Technical Contents

Engineering Guide: Laser Cut Steel Sheet

Engineering Insight: Precision in Laser Cut Steel Sheet Fabrication

In the domain of high-end sheet metal fabrication, laser cutting has emerged as the benchmark for accuracy, repeatability, and clean edge quality—particularly when applied to steel sheets. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a performance metric; it is a foundational requirement for industries where dimensional integrity directly impacts safety, functionality, and long-term reliability. Whether producing components for aerospace, defense systems, or large-scale infrastructure projects such as those associated with Olympic facilities, the margin for error is effectively zero.

Laser cutting steel sheets with micron-level precision demands more than advanced hardware—it requires deep engineering insight, rigorous process control, and a culture of quality that permeates every stage of production. The thermal dynamics of laser interaction with steel, material grain consistency, beam focus stability, and assist gas purity all influence the final cut quality. Even minor deviations in any of these parameters can result in taper, dross formation, or microstructural changes that compromise part performance.

Our expertise at Wuxi Lead stems from over a decade of serving mission-critical sectors, including military and large-scale public infrastructure. Projects such as structural support elements for Olympic venues demanded not only flawless dimensional accuracy but also compliance with international material standards and fatigue resistance under extreme loads. In military applications, our laser-cut steel components have been integrated into mobile defense platforms where reliability under harsh conditions is non-negotiable. These experiences have refined our approach to laser cutting, embedding precision into every workflow—from CAD modeling and nesting optimization to in-process monitoring and post-cut inspection.

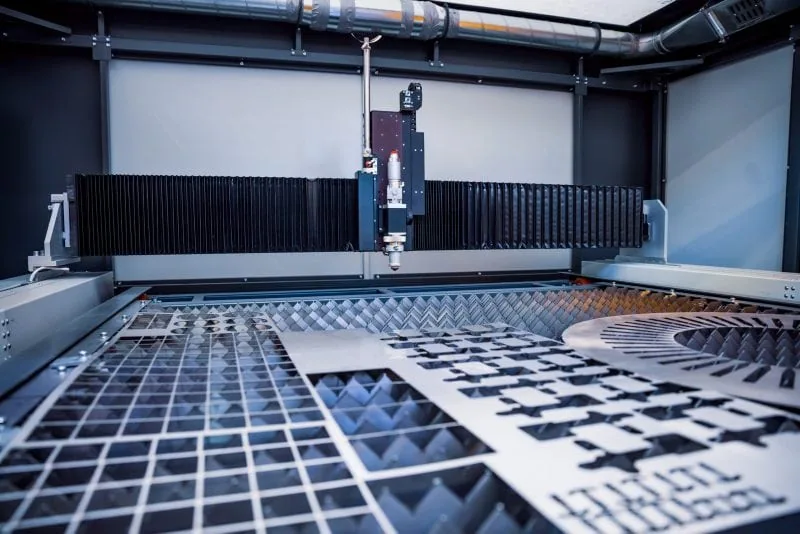

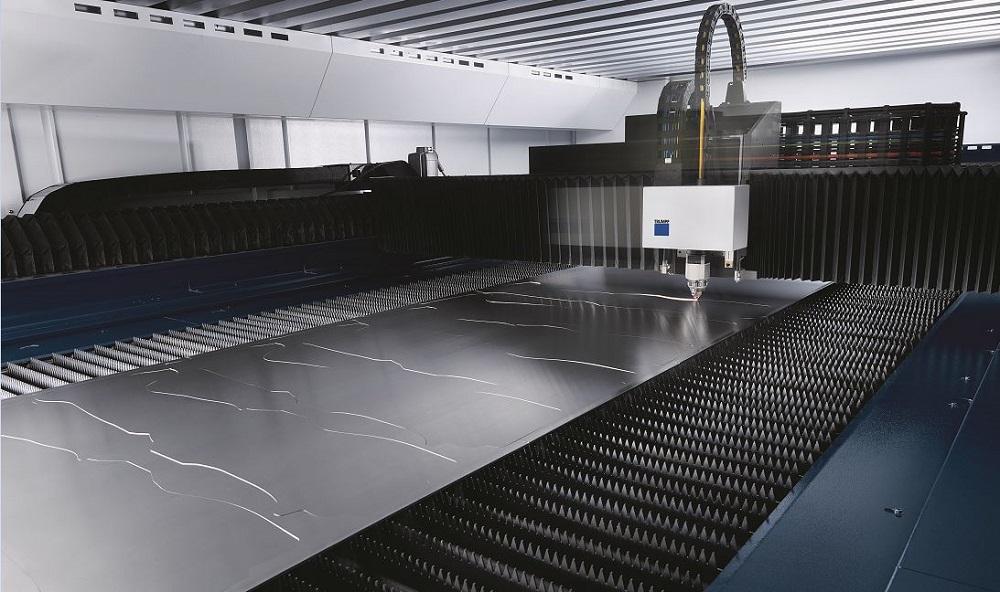

We utilize fiber laser systems with dynamic beam control, enabling superior edge quality on mild steel, stainless steel, and high-strength low-alloy (HSLA) grades up to 25 mm in thickness. Our CNC-controlled cutting beds are calibrated daily, and real-time sensors monitor kerf width and pierce consistency, ensuring repeatability across production runs of any scale.

The following table outlines the core technical capabilities of our laser cutting systems for steel sheets:

| Parameter | Specification |

|---|---|

| Maximum Cutting Thickness | 25 mm (mild steel) |

| Positioning Accuracy | ±0.03 mm/m |

| Repeatability | ±0.02 mm |

| Minimum Hole Diameter | 1.0 × material thickness |

| Cut Edge Roughness (Ra) | ≤ 6.3 µm (up to 10 mm thickness) |

| Lead Time (Standard Orders) | 5–7 working days (including inspection) |

| Supported File Formats | DWG, DXF, STEP, IGES, PDF (with dimensions) |

| Quality Standards | ISO 9001:2015, ISO 13920 (weld prep tolerances) |

Every laser-cut steel sheet we produce undergoes full dimensional verification using coordinate measuring machines (CMM), with material traceability and first-article inspection reports available upon request. For clients in regulated industries, this level of documentation is not optional—it is essential.

Precision in laser cutting is not an isolated operation. It is the result of integrated engineering excellence, proven process discipline, and a commitment to delivering components that perform flawlessly in the most demanding environments. At Wuxi Lead Precision Machinery, we do not just meet specifications—we help define them.

Precision Specs & Tolerances

Technical Capabilities: Precision Laser Cutting for Steel Sheet Fabrication

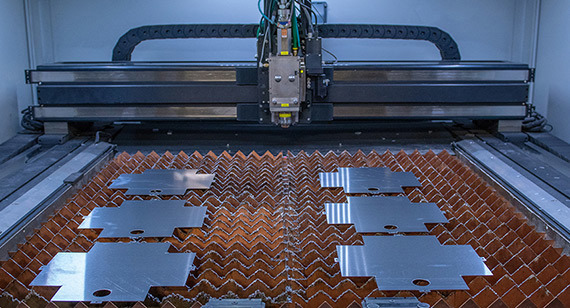

Wuxi Lead Precision Machinery delivers uncompromising accuracy and versatility in laser cutting carbon and stainless steel sheets through advanced 5-axis CNC fiber laser technology. Our systems process materials from 0.5 mm to 25 mm thickness, accommodating complex geometries including beveled edges, countersinks, and intricate contours in a single setup. This eliminates secondary operations, reducing lead times while maintaining strict dimensional integrity. High-power resonators (up to 12 kW) ensure clean, dross-free cuts across all thickness ranges, with adaptive focus control optimizing edge quality for subsequent welding or coating. Integrated material handling systems manage sheets up to 4000 x 2000 mm, maximizing throughput without compromising repeatability.

Critical to our process is real-time monitoring via CNC-integrated sensors that adjust power, speed, and gas pressure dynamically. This mitigates thermal distortion in thin-gauge materials while sustaining precision in thick-section cutting. All programming leverages offline nesting software to minimize kerf loss and material waste, aligning with sustainable manufacturing principles without sacrificing throughput. Our engineering team collaborates directly with clients to refine part designs for optimal manufacturability, ensuring cost efficiency from prototype to volume production.

Quality control is anchored by Zeiss CONTURA CMM systems operating in a temperature-stabilized metrology lab. Every critical dimension undergoes 100% verification against CAD models, with full traceability through our digital quality management platform. First-article inspections include comprehensive GD&T analysis, surface roughness validation, and material certification cross-referencing. This rigorous protocol meets aerospace AS9100 and automotive IATF 16949 requirements, providing clients with auditable data packets for every shipment.

The following table details achievable tolerances under standard production conditions, validated per ISO 2768-mK and client-specific specifications:

| Parameter | Specification | Standard Reference |

|---|---|---|

| Positional Tolerance | ±0.1 mm (sheets ≤ 6 mm) | ISO 2768-mK |

| ±0.2 mm (sheets > 6 mm to 25 mm) | ||

| Linear Dimension | ±0.05 mm (critical features) | Client Drawings |

| Bevel Angle Accuracy | ±0.5° | Internal Standard |

| Edge Perpendicularity | 0.1 mm per 10 mm thickness | ISO 13920 |

| Hole Diameter Tolerance | +0.1 / -0.0 mm | ISO 2768-fine |

| Surface Roughness (Ra) | ≤ 3.2 µm (stainless steel) | ISO 1302 |

| ≤ 6.3 µm (carbon steel) |

These capabilities enable Wuxi Lead to support mission-critical applications in energy, transportation, and industrial automation where precision directly impacts system performance. Our commitment to process stability—evidenced by sub-1.33 Cpk values across key parameters—ensures consistent part conformance, reducing client scrap rates and assembly rework. Partner with us to transform complex steel sheet designs into production-ready components with certified accuracy.

Material & Finish Options

Material Selection for High-Precision Laser Cutting in Sheet Metal Fabrication

Selecting the appropriate material for laser cut steel sheet applications is critical to achieving optimal performance, durability, and cost-efficiency in industrial manufacturing. While the term “laser cut steel sheet” commonly refers to carbon or stainless steel, advanced fabrication projects often require alternative metals such as aluminum and titanium, depending on mechanical, thermal, and environmental demands. At Wuxi Lead Precision Machinery, we support a full spectrum of high-grade materials, ensuring compatibility with our fiber laser cutting systems for clean, burr-free edges and tight tolerances.

Steel remains the most widely used material due to its strength, weldability, and cost-effectiveness. Carbon steel is ideal for structural components, enclosures, and machinery frames where high tensile strength is required. Stainless steel, particularly grades 304 and 316, offers excellent corrosion resistance and aesthetic finish, making it suitable for food processing equipment, medical devices, and outdoor applications. Our laser systems achieve precise cuts in steel sheets up to 25 mm thick, maintaining dimensional accuracy within ±0.1 mm.

Aluminum is favored in aerospace, transportation, and electronics industries due to its low density, high thermal conductivity, and natural corrosion resistance. While more reflective than steel, modern fiber lasers effectively process aluminum alloys such as 5052, 6061, and 7075. Aluminum’s lightweight nature reduces overall product weight without sacrificing structural integrity. It also responds well to secondary finishing processes, particularly anodizing.

Titanium is reserved for high-performance applications in aerospace, defense, and medical implants. With an exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosive environments, titanium is challenging to machine but highly compatible with high-precision laser cutting. Our systems utilize optimized parameters to minimize heat-affected zones and prevent oxidation during cutting, ensuring material integrity.

Surface Finishing: Anodizing for Aluminum Components

Anodizing is a critical electrochemical process for aluminum parts, enhancing surface hardness, wear resistance, and corrosion protection. It also allows for color coding and improved adhesion for paint primers. At Wuxi Lead, we recommend Type II (sulfuric acid) and Type III (hardcoat) anodizing based on application requirements. Parts must be free of contaminants and laser oxide residues before anodizing, which our post-processing cleaning lines ensure.

Below is a comparative overview of key material specifications relevant to laser cutting performance.

| Material | Typical Thickness Range (mm) | Tensile Strength (MPa) | Reflectivity | Max Laser Power Compatibility | Common Grades |

|---|---|---|---|---|---|

| Carbon Steel | 0.5 – 25 | 370 – 550 | Low | 6 kW | Q235, Q345 |

| Stainless Steel | 0.5 – 20 | 515 – 690 | Medium | 6 kW | 304, 316, 430 |

| Aluminum | 0.5 – 15 | 110 – 570 | High | 4 kW (with anti-reflective tech) | 5052, 6061, 7075 |

| Titanium | 0.5 – 12 | 240 – 1100 | Medium | 4 kW (with inert gas assist) | Gr2, Gr5 (Ti-6Al-4V) |

Material selection directly impacts production efficiency, lifecycle performance, and total cost of ownership. Wuxi Lead Precision Machinery provides expert consultation to match your design requirements with the optimal material and finishing process, ensuring superior results in every laser-cut component.

Manufacturing Process & QC

Laser Cut Steel Sheet Production Process: Precision from Concept to Volume

Achieving zero defects in laser cut steel sheet fabrication demands a rigorously controlled, phase-gated production process. At Wuxi Lead Precision Machinery, we integrate advanced technology with stringent quality protocols across Design, Prototyping, and Mass Production stages to deliver flawless components for demanding industrial applications.

The process begins with comprehensive Design validation. Our engineering team collaborates closely with the client to review CAD files, ensuring manufacturability and optimal nesting for material yield. Critical factors including material grade (typically mild steel Q235B or stainless 304/316 per ASTM/AISI standards), thickness, required tolerances per ISO 2768-mK, and part geometry are meticulously analyzed. Thermal distortion compensation algorithms are applied within our nesting software to counteract inherent laser cutting effects, preventing warpage and dimensional drift before cutting commences. This proactive engineering review eliminates fundamental design flaws that could propagate into production defects.

Prototyping is the critical verification phase. Using the same production-grade fiber laser systems destined for volume work, we produce initial samples. Each prototype undergoes exhaustive First Article Inspection (FAI) against the approved drawing. Dimensional accuracy is verified using calibrated Coordinate Measuring Machines (CMMs), surface quality is assessed for dross-free edges and consistent kerf width, and material properties are confirmed. Geometric Dimensioning and Tolerancing (GD&T) checks are performed rigorously. Only upon client sign-off of the prototype, confirming all specifications are met with zero non-conformities, does the project advance. This stage validates the entire process chain and establishes the definitive quality benchmark.

Mass Production executes under a closed-loop quality management system designed for zero defects. Real-time monitoring tracks laser power, gas pressure, and cutting speed for every part. In-process inspections occur at defined intervals using automated vision systems and manual spot checks against critical dimensions. Statistical Process Control (SPC) charts monitor key parameters, triggering immediate corrective action if trends approach tolerance limits. Every sheet undergoes post-cut verification for flatness and dimensional integrity before proceeding to secondary operations or shipment. Our integrated ERP system provides full traceability from raw material coil batch to final shipment, ensuring accountability and enabling rapid root cause analysis should any anomaly occur – though our target and consistent outcome is zero defects reaching the customer.

This disciplined progression, underpinned by advanced machinery and uncompromising quality focus, guarantees the dimensional precision and surface integrity required for seamless integration into your final assembly.

Wuxi Lead Precision Laser Cutting Specifications (Steel Sheet)

| Parameter | Capability Range | Standard Tolerance (Per ISO 2768-mK) |

|---|---|---|

| Material Thickness | 0.5 mm – 25 mm | ±0.1 mm (≤ 3mm), ±0.2 mm (>3mm-6mm) |

| Positional Accuracy | Full work envelope | ±0.05 mm |

| Edge Perpendicularity | All thicknesses | ≤ 0.1 mm |

| Surface Roughness (Ra) | Mild & Stainless Steel | ≤ 6.3 µm (Typical) |

| Max Work Area | 3000 mm x 15000 mm | N/A |

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Excellence in Laser Cut Steel Sheet Fabrication

When precision, reliability, and speed define your manufacturing requirements, choosing the right partner becomes critical. At Wuxi Lead Precision Machinery, we specialize in high-accuracy laser cutting of steel sheets, delivering components that meet the most stringent industrial standards. As a trusted name in sheet metal fabrication based in China, we combine advanced technology with decades of engineering expertise to serve global clients across aerospace, automotive, energy, and industrial equipment sectors.

Our state-of-the-art fiber laser cutting systems ensure clean, burr-free edges with tight tolerances down to ±0.05 mm. Whether you require low-volume prototypes or high-volume production runs, our flexible manufacturing lines adapt seamlessly to your project’s scale and complexity. We process a wide range of steel grades—including mild steel, stainless steel, and high-strength low-alloy (HSLA) steels—in thicknesses from 0.5 mm to 25 mm, supporting diverse application needs.

What sets us apart is our end-to-end quality control. Every laser cut steel sheet undergoes rigorous inspection using coordinate measuring machines (CMM) and optical profiling systems to verify dimensional accuracy and edge quality. Our ISO 9001-certified processes guarantee consistency across batches, ensuring that your parts perform reliably in final assembly.

We understand that modern manufacturing demands more than just cutting—it requires collaboration. Our engineering team works closely with clients during the design-for-manufacturability (DFM) phase, offering material selection guidance, cost optimization strategies, and rapid prototyping support. This proactive approach reduces lead times, minimizes waste, and enhances overall production efficiency.

Below are key capabilities of our laser cutting services:

| Specification | Detail |

|---|---|

| Material Types | Mild Steel, Stainless Steel, HSLA Steel |

| Thickness Range | 0.5 mm – 25 mm |

| Maximum Cutting Area | 4000 mm × 2000 mm |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Edge Quality | Burr-free, minimal dross |

| Tolerance | ±0.05 mm (standard), tighter on request |

| Lead Times | From 5 days (prototypes), scalable for volume |

| Certifications | ISO 9001:2015, In-House Quality Audits |

At Wuxi Lead Precision Machinery, we don’t just cut metal—we build partnerships grounded in technical excellence and responsive service. Our logistics network ensures timely delivery to North America, Europe, Southeast Asia, and beyond, supported by comprehensive documentation and traceability.

If your business demands precision laser cut steel sheets produced with engineering integrity and operational efficiency, it’s time to connect. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a virtual tour of our facility. Let us become your trusted partner in precision sheet metal fabrication.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.