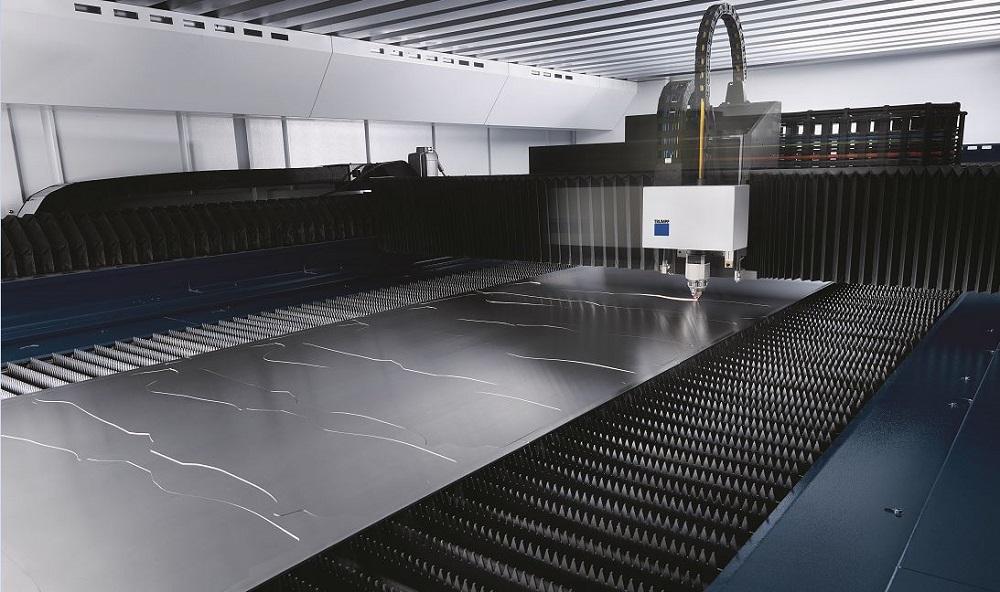

Laser cutting, when executed with true precision, offers unmatched accuracy, clean edge quality, and repeatability. However, achieving such results requires more than just high-powered equipment. It demands a holistic approach integrating advanced motion control systems, thermal compensation algorithms, real-time monitoring, and rigorous calibration protocols. At Lead Precision, our laser cutting platforms are built around rigid gantry structures, high-resolution linear encoders, and intelligent beam delivery systems that maintain focus stability across diverse material types and thicknesses.

Our commitment to precision is validated through decades of service in mission-critical industries. We have supplied laser fabrication systems used in Olympic-grade sports technology, where component consistency directly impacts athletic performance. More significantly, our machines meet stringent military-grade standards, producing parts for defense applications where failure is not an option. These projects demand full traceability, documented process validation, and compliance with ISO 13849 and IEC 62061 safety and performance directives—benchmarks we consistently achieve.

Precision also extends beyond hardware. Our proprietary CNC control systems utilize predictive path optimization, minimizing micro-vibrations and thermal distortion during high-speed cutting. Adaptive focusing adjusts the laser beam in real time based on material thickness and surface variance, ensuring consistent kerf width and edge squareness. These features are essential when processing advanced alloys such as titanium, Inconel, and high-strength steels commonly used in defense and energy sectors.

To illustrate the performance envelope of our laser cutting systems, the following table outlines key technical specifications achieved under controlled production conditions:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.02 mm over 1 meter |

| Repeatability | ±0.01 mm |

| Minimum Feature Size | 0.5 mm (carbon steel, 1 mm thickness) |

| Edge Roughness (Ra) | ≤ 3.2 µm (stainless steel, 3 mm) |

| Kerf Width Tolerance | ±0.05 mm |

| Maximum Cutting Speed | 120 m/min (thin sheet, <1 mm) |

| Material Thickness Range | 0.5 – 25 mm (steel), 0–20 mm (aluminum) |

| Beam Quality (BPP) | < 0.8 mm·mrad |

These specifications are not theoretical—they are consistently achieved across our installed base in high-mix, high-precision environments. At Wuxi Lead Precision Machinery, we do not just manufacture laser cutting systems; we engineer confidence. Whether supporting national defense programs or enabling breakthroughs in competitive engineering, our technology delivers the precision that industry leaders trust.

Precision Specs & Tolerances

Technical Capabilities: Precision Laser Cutting Fabrication

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication centered on high-precision laser cutting, engineered for demanding industrial applications. Our integrated manufacturing cell combines cutting-edge hardware with rigorous process control to achieve exceptional dimensional accuracy and surface integrity across diverse materials including stainless steel, aluminum, carbon steel, and specialty alloys. Standard processing capacity spans material thicknesses from 0.5mm to 25mm, accommodating both prototype development and high-volume production runs with consistent repeatability. The foundation of our capability lies in eliminating secondary operations through precision-first methodology, directly translating design intent into finished components.

Our core laser processing platform features state-of-the-art 5-axis CNC laser cutting systems. This technology transcends conventional 2D limitations, enabling the precise fabrication of complex bevels, countersinks, and contoured edges within a single setup. The simultaneous 5-axis motion control ensures geometric complexity is achieved without manual repositioning, significantly reducing cumulative error potential and cycle times for intricate parts. This capability is critical for aerospace brackets, fluid power manifolds, and medical device housings requiring tight angular tolerances and seamless feature integration. Material handling automation integrated with the laser cells guarantees optimal throughput while maintaining stringent flatness specifications pre- and post-processing.

Quality assurance is systematically embedded throughout production, not applied as a final check. Every critical dimension and geometric feature undergoes verification via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM). Our certified metrology technicians execute inspection routines aligned with ASME Y14.5 standards, utilizing calibrated probes and advanced software for comprehensive GD&T analysis. This provides objective, traceable data on form, position, and profile deviations against the original CAD model. All inspection results are documented in certified measurement reports, available to clients as part of our quality deliverables, ensuring full transparency and compliance with stringent industry requirements like ISO 9001 and AS9100.

Material thickness directly influences achievable precision. The following table details our standard tolerance capabilities under controlled production conditions, reflecting our commitment to predictable, high-fidelity output:

| Material Thickness Range | Dimensional Tolerance | Angular Tolerance | Edge Quality Standard |

|---|---|---|---|

| 0.5 mm – 3.0 mm | ±0.05 mm | ±0.5° | ISO 9013 Class C |

| 3.1 mm – 10.0 mm | ±0.10 mm | ±0.75° | ISO 9013 Class C |

| 10.1 mm – 20.0 mm | ±0.15 mm | ±1.0° | ISO 9013 Class D |

| 20.1 mm – 25.0 mm | ±0.20 mm | ±1.5° | ISO 9013 Class D |

These tolerances represent our standard production capability for critical features under optimal process parameters. Wuxi Lead Precision Machinery collaborates closely with engineering teams during Design for Manufacturability (DFM) reviews to confirm feasibility and establish achievable specifications for the most challenging geometries, ensuring your components meet functional requirements without unnecessary cost escalation. Our technical sales engineers provide detailed capability assessments based on your specific part drawings.

Material & Finish Options

Material selection is a critical step in laser cutting fabrication, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in high-precision sheet metal fabrication, leveraging advanced fiber laser technology to process a range of engineering-grade materials. Understanding the properties and compatibility of aluminum, steel, and titanium with laser cutting processes enables designers and engineers to make informed decisions that align with functional and aesthetic requirements.

Aluminum is widely used in aerospace, electronics, and transportation industries due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is highly suitable for laser cutting, especially in grades such as 5052, 6061, and 7075. However, aluminum’s high reflectivity and thermal conductivity require optimized laser parameters to ensure clean, precise cuts. Post-processing treatments like anodizing further enhance its surface properties, improving wear resistance and enabling color customization for branding or identification purposes.

Steel remains a dominant material in structural and industrial applications. Mild steel (e.g., Q235, Q345) offers high strength and cost-effectiveness, making it ideal for enclosures, frames, and machinery components. Stainless steel grades such as 304 and 316 provide superior corrosion resistance and a clean aesthetic, often used in medical, food processing, and architectural applications. Laser cutting delivers exceptional edge quality on steel, with minimal burr formation and high dimensional accuracy. For enhanced durability, stainless steel components may undergo passivation or electropolishing, while carbon steel can be powder coated or galvanized.

Titanium and its alloys, particularly Grade 2 and Grade 5 (Ti-6Al-4V), are essential in high-performance sectors such as aerospace, defense, and biomedical engineering. Titanium offers an outstanding strength-to-density ratio and exceptional resistance to extreme environments, including high temperatures and corrosive media. While more challenging to process due to its low thermal conductivity and reactivity at elevated temperatures, titanium can be precisely cut using high-power fiber lasers under controlled conditions to prevent oxidation and maintain material integrity.

Anodizing is a key surface treatment for aluminum components, forming a durable, non-conductive oxide layer that increases surface hardness and corrosion resistance. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly specified, with the latter offering thicker coatings for severe wear environments. Color anodizing is also available for visual differentiation or design integration.

The following table summarizes key material specifications relevant to laser cutting fabrication:

| Material | Common Grades | Max Thickness (mm) | Tolerance (± mm) | Surface Finish Options |

|---|---|---|---|---|

| Aluminum | 5052, 6061, 7075 | 25 | 0.1 | Anodizing, Mill Finish, Bead Blast |

| Mild Steel | Q235, Q345 | 30 | 0.2 | Powder Coating, Galvanizing, Painting |

| Stainless Steel | 304, 316 | 25 | 0.15 | Passivation, Brushed, Polished |

| Titanium | Gr2, Gr5 (Ti-6Al-4V) | 15 | 0.1 | Anodizing, Passivation, Bare Mill |

At Wuxi Lead Precision Machinery, we support comprehensive material and finish selection based on application demands, ensuring optimal performance and manufacturability. Our engineering team collaborates closely with clients to recommend the best material-process combination for mission-critical components.

Manufacturing Process & QC

Precision Laser Cutting Fabrication: From Concept to Zero-Defect Production

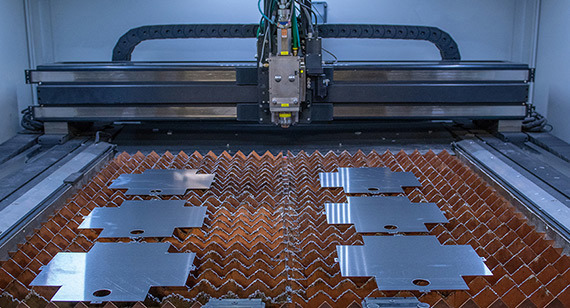

At Wuxi Lead Precision Machinery, we engineer laser cutting fabrication as a seamless, quality-driven continuum. Our industrial process eliminates defects at origin, transforming client specifications into flawless sheet metal components. This begins with rigorous digital design validation. Every CAD model undergoes comprehensive manufacturability analysis, identifying potential stress points, kerf width implications, and thermal distortion risks before metal meets beam. Our engineers collaborate directly with clients to optimize part geometry, material selection, and nesting efficiency, ensuring designs align precisely with the capabilities of our fiber laser systems. This phase prevents costly downstream errors by resolving tolerance stack-up issues and material compatibility concerns in the virtual environment.

Prototyping transitions validated designs into physical reality under controlled conditions. We utilize our high-precision laser platforms to produce initial samples, applying the exact parameters intended for volume production. Each prototype undergoes stringent metrology: coordinate measuring machines (CMM) verify dimensional accuracy against the original CAD file, while visual and tactile inspections assess edge quality, burr formation, and surface integrity. This critical validation loop confirms process stability and component functionality. Only when prototypes meet or exceed all specifications—verified against ISO 2768-mK or client-specific standards—does the project advance. This step is non-negotiable; it is the foundation of our zero-defect commitment.

Mass production leverages fully automated workflows governed by real-time quality assurance protocols. Programs generated during prototyping are deployed on our multi-kilowatt fiber laser systems, integrated with automated material handling and sorting. In-process inspection occurs continuously: integrated sensors monitor laser power stability, assist gas pressure, and focal point position, while inline cameras detect anomalies like incomplete cuts or positional drift. Statistical process control (SPC) tracks key metrics per batch, triggering immediate corrective action if deviations approach tolerance limits. Final inspection employs 100% automated vision systems for critical features, supplemented by random CMM spot checks. This layered approach ensures every component shipped meets the exacting standards demanded by aerospace, medical, and advanced industrial applications.

Our laser cutting capabilities deliver consistent precision across diverse production scales. Key technical specifications include:

| Parameter | Specification | Industrial Relevance |

|---|---|---|

| Material Thickness | 0.5 mm – 25 mm | Broad range for structural & precision parts |

| Positional Accuracy | ±0.05 mm | Critical for complex assemblies |

| Edge Quality (Ra) | ≤ 3.2 µm (up to 6mm mild steel) | Minimizes secondary finishing needs |

| Max. Cutting Speed | 100 m/min (thin sheet) | Optimizes throughput for high-volume runs |

| Tolerance Class | ISO 2768-mK (standard) | Meets stringent global engineering norms |

| Nesting Software | Advanced AI-driven optimization | Reduces material waste by 18-22% |

Zero defects are achieved not through inspection alone, but by embedding quality into every process tier—from the first digital line to the final packaged part. Wuxi Lead’s integrated methodology ensures your fabrication yield is maximized, lead times are predictable, and component reliability is uncompromised. This is precision manufacturing engineered for mission-critical success.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Laser Cutting Fabrication Excellence

In the competitive landscape of modern manufacturing, precision, speed, and reliability define success. At Wuxi Lead Precision Machinery, we understand the demands of high-volume, high-accuracy sheet metal fabrication. Our advanced laser cutting technology, combined with decades of engineering expertise, positions us as the ideal strategic partner for global OEMs, contract manufacturers, and industrial innovators.

We specialize in delivering end-to-end laser cutting fabrication solutions tailored to your exact specifications. From prototype development to large-scale production runs, our state-of-the-art facilities in Wuxi, China, are equipped with high-power fiber laser systems capable of processing a wide range of materials—including carbon steel, stainless steel, aluminum, and specialty alloys—with micron-level accuracy and exceptional edge quality. Our integrated workflow ensures seamless transition from design to delivery, minimizing lead times and maximizing consistency.

Our commitment to quality is reinforced through rigorous process controls and full traceability. Every component is inspected using precision metrology equipment, ensuring compliance with international standards such as ISO 9001 and IATF 16949. Whether you require simple blanks or complex formed assemblies, our team of experienced engineers collaborates closely with your design and procurement teams to optimize manufacturability, reduce material waste, and lower total production costs.

By partnering with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a technology-driven manufacturing ally focused on scalability, innovation, and long-term value.

Explore our laser cutting capabilities and discover how we can support your next fabrication project with unmatched precision and service.

| Specification | Detail |

|---|---|

| Laser Type | High-Power Fiber Laser |

| Maximum Power | Up to 12,000 W |

| Material Thickness Range | 0.5 mm – 25 mm (varies by material) |

| Max Cutting Area | 1500 mm × 3000 mm |

| Positioning Accuracy | ±0.03 mm/m |

| Repeatability | ±0.02 mm |

| Supported Materials | Carbon Steel, Stainless Steel, Aluminum, Galvanized Steel, Copper Alloys |

| Software Integration | AutoCAD, SolidWorks, DXF/DWG, STEP |

| Quality Standards | ISO 9001, IATF 16949 |

| Secondary Processes | Bending, Welding, Surface Treatment, Assembly |

Contact us today to discuss your laser cutting fabrication requirements. Our engineering team is ready to support your project with technical consultation, rapid prototyping, and scalable production solutions. For inquiries, quotations, or design reviews, email us at [email protected]. Let Wuxi Lead Precision Machinery be your trusted partner in precision manufacturing—where advanced technology meets industrial reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.