Technical Contents

Engineering Guide: Ir Parts

Engineering Insight: Precision Imperatives for IR Component Manufacturing

Infrared (IR) component manufacturing demands uncompromising precision due to the physics of thermal and optical performance. Minute deviations in dimensional tolerances or surface integrity directly compromise signal clarity, thermal stability, and system calibration. A variance of ±0.005mm in lens housing alignment can induce critical beam distortion, while surface roughness exceeding Ra 0.4μm scatters IR wavelengths, degrading sensor accuracy. These components operate in mission-critical environments—military targeting systems, aerospace thermal imaging, and scientific instrumentation—where failure is not an option. Material selection further complicates production; aluminum alloys like 6061-T6 and titanium Ti-6Al-4V require specialized CNC strategies to manage thermal expansion coefficients and maintain micron-level stability under operational stress. At Wuxi Lead Precision Machinery, we treat every IR part as a functional extension of the end system, not merely a machined artifact.

Our process begins with thermal distortion modeling and in-process metrology to preempt micro-deformations during machining. Multi-axis Swiss turning and diamond milling ensure geometric perfection, while proprietary stress-relief cycles eliminate latent material inconsistencies. The table below reflects our baseline capabilities for IR-grade production, validated through decades of aerospace and defense collaboration.

| Parameter | Standard Capability | Military/Olympic Tier Requirement |

|---|---|---|

| Dimensional Tolerance | ±0.001mm | ±0.0005mm |

| Surface Roughness (Ra) | 0.8μm | 0.2μm (optical grade) |

| Geometric Accuracy | 0.002mm flatness | 0.0008mm flatness |

| Material Compliance | ASTM B209/B348 | MIL-A-46100/AMS 4928 |

| Inspection Protocol | CMM + optical comparator | Full spectral analysis + ETD |

Wuxi Lead’s authority in this niche stems from direct involvement in tier-1 defense supply chains and Olympic-grade timing systems. We manufactured calibration housings for the 2022 Winter Olympics biometric sensors—components requiring sub-micron repeatability across -40°C to +85°C thermal cycles. Similarly, our work on naval IR guidance subsystems demanded zero-defect delivery under ITAR-controlled workflows, with 100% traceability from raw billet to final assembly. This experience ingrained a culture where “precision” transcends machining—it encompasses environmental controls, operator certification, and real-time SPC data fusion.

For IR applications, tolerances are not specifications; they are performance guarantees. Our facility operates under ISO 9001:2015 and AS9100D frameworks, with dedicated cleanrooms for post-machining optical finishing. When your IR system’s reliability hinges on invisible wavelengths, partner with engineers who measure success in nanometers. Wuxi Lead delivers not just parts, but validated performance continuity from blueprint to battlefield or laboratory.

Precision Specs & Tolerances

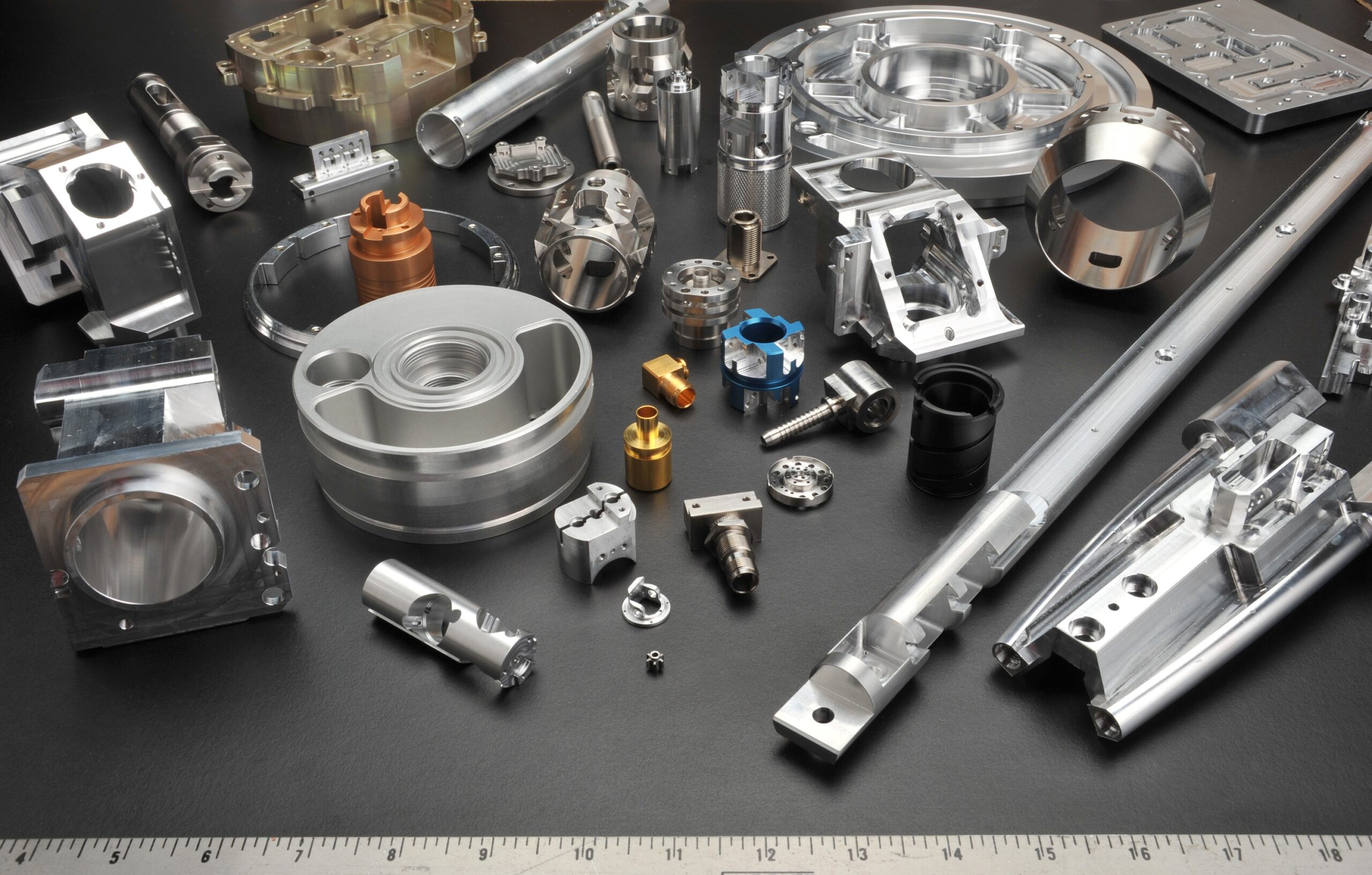

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for industries requiring the highest levels of precision, repeatability, and material integrity. Our core technical capabilities are anchored in state-of-the-art 5-axis CNC machining, enabling us to produce complex, high-performance IR (Infrared) components and other mission-critical parts used in aerospace, defense, medical, and semiconductor applications. The integration of multi-axis technology allows simultaneous machining from five different angles, minimizing setup cycles and ensuring superior geometric accuracy across intricate part geometries.

Our 5-axis CNC machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to maintain consistent cutting performance and dimensional stability. This level of control is essential when working with exotic alloys, stainless steels, aluminum, and other materials commonly specified in IR system components where thermal stability and surface finish are critical. With a maximum work envelope of 1,200 x 800 x 600 mm and sub-micron positioning accuracy, our machines support both prototype development and high-volume production runs with equal precision.

Complementing our machining capabilities is a rigorous quality control protocol centered on Coordinate Measuring Machine (CMM) inspection. Every IR part undergoes comprehensive dimensional verification using Zeiss and Hexagon CMM systems, which provide 3D metrology data with traceability to international standards (ISO 9001 and IATF 16949). These inspections validate critical features such as flatness, concentricity, angular alignment, and bore tolerances—parameters that directly impact the optical and mechanical performance of infrared assemblies.

In addition to CMM, our QC process includes surface roughness testing, material certification, and first-article inspection reports (FAIR), ensuring full compliance with customer engineering specifications. All inspection data is documented and archived for lot traceability, supporting stringent regulatory requirements in defense and aerospace sectors.

The following table outlines the standard tolerance capabilities we achieve across common machining parameters. These values reflect our baseline performance under controlled environmental conditions and may be tightened further based on specific design requirements and material behavior.

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm |

| Hole Diameter | ±0.008 mm | ±0.003 mm |

| Positional Tolerance | ±0.010 mm | ±0.005 mm |

| Flatness | 0.005 mm per 100 mm | 0.002 mm per 100 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm (polished finish) |

| Angular Accuracy | ±0.005° | ±0.002° |

By combining 5-axis CNC machining with certified metrology and process control, Wuxi Lead Precision Machinery ensures that every IR component meets the exacting demands of modern optomechanical systems. Our technical capabilities are designed not only to meet specifications but to deliver long-term reliability in the most challenging operational environments.

Material & Finish Options

Material Selection for Precision IR Components: Performance-Driven Choices

Material selection critically impacts the thermal stability, dimensional accuracy, and longevity of infrared (IR) components. At Wuxi Lead Precision Machinery, we prioritize metallurgical integrity to ensure your parts withstand demanding operational environments. Below we detail optimal choices for aluminum, steel, and titanium alloys, alongside essential finishing considerations.

Aluminum alloys (e.g., 6061-T6, 7075-T6) offer an exceptional strength-to-weight ratio and thermal conductivity, making them ideal for lightweight IR housings and heat-sensitive assemblies. While cost-effective and easily machinable, untreated aluminum lacks sufficient corrosion resistance for harsh conditions. Anodizing is non-negotiable here—Type II (sulfuric acid) provides moderate wear protection, while hardcoat Type III anodizing delivers 50–70 μm thickness for extreme abrasion resistance. Note that anodizing adds dimensional tolerance; we compensate during CNC programming to maintain micron-level precision.

Steel variants like 304/316 stainless steel or 4140 alloy dominate high-strength, high-temperature IR applications. Stainless grades excel in corrosive environments (e.g., medical or marine IR sensors), though 316’s molybdenum content offers superior chloride resistance over 304. Tool steels (e.g., A2, D2) suit wear-prone components but require post-machining heat treatment. Avoid anodizing steel; instead, specify passivation for stainless or electroless nickel plating for enhanced hardness.

Titanium (Grade 5 Ti-6Al-4V) is the premium solution for weight-critical aerospace or defense IR systems. Its near-zero thermal expansion ensures stability under rapid temperature shifts, while unmatched corrosion resistance eliminates coating needs in most scenarios. However, titanium’s low thermal conductivity demands aggressive coolant strategies during CNC milling to prevent work hardening.

Key Material Properties Comparison

| Property | Aluminum 7075-T6 | Stainless Steel 316 | Titanium Grade 5 |

|---|---|---|---|

| Density (g/cm³) | 2.81 | 8.00 | 4.43 |

| Tensile Strength | 572 MPa | 620 MPa | 900 MPa |

| Thermal Conductivity | 130 W/m·K | 16.2 W/m·K | 6.7 W/m·K |

| Corrosion Resistance | Moderate (requires anodizing) | Excellent (passivation recommended) | Exceptional (typically uncoated) |

| Machinability | Excellent | Good | Fair (tool wear high) |

Anodizing remains pivotal for aluminum IR components, but thickness must align with functional requirements. Over-specifying hardcoat can induce microcracks under thermal cycling—our engineers validate coating parameters against your part’s stress profile. For steel, precision grinding post-plating maintains critical tolerances. Titanium rarely needs finishing beyond glass bead blasting for surface uniformity.

Material choice must balance performance, manufacturability, and lifecycle cost. Wuxi Lead integrates metallurgical analysis with CNC process planning to eliminate field failures. Share your IR component’s operational parameters—thermal load, environmental exposure, and tolerance stack-ups—and our engineering team will prescribe a validated material-finish solution. Contact us for a technical consultation to optimize your design for yield and reliability.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for IR (infrared) parts is engineered to deliver precision, consistency, and zero-defect performance. These components, often used in thermal imaging, sensing, and defense applications, demand exceptional material integrity, dimensional accuracy, and surface finish. Our end-to-end workflow integrates advanced design validation, rigorous prototyping, and tightly controlled mass production to ensure every part meets exacting specifications.

The process begins with design engineering, where our technical team collaborates closely with clients to analyze CAD models, material requirements, and functional performance criteria. We assess thermal conductivity, reflectivity, and mechanical stability under operational conditions, selecting from high-purity metals such as oxygen-free copper, aluminum alloys, and specialized stainless steels. Finite element analysis (FEA) and thermal simulation tools are employed to predict behavior under real-world loads and temperatures, enabling preemptive optimization.

Prototyping follows design finalization, serving as both a functional and dimensional validation phase. Using 5-axis CNC machining, wire EDM, and ultra-precision turning, we produce initial units that replicate final production methods. Each prototype undergoes comprehensive metrology inspection using coordinate measuring machines (CMM), optical profilometers, and laser interferometry. Surface roughness, geometric tolerances, and coating adhesion (if applicable) are verified against ISO 1302 and ASME Y14.5 standards. Client feedback is incorporated at this stage, ensuring alignment before scaling to volume manufacturing.

Mass production is executed within our ISO 9001 and IATF 16949 certified facility, leveraging automated CNC cells, in-process gauging, and real-time SPC (statistical process control) monitoring. Each IR part is traceable through serialized lot tracking, with full documentation of machining parameters, inspection data, and material certifications. Our zero-defect philosophy is enforced through multi-stage quality gates: pre-machining material verification, in-process dimensional checks, and 100% post-production inspection for critical features.

All finished parts are cleaned in ultrasonic systems to remove micro-contaminants and packaged in ESD-safe, climate-controlled containers to preserve surface integrity. Final delivery includes a complete quality dossier, dimensional reports, and compliance documentation tailored to aerospace, medical, or industrial OEM requirements.

Below are key specifications supported in our IR parts manufacturing process:

| Parameter | Capability | Tolerance / Finish |

|---|---|---|

| Materials | OFE Copper, 6061-T6 Al, 316L SS, Invar | High purity, certified mill test |

| Machining Accuracy | ±0.002 mm | GD&T compliant |

| Surface Roughness | Ra ≤ 0.2 µm (polished), Ra ≤ 1.6 µm (machined) | Meets MIL-STD-171 |

| Max Part Size | 500 mm × 400 mm × 300 mm | Custom fixturing available |

| Coating Options | Gold plating, NiP, DLC, anti-reflective | Adhesion tested per ASTM C633 |

| Production Volume | 1 – 50,000+ units/year | Scalable with automated cells |

| Quality Standards | ISO 9001, IATF 16949, ISO 14001 | Full traceability and PPAP support |

Through disciplined process control and engineering excellence, Wuxi Lead ensures that every IR component performs reliably in the most demanding environments.

Why Choose Wuxi Lead Precision

Elevate Your Infrared Component Production with Precision Engineering

In the demanding realm of infrared technology manufacturing, component precision directly dictates system performance and reliability. Sub-micron deviations in optical mounts, detector housings, or thermal management assemblies can compromise signal integrity and operational lifespan. Wuxi Lead Precision Machinery exists to eliminate these risks through uncompromising custom metal manufacturing for IR-critical applications. We transform complex engineering specifications into flawless physical components, ensuring your infrared systems meet the highest standards of performance and durability. Our integrated approach bridges design intent with production reality, mitigating supply chain vulnerabilities while accelerating time-to-market for mission-critical hardware.

Wuxi Lead combines advanced multi-axis CNC machining with rigorous metrology protocols to achieve dimensional stability unattainable through conventional methods. Our facility operates under ISO 9001-certified processes, with dedicated cleanroom environments for sensitive IR sub-assemblies. Every part undergoes 100% in-process inspection using calibrated CMMs and optical comparators, guaranteeing compliance with aerospace and defense-grade tolerances. This commitment extends beyond machining—we provide DFM analysis to optimize your designs for manufacturability, reducing costs without sacrificing fidelity. Clients consistently achieve first-pass yield rates exceeding 99.2% on complex geometries, minimizing scrap and rework during high-volume production runs.

Critical specifications for infrared component manufacturing demand exceptional control. The table below outlines our core capabilities for materials commonly used in IR systems:

| Specification | Capability Range | Typical Application Target |

|---|---|---|

| Tolerance | ±0.005 mm to ±0.0002 mm | Optical lens mounts, detector flanges |

| Surface Finish (Ra) | 0.8 μm to 0.05 μm | Sealing surfaces, thermal interfaces |

| Materials | Aluminum 6061-T6, 7075; Stainless 316L, 17-4PH; Invar; Copper C101 | Sensor housings, cryogenic components |

| Max Work Envelope | 1200 x 800 x 650 mm | Large-format thermal imaging assemblies |

| Secondary Operations | Passivation, anodizing (Type II/III), precision welding, laser marking | Corrosion resistance, EMI shielding |

Partnering with Wuxi Lead means accessing engineering expertise that anticipates failure points before production begins. Our technical team collaborates directly with your engineers to resolve thermal expansion mismatches, vibration sensitivities, and material compatibility issues inherent in IR systems. We maintain strategic inventory buffers for critical alloys, ensuring uninterrupted production even during global material shortages. This proactive partnership model has enabled defense contractors and semiconductor equipment manufacturers to reduce component lead times by 35% while exceeding IPC-6012 Class 3 reliability benchmarks.

Do not let manufacturing limitations constrain your infrared innovation. Contact our engineering team today to discuss your specific requirements and receive a tailored production strategy. Email [email protected] with your component drawings or specifications for a confidential review. Our specialists will respond within 12 business hours with actionable insights on optimizing cost, lead time, and performance. Wuxi Lead Precision Machinery stands ready to become your trusted precision manufacturing partner—where exacting standards meet uncompromised delivery. Elevate your IR component production with a single email to [email protected].

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.