Technical Contents

Engineering Guide: Large Metal Fabrication

Engineering Insight: Precision as the Foundation of Large-Scale Metal Fabrication

In large metal fabrication, precision transcends mere specification adherence; it becomes the critical determinant of structural integrity, assembly efficiency, and long-term operational reliability. When working with massive components—structural frames exceeding 10 meters, heavy-duty enclosures, or complex welded assemblies—microscopic deviations compound catastrophically. A tolerance error of ±0.5mm on a single joint becomes a multi-millimeter misalignment across a 20-meter span, jeopardizing load distribution, sealing integrity, and final product performance. This reality demands processes engineered not just for size, but for uncompromising dimensional control throughout every stage: laser cutting, bending, welding, and finishing. Thermal distortion during welding, material springback in high-tensile steel bending, and gravitational sag in oversized assemblies present unique challenges that standard workshops cannot consistently overcome. True precision at scale requires integrated metrology, adaptive process control, and deep material science expertise to anticipate and neutralize these variables before they impact the final component.

Wuxi Lead Precision Machinery operates at this demanding intersection of scale and accuracy. Our facility is engineered specifically for large-format work, featuring 12-meter laser cutting beds with dynamic distortion compensation, 800-ton press brakes with real-time angle monitoring, and robotic welding cells guided by laser tracking systems. This capability is rigorously proven through mission-critical applications. We delivered structural components for the Beijing 2022 Winter Olympics infrastructure, where sub-millimeter alignment tolerances across multi-story steel frameworks were non-negotiable for safety and aesthetics under extreme environmental loads. Similarly, our adherence to stringent MIL-STD-810G vibration and shock testing protocols for military-grade vehicle chassis assemblies demonstrates our commitment to zero-defect manufacturing where failure is not an option. These projects demanded more than equipment; they required a culture of precision embedded in every technician and engineer, validated by third-party certification bodies.

Our commitment translates directly to client value: reduced field rework, accelerated assembly timelines, and elimination of costly scrap in high-value projects. The table below outlines core capabilities enabling this precision for large-scale fabrication:

| Specification Parameter | Capability Range | Precision Standard |

|---|---|---|

| Maximum Material Thickness | Carbon Steel: 25mm | ±0.1mm flatness tolerance |

| Stainless Steel: 20mm | across 10m span | |

| Aluminum: 30mm | ||

| Largest Work Envelope | 12,000mm x 3,200mm x 1,500mm | Laser-cut part flatness: |

| (L x W x H) | ≤0.3mm/m | |

| Press Brake Capacity | 800 Tons | Bending angle tolerance: |

| ±0.5° | ||

| Welding Accuracy (Robotic) | Full-penetration welds up to | Angular distortion control: |

| 25mm thickness | ≤1mm per 5m length | |

| In-Process Metrology | Laser trackers, CMM validation | Real-time thermal compensation |

Precision in large metal fabrication is not an optional premium; it is the essential engineering discipline that separates functional infrastructure from costly failure. At Wuxi Lead Precision Machinery, we engineer this precision into every large-scale project, leveraging proven experience from the world’s most demanding applications to ensure your fabrication delivers exacting performance, on time and within specification.

Precision Specs & Tolerances

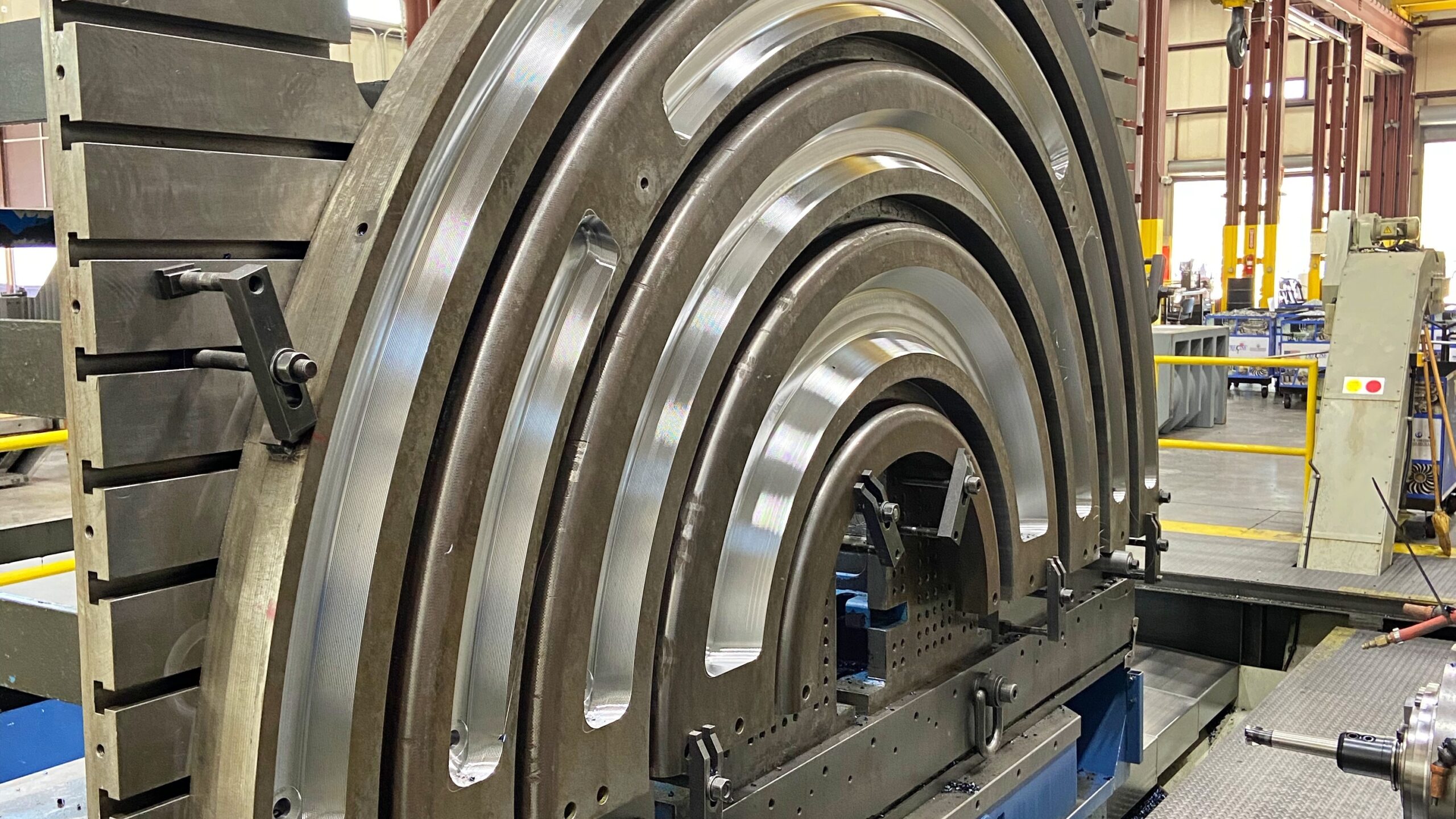

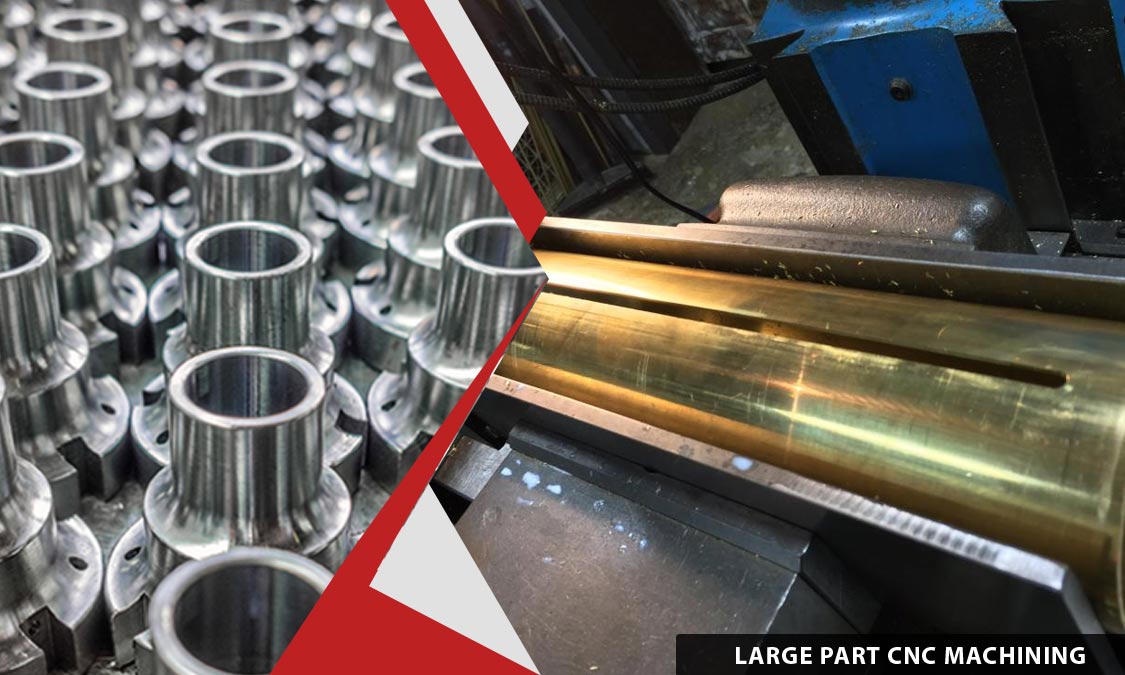

Wuxi Lead Precision Machinery delivers advanced technical capabilities in large metal fabrication, engineered to meet the exacting standards of high-performance industries such as aerospace, energy, transportation, and industrial equipment. Our facility integrates state-of-the-art 5-axis CNC machining systems with precision sheet metal processing technologies, enabling us to produce complex geometries and large-scale components with superior accuracy and repeatability. This multi-axis machining capability allows simultaneous cutting from five different angles, minimizing setup changes and ensuring tight tolerances across intricate features. The result is reduced cycle time, enhanced surface finish, and the ability to fabricate highly sophisticated parts from a single workpiece.

Our production floor is equipped with high-power fiber laser cutting systems, automated bending cells, and robotic welding platforms, all synchronized under a digital manufacturing framework. These systems support the processing of a wide range of ferrous and non-ferrous materials, including carbon steel, stainless steel, aluminum, and specialty alloys, in thicknesses ranging from 0.5 mm to 25 mm. With a maximum processing size of 4,000 mm x 2,000 mm on our laser platforms and extended bed lengths on forming equipment, we are fully capable of handling large-format sheet and plate fabrication with consistent edge quality and dimensional stability.

Quality control is embedded at every stage of production. All critical components undergo comprehensive inspection using a Zeiss DuraMax and Global Performance series Coordinate Measuring Machine (CMM), ensuring full compliance with ISO 10360 standards. Our CMM system provides micron-level verification of geometric dimensions, positional tolerances, and surface profiles, with digital reporting traceable to international standards. In addition to CMM, we employ laser trackers, optical comparators, and surface roughness testers to validate both macro and micro characteristics of finished parts.

The following table outlines the standard and precision tolerances achievable across key fabrication processes:

| Process | Dimensional Tolerance | Angular Tolerance | Feature Position Tolerance | Surface Roughness (Ra) |

|---|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | ±0.05° | ±0.01 mm | 0.8 – 3.2 µm |

| Fiber Laser Cutting | ±0.1 mm | ±0.2° | ±0.15 mm | 6.3 – 12.5 µm |

| Precision Bending | ±0.2 mm | ±0.5° | N/A | N/A |

| Robotic MIG/TIG Welding | ±0.5 mm (post-weld) | ±1.0° | ±0.3 mm | 6.3 – 25 µm |

| CMM Inspection Capability | Measurement Accuracy: 1.9 + L/300 µm | Full 3D GD&T Analysis | Maximum Working Volume: 1000 x 800 x 700 mm | N/A |

These technical capabilities are reinforced by a certified quality management system compliant with ISO 9001:2015 and AS9100D for aerospace applications. Wuxi Lead Precision Machinery is structured to support low-volume prototypes through high-mix production runs, delivering large metal fabrication solutions with engineering precision and industrial scalability.

Material & Finish Options

Material Selection for Large-Scale Sheet Metal Fabrication

Selecting the optimal material is foundational to the performance, longevity, and cost-efficiency of large-scale sheet metal components. At Wuxi Lead Precision Machinery, we prioritize materials that balance structural integrity, manufacturability, and environmental resilience for demanding industrial applications. Below, we detail critical considerations for aluminum, steel, and titanium, alongside essential finishing protocols.

Aluminum remains the premier choice for weight-sensitive applications requiring corrosion resistance and weldability. Grades like 5052-H32 and 6061-T6 dominate aerospace, transportation, and marine structures due to their favorable strength-to-weight ratio and seamless compatibility with CNC bending and laser cutting. Aluminum’s natural oxide layer provides baseline corrosion protection, but for extreme environments—such as chemical processing or coastal infrastructure—anodizing is non-negotiable. Type II (sulfuric acid) anodizing delivers standard wear resistance, while Type III (hard coat) achieves 50+ microns thickness for abrasion-heavy use, enhancing surface hardness to 600+ HV.

Carbon and stainless steel variants offer unmatched strength and thermal stability for heavy machinery, energy infrastructure, and structural frameworks. Low-carbon steels (e.g., A36, SPCC) excel in weldability and cost-effectiveness for large enclosures or chassis. For corrosive settings, 304 and 316 stainless steel provide superior resistance via chromium-nickel composition, though machining demands specialized tooling to mitigate work hardening. Note that steel’s higher density increases transport and handling costs at scale—factor this into lifecycle calculations.

Titanium, particularly Grade 5 (Ti-6Al-4V), is reserved for mission-critical applications where failure is unacceptable. Its exceptional strength-to-weight ratio and immunity to saltwater/chemical corrosion justify use in offshore platforms, aerospace components, and medical equipment. However, titanium’s reactivity necessitates strict inert-atmosphere welding protocols and dedicated CNC toolpaths to prevent galling. Material cost and machining complexity are significant; deploy it only where aluminum or steel cannot meet specifications.

Material performance hinges on precise technical parameters. Refer to the comparative specifications below:

| Material | Key Grades | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum | 5052-H32, 6061-T6 | 2.7 | 193–310 | Excellent (with anodizing) |

| Steel | A36, 304/316 SS | 7.8–8.0 | 400–900 | Moderate (carbon) / Excellent (stainless) |

| Titanium | Grade 2, Grade 5 | 4.5 | 345–900 | Exceptional |

Finishing, particularly anodizing for aluminum, is not merely cosmetic—it is a functional requirement. Inconsistent anodizing depth or poor sealing compromises part lifespan. Wuxi Lead implements in-house anodizing with real-time thickness monitoring and ASTM B137 compliance testing, ensuring uniform coverage even on large, complex geometries. Always specify required anodizing type and thickness upfront; retrofitting post-fabrication risks dimensional inaccuracies.

Material selection must align with your operational environment, load requirements, and total cost of ownership. Partner with a fabricator possessing metallurgical expertise and process control to transform specifications into reliable, high-precision components. Wuxi Lead’s integrated material sourcing and fabrication ecosystem guarantees traceability from mill certification to finished part.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our large metal fabrication process is engineered for precision, consistency, and zero-defect delivery. We follow a disciplined workflow that spans from initial design through prototyping to full-scale mass production, ensuring every component meets the highest standards of quality and performance.

The process begins with collaborative design engineering. Our team works closely with clients to analyze technical drawings, material specifications, and functional requirements. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry for manufacturability, structural integrity, and cost-efficiency. Design for manufacturability (DFM) reviews are conducted to identify and resolve potential issues before any material is cut, minimizing rework and ensuring seamless transition to the next phase.

Prototyping follows design validation. We produce functional prototypes using high-precision laser cutting, CNC bending, and robotic welding systems. These prototypes are subjected to rigorous in-house testing, including dimensional inspection via coordinate measuring machines (CMM), weld integrity checks, and fitment validation in simulated assembly environments. This stage is critical for confirming design accuracy, verifying material behavior, and ensuring compatibility with downstream processes or assembly lines. Client feedback is incorporated at this stage to finalize the production-ready design.

Once approved, we transition to mass production with the same tooling, fixtures, and programming used in prototyping, ensuring perfect scalability. Our production floor integrates automated material handling, real-time process monitoring, and statistical process control (SPC) to maintain tight tolerances across thousands of parts. Each stage—from cutting and forming to welding and surface finishing—is governed by standardized work instructions and inspected at defined control points.

To achieve zero defects, we employ a multi-layered quality assurance system. Every batch undergoes 100% visual inspection, with random samples subjected to non-destructive testing (NDT) and dimensional audits. Our ISO 9001-certified quality management system ensures traceability from raw material to final shipment, with full documentation available for every order.

The following table outlines key capabilities and tolerances for our large metal fabrication process:

| Parameter | Capability | Tolerance / Accuracy |

|---|---|---|

| Material Thickness | 0.5 mm – 25 mm | ±0.1 mm (cutting), ±0.2° (bending) |

| Max Part Size | 4000 mm × 1500 mm | ±0.5 mm |

| Cutting Methods | Fiber Laser, Plasma, Shearing | ±0.1 mm (laser) |

| Bending | CNC Press Brakes (up to 1000 tons) | ±0.25° |

| Welding | MIG, TIG, Spot, Robotic Welding | AWS D1.1 Compliant |

| Surface Finishes | Powder Coating, Anodizing, Passivation | Per customer specification |

| Quality Standards | ISO 9001, ISO 14001, IATF 16949 | Full CMM & NDT reports |

Through integrated design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers large metal fabrication solutions that are repeatable, reliable, and built to last.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Fabrication Excellence

In the demanding landscape of large-scale metal fabrication, selecting a partner transcends basic component sourcing. It demands a strategic alliance grounded in engineering rigor, process mastery, and unwavering commitment to your operational success. Wuxi Lead Precision Machinery stands as your definitive partner, engineered to resolve the critical challenges inherent in high-tolerance, high-volume sheet metal production. We understand that delays, dimensional inaccuracies, or inconsistent quality directly impact your throughput, profitability, and reputation. Our integrated manufacturing ecosystem, honed over decades serving global industrial leaders, delivers not just parts, but guaranteed solutions that elevate your entire production chain.

Precision is non-negotiable in large fabrication. Our facility operates at the forefront of technological capability, ensuring every bend, cut, and weld meets the most stringent specifications. We eliminate the guesswork and rework cycles that plague substandard suppliers through systematic process control and advanced metrology. Our engineers collaborate with your team from initial design review through final delivery, identifying optimization opportunities that reduce material waste, accelerate lead times, and enhance structural integrity. This proactive partnership approach translates directly into statistically significant reductions in your total cost of ownership and scrap rates.

The foundation of our reliability lies in measurable capability. The following specifications demonstrate our capacity to handle your most complex large fabrication requirements with absolute consistency:

| Capability | Lead Precision Standard | Typical Industry Benchmark | Advantage Delivered |

|---|---|---|---|

| Laser Cutting Thickness | Up to 30mm Carbon Steel | Up to 20mm Carbon Steel | Single-pass capability for thicker sections, reduced secondary ops |

| CNC Bending Tolerance | ±0.05mm per meter | ±0.2mm per meter | Superior geometric accuracy, seamless assembly |

| Punching Complexity | 120+ Tool Stations | 60-80 Tool Stations | Fewer setups, faster prototyping & production |

| Max. Part Dimensions | 4000mm x 2000mm | 3000mm x 1500mm | Accommodates large structural components |

| ISO Certification | ISO 9001:2015, ISO 14001 | ISO 9001:2015 | Integrated quality & environmental management |

Beyond technical prowess, our partnership model prioritizes your operational continuity. We implement vendor-managed inventory solutions tailored to your production schedule, maintain dedicated production cells for strategic accounts, and provide real-time production tracking dashboards. Our 24/7 technical support team, comprised of seasoned manufacturing engineers, ensures rapid resolution of any process deviation, minimizing downtime risk. This level of embedded support transforms your supply chain from a cost center into a strategic asset.

The true measure of a fabrication partner is their ability to consistently deliver under pressure while driving continuous improvement. Wuxi Lead Precision Machinery is engineered for this exact purpose. We invite you to move beyond transactional supplier relationships and initiate a precision partnership built on demonstrable results and shared growth objectives. Contact our engineering team directly to discuss your specific large fabrication challenges and receive a detailed capability assessment.

Initiate your precision partnership today. Contact [email protected] for immediate technical consultation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.