Technical Contents

Engineering Guide: Laser Cutting Companies

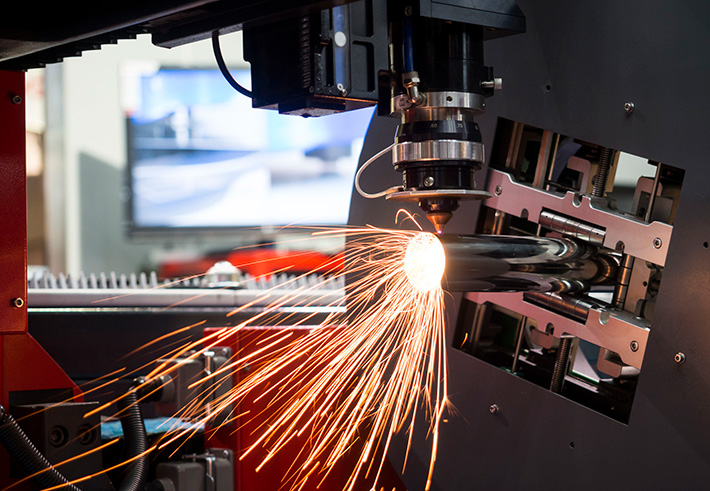

Engineering Insight: The Critical Role of Precision in Laser Cutting for Advanced Manufacturing

In the realm of sheet metal fabrication, precision is not merely a performance metric—it is the foundation upon which reliability, repeatability, and structural integrity are built. For laser cutting companies operating in high-stakes industries such as aerospace, defense, and advanced industrial equipment, even micron-level deviations can result in cascading failures across assembly lines or end-use applications. At Wuxi Lead Precision Machinery, we understand that precision engineering is inseparable from mission-critical performance.

Our engineering philosophy is rooted in decades of refining laser cutting technology to meet the most stringent global standards. With direct involvement in projects supporting Olympic infrastructure and military-grade equipment manufacturing, our systems have been tested under conditions where failure is not an option. These experiences have shaped our approach to machine rigidity, thermal compensation, motion control, and beam delivery—each element calibrated to ensure micron-level accuracy across extended production cycles.

Precision in laser cutting is influenced by multiple interdependent factors: laser source stability, beam path consistency, material handling dynamics, and real-time feedback systems. A high-powered fiber laser may offer exceptional cutting speed, but without a thermally stable machine frame and advanced motion control, the resulting part will lack dimensional consistency. At Lead Precision, our machines integrate granitic base structures to minimize vibration and thermal drift, coupled with linear motor drive systems that eliminate backlash and ensure sub-micron positioning accuracy.

Moreover, precision extends beyond hardware. Our proprietary CNC control systems utilize adaptive algorithms that adjust cutting parameters in real time based on material thickness, surface condition, and ambient variables. This level of intelligent control ensures uniform edge quality and tight tolerance adherence across diverse batch sizes—from prototype runs to high-volume production.

The following table outlines key performance specifications of our flagship fiber laser cutting systems, engineered for the most demanding fabrication environments:

| Parameter | Specification |

|---|---|

| Laser Source Power | 6 kW – 20 kW (IPG or Raycus) |

| Positioning Accuracy | ±0.03 mm/m |

| Repeatability | ±0.01 mm |

| Maximum Cutting Speed | 120 m/min (thin sheet, <3 mm) |

| Material Thickness Range | 0.5 mm – 30 mm (steel) |

| Beam Quality (BPP) | <0.8 mm·mrad |

| Control System | Siemens 840D /自主研发高性能数控系统 |

| Machine Frame Material | High-density granite composite |

| Cooling System | Closed-loop chiller, ±0.5°C stability |

| Operating Environment | 10–40°C, humidity 30–70% (non-condensing) |

These specifications reflect our commitment to delivering not just machinery, but engineered solutions that uphold the integrity of every cut. For laser cutting companies aiming to serve elite industrial sectors, partnering with a manufacturer that has proven its precision under Olympic and military scrutiny is not just an advantage—it is a necessity. At Wuxi Lead Precision Machinery, we don’t cut metal; we define its exactness.

Precision Specs & Tolerances

Technical Capabilities: Precision Beyond Laser Cutting

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication capabilities that extend significantly beyond standard laser cutting processes. Our core strength lies in integrating high-precision 5-axis CNC milling and turning centers, enabling the production of complex, fully finished components directly from raw plate or laser-cut blanks. This strategic capability addresses critical limitations inherent in standalone laser systems, particularly for parts requiring intricate 3D features, tight positional tolerances across multiple surfaces, or secondary operations like threading, counterbores, and precision hole patterns. Our 5-axis technology eliminates the need for multiple setups and fixtures, drastically reducing cumulative error and fixture-induced distortion while achieving geometric complexity unattainable with 2D laser profiling alone.

We process a comprehensive range of sheet metal alloys essential to demanding industries, including aerospace, medical device manufacturing, and advanced electronics. Our equipment handles carbon steels, stainless steels (300 & 400 series), aluminum alloys (2024, 5052, 6061, 7075), copper, brass, and titanium with equal proficiency. Material thickness capabilities span from 0.5mm up to 25mm, providing flexibility for both thin-gauge enclosures and robust structural components. Crucially, our process maintains the critical surface integrity and edge quality often compromised by laser heat-affected zones, ensuring optimal performance for subsequent finishing or assembly.

Rigorous quality control is non-negotiable. Every critical dimension and geometric feature undergoes verification using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss CONTURA and GLOBAL S series CMMs provide micron-level accuracy in a temperature-controlled metrology lab, validating conformance to even the most stringent ASME Y14.5 and ISO 1101 geometric dimensioning and tolerancing (GD&T) requirements. This systematic CMM inspection, performed per documented First Article Inspection (FAI) and in-process check plans, provides irrefutable data traceability and guarantees that parts meet the exact specifications demanded by high-reliability applications. It is the definitive step that transforms a cut blank into a certified, ready-to-assemble component.

The precision achievable through our integrated 5-axis CNC machining and CMM-verified quality process is consistently maintained across production volumes. As demonstrated in the tolerance specifications below, we deliver exceptional repeatability for both linear dimensions and critical geometric characteristics.

| Feature Type | Standard Capability | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | CMM |

| Hole Diameter | +0.03 / -0.00 mm | +0.01 / -0.00 mm | CMM / Air Gage |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | CMM (GD&T) |

| Flatness | 0.05 mm | 0.02 mm | CMM / Surface Plate |

| Perpendicularity | 0.05 mm | 0.02 mm | CMM (GD&T) |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Profilometer |

Partnering with Wuxi Lead transforms your laser-cut blanks into fully mission-critical components. We bridge the gap between basic cutting and true precision fabrication, ensuring your complex sheet metal parts meet the highest standards of accuracy, reliability, and functional performance, backed by comprehensive, data-driven quality assurance.

Material & Finish Options

Material Selection for High-Precision Laser Cutting in Sheet Metal Fabrication

Selecting the appropriate material is critical in laser cutting operations, particularly when serving high-end industries such as aerospace, medical devices, and advanced electronics. At Wuxi Lead Precision Machinery, we understand that material properties directly influence cutting precision, edge quality, and post-processing requirements. The most commonly processed materials in our facility include aluminum, stainless steel, and titanium—each offering distinct mechanical and thermal characteristics suited to specific applications.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and high thermal and electrical conductivity. It is particularly well-suited for lightweight structural components and enclosures in the electronics and transportation sectors. However, aluminum’s high reflectivity and thermal conductivity require optimized laser parameters to prevent back-reflection damage and ensure clean cuts. Our fiber laser systems are calibrated to handle aluminum grades such as 5052, 6061, and 7075 with precision tolerances down to ±0.1 mm.

Stainless steel remains a staple in industrial applications due to its durability, weldability, and resistance to oxidation. Grades like 304 and 316 are frequently used in medical instruments, food processing equipment, and architectural components. The chromium content in stainless steel forms a passive oxide layer, enhancing corrosion resistance while allowing for high-quality laser cutting with minimal dross. Our CNC-controlled cutting platforms maintain consistent beam focus and assist gas control to deliver burr-free edges, reducing secondary finishing efforts.

Titanium, though more challenging to process, is indispensable in high-performance environments. Its exceptional strength-to-density ratio and resistance to extreme temperatures make it ideal for aerospace and defense applications. Grade 2 and Grade 5 (Ti-6Al-4V) are commonly fabricated using our high-power lasers under inert gas shielding to prevent oxidation during cutting. Due to its low thermal conductivity, titanium requires precise heat input management to avoid microstructural changes near the heat-affected zone.

Post-cut surface finishing further enhances performance and aesthetics. Anodizing is a widely used electrochemical process for aluminum components, increasing surface hardness and corrosion resistance while allowing for color coding. We support anodizing preparation through precise edge deburring and surface cleaning, ensuring uniform coating adhesion.

Below is a comparative overview of key material specifications relevant to laser cutting performance.

| Material | Common Grades | Thickness Range (mm) | Tensile Strength (MPa) | Reflectivity | Recommended Laser Type |

|---|---|---|---|---|---|

| Aluminum | 5052, 6061, 7075 | 0.5 – 12.0 | 180 – 570 | High | Fiber Laser (with anti-reflective optics) |

| Stainless Steel | 304, 316 | 0.6 – 25.0 | 505 – 860 | Medium | Fiber Laser with Nitrogen/Oxygen Assist |

| Titanium | Grade 2, Grade 5 | 0.8 – 15.0 | 345 – 1000 | Low | High-Power Fiber Laser with Argon Shield |

Material choice must align with functional requirements, environmental exposure, and production efficiency. At Wuxi Lead Precision Machinery, we collaborate closely with engineering teams to recommend optimal materials and cutting strategies, ensuring superior part integrity and performance in final applications.

Manufacturing Process & QC

Precision Sheet Metal Fabrication: The Zero-Defect Production Process

Achieving true zero defects in sheet metal fabrication demands an integrated, rigorously controlled production sequence—not isolated stages. At Wuxi Lead Precision Machinery, we engineer our entire workflow around eliminating errors before they occur, ensuring every component meets exacting aerospace, medical, and industrial standards. This begins with intelligent design validation.

Design is the foundational defense against defects. Our engineering team collaborates closely with clients during the CAD phase, performing mandatory Design for Manufacturability (DFM) analysis. We scrutinize material selection, kerf allowances, heat-affected zone implications, and nesting efficiency specific to fiber laser capabilities. Critical tolerances are cross-verified against machine capabilities and material behavior models, preventing unbuildable features. This proactive review eliminates 80% of potential downstream errors before cutting commences.

Prototyping transitions design into physical validation under production conditions. We utilize the same high-precision fiber laser systems intended for mass production, not scaled-down alternatives. Each prototype undergoes comprehensive metrology: CMM verification of critical dimensions, surface roughness testing, and edge quality assessment against ISO 9013 standards. Dimensional stability after bending and forming is rigorously checked. Only when all prototype metrics consistently meet specification—verified across three consecutive units—does the process advance. This stage confirms process capability, not just part correctness.

Mass production executes the validated process with unwavering consistency. Our automated production cells integrate real-time monitoring at every touchpoint. Laser power, gas pressure, and nozzle condition are continuously logged and auto-adjusted. In-line vision systems inspect cut edges and part geometry immediately post-processing, rejecting anomalies before secondary operations. Statistical Process Control (SPC) charts track key parameters like positional accuracy and dimensional drift, triggering preventive maintenance before tolerances approach limits. Human oversight focuses on data analysis and exception handling, not manual inspection of every part.

This closed-loop methodology, from validated design through prototyped proof to monitored mass production, is enabled by our core machine specifications ensuring micron-level repeatability:

| Specification | Performance Metric | Impact on Zero Defects |

|---|---|---|

| Positioning Accuracy | ±0.02 mm | Ensures precise feature alignment |

| Repeatability | ±0.01 mm | Guarantees batch-to-batch consistency |

| Laser Power Stability | ±1% | Prevents cut quality variations |

| Inert Gas Purity Control | 99.999% | Eliminates oxidation defects |

| Real-Time Monitoring | 1000+ data points/sec | Enables immediate anomaly detection |

Zero defects is not an aspiration; it is the measurable outcome of eliminating variability at each process inflection point. Wuxi Lead’s integrated approach transforms precision from a goal into a standard operating procedure.

Why Choose Wuxi Lead Precision

Elevate Your Production with Wuxi Lead Precision Machinery

In the competitive landscape of sheet metal fabrication, precision, speed, and reliability define success. At Wuxi Lead Precision Machinery, we engineer advanced laser cutting solutions designed for high-volume, high-accuracy manufacturing environments. Our systems are built to meet the rigorous demands of modern laser cutting companies, delivering consistent performance, reduced downtime, and superior cut quality across a wide range of materials.

As a trusted partner in industrial automation and precision engineering, we specialize in fiber laser cutting machines that integrate seamlessly into advanced production workflows. Whether you are processing mild steel, stainless steel, aluminum, or other alloys, our machines are engineered for optimal energy efficiency, dynamic responsiveness, and long-term durability. We understand that your business depends on uptime and repeatability—our technology is designed with that priority in mind.

Partnering with Wuxi Lead Precision Machinery means more than acquiring equipment—it means gaining a strategic ally in manufacturing excellence. Our engineering team provides comprehensive support from initial consultation to installation, training, and after-sales service. We customize solutions based on your production volume, material mix, and facility requirements, ensuring maximum return on investment and operational scalability.

Our commitment extends beyond the machine. We offer remote diagnostics, predictive maintenance protocols, and spare parts logistics designed to minimize disruption. With a growing network of service technicians across Asia, Europe, and North America, we ensure rapid response and sustained performance, no matter your location.

Below are the key specifications of our flagship fiber laser cutting system, the LP-F3015:

| Specification | Detail |

|---|---|

| Laser Source Power | 1 kW – 6 kW (IPG or Raycus options) |

| Max Cutting Speed | 120 m/min |

| Positioning Speed | 150 m/min |

| Repeatability | ±0.03 mm |

| Worktable Size | 3000 mm × 1500 mm |

| Supported Materials | Mild steel, stainless steel, aluminum, brass, copper |

| Max Material Thickness | Up to 30 mm (mild steel), 25 mm (stainless), 20 mm (aluminum) |

| Control System | Siemens, Mitsubishi, or PA8000M (user-selectable) |

| Cooling System | Closed-loop chiller with intelligent temperature control |

| Operating Environment | 5°C – 40°C, humidity < 85% (non-condensing) |

Every machine is manufactured under strict ISO 9001 quality standards and subjected to rigorous performance testing before shipment. Our modular design philosophy allows for future upgrades, including automated loading/unloading systems and MES integration for Industry 4.0 readiness.

To learn how Wuxi Lead Precision Machinery can enhance your laser cutting operations, contact us today at [email protected]. Our engineering and sales team is ready to discuss your production goals, provide technical documentation, and arrange live cutting demonstrations. Let us help you achieve next-level precision, productivity, and profitability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.