Technical Contents

Engineering Guide: Large 3D Printing Service

Engineering Insight Precision Imperatives in Large-Scale Metal Additive Manufacturing

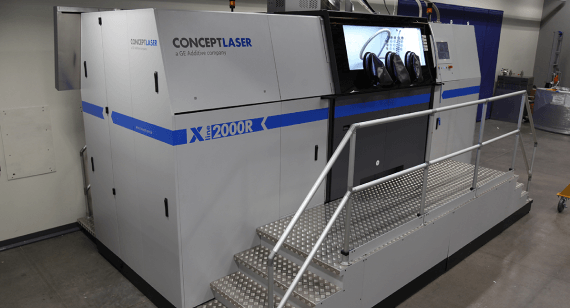

In the realm of large-format metal 3D printing, achieving dimensional accuracy transcends mere specification adherence; it defines functional viability and operational safety. For mission-critical components in aerospace, energy, and defense sectors, even micron-level deviations can cascade into catastrophic system failures or premature wear. The inherent thermal dynamics of large builds—significant heat accumulation, complex residual stress patterns, and potential for distortion—demand engineering rigor far beyond standard additive processes. True precision requires not only advanced hardware but a deep understanding of metallurgical behavior, thermal management, and post-processing science. At Wuxi Lead Precision Machinery, we treat precision as a non-negotiable engineering outcome, not a marketing claim.

Our approach integrates multi-axis real-time monitoring with predictive thermal modeling. We actively manage laser parameters, build plate temperature gradients, and inert gas flow dynamics throughout the entire build cycle, especially critical during the extended durations of large-part fabrication. This proactive control minimizes dimensional drift and internal stresses that compromise structural integrity. Crucially, precision extends beyond the as-printed state. Our proprietary stress-relief protocols and precision CNC post-machining ensure final components meet stringent geometric tolerances and surface finishes required for high-load applications. Material consistency is equally paramount; we implement rigorous powder characterization and recycling protocols to guarantee homogeneous mechanical properties throughout the build volume.

The scale of large-format printing intensifies these challenges. A minor thermal anomaly over a 1-meter build can manifest as millimeters of distortion—a critical error for assemblies requiring tight fits. Wuxi Lead’s engineering team leverages extensive experience with demanding applications to mitigate these risks. Our work supporting precision components for Olympic athletic equipment demonstrated the necessity of micro-accuracy for peak human performance. More significantly, our qualification and production of large structural elements for military land systems underscore our capability to deliver under the most stringent reliability and precision mandates, where failure is not an option. This experience directly informs our large-scale additive manufacturing protocols.

Wuxi Lead’s large-format metal additive capabilities are engineered for precision at scale, supported by integrated metrology and decades of high-stakes manufacturing expertise.

| Key Capability | Specification Detail | Precision Relevance |

|---|---|---|

| Max Build Volume | Ø 800 mm x 1500 mm H | Enables monolithic large structures reducing assembly tolerances |

| Layer Thickness Range | 20 μm – 80 μm | Fine control for critical surface features & thin walls |

| Typical Dimensional Tolerance | ± 0.1 mm / 100 mm (as-built) | Foundation for meeting tight final assembly specs |

| Post-Processing Capability | 5-Axis CNC Integrated Finishing | Achieves final tolerances down to ± 0.02 mm |

| Core Materials | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg | Validated process parameters for critical alloys |

| In-Process Monitoring | Melt Pool Analysis, Thermal Imaging | Real-time correction of thermal distortions |

This commitment to precision engineering, forged in applications where performance is measured in Olympic gold or battlefield reliability, defines Wuxi Lead’s value proposition. We don’t just print large metal parts; we deliver dimensionally assured, mission-ready components. Contact our engineering team to discuss how our precision-focused large-scale additive process can solve your most demanding manufacturing challenges.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision Metal Manufacturing

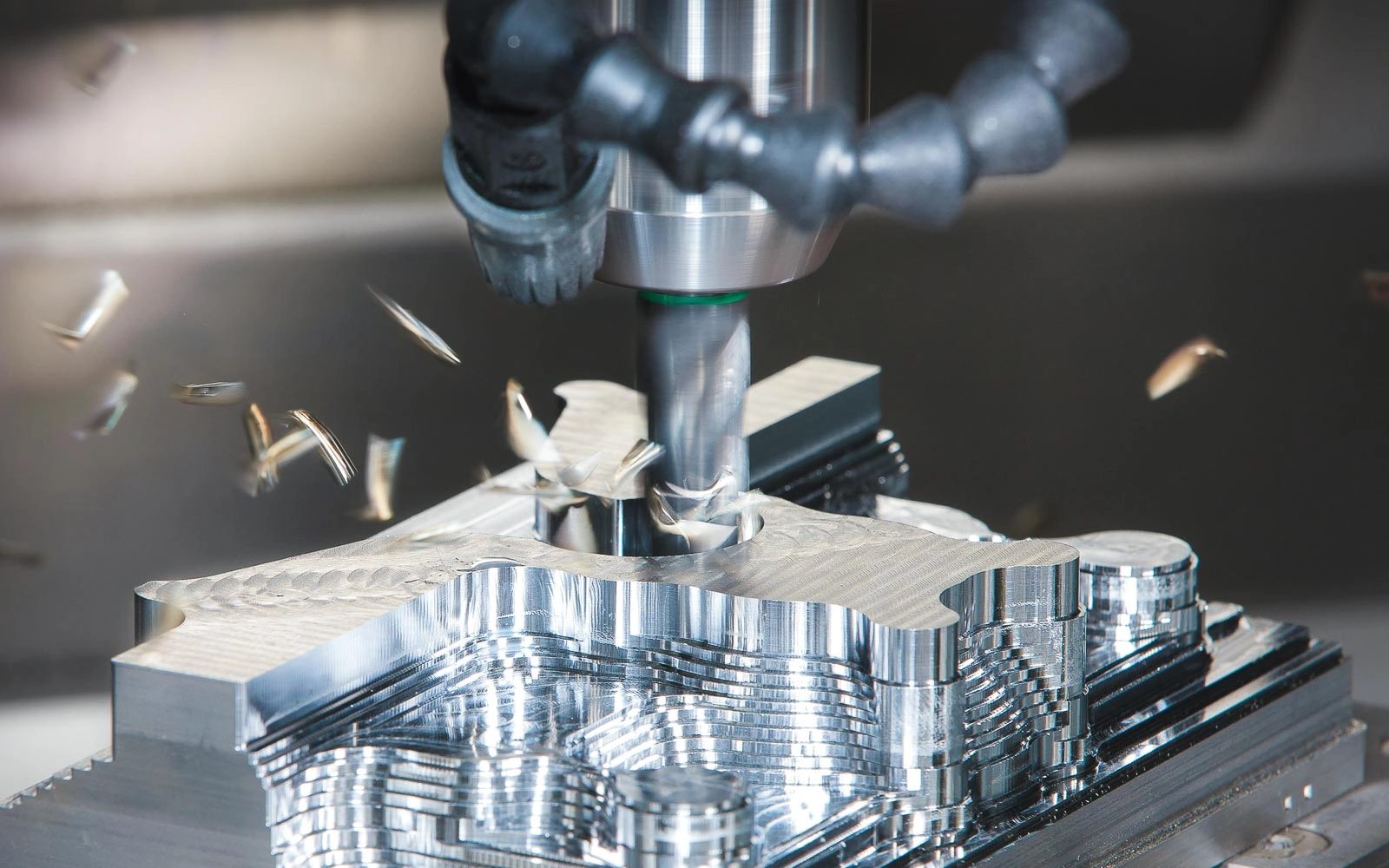

At Wuxi Lead Precision Machinery, our technical infrastructure is engineered to meet the most demanding requirements in custom metal manufacturing, particularly for large-scale 3D printed components requiring post-processing and precision integration. Our facility integrates state-of-the-art 5-axis CNC machining systems with comprehensive quality control protocols to deliver components that adhere to the strictest industry tolerances and surface finish specifications. This capability is essential for sectors such as aerospace, energy, medical, and high-performance automotive, where dimensional accuracy and material integrity are non-negotiable.

Our 5-axis CNC machining centers provide full simultaneous motion across all five axes, enabling complex geometries to be machined in a single setup. This reduces cumulative error, improves repeatability, and significantly enhances surface finish quality. With a large working envelope and high-torque spindles, our machines are capable of handling oversized 3D printed metal parts—commonly produced via DED or SLM processes—requiring precise milling, drilling, and contouring. The integration of high-resolution encoders and thermal compensation systems ensures long-term stability and micron-level accuracy, even during extended machining cycles.

Complementing our machining capabilities is a fully equipped metrology lab anchored by a coordinate measuring machine (CMM) with multi-sensor technology. Every critical component undergoes 100% inspection against CAD-defined GD&T (Geometric Dimensioning and Tolerancing) standards. Our CMM system supports both tactile probing and optical scanning, allowing for comprehensive evaluation of internal features, freeform surfaces, and tight-tolerance bores. Data from inspections is compiled into detailed first-article inspection (FAI) reports, providing full traceability and compliance with AS9100 and ISO 9001 standards.

All manufacturing and inspection workflows are supported by advanced CAM and quality software suites, including Siemens NX and PolyWorks, ensuring seamless data transfer from digital model to physical part. Process validation is conducted through statistical process control (SPC), with continuous monitoring of tool wear, spindle load, and environmental conditions to maintain consistency across production runs.

The following table outlines the standard technical specifications and achievable tolerances for our 5-axis CNC machining and inspection services:

| Parameter | Specification |

|---|---|

| Maximum Work Envelope | 2000 mm × 1200 mm × 1000 mm |

| Spindle Speed | Up to 24,000 rpm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Standard Surface Finish | Ra 0.8 µm (as machined), down to Ra 0.2 µm |

| Linear Tolerances | ±0.01 mm (standard), down to ±0.005 mm (tight) |

| Geometric Tolerances (GD&T) | ±0.01 mm (flatness, roundness, runout) |

| CMM Measurement Accuracy | ±1.5 + L/300 µm (L in mm) |

| Materials Supported | Titanium, Inconel, Stainless Steel, Aluminum, Tool Steels, Cobalt-Chrome |

These capabilities position Wuxi Lead as a trusted partner for high-complexity, high-integrity metal components derived from large 3D printed substrates, where precision finishing and rigorous quality assurance define project success.

Material & Finish Options

Strategic Material Selection for Large-Scale Metal Additive Manufacturing

Selecting the optimal material is a foundational engineering decision for large-format metal 3D printing projects, directly impacting part performance, longevity, and cost-efficiency. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your specific application demands, environmental exposure, and functional requirements. Understanding the nuanced advantages of Aluminum, Steel, and Titanium alloys is critical for achieving mission-critical results in aerospace, energy, and industrial sectors. This selection process transcends basic composition; it requires analyzing thermal behavior, fatigue resistance, and post-processing compatibility inherent to the additive build process.

Aluminum alloys, particularly AlSi10Mg, offer an exceptional strength-to-weight ratio essential for weight-sensitive applications like drone components and automotive brackets. Their inherent thermal conductivity makes them suitable for heat exchangers and enclosures. Steel variants, especially maraging steels and 17-4 PH stainless steel, provide superior hardness, wear resistance, and high-temperature stability. These are indispensable for tooling, heavy machinery parts, and components requiring stringent dimensional stability under load. Titanium alloys, predominantly Ti6Al4V, deliver outstanding corrosion resistance combined with high strength and biocompatibility. This makes them the unequivocal choice for demanding aerospace structural elements, marine hardware, and medical implants where failure is not an option.

Material performance specifications guide critical design choices. Consider the comparative properties below:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Key Corrosion Resistance | Primary Large-Scale Applications |

|---|---|---|---|---|

| Aluminum (AlSi10Mg) | 2.67 | 400 – 450 | Moderate (requires finish) | Lightweight frames, heat sinks, brackets |

| Steel (17-4 PH) | 7.75 | 1000 – 1300 | Good (stainless) | Tooling, hydraulic manifolds, shafts |

| Titanium (Ti6Al4V) | 4.43 | 900 – 1000 | Excellent | Aerospace brackets, marine connectors |

Surface finish selection is equally strategic. Anodizing, particularly hard anodizing for aluminum, is not merely cosmetic. It significantly enhances surface hardness, wear resistance, and corrosion protection, creating a durable, electrically insulating layer vital for parts operating in abrasive or corrosive environments. Our precision anodizing processes are tightly controlled to ensure uniform coating thickness and adherence, meeting stringent aerospace and military specifications (e.g., MIL-A-8625). This finish is crucial for extending service life in demanding operational conditions where raw metal would degrade prematurely.

Partnering with Wuxi Lead ensures your material and finish selection leverages our deep metallurgical expertise in additive manufacturing. We conduct thorough application reviews, considering build orientation effects, residual stress management, and final part certification requirements. Our engineering team provides data-driven recommendations, moving beyond generic material datasheets to optimize your specific large-part build for performance, reliability, and total cost of ownership. Contact us to define the precise material strategy for your next high-value additive project.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for large-scale 3D printing services is engineered to deliver precision, repeatability, and zero-defect outcomes across every phase—from initial design to full-scale manufacturing. We specialize in custom metal components for industries where failure is not an option, including aerospace, energy, and advanced industrial equipment. Our integrated workflow ensures seamless transition between stages while maintaining strict quality control at every touchpoint.

The process begins with collaborative design engineering. Our team works directly with clients to refine CAD models, perform topology optimization, and conduct thorough design-for-additive-manufacturing (DfAM) analysis. This stage includes thermal and structural simulations to predict performance under operational loads, ensuring the component meets all functional and regulatory requirements before any material is printed. Material selection is carefully matched to application demands, with options including Inconel 718, titanium Ti-6Al-4V, stainless steel 316L, and aluminum AlSi10Mg.

Prototyping follows design validation, where we produce functional prototypes using our large-format metal additive systems. These systems support build envelopes up to 1000 x 600 x 500 mm, enabling the fabrication of full-scale parts without segmentation. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical scanning, and ultrasonic testing to verify dimensional accuracy and internal integrity. Feedback from this phase is used to fine-tune parameters such as laser power, scan speed, and support structure layout, ensuring optimal results in mass production.

Once prototype approval is achieved, we transition to high-integrity serial production. Our factory integrates automated powder handling, inert gas recycling, and real-time melt pool monitoring to maintain consistency across builds. Each layer is monitored via in-situ sensors that detect anomalies and trigger corrective actions, minimizing the risk of defects. Post-processing is performed in-house, including heat treatment, hot isostatic pressing (HIP), precision machining, and surface finishing, all conducted under controlled environments to preserve material properties.

Quality assurance is embedded throughout the entire workflow. We adhere to ISO 9001 and AS9100 standards, with full traceability from raw material batch to final inspection report. Every component is delivered with a comprehensive quality dossier, including metallurgical analysis, mechanical test results, and dimensional certification.

The table below outlines key capabilities of our large 3D printing production system:

| Parameter | Specification |

|---|---|

| Build Envelope | 1000 x 600 x 500 mm |

| Layer Thickness | 20–60 µm |

| Positional Accuracy | ±0.1 mm / 100 mm |

| Surface Roughness (as-built) | Ra 12–16 µm |

| Common Materials | Inconel 718, Ti-6Al-4V, SS316L, AlSi10Mg |

| Post-Processing Options | HIP, CNC Machining, Polishing, Coating |

| In-Process Monitoring | Melt Pool, Thermal Imaging, Gas Analysis |

By aligning advanced technology with disciplined process control, Wuxi Lead Precision Machinery ensures that every part produced meets the highest standards of performance, reliability, and zero-defect manufacturing.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Strategic Advantage in Industrial Metal Additive Manufacturing

When your 3D printing requirements shift from prototype to production-scale metal components, the margin for error vanishes. Thermal distortion, material inconsistency, and geometric complexity demand more than a printer operator—they require an engineering partner with deep metallurgical expertise and industrial-grade process control. At Wuxi Lead Precision Machinery, we bridge the gap between ambitious design and flawless execution for large-format metal additive manufacturing. Our facility in Wuxi integrates certified aerospace-grade build systems with proprietary post-processing workflows, ensuring every part meets stringent AS9100 and ISO 13485 standards. We do not merely run builds; we de-risk your supply chain through predictive simulation, in-situ monitoring, and full material traceability from powder to finished component.

Our technical foundation rests on scalable infrastructure engineered for mission-critical applications. Below are core capabilities defining our production environment:

| Specification | Capability Detail | Industrial Relevance |

|---|---|---|

| Build Volume | 500 x 500 x 500 mm (up to 1000 x 800 x 600 mm) | Enables single-piece fabrication of structural aerospace brackets, hydraulic manifolds, and energy sector housings |

| Material Compatibility | Inconel 718/625, Ti-6Al-4V, AlSi10Mg, Maraging Steel 300 | Supports extreme-temperature, high-stress, and biocompatible applications |

| Dimensional Accuracy | ±0.05 mm per 100 mm (post-machining: ±0.005 mm) | Eliminates fit/assembly failures in precision assemblies |

| Surface Finish | As-built: Ra 12–25 μm; Polished: Ra 0.8–1.6 μm | Meets fluid dynamics and fatigue resistance requirements |

| Quality Assurance | Full build monitoring, CT scanning, mechanical testing per ASTM F3301 | Guarantees structural integrity for safety-critical parts |

Unlike volume-focused service bureaus, we specialize in low-to-mid volume runs where quality consistency dictates program success. Our engineers collaborate from DfAM (Design for Additive Manufacturing) validation through final inspection, applying decades of experience in mitigating warpage in thin-walled geometries and optimizing support structures for minimal post-processing. This proactive approach reduces lead times by 30% while ensuring first-article approval rates exceed 95%. For industries where component failure is not an option—such as aerospace, medical implants, or oil and gas—we embed failure mode analysis into every build strategy.

Your project demands more than machine uptime; it requires a partner who treats your specifications as non-negotiable commitments. Lead Precision invests in closed-loop powder management, climate-controlled build chambers, and NDT-certified technicians to deliver parts that perform identically across batches. We secure your intellectual property through encrypted data protocols and dedicated production cells, providing audit trails compliant with ITAR and GDPR frameworks.

Transform your additive manufacturing vision into certified reality. Contact our engineering team directly to discuss material qualifications, build orientation strategies, or scalability roadmaps. Submit your CAD files and requirements to [email protected] for a technical feasibility assessment within 24 business hours. Let us demonstrate how precision-engineered partnership accelerates your path to production.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.