Technical Contents

Engineering Guide: Inspection Of Machined Parts

Engineering Insight Precision Inspection as the Final Quality Gate

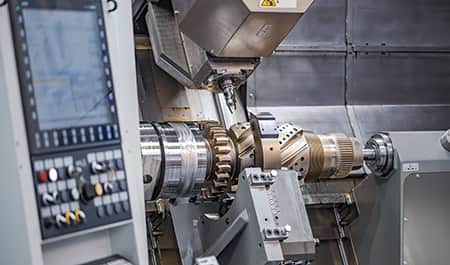

In precision CNC machining, the manufacturing process concludes not with the last toolpath, but with rigorous final inspection. This critical phase transcends basic dimensional verification; it is the definitive validation that a component meets the exacting functional, safety, and performance criteria demanded by advanced industries. Precision is not merely a target specification—it is the non-negotiable foundation for reliability, especially in sectors where failure carries severe consequences. Skipping or compromising inspection risks field failures, costly recalls, and irreparable damage to reputation. At Wuxi Lead Precision Machinery, we treat inspection as an integral engineering discipline, not a perfunctory checkpoint. Our process begins with understanding the part’s ultimate application, ensuring measurement strategies align with real-world functional requirements rather than just nominal drawings.

Our inspection protocol leverages metrology-grade equipment operated by ASQ-certified technicians. We employ multi-sensor coordinate measuring machines (CMMs) capable of sub-micron resolution, complemented by optical comparators, surface roughness testers, and advanced vision systems. Crucially, inspection planning is synchronized with the initial CNC programming phase. This concurrent engineering approach identifies critical-to-quality (CTQ) features early, defining optimal datum structures, measurement sequences, and required uncertainties. Statistical process control (SPC) data from machining feeds directly into our inspection sampling plans, enabling proactive correction before non-conformances occur. This integrated methodology ensures every report provides actionable engineering insight, not just pass/fail data.

The following table outlines core inspection capabilities underpinning our zero-defect commitment for mission-critical components:

| Measurement Parameter | Capability Range | Typical Uncertainty | Primary Equipment Used |

|---|---|---|---|

| Dimensional Accuracy | 0.0001 mm (4µin) to 1000 mm | ±1.5 µm + L/250 | Zeiss CONTURA CMM |

| Geometric Tolerances (GD&T) | All ISO 1101 symbols | ±2.0 µm | Hexagon GLOBAL S CMM |

| Surface Roughness (Ra) | 0.01 µm to 12.5 µm | ±5% of reading | Mitutoyo SJ-410 Profilometer |

| Form Deviation (Flatness) | < 0.5 µm over 100 mm | ±0.3 µm | Zygo NewView 9000 Interferometer |

This technical rigor is proven in practice. Our inspection systems have validated components for Olympic Games infrastructure requiring absolute thermal stability under dynamic loads and military subsystems where tolerances below 5µm directly impact operational safety. These projects demanded inspection protocols exceeding standard AS9100 or ISO 2768, incorporating environmental simulation and multi-axis functional testing. The experience underscores a fundamental truth: precision machining without equally precise, intelligent inspection delivers only expensive raw material. At Lead Precision, we engineer confidence into every component through verification that matches the ambition of the design. Trust your critical parts to a process where measurement science is as advanced as the machining itself.

Precision Specs & Tolerances

Precision Inspection of Machined Parts at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we integrate advanced metrology with high-performance 5 Axis CNC machining to deliver components that meet the most stringent quality standards demanded by aerospace, medical, automotive, and industrial equipment sectors. Our technical capabilities in inspection are designed to ensure every machined part conforms precisely to engineering specifications, with full traceability and documented validation.

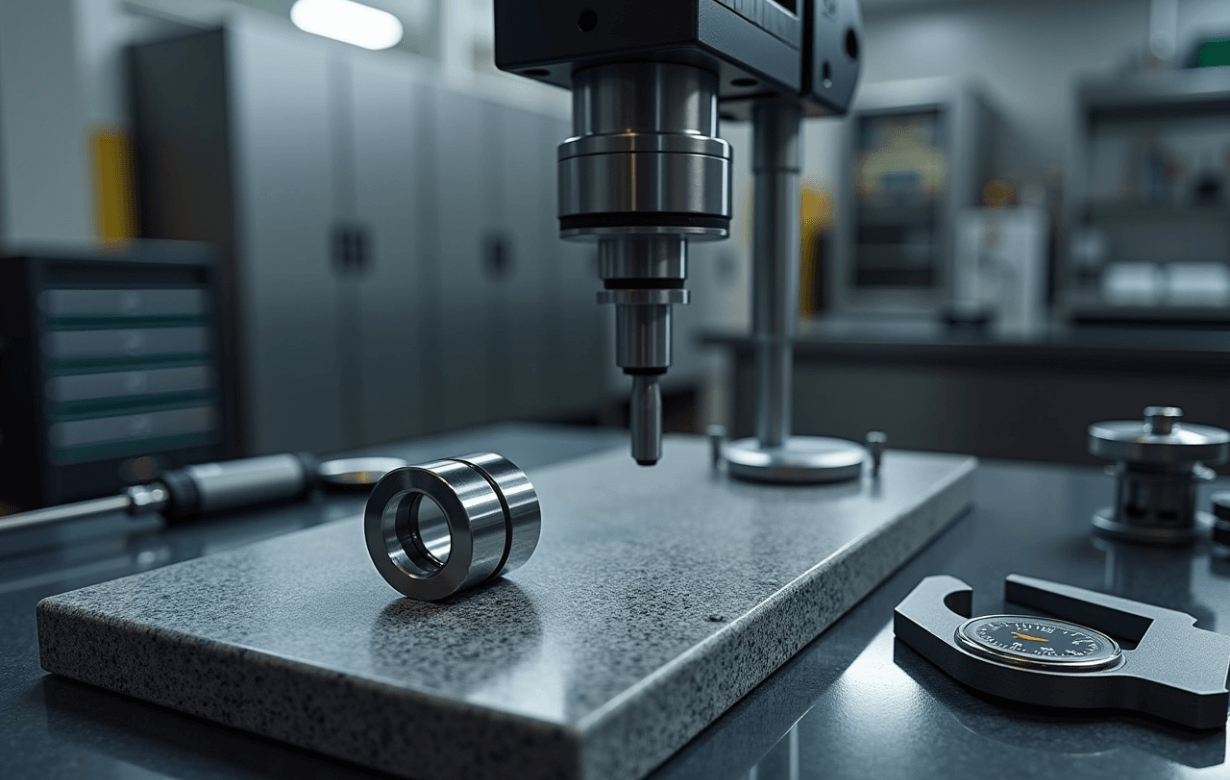

Our quality control process begins with in-process inspection protocols and culminates in final verification using state-of-the-art Coordinate Measuring Machines (CMM). These machines provide three-dimensional measurement accuracy down to micrometer levels, enabling comprehensive analysis of geometric dimensions, form tolerances, and positional relationships. Equipped with high-resolution tactile probes and advanced software such as PC-DMIS, our CMM systems generate detailed inspection reports that include deviation maps, GD&T analysis, and first-article inspection documentation compliant with ISO 9001 and IATF 16949 standards.

All inspection operations are performed in a climate-controlled metrology lab to eliminate thermal distortion, ensuring measurement repeatability and long-term data integrity. Our quality engineers are certified in geometric dimensioning and tolerancing (GD&T) and work closely with design and manufacturing teams to interpret complex blueprints and validate critical features such as runout, flatness, concentricity, and profile tolerances.

In addition to CMM-based inspection, we employ auxiliary metrology tools including optical comparators, surface roughness testers, and calibrated handheld instruments for rapid verification during production runs. This multi-tiered inspection strategy allows us to detect and correct deviations in real time, minimizing scrap and ensuring consistent part-to-part uniformity.

Our 5 Axis CNC machining centers are equipped with on-machine probing systems that enable pre-machining stock validation and post-machining in situ checks. This capability reduces setup time, improves first-run success rates, and ensures tight alignment between design intent and physical output. By combining continuous process monitoring with end-of-line CMM validation, we achieve a closed-loop quality system that supports both high-mix prototyping and high-volume production.

Wuxi Lead Precision Machinery adheres to strict tolerance standards across a wide range of materials, including aluminum, stainless steel, titanium, and engineering plastics. The table below outlines our typical achievable tolerances under controlled conditions.

| Feature Type | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | Up to 300 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed or honed |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | Relative to datum |

| Flatness | 0.05 mm | 0.01 mm | Over 100 mm span |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Machined finish |

| Angular Tolerance | ±0.1° | ±0.05° | Critical interfaces |

All inspection data is archived digitally and available to clients upon request, supporting full production traceability and audit readiness. At Wuxi Lead, precision is not just achieved—it is verified, documented, and guaranteed.

Material & Finish Options

Material Selection for Precision Machined Part Inspection

Material choice fundamentally impacts inspection methodology and accuracy in precision CNC machining. At Wuxi Lead Precision Machinery, we emphasize that understanding the thermal, mechanical, and surface properties of Aluminum, Steel, and Titanium is critical for reliable metrology. Incorrect assumptions during measurement can lead to false rejects or acceptance of out-of-spec parts, causing significant downstream costs. Material behavior under probe force, thermal drift, and surface finish directly influences CMM, optical comparator, and manual gauge results. Selecting the optimal material isn’t just about part function; it dictates the inspection protocol’s rigor and equipment calibration requirements.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are prevalent due to machinability and strength-to-weight ratio. However, their high thermal expansion coefficient (23.6 µm/m·°C) demands strict thermal stabilization before precision measurement. Aluminum’s relative softness also necessitates careful probe force calibration on CMMs to avoid surface deformation, especially on thin features. Steel variants like 4140 and 17-4 PH offer superior hardness and dimensional stability but introduce challenges with magnetic properties potentially affecting certain probes and higher density requiring robust fixturing. Titanium alloys (e.g., Ti-6Al-4V) present the most complex inspection scenario. Their low thermal conductivity causes significant localized heating during machining, leading to delayed thermal stabilization. Extreme hardness requires diamond-tipped probes, and the material’s propensity for galling can compromise surface finish readings critical for sealing surfaces.

Anodizing, a common finish for Aluminum parts, adds a critical layer to the inspection process. The conversion coating thickness directly consumes dimensional tolerance. For example, a Type II (sulfuric acid) anodize layer of 15-25 µm per side reduces critical diameters and increases hole sizes proportionally. Verifying final dimensions must occur post-anodizing, as the process slightly alters underlying geometry. Coating thickness uniformity itself requires verification using eddy current or XRF gauges per ASTM B244 standards. Neglecting to account for anodize thickness in the inspection plan is a frequent source of assembly failures.

The following table summarizes key material properties affecting inspection parameters:

| Material | Density (g/cm³) | Thermal Expansion Coefficient (µm/m·°C) | Typical Hardness (HB) | Critical Inspection Consideration |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 23.6 | 95 | Thermal stabilization time; probe force sensitivity |

| Steel 4140 | 7.85 | 11.3 | 217 | Magnetic interference; fixture stability requirements |

| Titanium Ti-6Al-4V | 4.43 | 8.6 | 360 | Extended thermal soak time; diamond probe necessity |

Wuxi Lead Precision Machinery integrates material science expertise into our inspection planning from the quotation stage. We establish tailored measurement protocols, including mandatory thermal soak times, probe calibration specific to material hardness, and explicit anodize thickness allowances in our dimensional reports. This proactive approach ensures measurement integrity, prevents costly disputes, and guarantees parts perform as designed in your final assembly. Understanding these material-inspection interactions is non-negotiable for true precision manufacturing.

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept

At Wuxi Lead Precision Machinery, the foundation of zero-defect production begins in the design phase. Our engineering team collaborates closely with clients to translate conceptual requirements into manufacturable, high-tolerance designs. Utilizing advanced CAD/CAM software such as Siemens NX and SolidWorks, we conduct comprehensive design for manufacturability (DFM) analysis to identify potential risks related to geometry, material selection, and feature complexity. This proactive approach ensures dimensional stability, minimizes stress concentrations, and optimizes tool paths before any material is cut. All designs undergo internal peer review and are validated against international standards including ISO 2768 and ASME Y14.5 for geometric dimensioning and tolerancing (GD&T). This stage is critical to prevent downstream deviations and to establish a clear inspection baseline.

Prototyping: Validation Through Precision Machining

Once the design is finalized, we proceed to prototype manufacturing using our state-of-the-art CNC machining centers. Prototypes are produced under the same environmental and procedural conditions as mass production to ensure accurate process simulation. Each prototype undergoes a full first-article inspection (FAI), where every critical dimension is verified using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. This inspection report is documented and shared with the client for approval. Any discrepancies trigger immediate root cause analysis and process refinement. The prototyping stage is not merely a trial run—it is a validation loop that confirms tooling, fixturing, and inspection protocols meet the zero-defect standard. Only after achieving full dimensional compliance and functional performance do we authorize transition to mass production.

Mass Production: Sustained Accuracy and Full Traceability

In mass production, Wuxi Lead implements a closed-loop quality control system. Every batch is subject to in-process inspections at predefined intervals, with real-time data fed back to CNC machines for adaptive correction. We employ statistical process control (SPC) to monitor trends and maintain process capability indices (Cp/Cpk) above 1.67. Final inspection includes 100% verification of critical features and random sampling for non-critical dimensions per ANSI/ASQ Z1.4 standards. All inspection data is stored digitally with full part traceability, including machine ID, operator, tooling used, and environmental conditions.

The following table outlines our standard inspection capabilities:

| Parameter | Equipment Used | Accuracy / Resolution | Standard Compliance |

|---|---|---|---|

| Dimensional Tolerance | CMM (ZEISS PRISMO) | ±0.001 mm | ISO 2768, ASME Y14.5 |

| Surface Roughness | Mitutoyo Surftest SJ-410 | 0.01 μm Ra | ISO 1302 |

| Geometric Tolerances | Optical Comparator, CMM | ±0.002 mm | ISO 1101 |

| Thread & Pitch Diameter | Thread Gauges, CMM | Class 6G/6h Precision | ISO 965 |

| Visual & Surface Defects | Digital Microscope (400x) | Sub-micron detection | ASTM E3 |

Through integrated design validation, rigorous prototyping, and disciplined mass production controls, Wuxi Lead Precision Machinery ensures every machined component meets the highest standards of quality and reliability.

Why Choose Wuxi Lead Precision

Elevate Your Quality Assurance with Lead Precision’s Inspection Expertise

In high-stakes manufacturing, dimensional accuracy isn’t optional—it’s the foundation of reliability, safety, and compliance. Sub-micron deviations can trigger catastrophic field failures, costly recalls, or rejected shipments. At Wuxi Lead Precision Machinery, we engineer inspection protocols that eliminate guesswork, ensuring every machined component meets or exceeds your most stringent tolerances. Our ISO 9001-certified facility integrates metrology-grade technology with decades of CNC mastery, transforming inspection from a checkpoint into a strategic advantage.

We deploy advanced systems calibrated to NIST standards, operating beyond typical industry capabilities. Our Zeiss CONTURA CMMs resolve features to ±1.5 + L/300 µm, while non-contact optical comparators capture complex geometries at 5-micron resolution. Surface roughness, thread integrity, and form deviations undergo rigorous validation against ASME Y14.5 and ISO 1101 benchmarks. This isn’t generic quality control; it’s precision forensic analysis tailored to aerospace, medical, and semiconductor applications where failure is not an option.

Critical inspection capabilities include:

| Equipment Type | Accuracy Range | Key Applications |

|---|---|---|

| 5-Axis CMM (Zeiss) | ±1.5 + L/300 µm | Complex contours, GD&T validation |

| Optical Comparator | 5 µm resolution | Thread profiles, micro-features |

| Surface Roughness Tester | Ra 0.01 µm | Sealing surfaces, bearing interfaces |

| Vision System (Keyence) | 2 µm pixel accuracy | Tiny holes, edge burrs, 2D geometry |

| Roundness Tester | 0.1 µm repeatability | Precision shafts, hydraulic components |

Partnering with Lead Precision means embedding quality into your supply chain from prototype to production. Our engineers collaborate pre-machining to optimize part design for inspectability—reducing scrap rates by up to 30% and accelerating time-to-shipment. Real-time SPC data flows directly to your team via secure dashboards, providing full traceability without slowing throughput. When your OEM client demands a full FAI report or PPAP documentation, we deliver certified results within 24 hours, not weeks.

The cost of inadequate inspection extends far beyond rework—it erodes brand trust and market position. Chinese manufacturing partners often face skepticism, but Lead Precision shatters that narrative with transparency and technical rigor. We invite you to verify our capabilities through a no-obligation first-part inspection. Submit your drawing, and our metrology team will return a comprehensive deviation report with actionable insights—proving value before you place a single order.

Your next critical component deserves uncompromising validation. Contact us today to schedule your inspection audit and experience precision engineering without borders. Email [email protected] with “Inspection Audit Request” in the subject line. We respond within 4 business hours with a dedicated project engineer and timeline. Trust Lead Precision to be the final gatekeeper of your quality promise—where every micron matters.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.