Technical Contents

Engineering Guide: Island Machining

Engineering Insight: Island Machining Precision in Critical Applications

Island machining represents a sophisticated CNC milling technique essential for producing complex 3D geometries where isolated raised features—resembling islands within a sea of material—must be machined with extreme accuracy relative to the surrounding structure. This process demands exceptional machine stability, advanced toolpath strategies, and rigorous thermal control. The core challenge lies in maintaining micron-level positional fidelity while navigating tight internal corners and varying wall thicknesses, where even minor deflection or thermal drift compromises the entire component’s function. At Wuxi Lead Precision Machinery, we recognize that success in island machining hinges on the seamless integration of machine tool rigidity, predictive compensation algorithms, and deep process understanding. Sub-micron thermal compensation systems and real-time tool deflection monitoring are non-negotiable for achieving the required tolerances, especially when working with challenging aerospace alloys or hardened tool steels where residual stress relief can distort features post-machining.

Precision in island machining transcends dimensional accuracy; it encompasses surface integrity, edge definition, and geometric conformity critical for assemblies operating under high stress or vacuum conditions. Inadequate control leads to stress concentrations at island bases, compromising fatigue life, or misaligned interfaces causing assembly failures. Our engineering protocols enforce strict in-process metrology at multiple stages, utilizing coordinate measuring machines (CMMs) with sub-micron resolution to validate critical datums before final finishing passes. This iterative verification ensures that islands maintain positional accuracy within the global workpiece coordinate system, a requirement often dictated by fluid dynamics or optical alignment in high-performance systems. Material behavior during machining is equally critical; our proprietary cutting parameter libraries, developed through decades of empirical testing, optimize chip evacuation and minimize heat generation in deep pockets surrounding islands.

The table below outlines key precision parameters achievable through our validated island machining processes for mission-critical components:

| Specification Category | Typical Capability | High-Precision Capability | Material Examples |

|---|---|---|---|

| Positional Tolerance | ±0.005 mm | ±0.001 mm | Ti-6Al-4V, Inconel 718 |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Hardened Steel (58 HRC) |

| Feature Flatness | 0.008 mm over 100 mm | 0.002 mm over 50 mm | Aluminum 7075-T7351 |

| Edge Radius Consistency | ±0.010 mm | ±0.003 mm | Copper Alloys (C18150) |

| Thermal Drift Compensation | < 2 µm over 8 hours | < 0.5 µm over 4 hours | Aerospace Composites |

Wuxi Lead Precision Machinery’s expertise in island machining is rigorously proven in applications where failure is not an option. Our processes have delivered components for Olympic-grade timing systems requiring nanosecond synchronization and critical subsystems for military platforms operating in extreme environments. This heritage informs every machining strategy we deploy, ensuring your most demanding island features meet the uncompromising standards of global aerospace, defense, and advanced instrumentation sectors. Precision isn’t merely a specification we target—it is the foundational requirement we engineer into every process.

Precision Specs & Tolerances

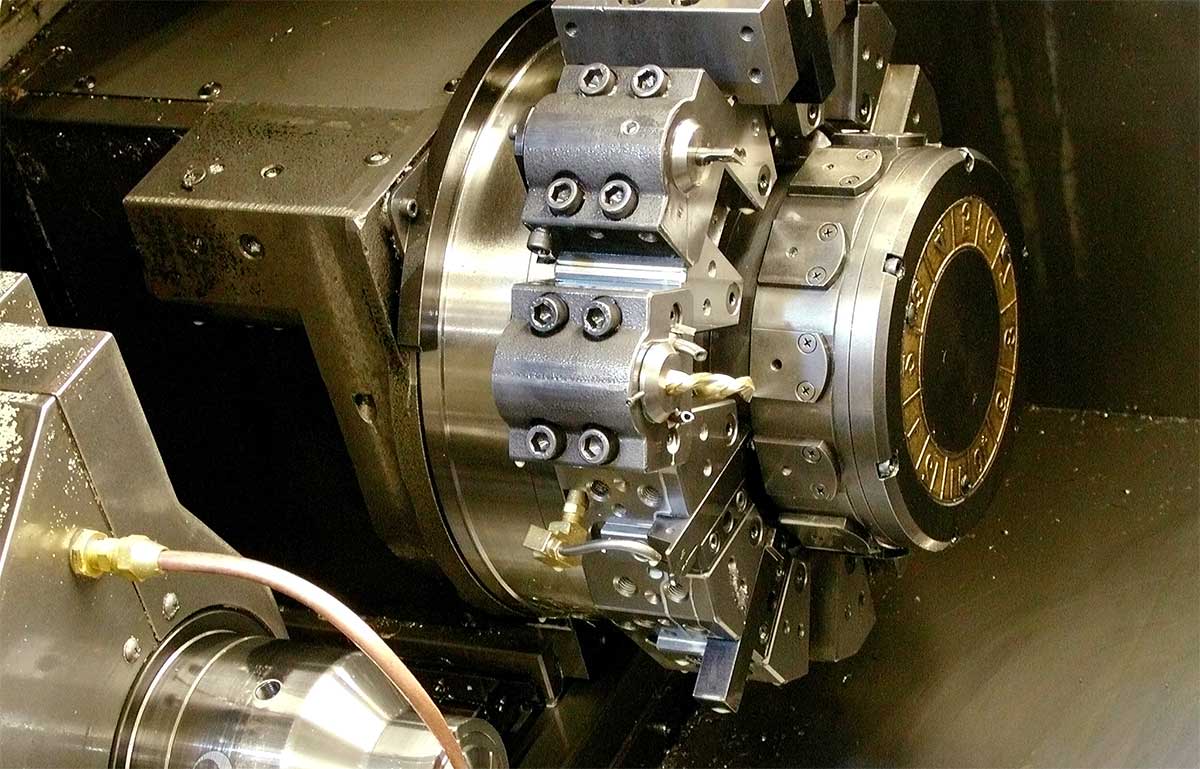

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions through island machining, a high-efficiency production methodology that integrates dedicated cells of multi-axis CNC machines, automation, and real-time quality control. This approach enables uninterrupted, high-precision machining of complex metal components, primarily serving aerospace, medical, energy, and industrial equipment sectors. At the core of our island machining capability is a fleet of state-of-the-art 5-axis CNC machining centers, equipped with high-torque spindles, dynamic tool changers, and integrated probing systems. These machines allow simultaneous multi-directional cutting, reducing setup cycles and ensuring geometric accuracy across intricate contours and deep cavities.

Our 5-axis platforms support full 360° rotation and ±180° indexing, enabling single-setup machining of parts that would otherwise require multiple fixtures and operations. This not only enhances dimensional consistency but also significantly reduces lead times and the risk of human error. All systems within the machining island are networked and monitored via a centralized control system, allowing for adaptive machining strategies, predictive maintenance, and seamless data flow between design, production, and quality assurance.

Quality is embedded at every stage of the island machining process. In-process probing verifies workpiece alignment and detects tool wear, while post-machining inspection is conducted using a Zeiss DuraMax and O-Inspect 555 Coordinate Measuring Machine (CMM). These systems provide micron-level verification of critical features, including positional tolerances, surface finishes, and complex geometries defined by GD&T. All inspection data is documented and traceable, supporting full compliance with AS9100, ISO 13485, and other industry-specific standards.

We specialize in machining high-performance alloys such as Inconel, titanium, stainless steel, and aluminum, with an emphasis on tight-tolerance, low-volume to mid-volume production runs. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, reduce cost drivers, and ensure producibility within the island environment.

The following table outlines our standard machining capabilities and achievable tolerances:

| Specification | Capability |

|---|---|

| Machine Types | 5-axis CNC milling, CNC turning with live tooling |

| Spindle Speed | Up to 24,000 RPM |

| Work Envelope (Max) | 1,200 mm × 800 mm × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Linear Tolerances | ±0.010 mm (standard), ±0.005 mm (tight) |

| Angular Tolerances | ±0.02° |

| Surface Roughness (Ra) | 0.8 µm (standard), down to 0.4 µm (polished/finishing pass) |

| Materials Processed | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Inconel (625, 718), Brass, Tool Steels |

| Inspection Equipment | Zeiss CMM, Optical Comparators, Calibrated Hand Tools |

| Data Traceability | Full first-article and batch inspection reports (FAIR), SPC data available |

Wuxi Lead Precision Machinery’s island machining capability represents the convergence of automation, precision engineering, and rigorous quality control—ensuring reliable delivery of mission-critical components to global OEMs.

Material & Finish Options

Material Selection for Precision Island Machining

Island machining demands exceptional material stability and machinability due to the inherent challenges of unsupported features and thin walls. Selecting the optimal metal alloy is not merely a cost decision; it directly impacts dimensional accuracy, surface integrity, tool life, and final part performance. At Wuxi Lead Precision Machinery, our decades of experience in high-tolerance CNC milling dictate rigorous material evaluation for complex geometries. Aluminum alloys, particularly 6061-T6 and 7075-T6, are prevalent for aerospace and electronics housings. 6061 offers excellent machinability and moderate strength, ideal for prototypes and less demanding structural components. 7075-T6 provides superior strength-to-weight ratio crucial for flight-critical parts but requires precise toolpath strategies and sharp tooling to manage its tendency for chip welding and higher cutting forces. Thermal management is critical; aluminum’s high conductivity aids heat dissipation but demands stable coolant application to prevent localized warping during intricate island cuts.

Steel selections like 4140 and 17-4PH stainless dominate applications requiring high strength, wear resistance, and fatigue performance, such as hydraulic manifolds or medical implants. 4140 offers good machinability in the pre-hardened state and responds well to heat treatment post-machining. 17-4PH provides excellent corrosion resistance and can be precipitation hardened to very high strengths, though its lower thermal conductivity necessitates reduced feed rates and meticulous thermal control during prolonged island milling to avoid work hardening and dimensional drift. Titanium alloys, primarily Ti-6Al-4V (Grade 5), are essential for extreme strength-to-weight ratio and biocompatibility in aerospace and medical sectors. However, titanium’s low thermal conductivity and high chemical reactivity pose significant challenges. It generates intense heat at the cutting edge, demanding specialized tool coatings, rigid setups, and aggressive coolant delivery to prevent galling, built-up edge, and microstructural damage – risks amplified when machining delicate islands.

Anodizing is the definitive surface treatment for aluminum components requiring enhanced corrosion resistance, electrical insulation, or wear resistance, especially critical for assemblies with tight tolerance interfaces. Standard clear or colored Type II anodizing provides basic protection. For island-machined parts subject to abrasion or stringent sealing requirements, hardcoat Type III anodizing is imperative. It forms a dense, thick oxide layer (typically 25-50μm) that significantly improves surface hardness while maintaining dimensional stability within tight tolerances when controlled precisely – a capability Wuxi Lead masters through in-house anodizing process validation. Incorrect anodizing thickness or sealing can distort micron-level features on complex islands.

Material properties dictate machining strategy. The following table summarizes critical characteristics for common island machining alloys:

| Material | Key Alloy | Thermal Conductivity (W/mK) | Max Hardness (HB) |

|---|---|---|---|

| Aluminum | 6061-T6 | 167 | 95 |

| Aluminum | 7075-T6 | 130 | 150 |

| Steel | 4140 (Annealed) | 42 | 229 |

| Steel | 17-4PH (H900) | 18 | 440 |

| Titanium | Ti-6Al-4V | 7 | 360 |

Material choice must align with functional requirements, manufacturability constraints of the specific geometry, and post-processing needs. Wuxi Lead Precision Machinery collaborates early in the design phase to recommend the optimal material-finish combination, ensuring your island-machined components meet the highest standards of precision and reliability. Contact our engineering team for material-specific process validation.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, island machining represents a strategic evolution in high-precision metal manufacturing, combining advanced CNC multi-tasking with rigorous process control to deliver complex, high-integrity components. Our approach integrates Design, Prototyping, and Mass Production into a seamless, zero-defect workflow, ensuring repeatability, accuracy, and compliance with the most demanding industrial standards.

The process begins with collaborative design engineering. Leveraging 3D CAD/CAM software and finite element analysis, our engineering team works closely with clients to refine part geometry, material selection, and tolerance specifications. This stage includes manufacturability analysis to optimize toolpaths, minimize setup changes, and eliminate potential failure points before any metal is cut. Design validation is achieved through digital twins and simulation of the island machining sequence, where multiple operations—turning, milling, drilling, and probing—are executed within a single setup on multi-axis platforms.

Prototyping follows with the deployment of our DMG MORI NTX 1000 and Makino Integrex i-200 machines, configured for island cell operations. These platforms allow complete part fabrication without manual intervention, reducing human error and ensuring dimensional consistency. Each prototype undergoes full CMM inspection, surface roughness testing, and first-article reporting per AS9102 or PPAP standards, depending on industry requirements. Feedback from this phase is integrated into final process adjustments, ensuring the transition to mass production is risk-free.

Mass production is executed within dedicated island cells, each consisting of a multi-axis CNC machine, automated tool changers, in-process probing, and robotic part handling. These cells operate under a closed-loop quality system, where real-time data from sensors and vision systems monitor tool wear, thermal drift, and geometric accuracy. Our statistical process control (SPC) framework ensures every batch remains within ±0.002 mm tolerance, with 100% traceability via serialized part marking and digital process logs.

Zero defects is not a target—it is our mandate. We enforce this through preventive maintenance schedules, operator certification, and automated inspection gates at critical stages. Every component is verified against the original CAD model using 3D scanning and automated optical comparison. Non-conforming parts are immediately quarantined and analyzed through root cause failure analysis (RCFA), with corrective actions implemented in real time.

The following table outlines the core specifications of our island machining capabilities:

| Parameter | Specification |

|---|---|

| Machine Platforms | DMG MORI NTX 1000, Makino Integrex i-200 |

| Axis Configuration | 5-axis simultaneous, Y-axis & B-axis capable |

| Spindle Speed | Up to 12,000 rpm |

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.0005 mm |

| Tool Capacity | Up to 120 tools (automatic changer) |

| Work Envelope (max) | Ø400 mm x 300 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel |

| Surface Finish (typical) | Ra 0.4 µm to Ra 1.6 µm |

| In-Process Inspection | On-machine probing, laser tool measurement |

| Production Throughput | 24/7 unattended operation (up to 72 hours) |

By integrating precision engineering with intelligent automation, Wuxi Lead Precision Machinery delivers island machining solutions that redefine efficiency, quality, and reliability in custom metal manufacturing.

Why Choose Wuxi Lead Precision

Elevate Complex Component Production Through Strategic Partnership

Island machining represents a critical advancement for manufacturers facing intricate geometries requiring minimal setup transitions. At Wuxi Lead Precision Machinery, we transform this capability into your competitive advantage through engineered solutions that eliminate costly repositioning errors and accelerate time-to-market. Our dedicated approach ensures complex aerospace structural components, medical implant fixtures, and energy sector manifolds achieve uncompromised dimensional stability and surface integrity—all within a single machining sequence. This methodology directly translates to reduced scrap rates, lower total production costs, and accelerated project lifecycles for your most demanding applications.

Partnering with Lead Precision means accessing a vertically integrated facility engineered for high-mix, low-volume precision work. Our 12,000m² ISO 9001-certified campus houses 47 state-of-the-art 5-axis machining centers, including DMG MORI and Makino platforms with integrated probing and adaptive control systems. Every island machining project undergoes rigorous DFMEA analysis and iterative process validation under controlled environmental conditions. Our engineering team collaborates from initial design review through final inspection, leveraging Renishaw XL-80 laser interferometer calibration and Zeiss CONTURA CMM verification to guarantee tolerances remain within ±0.001mm across multi-face operations. Material expertise spans titanium alloys (Ti-6Al-4V, Ti-5553), Inconel 718, 17-4PH stainless, and hardened tool steels up to HRC 60.

Technical Capabilities for Island Machining Excellence

| Specification | Value |

|---|---|

| Max Work Envelope | 1,200 x 800 x 650 mm |

| Positioning Accuracy | ±0.001 mm over full travel |

| Surface Finish (Ra) | 0.4 µm achievable on critical faces |

| Material Removal Rate | Up to 1,200 cm³/min (aluminum) |

| In-Process Metrology | On-machine probing with 0.5 µm repeatability |

| Lead Time Reduction | 35-50% vs. conventional multi-setup methods |

This precision ecosystem is sustained by our proprietary SmartMach™ process monitoring suite, which continuously analyzes tool wear, vibration signatures, and thermal drift in real-time. The result is predictable first-article success and batch consistency demanded by Tier 1 aerospace and medical OEMs. We maintain full material traceability from certified mill certificates through final packaging, with NADCAP-accredited non-destructive testing available for mission-critical components.

Initiate your project with engineering collaboration, not just procurement. Submit your 3D CAD model and technical requirements to [email protected] for a dedicated feasibility assessment within 24 business hours. Our application engineers will provide a comprehensive process plan including setup optimization, fixture design validation, and a transparent cost breakdown—no generic quotations. For urgent prototyping needs, reference “ISLAND-FAST” in your subject line to activate our 72-hour rapid response protocol. Wuxi Lead Precision Machinery: Where complex geometry becomes your manufacturing certainty.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.