Technical Contents

Engineering Guide: Instant Quote Cnc Machining

Engineering Insight: The Critical Role of Precision in Instant Quote CNC Machining

In high-end manufacturing, precision is not merely a performance metric—it is the foundation of reliability, safety, and performance. When engaging with an instant quote CNC machining service, the speed of response must never come at the expense of engineering rigor. At Wuxi Lead Precision Machinery, we understand that every micron matters, especially when components are destined for aerospace, defense, medical, or high-performance industrial applications. Our approach to instant quoting integrates speed with uncompromised precision, ensuring that clients receive not just fast turnaround, but technically sound and manufacturable solutions from the outset.

Precision in CNC machining transcends tight tolerances. It encompasses material behavior under stress, thermal stability, surface integrity, and geometric consistency across production runs. These factors are particularly critical when machining complex geometries or working with exotic alloys such as Inconel, titanium, or high-strength aluminum. Our decades of experience in serving Olympic-grade sports engineering and military defense projects have instilled a culture of zero-defect manufacturing. For instance, components developed for Olympic bobsled chassis or military-grade communication enclosures demand repeatability within ±0.005 mm, where even microscopic deviations can compromise aerodynamic efficiency or electromagnetic shielding.

Our instant quote system is engineered to reflect this standard. Unlike generic platforms that prioritize speed over technical validation, our quoting engine is backed by a team of senior CNC engineers who perform real-time manufacturability analysis. This includes assessing tool access, fixture requirements, residual stress management, and post-processing needs—all before the quote is issued. This proactive engineering review reduces downstream delays, minimizes design iterations, and ensures that the final product meets not only dimensional specifications but functional performance criteria.

Wuxi Lead Precision Machinery operates a fully integrated digital manufacturing environment, where CAD/CAM systems are synchronized with shop-floor CNC machines, including 5-axis milling, precision turning, and wire EDM. This digital thread enables seamless translation from design to production, maintaining data fidelity and process control throughout.

The following table outlines key precision capabilities that underpin our instant quote CNC machining service:

| Specification | Performance Level |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Standard Tolerances | ±0.01 mm (machining), ±0.005 mm (precision grinding) |

| Surface Finish (Ra) | As low as 0.2 µm |

| Maximum Work Envelope | 2000 x 1200 x 800 mm (5-axis) |

| Material Compatibility | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Brass, Plastics |

| Quality Certification | ISO 9001:2015, AS9100 (aerospace compliance in process) |

Precision is not an add-on—it is engineered into every stage of production. With Wuxi Lead Precision Machinery, the instant quote is not just a price; it is a commitment to performance, backed by proven expertise in mission-critical manufacturing.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

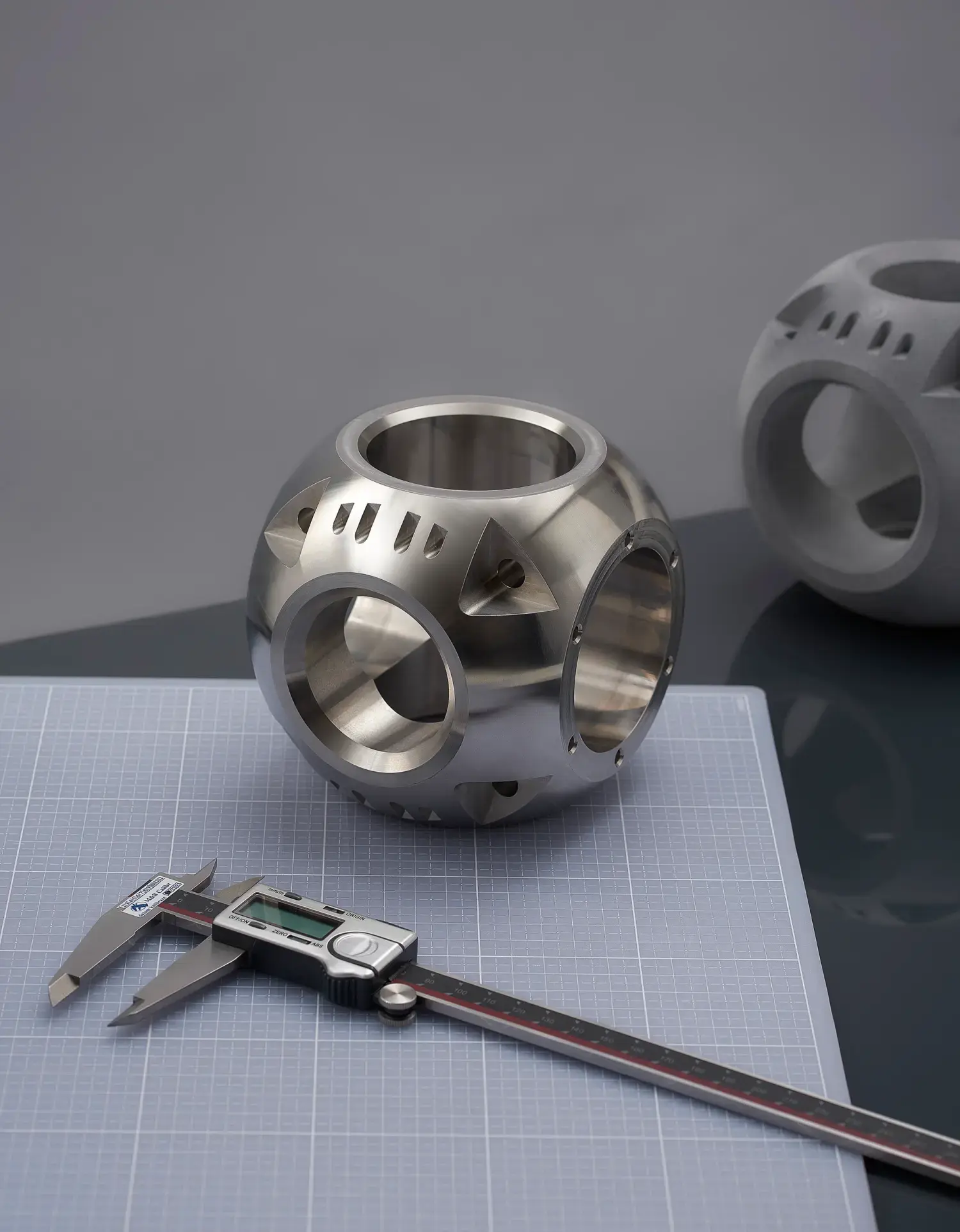

Wuxi Lead Precision Machinery delivers uncompromising precision through advanced multi-axis CNC machining, forming the cornerstone of our instant quote service for high-value components. Our core strength resides in a modern fleet of 5-axis CNC machining centers, enabling the production of geometrically complex parts in a single setup. This capability eliminates cumulative errors inherent in multi-operation workflows, significantly enhancing dimensional accuracy and surface finish while reducing lead times. We routinely machine challenging materials including aerospace-grade aluminum alloys, titanium, stainless steel, Inconel, and specialized engineering plastics to exacting specifications. The integration of high-torque spindles, rigid machine structures, and sophisticated toolpath simulation software ensures optimal metal removal rates without sacrificing the micron-level precision demanded by industries such as aerospace, medical device manufacturing, and semiconductor equipment.

Rigorous quality control is non-negotiable in precision manufacturing. Every critical dimension undergoes verification using state-of-the-art Coordinate Measuring Machines (CMMs) equipped with advanced tactile and optical probes. Our certified metrology lab operates under strict ISO 9001:2015 protocols, providing comprehensive first-article inspection reports (FAIR) and in-process verification. This systematic approach, combined with real-time process monitoring on the shop floor, guarantees consistent adherence to specifications and provides full traceability for every component we produce. Material certifications and detailed inspection documentation are standard deliverables, ensuring complete confidence in part integrity and performance.

The achievable precision for your specific geometry and material is a key factor in our instant quoting system. The following table outlines our standard and advanced tolerance capabilities, reflecting the proven performance of our equipment and processes under controlled conditions:

| Feature Type | Standard Capability | Advanced Capability (Requires Specific Process Control) | Units |

|---|---|---|---|

| Linear Dimensions | ±0.025 | ±0.005 to ±0.010 | mm |

| Geometric Tolerances | ±0.050 | ±0.010 to ±0.025 | mm |

| Hole Diameter | H7 / h7 | H6 / h6 | |

| Surface Roughness | Ra 1.6 | Ra 0.4 to Ra 0.8 | µm |

| Positional Accuracy | ±0.025 | ±0.005 to ±0.010 | mm |

These capabilities are not theoretical benchmarks but represent the consistent, repeatable results achieved daily within our facility. Our engineering team actively reviews all RFQs submitted through the instant quote portal, assessing geometric complexity, material suitability, and required tolerances against this proven performance envelope. This ensures the quotes generated are not only rapid but also technically feasible and reliably achievable, forming a solid foundation for successful, high-precision manufacturing partnerships. Partner with Wuxi Lead for components where dimensional integrity is paramount.

Material & Finish Options

Material selection is a critical step in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-accuracy machining of aluminum, steel, and titanium—three of the most widely used engineering metals across aerospace, automotive, medical, and industrial sectors. Each material offers distinct mechanical properties and is selected based on application requirements such as strength, weight, corrosion resistance, and thermal stability.

Aluminum is favored for its excellent strength-to-weight ratio, machinability, and thermal conductivity. It is particularly suitable for lightweight structural components, heat sinks, and enclosures. The most commonly used grade is 6061-T6, which provides good weldability and moderate strength. For more demanding applications, 7075-T6 offers higher tensile strength, making it ideal for aerospace fittings and high-stress components. Aluminum is also highly compatible with anodizing, a surface treatment that enhances wear and corrosion resistance while allowing for color coding.

Steel, particularly stainless steel grades such as 303, 304, and 17-4 PH, is selected when superior strength, hardness, and corrosion resistance are required. 304 stainless steel is widely used in medical and food processing equipment due to its excellent resistance to oxidation and ease of sterilization. 17-4 PH, a precipitation-hardening stainless steel, delivers exceptional strength and is often used in aerospace and high-performance mechanical systems. Carbon steels like 1018 and 4140 are also machined for applications requiring high toughness and wear resistance, such as shafts and gears.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice in extreme environments where high strength, low density, and outstanding corrosion resistance are essential. Its biocompatibility makes it ideal for medical implants, while its performance at elevated temperatures suits it for aerospace and defense applications. Although more challenging to machine due to its low thermal conductivity and tendency to gall, titanium delivers unmatched performance in critical-load scenarios.

Surface finishing plays a vital role in the functionality and longevity of machined parts. Anodizing, particularly Type II (sulfuric acid) and Type III (hardcoat), is a standard finish for aluminum components. It creates a controlled oxide layer that improves surface hardness, wear resistance, and electrical insulation. Type III anodizing, also known as hard anodizing, produces thicker coatings suitable for high-wear environments.

Below is a comparative overview of key material properties and finishing options:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Compatible Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Aerospace, heat sinks, enclosures | Anodizing (Type II/III), bead blast |

| Stainless Steel | 304, 316, 17-4 PH | 505–1310 | 7.9 | Medical, food processing, automotive | Passivation, electropolishing |

| Titanium | Ti-6Al-4V (Gr5) | 900–1000 | 4.5 | Aerospace, medical implants | Anodizing, polishing |

Selecting the right material and finish ensures optimal performance and cost-effectiveness in your CNC-machined components. At Wuxi Lead Precision Machinery, our engineering team supports clients in making informed material decisions based on functional requirements, environmental exposure, and production volume.

Manufacturing Process & QC

Our Production Process: Precision Engineered from Concept to Volume

At Wuxi Lead Precision Machinery, we transform complex designs into flawless, high-volume components through a rigorously controlled, three-stage production process. This integrated methodology, honed over years serving demanding aerospace, medical, and industrial clients, is the cornerstone of our Zero Defects commitment. We eliminate costly iterations and delays by embedding quality assurance at every phase, ensuring your final parts meet exacting specifications without compromise.

The journey begins with meticulous Design Validation and Process Planning. Our engineering team collaborates closely with your CAD data, conducting comprehensive manufacturability analysis (DFM). We identify potential geometric challenges, material constraints, and fixture requirements before metal cutting commences. This proactive review optimizes toolpaths, selects the ideal CNC platform (5-axis milling, turning, or mill-turn), and establishes critical process parameters. Crucially, this stage defines the inspection plan, integrating CMM, optical comparators, and in-process gauging points to verify tolerances continuously. This upfront rigor prevents downstream errors and forms the blueprint for consistent output.

Prototyping is not merely a sample phase; it is the critical validation step for Zero Defects. We produce initial units using the exact materials, tooling, and controlled processes intended for full production. This allows us to physically verify form, fit, function, and, most importantly, dimensional accuracy against your specifications. The data gathered here is non-negotiable – it confirms the process capability and refines the inspection protocol. Below are the typical precision standards we achieve and validate during prototyping for critical features:

| Feature Type | Standard Tolerance | Capable Tolerance (Verified) | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM, High-Precision Mic |

| Geometric Form | 0.015 mm | 0.008 mm | CMM, Optical Comparator |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm | Profilometer |

| Hole Position | ±0.015 mm | ±0.008 mm | CMM, Precision Pin Gages |

Only upon successful prototype sign-off, confirming the process is statistically capable and inspection methods are validated, do we initiate Mass Production. Here, our Zero Defects system operates at full strength. Production runs leverage automated material handling, real-time tool wear monitoring, and continuous SPC (Statistical Process Control) on critical dimensions. Every shift commences with first-article inspection against the approved prototype. In-process checks occur at predefined intervals, and 100% of critical features on the final batch undergo verification. Our proprietary 7-Point Verification System cross-references machining data, inspection results, and material certifications, ensuring absolute traceability and eliminating escape risk.

This seamless transition from validated design through rigorously proven prototyping into tightly controlled volume manufacturing is how Wuxi Lead guarantees Zero Defects. We don’t just produce parts; we deliver certified precision, batch after batch, safeguarding your uptime, reputation, and bottom line. Your complex requirements demand nothing less than a process engineered for perfection from the first cut to the final shipment.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and long-term value. As a global leader in high-end CNC machining, we specialize in transforming complex engineering designs into flawless, production-ready components. Our commitment to excellence is built on advanced technology, rigorous quality control, and a deep understanding of the demands faced by industries such as aerospace, medical devices, automation, and high-performance manufacturing.

When you partner with Lead Precision, you gain more than a supplier—you gain a strategic manufacturing ally. Our instant quote CNC machining service is engineered for speed and accuracy, allowing engineers and procurement teams to receive detailed, transparent pricing within hours, not days. This rapid turnaround accelerates your development cycles, reduces time-to-market, and supports agile decision-making across your supply chain.

Our facility in Wuxi, China, is equipped with a comprehensive range of CNC capabilities, including 3-axis, 4-axis, and 5-axis milling, precision turning, and multi-axis Swiss machining. We work with a wide array of materials—from aerospace-grade aluminum and titanium to medical-grade stainless steel and high-performance engineering plastics—ensuring your components meet exacting mechanical and regulatory standards.

What sets us apart is our integrated approach to quality and communication. Every project undergoes strict in-process inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers. Our team of certified engineers collaborates directly with clients throughout the production cycle, offering DFM feedback, real-time updates, and full traceability documentation.

We understand that precision machining is not just about tolerances and materials—it’s about trust, consistency, and partnership. That’s why we’ve built our operations around international standards, including ISO 9001:2015 certification, ensuring every component we produce meets the highest benchmarks for performance and reliability.

For engineering teams demanding accuracy, scalability, and responsive service, Lead Precision is the partner you can rely on. Whether you’re prototyping a new medical device or scaling up production of critical aerospace components, our instant quote system and expert team are ready to support your success.

Contact us today to experience the difference precision engineering makes. Send your drawings and requirements to [email protected] and receive a detailed quote within hours. Let’s build the future of manufacturing—together.

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis milling, CNC turning, Swiss machining |

| Tolerances | As tight as ±0.002 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, PEEK, Delrin, and more |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), 500 x 400 x 400 mm (high-precision) |

| Lead Times | As fast as 5–7 days for standard prototypes |

| Quality Standards | ISO 9001:2015 certified, full inspection reporting, First Article Inspection (FAI) available |

| File Formats Accepted | STEP, IGES, DWG, DXF, PDF, SolidWorks, AutoCAD |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.