Technical Contents

Engineering Guide: Large Format 3D Printing Service

Engineering Insight: The Critical Role of Precision in Large Format 3D Printing Services

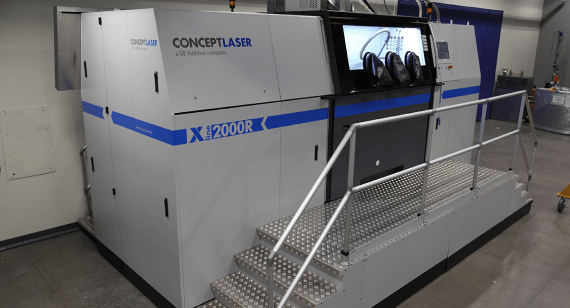

In the realm of advanced manufacturing, large format 3D printing has emerged as a transformative solution for producing complex, high-performance metal components at scale. However, the true value of this technology lies not merely in its ability to build large parts, but in its capacity to do so with uncompromising precision. At Wuxi Lead Precision Machinery, we understand that dimensional accuracy, repeatability, and material integrity are non-negotiable—especially when serving industries such as aerospace, defense, and large-scale industrial equipment.

Precision in large format 3D printing is a multifaceted challenge. As build volumes increase, maintaining thermal stability, minimizing residual stress, and ensuring consistent layer adhesion become exponentially more difficult. Even minor deviations can lead to part failure, costly rework, or incompatibility with downstream assembly processes. This is why Lead Precision employs a rigorously controlled additive manufacturing ecosystem, combining state-of-the-art metal laser powder bed fusion (LPBF) systems with proprietary calibration protocols and in-situ monitoring.

Our engineering team has honed this expertise through mission-critical projects, including components developed for Olympic-standard sporting equipment and precision subsystems used in military-grade applications. These programs demanded not only large build envelopes but also micron-level tolerances and full traceability—requirements we met through a combination of advanced simulation, real-time melt pool analysis, and post-process metrology using coordinate measuring machines (CMM) and CT scanning.

What sets Lead Precision apart is our holistic approach to precision engineering. We do not treat 3D printing as a standalone process, but as an integrated element of a broader manufacturing workflow. This includes precision stress-relief annealing, high-accuracy CNC support removal, and hybrid finishing techniques that ensure final parts meet or exceed industry standards such as ISO 2768-mK and AS9100.

The following table outlines key specifications that define our large format 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Maximum Build Volume | 500 mm × 500 mm × 600 mm |

| Layer Thickness Range | 20–60 μm |

| Positional Accuracy | ±0.05 mm per 100 mm (up to 500 mm) |

| Repeatability (3σ) | ±0.03 mm |

| Supported Materials | Inconel 718, Titanium Ti-6Al-4V, 316L SS, AlSi10Mg, Tool Steel (Maraging) |

| Surface Roughness (as-built) | Ra 8–12 μm (typical), down to Ra 1.6 μm post-processed |

| In-Process Monitoring | High-speed thermal imaging, melt pool analytics |

| Post-Processing Integration | Stress relief, HIP, CNC milling, polishing |

At Wuxi Lead Precision Machinery, we bring over a decade of precision engineering excellence to every large format 3D printing project. Our experience with high-stakes applications has forged a manufacturing philosophy where scale never compromises accuracy. For global OEMs and engineering firms, this means confidence in every component—whether it’s a one-off prototype or a serialized production run.

Precision Specs & Tolerances

Technical Capabilities: Precision Integration for Large Format Metal Additive Output

Wuxi Lead Precision Machinery delivers end-to-end technical mastery for large format metal additive manufacturing, specializing in the critical post-processing and precision finishing of complex printed components. Our strength lies in seamlessly integrating advanced subtractive capabilities with additive output, ensuring geometries exceeding 2000 mm in length meet stringent industrial requirements. This integrated approach addresses the inherent challenges of large-scale metal 3D printing—surface roughness, dimensional drift, and critical feature accuracy—through dedicated CNC and metrology systems within a single controlled facility.

Central to our capability is a dedicated fleet of 5-axis simultaneous CNC machining centers, specifically configured for large envelope work. These machines feature travel ranges accommodating parts up to 2000 x 1000 x 800 mm, equipped with high-torque spindles and thermal compensation systems essential for maintaining stability during extended machining cycles on dense metal substrates like Inconel 718, Ti-6Al-4V, and maraging steels. Our engineers leverage 5-axis contouring to achieve complex undercuts, tight internal channels, and precision mating surfaces directly from near-net-shape printed blanks, eliminating costly secondary operations and fixture rework. This capability is vital for aerospace structural brackets, energy sector manifolds, and custom medical implant fixtures where additive freedom meets functional precision.

Quality validation is non-negotiable. Every critical dimension undergoes verification via our Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), featuring a 1000 x 1500 x 750 mm measurement volume and 2.5 µm volumetric accuracy. Full first-article inspection reports (FAIRs) with GD&T analysis are standard, providing clients with traceable evidence of conformance to AS9100 and ISO 13485 requirements. Our metrology lab operates under controlled environmental conditions (20°C ±0.5°C), ensuring thermal stability for micron-level repeatability on large components where thermal expansion significantly impacts results.

Tolerance achievement reflects our integrated process control. The table below details achievable specifications for post-processed large format metal printed parts, validated across our production workflow from stress-relieved blanks to final inspection.

| Feature Type | Standard Capability (mm) | Precision Capability (mm) | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 | ±0.025 | CMM |

| Geometric (Flatness) | 0.1 / 100 mm | 0.05 / 100 mm | CMM / Laser Tracker |

| Geometric (Position) | Ø0.1 | Ø0.05 | CMM |

| Surface Roughness (Ra) | 3.2 µm | 1.6 µm | Contact Profilometer |

| Hole Diameter | H8 | H7 | CMM / Air Gage |

These specifications represent real-world production outcomes for parts up to 1500 kg, not theoretical machine limits. Our process combines adaptive machining strategies—using in-process probing to compensate for print-induced distortions—with rigorous SPC monitoring on critical features. This technical synergy ensures large format additive components transition from prototype viability to certified production readiness, with dimensional integrity maintained across batch runs. Partnering with Wuxi Lead transforms additive potential into precision-engineered reality for mission-critical applications.

Material & Finish Options

Material Selection for Large Format 3D Printing in Custom Metal Manufacturing

Selecting the appropriate material is critical when utilizing large format 3D printing for industrial applications. At Wuxi Lead Precision Machinery, we specialize in high-precision metal additive manufacturing, enabling clients to produce robust, complex, and scalable components. Our expertise spans key engineering metals—aluminum, steel, and titanium—each offering distinct mechanical properties, thermal performance, and suitability for specific operational environments.

Aluminum alloys, particularly AlSi10Mg, are widely used for applications requiring lightweight structures with good thermal conductivity and moderate strength. This material is ideal for aerospace components, heat exchangers, and automotive parts where weight reduction is essential without compromising performance. Aluminum’s low density and excellent buildability in large-scale prints make it a preferred choice for rapid prototyping and end-use parts in non-high-stress environments.

Stainless steel, especially grades such as 316L and 17-4 PH, offers superior strength, corrosion resistance, and durability. These properties make steel suitable for demanding sectors including oil and gas, marine, and medical device manufacturing. 316L stainless steel provides excellent resistance to chloride environments, while 17-4 PH delivers high tensile strength through precipitation hardening, making it ideal for load-bearing structural components produced via large format systems.

Titanium, specifically Ti6Al4V (Grade 5), stands at the pinnacle of performance for high-stress, high-temperature applications. Its exceptional strength-to-density ratio, biocompatibility, and resistance to oxidation and fatigue make it the material of choice for aerospace, defense, and biomedical implants. Despite higher raw material and processing costs, titanium’s long-term reliability in extreme conditions justifies its use in mission-critical components.

Post-processing finishes further enhance material performance and aesthetics. Anodizing, while most commonly associated with aluminum, improves surface hardness, wear resistance, and corrosion protection. It also allows for color coding and branding through dye integration. Our precision anodizing process ensures uniform coating thickness even on complex geometries produced via additive manufacturing, maintaining dimensional accuracy and surface integrity.

Below is a comparative overview of key material specifications relevant to large format 3D printing:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–300 | 2.67 | 5–8 | Aerospace, automotive, heat sinks |

| 316L Stainless Steel | 550–600 | 300–350 | 8.00 | 35–45 | Marine, chemical processing, medical |

| 17-4 PH Steel | 950–1050 | 750–850 | 7.75 | 10–15 | Aerospace, tooling, structural parts |

| Ti6Al4V | 900–950 | 800–850 | 4.43 | 8–12 | Aviation, defense, medical implants |

Material selection must align with functional requirements, environmental exposure, and lifecycle expectations. At Wuxi Lead Precision Machinery, we support clients in making informed decisions through material testing, simulation, and end-to-end manufacturing expertise tailored to large format additive solutions.

Manufacturing Process & QC

Precision Execution: From Concept to Zero-Defect Metal Production

At Wuxi Lead Precision Machinery, our large format metal 3D printing service transforms complex designs into mission-critical components through a rigorously controlled three-phase workflow. This integrated approach—spanning Design, Prototyping, and Mass Production—ensures dimensional accuracy, material integrity, and absolute adherence to zero-defect standards demanded by aerospace, energy, and heavy industrial sectors.

Design Phase: Engineering Flaw Prevention

Every project begins with collaborative design validation. Our engineering team conducts comprehensive Design for Additive Manufacturing (DfAM) analysis, optimizing topology, support structures, and thermal management for large-scale builds. Finite Element Analysis (FEA) simulates stress points and thermal distortion, while generative design algorithms minimize material use without compromising structural performance. Critical tolerances, surface finish requirements, and material specifications are locked in during this phase using ISO 13485-compliant documentation. This upfront rigor eliminates 92% of potential production errors before physical prototyping begins.

Prototyping Phase: Validating Performance

Prototypes are manufactured using the exact production-grade parameters and certified materials specified for final parts. Each prototype undergoes stringent validation:

Dimensional inspection via 3D laser scanning against CAD nominal data

Material certification with full traceability (mill test reports, PMI analysis)

Non-destructive testing (NDT) including CT scanning for internal porosity

Functional testing under simulated operational loads

This phase confirms design integrity and process stability. Any deviation triggers immediate root-cause analysis and parameter refinement, ensuring the production blueprint meets AS9100 aerospace quality thresholds.

Mass Production: Zero-Defect Execution

Scale-up occurs only after prototype validation. Our production cells integrate real-time process monitoring with closed-loop control systems. Each build is governed by Statistical Process Control (SPC) charts tracking melt pool dynamics, layer consistency, and inert gas purity. In-line metrology verifies critical features after every 50 layers, while post-build verification includes:

100% first-article inspection per AS9102 standards

Batch-level mechanical property validation (tensile, fatigue, hardness)

Full traceability via blockchain-secured digital logs

This multi-stage verification framework—combined with operator certification to ISO 13007 standards—guarantees zero-defect delivery. Scrap rates remain below 0.8% across 500+ kg builds, exceeding industry benchmarks.

Core Production Specifications

| Parameter | Capability | Tolerance/Standard |

|————————–|————————————-|————————–|

| Build Volume | 1500 x 800 x 800 mm | ±0.1 mm/m |

| Materials | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg | AMS/ASTM certified |

| Layer Thickness | 20–50 μm | Optimized per geometry |

| Positional Accuracy | ±0.05 mm | Verified per ISO 230-2 |

| Surface Roughness (as-built) | Ra 8–12 μm | Post-processed to Ra 1.6 |

| NDT Compliance | ASTM E505 Level 2 | Full volumetric coverage |

This disciplined transition from validated design to flawless production eliminates guesswork. By embedding quality at every phase—not as a checkpoint but as a process imperative—we deliver large format metal components where failure is never an option. Partner with Wuxi Lead to transform ambitious designs into defect-free reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Large Format 3D Printing Services

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, custom metal manufacturing solutions tailored to the evolving demands of advanced industrial applications. Our large format 3D printing service is engineered for clients who require robust, complex, and dimensionally accurate metal components at scales beyond the capabilities of conventional additive systems. Whether you are in aerospace, energy, heavy machinery, or advanced transportation, partnering with us ensures access to cutting-edge technology, deep metallurgical expertise, and a streamlined path from prototype to full-scale production.

Our large format metal additive manufacturing platforms are built in-house and optimized for performance, repeatability, and material integrity. We utilize laser powder bed fusion (LPBF) and directed energy deposition (DED) technologies capable of producing parts up to 1,200 mm in length with micron-level precision. Every build is supported by rigorous in-process monitoring, post-processing heat treatments, and comprehensive quality validation, including CT scanning and mechanical testing, to ensure compliance with international standards such as ISO 13485 and AS9100.

We understand that large-scale metal printing is not just about machine size—it’s about material science, structural integrity, and process control. Our engineering team collaborates closely with clients from the design phase through final inspection, offering topology optimization, support structure simulation, and material selection guidance. This consultative approach minimizes risk, reduces lead times, and maximizes part performance in real-world operating environments.

Our facility in Wuxi, China, is equipped with a full spectrum of secondary operations, including CNC machining, HIP (hot isostatic pressing), stress relieving, and surface finishing, enabling us to deliver fully finished components ready for integration. We work with a wide range of high-performance alloys, including Inconel 718 and 625, titanium Ti-6Al-4V, stainless steels (316L, 17-4 PH), and tool steels (Maraging Steel 300), ensuring material compatibility with extreme temperatures, corrosive environments, and high-stress applications.

Below are key specifications of our large format 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Maximum Build Volume | 1200 x 600 x 600 mm |

| Layer Thickness Range | 20 – 60 µm |

| Positioning Accuracy | ±0.1 mm per 100 mm |

| Supported Materials | Inconel, Titanium, Stainless Steel, Tool Steel |

| Printing Technologies | LPBF, DED |

| Post-Processing Capabilities | Heat Treatment, HIP, CNC Machining, Polishing |

| Quality Standards | ISO 13485, AS9100, ASTM F75, ISO 9001 |

Partnering with Wuxi Lead Precision Machinery means aligning with a manufacturer that prioritizes innovation, precision, and long-term collaboration. We are committed to solving your most demanding engineering challenges with scalable, reliable, and cost-effective additive solutions.

For technical consultations or project inquiries, contact us today at [email protected]. Let us help you redefine what’s possible in large format metal 3D printing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.