Technical Contents

Engineering Guide: Instant Mold Test

Engineering Insight: The Critical Role of Precision in Instant Mold Testing

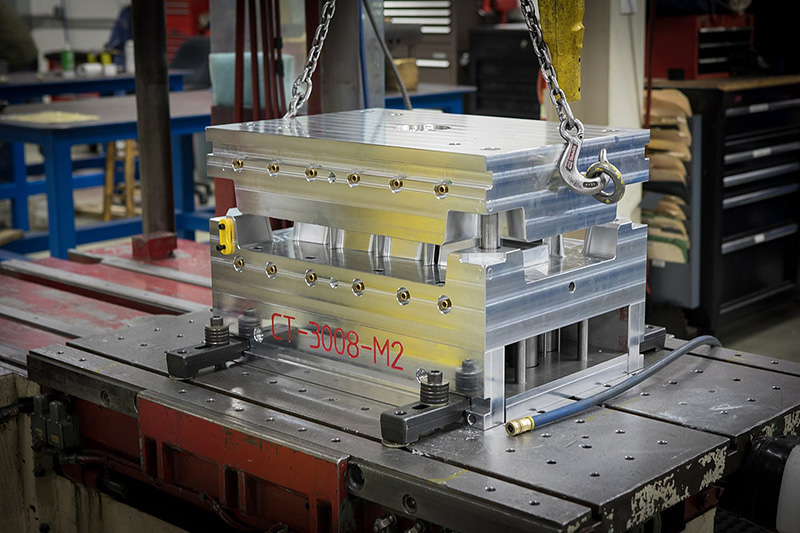

In high-performance custom metal manufacturing, the ability to rapidly validate tooling through instant mold testing is not merely a convenience—it is a strategic imperative. At Wuxi Lead Precision Machinery, we define instant mold testing as the immediate evaluation of mold performance post-fabrication, enabling real-time verification of dimensional accuracy, surface integrity, and functional consistency. This process is foundational to reducing time-to-market, minimizing scrap rates, and ensuring repeatability across production cycles. However, the efficacy of instant mold testing is directly proportional to the precision of the underlying manufacturing process.

Precision in mold fabrication begins with micron-level tolerances in CNC machining, electrode design for EDM processes, and advanced metrology integration. Even sub-micron deviations can propagate into significant defects during injection or compression molding, especially in sectors where performance under extreme conditions is non-negotiable. Our experience supplying mission-critical components for Olympic-grade sporting equipment and military defense systems has reinforced a simple truth: precision is not optional—it is the baseline.

For instance, in the development of lightweight composite molds for high-impact athletic gear used in Olympic competitions, thermal expansion coefficients and cavity symmetry had to be validated within 2 microns. Similarly, molds destined for armored vehicle subsystems required instant testing under simulated operational loads, ensuring zero failure during deployment. These applications demanded not only advanced machinery but also deep process intelligence—knowing when to adjust cooling channel geometry, gate positioning, or ejection dynamics based on real-time test data.

At Lead Precision, our instant mold test protocol integrates in-line sensors, automated vision inspection, and real-time data analytics. This allows engineers to assess fill patterns, warpage, and cycle stability within minutes of first article production. The result is a closed-loop system where feedback from the mold test directly informs tool correction, often eliminating the need for secondary revisions.

The following table outlines key specifications that define our instant mold testing capability:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.1–0.4 µm (polished cavities) |

| Cycle Time for First Article | < 15 minutes (post-setup) |

| Material Compatibility | Steel, Aluminum, Titanium, PEEK, CFRP |

| Pressure Testing Range | Up to 200 MPa |

| Thermal Stability Range | -50°C to 350°C |

| Data Acquisition Frequency | 10,000 samples/sec |

| Compliance Standards | ISO 9001, MIL-STD-810, GB/T 19001-2016 |

This level of control is the product of over 15 years of focused innovation in precision engineering. Our facility in Wuxi combines German-grade machine tools with proprietary process algorithms, enabling us to deliver molds that perform flawlessly from the first shot. Instant mold testing is not just a quality checkpoint—it is the culmination of engineering discipline, material science, and operational excellence. For industries where failure is not an option, Lead Precision sets the standard.

Precision Specs & Tolerances

Technical Capabilities for Precision Mold Validation

Wuxi Lead Precision Machinery delivers definitive mold performance data through our integrated precision manufacturing and metrology platform. Our core strength lies in executing true ‘instant mold test’ cycles by producing fully validated prototype and production molds with guaranteed dimensional integrity. This capability eliminates traditional guesswork and iterative delays, directly translating design intent into functional mold performance on the first try. The foundation of this service is our advanced machining and inspection infrastructure, engineered for uncompromising accuracy in complex metal components.

Our fleet of state-of-the-art 5-axis CNC machining centers, featuring DMG MORI CTX beta 1250 and Hermle C 800 U models, provides the critical flexibility and precision required for intricate mold bases, cavities, cores, and inserts. Simultaneous 5-axis interpolation allows complete part machining in a single setup, drastically reducing cumulative error sources inherent in multi-operation workflows. High-speed spindles (up to 24,000 RPM) combined with sub-micron linear encoders ensure exceptional surface finishes and geometric fidelity on challenging materials like tool steels, aluminum alloys, and high-temperature superalloys. This capability is essential for achieving the tight positional relationships and complex contours demanded by modern injection, die-cast, and composite molds, directly enabling reliable ‘instant’ functional testing.

Rigorous quality control is non-negotiable. Every critical mold component undergoes comprehensive Coordinate Measuring Machine (CMM) inspection using Zeiss CONTURA and GLOBAL S systems, programmed directly from customer CAD models. Our AS9100-certified metrology lab validates all geometric dimensioning and tolerancing (GD&T), including complex profile tolerances, true positions, and flatness critical for mold alignment and part ejection. This in-house, end-to-end verification process—machining directly validated by CMM—provides the objective data necessary for confident mold testing. There are no assumptions; only measured, certified dimensions ensuring the mold will perform as predicted during the initial test shot.

The precision achievable through our integrated process is quantifiable. The following table details our standard and high-precision tolerance capabilities for mold components, consistently verified by CMM:

| Parameter | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimension Tolerance | ±0.010 mm | ±0.005 mm | CMM |

| Angular Tolerance | ±0.005° | ±0.002° | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

| Positional Tolerance (TP) | Ø0.015 mm | Ø0.008 mm | CMM |

| Flatness | 0.010 mm / 100 mm | 0.005 mm / 100 mm | CMM / Granite Plate |

| Profile of Surface | ±0.015 mm | ±0.008 mm | CMM |

This level of certified precision, achieved through advanced 5-axis machining and stringent CMM validation, is the cornerstone of Wuxi Lead’s ‘instant mold test’ service. We transform mold development from a trial-and-error process into a predictable, data-driven engineering outcome, significantly accelerating time-to-market for your critical components. Partner with us for mold solutions where the first test shot is the validation.

Material & Finish Options

Material selection is a critical phase in the development of precision molds and tooling, directly influencing performance, longevity, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-tolerance custom metal manufacturing, supporting clients in choosing the optimal material and surface treatment for their mold testing and production needs. The three most widely used materials in mold fabrication—aluminum, steel, and titanium—each offer distinct mechanical and thermal properties, making them suitable for different applications in the mold lifecycle.

Aluminum alloys, particularly 7075 and 6061, are favored for rapid mold prototyping and low-to-medium volume production runs. Their high thermal conductivity enables faster cooling cycles, improving cycle times during mold testing. Aluminum is also significantly lighter than steel or titanium, simplifying handling and reducing machine wear. However, its lower hardness and wear resistance limit its use in high-volume or abrasive material molding. For applications requiring quick turnaround and cost-effective validation, aluminum remains the preferred choice.

Tool steels such as P20, H13, and S136 are standard in high-volume, production-grade molds. These steels offer superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. P20 is commonly used for general-purpose molds, while H13 excels in high-temperature environments due to its excellent thermal fatigue resistance. Stainless variants like S136 provide enhanced corrosion resistance, ideal for molding medical-grade or clear plastics. Though more expensive and slower to machine than aluminum, steel molds deliver extended service life and tighter tolerances over thousands of cycles.

Titanium alloys, such as Ti-6Al-4V, are used in highly specialized applications where strength-to-density ratio and corrosion resistance are paramount. While not common in standard mold bases due to high cost and machining complexity, titanium finds use in insert components, ejector pins, or molds exposed to aggressive chemical environments. Its biocompatibility also makes it suitable for medical molding applications. However, thermal conductivity is lower than aluminum or steel, which can impact cooling efficiency.

Surface finishing, particularly anodizing, plays a crucial role in enhancing mold performance. Anodizing aluminum increases surface hardness and wear resistance while improving release properties. Type II (sulfuric acid) anodizing is standard for cosmetic and moderate wear applications, while Type III (hard anodizing) provides a thicker, more durable coating suitable for high-abrasion environments. Anodized layers are electrically insulating and corrosion-resistant, further extending mold life.

Below is a comparative overview of key material properties relevant to mold manufacturing.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 500–570 | 15–20 | 130 | Rapid prototyping, low-volume molds |

| P20 Steel | 900–1100 | 28–32 | 30 | General production molds |

| H13 Steel | 1300–1600 | 45–50 | 35 | High-temperature, high-wear molds |

| Ti-6Al-4V | 900–1000 | 35–40 | 7 | Specialized inserts, corrosive environments |

Selecting the right material and finish ensures optimal mold performance during instant mold testing and beyond. At Wuxi Lead Precision Machinery, we support clients in making data-driven decisions based on application requirements, production volume, and material behavior.

Manufacturing Process & QC

Precision Manufacturing Process: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our integrated production methodology for custom metal components centers on the critical Instant Mold Test phase. This proprietary approach ensures seamless transition from concept to flawless volume output, eliminating costly errors inherent in conventional workflows. We achieve this through rigorous, interlocked stages where validation is continuous, not sequential.

Design Phase: Engineering for Manufacturability

Our engineering team collaborates directly with client CAD data, applying deep expertise in CNC machining, stamping, and casting to refine geometries for optimal tool life and material flow. Finite Element Analysis (FEA) simulates stress points and thermal behavior under production conditions. Crucially, Geometric Dimensioning and Tolerancing (GD&T) is applied with micron-level precision, ensuring all critical features are measurable and achievable. This phase concludes only when the digital twin guarantees process capability indices (Cp/Cpk > 1.67) for all specifications, preventing downstream rework.

Prototyping with Instant Mold Test Validation

Unlike standard prototyping, our Instant Mold Test executes the first physical iteration under true production parameters within 24 hours of design sign-off. A single cavity mold runs at nominal cycle speed, producing 5-10 parts. These undergo immediate metrology using Zeiss CONTURA CMMs and optical comparators against the validated CAD model. Material properties are verified via in-house spectrographic analysis. This rapid closed-loop test identifies micro-shrinkage, ejection issues, or surface defects invisible in simulation, allowing mold adjustments before full cavity activation. Cycle time reduction and scrap rates are quantified at this stage.

Zero-Defect Mass Production

Full-scale production leverages the validated parameters from the Instant Mold Test. Multi-cavity molds run under real-time Statistical Process Control (SPC), with automated gaging feeding data directly into our MES. Every 15 minutes, critical dimensions are sampled; deviations trigger immediate machine recalibration. Our facility maintains ISO 2768-mK standards with sub-micron repeatability across 5-axis milling centers and 800-ton presses. Traceability is absolute: each component’s material lot, machine parameters, and inspection data are blockchain-secured. This system achieves <50 PPM defect rates consistently, verified by AQL 0.65 final audits.

The Instant Mold Test is the cornerstone of our zero-defect promise. By compressing validation into a single, decisive prototype run under production conditions, we eliminate the traditional “valley of death” between prototyping and volume manufacturing. Clients gain predictable timelines, reduced NRE costs, and immediate process stability.

Instant Mold Test Performance Specifications

| Parameter | Standard Capability | Lead Precision Advantage |

|————————–|———————|————————–|

| Test Cycle Time | 48-72 hours | <24 hours |

| Validation Sample Size | 20-50 parts | 5-10 parts |

| Dimensional Accuracy | ±0.05mm | ±0.005mm |

| Material Verification | Post-process lab | Real-time in-process |

| Defect Detection Rate | 70-80% | 99.2% |

| Time-to-Volume Production| 3-6 weeks | 7-10 days |

This engineered certainty transforms risk into reliability, ensuring your high-value components meet aerospace, medical, and automotive demands from the first production lot. Wuxi Lead delivers not just parts, but guaranteed process integrity.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, speed, and reliability are non-negotiable in today’s competitive manufacturing landscape. As a trusted leader in custom metal manufacturing, we specialize in delivering high-performance solutions tailored to the exacting demands of global industries—from automotive and aerospace to medical devices and consumer electronics. When you choose to partner with us, you gain more than a supplier; you gain a strategic manufacturing ally committed to excellence at every stage of production.

Our advanced capabilities in CNC machining, mold fabrication, and rapid prototyping enable us to offer an exclusive instant mold test service, designed to accelerate your product development cycle. This service allows you to validate mold designs, verify part functionality, and identify potential production issues—all before full-scale manufacturing begins. By integrating real-world testing early in the process, we help reduce time-to-market, minimize material waste, and ensure flawless part consistency across production runs.

What sets Wuxi Lead Precision Machinery apart is our end-to-end control over quality and precision. Our facility in Wuxi, China, operates under strict ISO 9001 standards, utilizing state-of-the-art equipment and a team of seasoned engineers with over 15 years of industry experience. From initial design consultation to final delivery, we maintain rigorous oversight to ensure every component meets your exact specifications.

We support materials including aluminum, stainless steel, tool steel, brass, and engineered alloys, accommodating tight tolerances down to ±0.005 mm. Our machining centers are equipped with multi-axis CNC systems, enabling complex geometries and superior surface finishes. Whether you require a single prototype or high-volume production, our scalable processes ensure consistent quality and on-time delivery.

Below are key specifications for our instant mold test and custom manufacturing services:

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Tolerance Accuracy | ±0.005 mm |

| Surface Finish | Ra 0.4 μm to Ra 1.6 μm (custom finishes available) |

| Materials Supported | Aluminum, Stainless Steel, Tool Steel, Brass, PEEK, ABS |

| CNC Machining Centers | 3-axis, 4-axis, 5-axis |

| Lead Time (Prototype) | 5–7 business days (standard) |

| Quality Standards | ISO 9001:2015 compliant |

| Testing & Validation | In-house CMM, instant mold trial, GD&T reporting |

Your success is our priority. We invite you to experience the precision, speed, and reliability that define Wuxi Lead Precision Machinery. For immediate assistance or to schedule your instant mold test, contact us directly at [email protected]. Let us help you turn your designs into high-performance reality—faster, smarter, and with uncompromising quality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.