Technical Contents

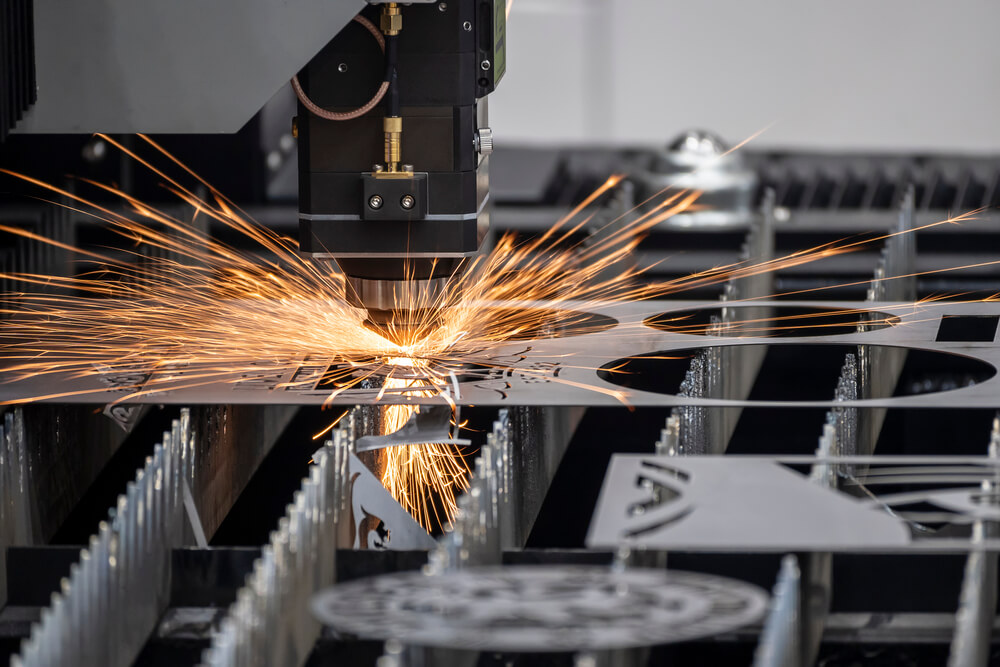

Engineering Guide: Laser Cut Parts

Engineering Insight: The Critical Role of Precision in Laser Cut Parts

In the realm of high-end sheet metal fabrication, precision is not merely a performance metric—it is the foundation of functional integrity, reliability, and long-term value. Nowhere is this more evident than in laser cut parts, where micron-level accuracy directly influences fit, assembly, and performance in complex mechanical systems. At Wuxi Lead Precision Machinery, we recognize that the margin for error in advanced manufacturing is effectively zero, particularly when serving industries such as aerospace, defense, and high-performance industrial equipment.

Laser cutting, when executed with precision engineering, delivers clean, burr-free edges, tight tolerances, and repeatability across large production runs. However, achieving this consistency demands more than state-of-the-art equipment—it requires deep process knowledge, rigorous quality control, and a culture of engineering excellence. Our facility in Wuxi integrates fiber laser technology with intelligent motion control and real-time monitoring systems to ensure every cut meets exact dimensional and thermal specifications. This capability is essential for components used in mission-critical applications where failure is not an option.

Our experience in delivering laser cut parts for Olympic-standard sporting equipment and military-grade systems underscores our commitment to precision. These projects demanded not only adherence to exacting technical standards but also the ability to innovate under tight deadlines and stringent regulatory requirements. For example, components used in high-speed track cycling equipment required weight optimization without sacrificing structural integrity—achieved through precise kerf control and minimal heat-affected zones. Similarly, military communication enclosures required RF shielding performance that could only be ensured through consistent edge quality and dimensional stability across hundreds of units.

The success of such projects is rooted in our engineering-first approach. We begin every job with a detailed design for manufacturability (DFM) review, optimizing material selection, nesting efficiency, and cutting parameters to maximize precision and minimize waste. Our technicians work closely with clients to understand the end-use environment, ensuring that every laser cut part performs as intended under real-world conditions.

Below are key specifications that define our laser cutting capabilities:

| Parameter | Specification |

|---|---|

| Laser Type | High-Power Fiber Laser |

| Maximum Cutting Thickness | 25 mm (Mild Steel), 20 mm (Stainless), 15 mm (Aluminum) |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Minimum Hole Diameter | 1.0 x Material Thickness (typical) |

| Edge Quality | Burr-free, Ra < 3.2 µm (standard) |

| Tolerance (Standard) | ±0.1 mm (IT7–IT8) |

| Material Compatibility | Carbon Steel, Stainless Steel, Aluminum, Brass, Copper |

At Wuxi Lead Precision Machinery, we do not simply cut metal—we engineer solutions. Our expertise in laser cutting, backed by proven performance in elite industrial and defense applications, positions us as a trusted partner for manufacturers who demand nothing less than perfection. Precision isn’t our goal. It’s our standard.

Precision Specs & Tolerances

Technical Capabilities: Precision Laser Cutting at Wuxi Lead Precision Machinery

Wuxi Lead Precision Machinery delivers uncompromising accuracy and repeatability in laser cut parts manufacturing, serving demanding aerospace, medical, and industrial sectors. Our core competence lies in integrating advanced multi-axis laser technology with rigorous metrology protocols to transform complex sheet metal designs into reality. We understand that dimensional fidelity is non-negotiable in high-integrity applications, driving our investment in state-of-the-art equipment and systematic quality assurance.

Our production floor is anchored by high-power 5-axis CNC fiber laser cutting systems. These platforms offer exceptional versatility, processing carbon steel, stainless steel, aluminum, and specialized alloys with thicknesses ranging from 0.5mm to 25mm. The 5-axis capability is critical for producing intricate three-dimensional contours and beveled edges in a single setup, eliminating secondary operations and preserving geometric integrity. Automated material handling systems feed sheet stock with micron-level positional accuracy, while intelligent collision avoidance and real-time power modulation ensure consistent cut quality across varying geometries and material batches. This technological foundation enables us to achieve cutting speeds up to 40m/min on thin gauges without sacrificing edge squareness or surface finish, directly impacting project lead times and cost efficiency for our clients.

Quality control is not a final step but an integrated process woven throughout production. Every critical laser cut part undergoes comprehensive verification using calibrated Coordinate Measuring Machines (CMMs). Our metrology lab utilizes multiple CMM units, including bridge-type and portable arms, capable of measuring features down to ±0.005mm. This data is meticulously compared against the original CAD model using advanced software, generating detailed first-article inspection reports (FAIR) and AS9102 documentation upon request. Statistical process control (SPC) methodologies are applied to monitor key parameters like hole diameter consistency and linear dimension stability, enabling proactive correction before deviations affect output. Material traceability is maintained from raw stock receipt through final inspection, ensuring full compliance with stringent industry standards.

The achievable dimensional precision for laser cut parts is demonstrably tight, reflecting our process control maturity. The following table outlines typical tolerance capabilities under standard production conditions for common materials:

| Material Thickness | Feature Type | Typical Tolerance | Notes |

|---|---|---|---|

| 0.5mm – 3.0mm | Linear Dimensions | ±0.05mm | Within sheet plane |

| 0.5mm – 3.0mm | Hole Diameter | +0.05mm / -0.00mm | Perpendicularity < 0.1mm/m |

| 3.0mm – 10.0mm | Linear Dimensions | ±0.10mm | Within sheet plane |

| 3.0mm – 10.0mm | Hole Diameter | +0.10mm / -0.00mm | Perpendicularity < 0.15mm/m |

| >10.0mm | Linear Dimensions | ±0.15mm | Within sheet plane |

| >10.0mm | Hole Diameter | +0.15mm / -0.00mm | Perpendicularity < 0.20mm/m |

| All Thicknesses | Angular Features (5-Axis) | ±0.5° | Depends on feature complexity & depth |

These tolerances represent our standard production capability; tighter specifications are achievable through dedicated process validation and are subject to engineering review. Surface roughness (Ra) typically ranges from 3.2μm to 12.5μm depending on material and thickness. Partnering with Wuxi Lead ensures your laser cut components meet the exacting demands of precision assembly, eliminating downstream fit issues and enhancing overall product performance. Our commitment to measurable accuracy underpins every part we deliver.

Material & Finish Options

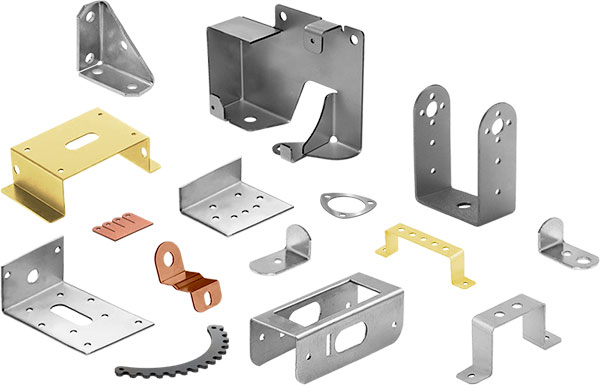

Material Selection for Precision Laser Cut Parts

Selecting the appropriate material is critical when producing high-precision laser cut parts for industrial applications. At Wuxi Lead Precision Machinery, we specialize in processing a range of advanced sheet metals, with aluminum, steel, and titanium being the most widely used due to their distinct mechanical properties and performance characteristics. Each material offers unique advantages depending on the application’s requirements for strength, weight, corrosion resistance, and thermal stability.

Aluminum is a preferred choice for lightweight structural components, particularly in aerospace, electronics, and transportation industries. Its excellent strength-to-weight ratio, combined with high thermal and electrical conductivity, makes it ideal for heat sinks, enclosures, and chassis. Aluminum responds exceptionally well to laser cutting, producing clean edges with minimal dross. It is also highly compatible with post-processing finishes such as anodizing, which enhances surface hardness and corrosion resistance.

Steel, particularly low-carbon and stainless grades, remains a dominant material in industrial fabrication. Mild steel offers high tensile strength and cost efficiency, making it suitable for machinery frames, brackets, and enclosures. Stainless steel, especially grades 304 and 316, adds superior corrosion resistance and aesthetic appeal, ideal for medical devices, food processing equipment, and outdoor applications. Laser cutting ensures precise contouring of steel sheets with tight tolerances, while minimal heat-affected zones preserve material integrity.

Titanium is reserved for mission-critical applications where extreme strength, temperature resistance, and biocompatibility are required. Commonly used in aerospace, defense, and medical implant devices, titanium’s high melting point and resistance to oxidation present challenges during processing. However, our advanced fiber laser systems are optimized to cut titanium with precision, maintaining edge quality and dimensional accuracy.

Post-processing surface treatments further enhance part performance. Anodizing, primarily applied to aluminum, creates a durable, non-conductive oxide layer that improves wear resistance and allows for color coding. We offer both Type II (sulfuric acid) and Type III (hardcoat) anodizing, tailored to customer specifications.

The following table outlines key physical and processing properties of these materials for laser cutting applications.

| Material | Thickness Range (mm) | Tensile Strength (MPa) | Common Grades | Max Achievable Tolerance | Recommended Finishes |

|---|---|---|---|---|---|

| Aluminum | 0.5 – 12.0 | 110 – 310 | 5052, 6061, 7075 | ±0.1 mm | Anodizing, Powder Coating |

| Mild Steel | 0.8 – 25.0 | 360 – 440 | Q235, SPCC | ±0.15 mm | Zinc Plating, Painting |

| Stainless Steel | 0.8 – 20.0 | 505 – 860 | 304, 316, 430 | ±0.1 mm | Passivation, Electropolishing |

| Titanium | 0.5 – 10.0 | 240 – 900 | Grade 2, Grade 5 (Ti6Al4V) | ±0.1 mm | Bead Blasting, Anodizing (decorative) |

Material selection directly impacts both manufacturability and end-use performance. Our engineering team works closely with clients to match material properties with design intent, ensuring optimal function, durability, and cost-efficiency in every laser cut component.

Manufacturing Process & QC

Laser Cut Parts Production Process: Achieving Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, our laser cutting process is engineered for uncompromising precision and zero-defect delivery in high-end sheet metal fabrication. We integrate advanced technology with rigorous quality protocols across three critical phases, ensuring your parts meet exacting specifications consistently. This systematic approach minimizes risk and maximizes value for demanding industrial applications.

Design Phase: Precision Engineered at the Foundation

The journey begins with collaborative design validation. Our engineering team conducts thorough Design for Manufacturability (DFM) analysis on your CAD files, optimizing geometries for laser processing while maintaining structural integrity. We meticulously select the optimal material grade and thickness based on your functional requirements, environmental exposure, and regulatory standards. Critical factors like kerf width, heat-affected zone management, and nesting efficiency are simulated using advanced CAM software. This phase ensures the digital model translates flawlessly into physical reality, eliminating potential errors before metal meets laser. Early-stage validation prevents costly revisions and establishes the blueprint for zero-defect production.

Prototyping: Validating Performance Before Scale

Prototyping is not merely a formality; it is our critical quality gate. Using the same production-grade fiber laser systems intended for volume manufacturing, we produce functional prototypes under controlled conditions. Each prototype undergoes rigorous dimensional inspection via CMM (Coordinate Measuring Machine) and visual examination for edge quality, burr formation, and material integrity. We validate fit, function, and assembly compatibility with your downstream processes. Any deviation triggers immediate root cause analysis and process refinement. This iterative validation ensures the manufacturing parameters are perfected, guaranteeing that mass production starts with proven, defect-free methodology. Prototyping transforms theoretical design into verified production readiness.

Mass Production: Sustained Excellence Through Automated Control

Volume production leverages our fully integrated, automated workflow designed for zero-defect output. Parts are cut on high-precision Bystronic or Amada fiber laser systems with real-time monitoring of beam power, gas pressure, and focal position. Every piece undergoes 100% inline inspection using automated optical systems that detect micro-burrs, dimensional drift, or surface anomalies exceeding tolerances. Statistical Process Control (SPC) data is continuously analyzed to preemptively adjust parameters. Final inspection includes batch-level CMM verification against original CAD models. This closed-loop system, combined with operator expertise and ISO 9001-certified processes, ensures every shipment meets our stringent zero-defect commitment, protecting your assembly lines and end-product reliability.

Key Laser Cutting Process Specifications

| Parameter | Specification | Quality Impact |

|---|---|---|

| Material Thickness | 0.5 mm – 25 mm (Carbon Steel) | Ensures optimal cut quality across common gauges |

| Positional Accuracy | ±0.02 mm per 100 mm | Critical for precision assembly and fit-up |

| Edge Perpendicularity | ≤ 0.1 mm per 10 mm thickness | Guarantees flatness for welding and sealing |

| Surface Roughness (Ra) | ≤ 3.2 µm (for ≤ 3mm material) | Meets stringent aesthetic and functional needs |

| Kerf Width Control | ±0.05 mm tolerance | Maintains dimensional integrity on tight features |

This integrated process—grounded in engineering rigor, validated through prototyping, and executed with automated precision—delivers laser cut parts that consistently exceed industry standards. Partner with Wuxi Lead to transform your sheet metal designs into flawless, high-performance components, eliminating waste and ensuring operational continuity in your manufacturing ecosystem.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision Laser Cut Parts in Sheet Metal Fabrication

At Wuxi Lead Precision Machinery, we specialize in delivering high-accuracy laser cut parts tailored to the rigorous demands of modern industrial manufacturing. As a trusted partner in sheet metal fabrication, we combine advanced laser cutting technology with decades of engineering expertise to deliver components that meet exacting standards in aerospace, automotive, energy, and industrial equipment sectors.

Our state-of-the-art fiber and CO₂ laser systems enable us to process a wide range of metals—including stainless steel, carbon steel, aluminum, and copper—with precision tolerances down to ±0.05 mm. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing platform ensures consistent quality, rapid turnaround, and full traceability across every batch.

We understand that in high-end manufacturing, specifications are non-negotiable. That’s why every laser cut part undergoes a comprehensive inspection protocol using coordinate measuring machines (CMM) and optical comparators. Our ISO 9001-certified quality management system ensures compliance with international standards, giving you confidence in every component you receive.

Our engineering team works closely with your design and procurement staff from initial concept through to final delivery. We offer DFM (Design for Manufacturability) analysis to optimize part geometry, reduce material waste, and lower overall production costs—without compromising performance. With seamless integration into global supply chains, we support JIT (Just-in-Time) delivery models and provide full documentation packages, including material certifications and inspection reports.

When you partner with Wuxi Lead Precision Machinery, you’re not just sourcing parts—you’re gaining a strategic manufacturing ally committed to innovation, precision, and long-term collaboration.

Technical Capabilities for Laser Cut Parts

| Parameter | Specification |

|---|---|

| Material Types | Stainless Steel, Carbon Steel, Aluminum, Copper, Galvanized Steel |

| Material Thickness Range | 0.5 mm – 25 mm |

| Maximum Cutting Area | 1500 mm × 3000 mm (standard), up to 4000 mm × 12000 mm (custom) |

| Laser Source | Fiber Laser (up to 12 kW), CO₂ Laser (up to 6 kW) |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Tolerance (Standard) | ±0.05 mm (per ISO 2768-m) |

| Edge Quality | Burr-free, minimal dross, smooth surface finish |

| Secondary Operations | Bending, welding, surface treatment, assembly |

| Quality Standards | ISO 9001:2015, First Article Inspection, PPAP Level 3 available |

Contact us today to discuss your next project. Email us at [email protected] and receive a detailed quote with engineering feedback within 24 hours. Let Wuxi Lead Precision Machinery be your trusted partner in precision laser cutting and sheet metal fabrication.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.