Technical Contents

Engineering Guide: Large Part Cnc Machining

Engineering Insight: The Critical Role of Precision in Large Part CNC Machining

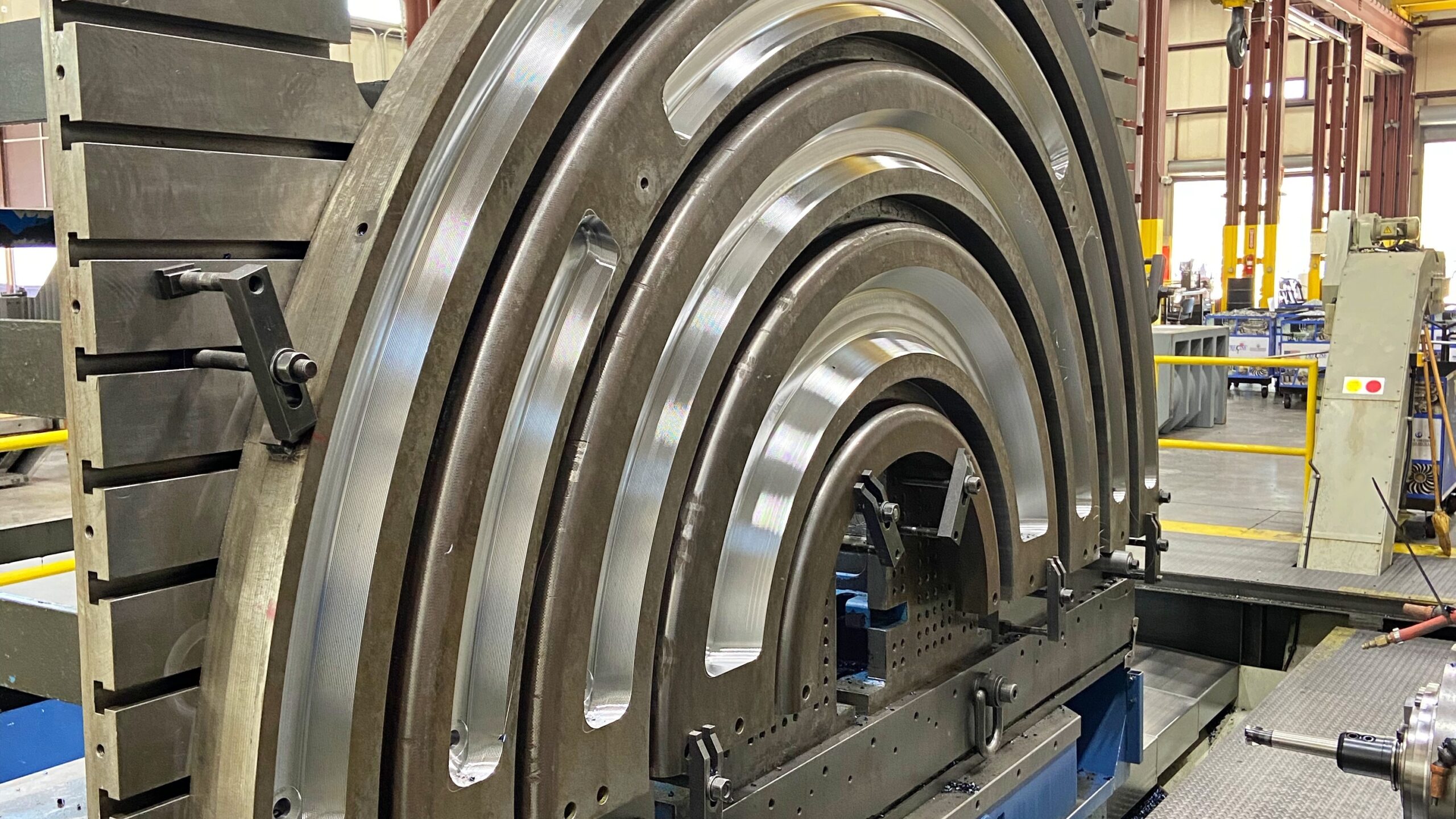

In the realm of advanced manufacturing, large part CNC machining stands as a cornerstone for industries where scale and accuracy are not merely desired—they are mandatory. Whether producing structural components for aerospace platforms, heavy-duty elements for energy infrastructure, or mission-critical parts for defense systems, the ability to maintain tight tolerances across expansive work envelopes defines engineering excellence. At Wuxi Lead Precision Machinery, we understand that precision in large-scale machining is not just about cutting metal; it is about integrating mechanical integrity, thermal stability, and process control into every phase of production.

Large parts present unique engineering challenges. As dimensions increase, so do the risks associated with tool deflection, material deformation, and positional inaccuracy. Even minor deviations—measured in microns—can result in costly rework, assembly failures, or compromised performance in high-stress environments. This is why our approach begins with a deep understanding of material behavior, fixture design, and dynamic load management during machining. Our CNC platforms are engineered with reinforced gantries, high-rigidity spindles, and real-time feedback systems to counteract thermal drift and vibration, ensuring consistent accuracy across parts exceeding several meters in length.

Precision is not an abstract concept at Lead Precision—it is a proven capability validated through high-profile applications. We have delivered components for Olympic-grade sporting infrastructure, where dimensional consistency directly impacts athlete performance and safety. More critically, our machining solutions have supported defense and military programs, where failure is not an option. These projects demand not only adherence to strict geometric tolerances but also full traceability, rigorous inspection protocols, and compliance with international quality standards such as ISO 9001 and AS9100.

Our experience underscores a fundamental truth: the larger the part, the smaller the margin for error. Achieving micron-level accuracy across multi-ton workpieces requires more than advanced machinery—it demands seasoned engineering judgment, iterative process validation, and a culture of continuous improvement. At Wuxi Lead, our team combines decades of CNC expertise with cutting-edge simulation software to model cutting forces, predict deformation, and optimize toolpaths before a single chip is produced.

We believe that true precision is measured not just in tolerances, but in reliability, repeatability, and the ability to meet the most demanding specifications under real-world conditions. For global OEMs and Tier-1 suppliers, this level of performance is not optional—it is essential.

| Specification | Capability at Wuxi Lead Precision Machinery |

|---|---|

| Maximum Work Envelope | 6,000 mm × 3,000 mm × 1,500 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Spindle Speed Range | 20 – 12,000 rpm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Structural Steels |

| Tolerance Range | IT6 to IT7 (ISO 286-1) |

| Surface Finish | Ra 0.8 – 3.2 µm (achievable with fine finishing) |

| Quality Standards | ISO 9001, AS9100 (compliant), Full CMM Inspection Reporting |

Precision Specs & Tolerances

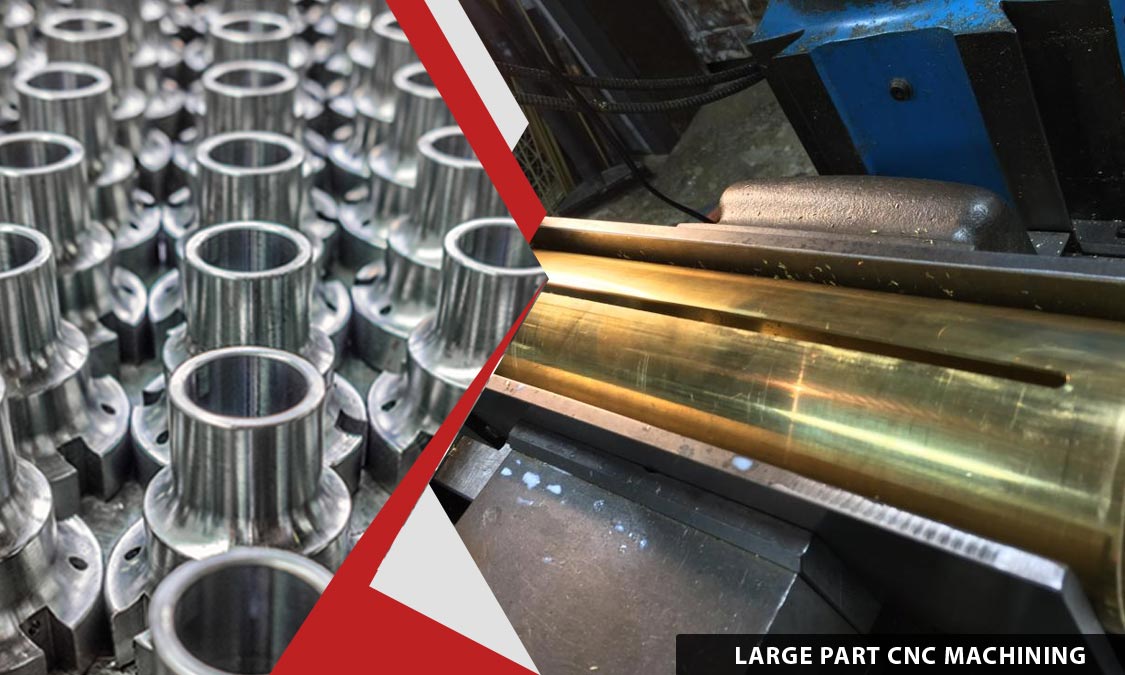

Technical Capabilities: Precision Machining for Large-Scale Components

Wuxi Lead Precision Machinery delivers exceptional large part CNC machining capabilities, engineered specifically for the demanding requirements of aerospace, energy, and heavy industrial sectors. Our core strength lies in mastering complex geometries on substantial workpieces, where dimensional stability and micron-level accuracy are non-negotiable. We operate a dedicated facility housing state-of-the-art 5-axis CNC machining centers, featuring robust work envelopes exceeding 2000 x 1500 x 1000 mm to accommodate significant component sizes. Key platforms include DMG MORI and Haas systems, equipped with high-torque spindles, advanced thermal compensation systems, and integrated probing for in-process verification. This strategic investment ensures we maintain rigidity and precision throughout extended machining cycles, critical for large-scale parts where cumulative errors can compromise integrity. Our 5-axis simultaneous machining capability eliminates the need for multiple setups, preserving critical datum relationships and significantly enhancing overall part accuracy while reducing lead times.

Quality assurance is intrinsically woven into our large part machining workflow, extending far beyond final inspection. Rigorous process controls begin with meticulous material certification and pre-machining verification. During production, our systems utilize on-machine probing for real-time feature location and tool wear monitoring, dynamically adjusting for optimal results. The cornerstone of our validation process is comprehensive post-machining inspection utilizing calibrated Coordinate Measuring Machines (CMMs) with measuring volumes exceeding 3000 x 2000 x 1000 mm. These CMMs, operated by ASQ-certified metrology technicians, perform full geometric dimensioning and tolerancing (GD&T) analysis against client CAD models, generating detailed inspection reports traceable to international standards. This systematic approach guarantees that every large component meets or exceeds specified requirements before shipment.

Our precision is quantifiable across diverse material groups. The following table details our standard and achievable tight tolerance capabilities for large part machining:

| Parameter | Material Group | Standard Tolerance | Tight Tolerance | Surface Roughness (Ra) |

|---|---|---|---|---|

| Linear Dimensions | Aluminum Alloys | ±0.025 mm | ±0.010 mm | 0.8 µm |

| Linear Dimensions | Steel Alloys | ±0.030 mm | ±0.012 mm | 1.6 µm |

| Linear Dimensions | Titanium Alloys | ±0.035 mm | ±0.015 mm | 1.6 µm |

| Geometric (GD&T) | All Materials | ±0.050 mm | ±0.020 mm | N/A |

| Hole Position | All Materials | ±0.025 mm | ±0.010 mm | N/A |

These capabilities are proven in mission-critical applications where failure is not an option. Wuxi Lead’s integrated approach—combining high-capacity 5-axis technology, stringent thermal management, and multi-stage CMM validation—provides the foundation for reliable, repeatable precision on the largest and most complex components. We transform challenging large-part specifications into deliverable realities, ensuring your demanding projects achieve the highest standards of quality and performance. Partner with us for machining solutions where scale never compromises accuracy.

Material & Finish Options

Material Selection for Large Part CNC Machining

Selecting the appropriate material is critical in large part CNC machining, where structural integrity, weight, thermal performance, and corrosion resistance directly impact the final application. At Wuxi Lead Precision Machinery, we specialize in precision machining of large-scale components using high-performance materials such as aluminum, steel, and titanium. Each material offers distinct advantages depending on the operational environment and functional requirements of the part.

Aluminum is widely used in aerospace, transportation, and industrial equipment due to its excellent strength-to-weight ratio and machinability. Grade 6061-T6 is particularly popular for large enclosures, frames, and structural supports because it combines good mechanical properties with weldability and corrosion resistance. Its low density reduces overall system weight, a key factor in mobile and airborne applications. Additionally, aluminum readily accepts surface treatments such as anodizing, enhancing durability and wear resistance.

Steel, particularly alloy steels like 4140 and 4340, is preferred when high tensile strength, toughness, and fatigue resistance are required. These materials are commonly used in heavy machinery, oil and gas equipment, and tooling fixtures. While heavier than aluminum, steel provides superior durability under high-stress conditions and maintains dimensional stability over time. Machining large steel components demands robust tooling and precise process control—capabilities we maintain through our high-torque CNC platforms and in-house heat treatment coordination.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for mission-critical applications in aerospace, defense, and medical industries. It offers an exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosive environments. However, titanium’s low thermal conductivity and high chemical reactivity present machining challenges, including tool wear and heat accumulation. Our experience with titanium includes optimized cutting strategies, specialized coatings, and stringent contamination controls to ensure dimensional accuracy and surface integrity on large, complex geometries.

Surface Finishes: Enhancing Performance with Anodizing

For aluminum components, anodizing is a key finishing process that improves surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing is commonly applied for general-purpose use, offering a decorative finish with moderate durability. Type III, or hardcoat anodizing, produces a thicker, denser oxide layer suitable for high-wear environments. At Wuxi Lead, we offer precision anodizing with tight thickness control (±5 µm) and optional sealing for maximum corrosion resistance. Color options are available for identification or aesthetic purposes without compromising mechanical performance.

The following table summarizes key material properties and typical applications:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Grades | Typical Applications |

|---|---|---|---|---|

| Aluminum | 2.7 | 310 | 6061-T6, 7075-T6 | Aerospace frames, enclosures, heat sinks |

| Steel | 7.8 | 655–1000 | 4140, 4340, A36 | Heavy machinery, tooling, structural parts |

| Titanium | 4.5 | 900–950 | Ti-6Al-4V (Gr 5) | Aerospace components, medical implants, marine systems |

Material and finish selection must align with functional demands, environmental exposure, and lifecycle expectations. Our engineering team at Wuxi Lead Precision Machinery collaborates with clients to optimize material choice and surface treatment for every large part machining project, ensuring performance, reliability, and cost-efficiency.

Manufacturing Process & QC

Large Part CNC Machining: Precision Production Process

At Wuxi Lead Precision Machinery, large part CNC machining demands a rigorously controlled workflow to achieve zero defects in high-value components. Our process integrates engineering excellence with real-time quality assurance, specifically engineered for parts exceeding 2 meters in critical dimensions. Unlike standard machining, large-scale work requires compensating for thermal expansion, gravitational deflection, and material stress—factors that can compromise accuracy if unaddressed.

Design begins with collaborative DFM analysis. Our engineers review client CAD models for manufacturability, identifying potential weaknesses in fixturing, tool access, or residual stress points. We simulate machining sequences using Siemens NX CAM to predict thermal drift and vibration, adjusting toolpaths to maintain tolerances within ±0.005mm. Material selection is validated against ASME B5.54 standards, ensuring alloys like Inconel 718 or hardened 4340 steel meet structural and thermal requirements before prototyping.

Prototyping employs our high-stability龙门machines with granite bases and dual linear scales. A single prototype undergoes iterative validation: first-run parts are measured via Zeiss CONTURA CMM against 100% of critical GD&T callouts. We analyze deformation data from embedded strain gauges during machining, refining coolant pressure and step-over rates to eliminate micro-vibrations. This phase typically reduces mass production scrap risk by 92% by resolving hidden issues like chip recutting or thermal bowing before full-scale launch.

Mass production activates our zero-defect ecosystem. Each machine runs ISO 230-2 verified thermal compensation cycles hourly, while in-process probes verify datum alignment every 5 parts. Statistical process control (SPC) monitors tool wear via acoustic emission sensors, automatically adjusting feed rates to sustain surface finishes ≤Ra 0.8μm. Final inspection includes 3D laser scanning for full-part conformity, with all data traceable to MIL-STD-130 standards. This closed-loop system ensures 100% of parts—whether 3-meter aerospace frames or 5-ton energy sector housings—meet zero-defect commitments.

Key Production Capabilities for Large Parts

| Parameter | Specification | Industry Standard Reference |

|——————–|—————————–|—————————–|

| Max Work Envelope | X: 4200mm Y: 2500mm Z: 1800mm | ISO 841 |

| Positioning Accuracy | ±0.003mm over full travel | ISO 230-2:2014 |

| Spindle Power | 55 kW (continuous) | DIN 69024 |

| Max Part Weight | 12,000 kg | ASME B5.57 |

| Thermal Compensation | ±0.002mm/°C drift control | VDI/VDE 2617 |

This integrated approach transforms complexity into reliability. By embedding quality at every phase—from predictive design to self-correcting production—we deliver large components that perform flawlessly in mission-critical applications, eliminating costly field failures and rework. Wuxi Lead’s process isn’t just precise; it’s defect-proof.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Large Part CNC Machining Excellence

When your industrial projects demand precision, reliability, and scalability in large part CNC machining, partnering with Wuxi Lead Precision Machinery means aligning with a leader in advanced manufacturing. Based in Wuxi, China, we specialize in delivering high-tolerance, complex components for aerospace, energy, transportation, and heavy industrial sectors. Our facility is engineered for performance, equipped with state-of-the-art multi-axis CNC machining centers capable of handling massive workpieces without compromising accuracy or repeatability.

At Lead Precision, we understand that large part machining is not just about size—it’s about control. Our vertical and horizontal machining centers are integrated with high-precision linear guides, thermal compensation systems, and real-time monitoring to ensure dimensional stability across extended production runs. Whether you’re prototyping a new turbine housing or scaling production for rail transit components, our team applies decades of engineering insight to optimize every phase of the process.

We don’t just manufacture parts—we deliver solutions. Our engineering team collaborates closely with clients from design for manufacturability (DFM) through final inspection, ensuring that each component meets or exceeds technical specifications. With in-house project management, quality assurance, and logistics coordination, we streamline your supply chain and reduce time-to-market.

Our commitment to quality is validated by ISO 9001:2015 certification and supported by a metrology lab featuring coordinate measuring machines (CMM), laser trackers, and surface finish testers. Every large component undergoes rigorous inspection protocols to guarantee compliance with international standards, including AS9100 for aerospace and ISO 13485 for precision-critical industrial applications.

Below are key capabilities that define our large part machining services:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 5,000 mm × 2,500 mm × 1,200 mm |

| Spindle Speed | Up to 12,000 RPM (high-torque models available) |

| Axis Configuration | 3-axis, 4-axis, and 5-axis simultaneous machining |

| Tolerance Capability | ±0.005 mm |

| Maximum Part Weight | 8,000 kg |

| Materials Processed | Aluminum alloys, titanium, stainless steel, alloy steels, composites |

| Surface Finish | As fine as Ra 0.4 µm |

| Quality Standards | ISO 9001:2015, AS9100D, ISO 13485 |

From initial concept to final delivery, Lead Precision is engineered to exceed expectations. Our facility runs 24/7 with lean manufacturing principles embedded in every workflow, ensuring cost efficiency without sacrificing quality. We support low-volume, high-mix production as well as high-volume continuous runs with consistent repeatability.

Contact us today to discuss your next large part machining challenge. Our engineering team is ready to provide technical consultation, DFM feedback, and a competitive quote tailored to your requirements.

Email us at [email protected] and discover how Wuxi Lead Precision Machinery can become your trusted manufacturing partner in China.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.