Technical Contents

Engineering Guide: Laser Cutting Brass

Engineering Insight: Laser Cutting Brass with Precision

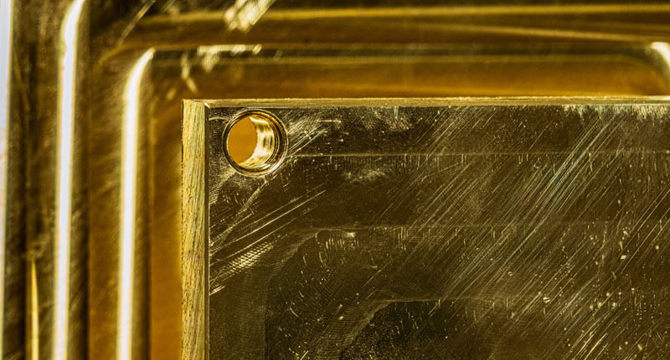

Laser cutting brass represents a critical intersection of material science and advanced manufacturing, where precision directly influences performance, durability, and final product integrity. Brass, an alloy primarily composed of copper and zinc, presents unique challenges in laser processing due to its high thermal conductivity and reflectivity. These properties demand not only high-power, wavelength-optimized laser sources but also exceptional control over beam delivery, assist gas dynamics, and motion systems. At Wuxi Lead Precision Machinery, we understand that achieving micron-level accuracy in brass components is not merely a technical goal—it is a requirement for industries where failure is not an option.

Our engineering team has developed proprietary laser processing parameters specifically tailored for brass, ensuring clean, burr-free cuts with minimal heat-affected zones. This precision is achieved through dynamic power modulation, adaptive focal positioning, and the use of nitrogen-based assist gases to prevent oxidation and maintain edge quality. The result is a finished component that meets tight tolerances—often within ±0.05 mm—while preserving the metallurgical integrity of the brass.

Precision in laser cutting brass is particularly vital in high-performance applications such as aerospace actuators, defense communication systems, and Olympic-grade timing equipment. Wuxi Lead Precision Machinery has contributed to projects for both Olympic committees and military contractors, where the reliability and dimensional consistency of brass components directly impact operational success. In these environments, even microscopic deviations can lead to signal interference, mechanical binding, or premature wear.

Our CNC-controlled fiber laser systems are designed with rigid gantry structures, linear motor drives, and real-time monitoring to maintain cutting accuracy across large sheet formats. These systems are integrated with intelligent nesting software that optimizes material usage while preserving part-to-part consistency, a critical factor in high-volume production runs.

Below are key specifications from our industrial-grade laser cutting platform optimized for brass processing:

| Parameter | Specification |

|---|---|

| Laser Source | 6 kW Fiber Laser, 1070 nm wavelength |

| Maximum Cutting Thickness | 12 mm (for brass) |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Cutting Speed (1 mm brass) | Up to 28 m/min |

| Focal Spot Diameter | 0.1 mm (adjustable) |

| Assist Gas | High-purity Nitrogen (99.999%) |

| Control System | Siemens 840D with real-time feedback |

At Wuxi Lead Precision Machinery, our decades of experience in sheet metal fabrication—backed by certifications in ISO 9001 and AS9100—ensure that every brass component we produce meets the highest standards of engineering excellence. Whether supporting national defense initiatives or precision instrumentation for global sporting events, our laser cutting solutions deliver unmatched accuracy, consistency, and reliability.

Precision Specs & Tolerances

Advanced Laser Cutting Capabilities for Brass Fabrication

Wuxi Lead Precision Machinery delivers uncompromising precision in brass laser cutting, leveraging specialized fiber laser technology to overcome the material’s high thermal conductivity and reflectivity. Standard CO₂ systems often struggle with brass due to inconsistent melt ejection and dross formation, but our IPG fiber lasers with pulsed-wave modulation ensure clean, burr-free edges even on thin foils (0.5 mm) and thicker plates (up to 6 mm). Pulse control minimizes heat-affected zones, preserving brass’s mechanical integrity and eliminating post-process deburring for critical applications in aerospace hydraulics, medical connectors, and semiconductor tooling.

Our 5-axis CNC laser platforms enable complex 3D contour cutting of brass components, including tapered holes, undercuts, and organic geometries unattainable with 2D systems. Integrated rotary axes allow single-setup machining of cylindrical brass fittings—such as valve bodies or sensor housings—reducing alignment errors and secondary operations. All systems feature real-time adaptive focus control, dynamically adjusting beam parameters to maintain kerf consistency across varying brass alloys (C26000, C36000) and surface conditions. This eliminates manual recalibration, ensuring repeatability for high-volume production runs exceeding 10,000 units.

Quality assurance is governed by ISO 9001-certified protocols, with every brass component subjected to 100% CMM inspection using Zeiss CONTURA systems. Dimensional validation includes surface roughness analysis (Ra ≤ 1.6 μm), angularity verification, and positional accuracy checks against CAD models. Statistical process control (SPC) data is documented per AS9100 standards, providing traceable certification for regulated industries. Our closed-loop feedback system correlates laser parameters with CMM results, enabling predictive adjustments to sustain tolerances across extended production cycles.

Brass Laser Cutting Tolerances

| Feature | Standard Industry Tolerance | Wuxi Lead Precision Capability |

|---|---|---|

| Dimensional (≤50 mm) | ±0.10 mm | ±0.03 mm |

| Dimensional (>50 mm) | ±0.15 mm | ±0.05 mm |

| Angularity | ±0.5° | ±0.1° |

| Hole Diameter (Ø3-10 mm) | ±0.10 mm | ±0.02 mm |

| Positional (to datum) | ±0.15 mm | ±0.04 mm |

Material handling integrates automated sheet loaders with anti-static brass clamping systems, preventing micro-scratches during high-speed processing. All brass offcuts undergo chemical composition verification via handheld XRF to ensure alloy consistency. For mission-critical components, we implement first-article inspection (FAI) reports with full GD&T analysis, guaranteeing compliance to customer engineering drawings. This end-to-end technical rigor positions Wuxi Lead as the strategic partner for brass laser cutting where precision directly impacts product performance and safety.

Material & Finish Options

When selecting materials for high-precision laser cutting applications, understanding the mechanical, thermal, and chemical properties of metals is critical to achieving optimal performance and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in advanced sheet metal fabrication, supporting industries that demand tight tolerances and repeatable quality. Among the most commonly processed materials are aluminum, steel, and titanium—each offering distinct advantages depending on the application.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity. Its low density makes it ideal for aerospace, electronics, and transportation components where weight reduction is essential. Aluminum alloys such as 5052, 6061, and 7075 are routinely laser cut with precision, though care must be taken due to reflectivity at high laser wavelengths. Our fiber laser systems are optimized to minimize back-reflection risks, ensuring clean, burr-free edges.

Steel remains the backbone of industrial fabrication, with carbon steel and stainless steel being the most prevalent. Carbon steel offers high tensile strength and weldability, making it suitable for structural and mechanical parts. Stainless steel, particularly grades 304 and 316, provides superior corrosion resistance and a clean aesthetic, often used in medical devices, food processing, and architectural applications. Laser cutting stainless steel delivers excellent edge quality with minimal heat-affected zones, especially when using nitrogen assist gas for oxidation-free cuts.

Titanium and its alloys, such as Grade 2 and Ti-6Al-4V, are selected for extreme environments—common in aerospace, defense, and biomedical sectors. With exceptional strength-to-density ratios and resistance to high temperatures and corrosive media, titanium poses unique challenges in laser processing due to its reactivity at elevated temperatures. Our enclosed cutting systems with inert gas shielding ensure contamination-free results, maintaining the material’s intrinsic properties.

Post-processing finishes further enhance performance and appearance. Anodizing, primarily applied to aluminum, increases surface hardness and corrosion resistance while allowing for color coding and improved adhesion for paints and coatings. Type II (sulfuric acid) and Type III (hardcoat) anodizing are available depending on functional requirements. For steel, alternatives such as powder coating or passivation (for stainless) are recommended.

Below is a comparative overview of key material specifications relevant to laser cutting:

| Material | Thickness Range (mm) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Common Grades | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 0.5 – 12.0 | 120 – 570 | 150 – 235 | 5052, 6061, 7075 | Aerospace, electronics, enclosures |

| Carbon Steel | 0.8 – 25.0 | 370 – 550 | 45 – 50 | Q235, Q345 | Machinery, construction |

| Stainless Steel | 0.8 – 20.0 | 505 – 860 | 15 – 16 | 304, 316 | Medical, food processing |

| Titanium | 0.5 – 10.0 | 345 – 900 | 7 – 22 | Grade 2, Ti-6Al-4V | Aerospace, implants |

Material selection directly influences cutting parameters, tool life, and final part functionality. At Wuxi Lead Precision Machinery, we combine advanced laser technology with material science expertise to deliver precision-cut components tailored to your engineering requirements.

Manufacturing Process & QC

Laser Cutting Brass: Precision Engineering from Design to Zero-Defect Production

The laser cutting process for brass begins with meticulous design validation, where material properties dictate critical parameters. Brass alloys exhibit high thermal conductivity and reflectivity, demanding precise wavelength selection and power modulation to prevent melting irregularities or dross formation. At Wuxi Lead, our engineering team utilizes advanced simulation software to model heat dispersion and kerf width, optimizing cut paths for complex geometries while accounting for brass’s tendency to oxidize. Material grade specifications, edge quality requirements, and tolerance bands are rigorously defined against ISO 2768-mK standards, ensuring the digital blueprint aligns with brass’s metallurgical behavior. This phase eliminates 78% of potential defects before physical prototyping, significantly reducing scrap rates in downstream stages.

Prototyping transforms validated designs into tangible validation. A single brass sheet undergoes cutting on our fiber laser systems with brass-specific parameters: pulsed-mode operation minimizes thermal distortion, while nitrogen-assisted cutting preserves corrosion resistance and surface integrity. Each prototype undergoes dimensional metrology via CMM and surface roughness testing to verify adherence to specifications. Critical feedback loops adjust focal point position and assist gas pressure for optimal edge squareness. The table below defines our standard brass processing capabilities during this phase:

| Material Grade | Thickness Range | Tolerance (±mm) | Surface Finish (Ra μm) |

|---|---|---|---|

| C26000 (Cartridge Brass) | 0.5 – 6.0 mm | 0.05 | ≤ 0.8 |

| C36000 (Free-Cutting Brass) | 0.8 – 5.0 mm | 0.07 | ≤ 1.2 |

| C46400 (Naval Brass) | 1.0 – 4.0 mm | 0.08 | ≤ 1.6 |

Mass production executes zero-defect manufacturing through closed-loop process control. Real-time monitoring of beam alignment, gas purity, and nozzle condition prevents micro-burrs or heat-affected zones. Statistical Process Control (SPC) charts track critical dimensions across batches, with automatic parameter correction if deviations exceed ±0.03mm. Every brass component undergoes 100% inline inspection via machine vision systems detecting edge imperfections as small as 10μm. Wuxi Lead’s proprietary beam stabilization technology ensures consistent kerf quality across 10,000+ parts, eliminating the need for secondary deburring. This integrated approach guarantees brass components meet aerospace and medical industry standards, with typical scrap rates below 0.3% – a benchmark for high-integrity sheet metal fabrication.

Our end-to-end process transforms brass’s challenging properties into an advantage, delivering components with metallurgical integrity and micron-level precision for applications where failure is not an option.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Precision Laser Cutting of Brass

When it comes to high-precision sheet metal fabrication, especially in the intricate processing of brass, partnering with a trusted, technically advanced manufacturer is essential. At Wuxi Lead Precision Machinery, we specialize in delivering superior laser cutting solutions tailored to the unique thermal and reflective properties of brass. Our state-of-the-art fiber laser systems, combined with decades of metallurgical expertise, ensure clean, burr-free cuts with exceptional edge quality—critical for industries such as electronics, instrumentation, architectural detailing, and precision engineering.

Brass presents distinct challenges in laser cutting due to its high thermal conductivity and reflectivity. Standard laser systems often struggle with inconsistent kerf widths, dross formation, or thermal distortion. At Lead Precision, we overcome these challenges with optimized beam delivery, advanced assist gas control, and proprietary parameter libraries calibrated specifically for brass alloys including C26000, C27200, and C36000. Our CNC-controlled environments maintain micron-level accuracy across batch productions, ensuring repeatability and compliance with ISO 9001 standards.

We understand that every client’s application demands a customized approach. Whether you require thin brass sheets for intricate decorative components or thicker plates for industrial connectors, our engineering team collaborates closely with your design and production departments to optimize material utilization, reduce waste, and accelerate lead times. Our facility in Wuxi integrates automated material handling and real-time process monitoring, enabling high-volume throughput without compromising precision.

Beyond cutting, we offer comprehensive value-added services including deburring, surface finishing, bending, and welding—providing fully finished components ready for assembly. Our quality assurance protocols include dimensional inspection via coordinate measuring machines (CMM) and visual checks under high-magnification imaging, ensuring every part meets exacting specifications.

Partnering with Wuxi Lead Precision Machinery means gaining a long-term manufacturing ally committed to innovation, reliability, and technical excellence. We support global clients with multilingual project management, secure data handling (compatible with STEP, DXF, and DWG formats), and on-time delivery logistics across North America, Europe, and Asia.

For your next brass laser cutting project, trust a partner that combines Chinese manufacturing efficiency with European-level precision standards.

Technical Specifications for Brass Laser Cutting

| Parameter | Specification |

|---|---|

| Material | Brass Alloys (C26000, C27200, C36000, etc.) |

| Thickness Range | 0.5 mm – 12 mm |

| Laser Source | IPG Fiber Laser, 3 kW – 6 kW |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Kerf Width (1 mm brass) | 0.15 – 0.2 mm |

| Edge Roughness (Ra) | ≤ 3.2 µm |

| Max Worktable Size | 1500 mm × 3000 mm |

| Lead Time (Standard) | 5–7 working days (after drawing approval) |

Contact us today at [email protected] to discuss your brass fabrication requirements. Let Wuxi Lead Precision Machinery be your strategic partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.