Technical Contents

Engineering Guide: Inspection Of Machined Parts

Engineering Insight: Precision Inspection Protocols for Mission-Critical Components

In mission-critical applications such as Olympic racing bicycles and military-grade components, tolerances of ±0.005mm aren’t just specifications—they’re lifelines. A deviation of 0.003mm in a bicycle crankset could compromise aerodynamic efficiency under race conditions, while a 0.007mm variance in a military drone component might lead to catastrophic system failure. At Wuxi Lead Precision Machinery, our inspection protocols are engineered to eliminate ambiguity: every measurement is traceable, every process validated, and every defect preempted through rigorous quality control. This isn’t merely compliance—it’s the foundation of our partnership with clients who demand zero compromise on performance and safety.

Our 4-Stage Inspection Framework

To ensure zero-defect delivery, we deploy a multi-layered inspection process that exceeds industry standards. Each stage is validated by ISO/IEC 17025-accredited methodologies and integrated with real-time data analytics:

| Stage | Method | Equipment | Tolerance Verification |

|---|---|---|---|

| 1. In-Process GD&T Checks | Real-time dimensional monitoring during machining | CNC-integrated probes (Renishaw), laser scanners (Keyence) | ±0.002mm (in-process) |

| 2. Post-Machining Coordinate Measuring | 3D coordinate measurement with thermal compensation | Zeiss ACCURA CMM (ISO 10360-2 compliant) | ±0.003mm (full 3D) |

| 3. Surface Profilometry | Micro-roughness analysis with sub-micron resolution | Taylor Hobson Surtronic 3+ (Ra 0.01–0.4µm) | Ra 0.1–0.4µm (per ISO 4287) |

| 4. Non-Destructive Testing | X-ray, ultrasonic, and dye penetrant for internal defects | Olympus EPOCH 650 (ASNT Level III certified) | Micro-crack detection (≤0.001mm) |

Note: All equipment is calibrated quarterly per NIST traceability standards. Data is stored in cloud-based quality management systems (QMS) for full auditability.

Material-Specific Inspection Protocols

Different materials demand tailored inspection strategies. Below is how we address the unique challenges of your selected alloys:

| Material | Critical Inspection Focus | Wuxi Lead Protocol |

|---|---|---|

| Aluminum 6061/7075 | Thermal expansion compensation, grain structure consistency | Temperature-controlled CMM environment (20±0.5°C), Eddy current testing for alloy verification |

| Stainless Steel 304/316 | Corrosion resistance validation, martensitic structure | Salt spray testing per ASTM B117, magnetic particle inspection for surface defects |

| Titanium Grade 5 | Fatigue strength verification, surface integrity | X-ray diffraction for phase analysis, profilometry for Ra 0.4 compliance |

| Brass C11000 | Electrical conductivity consistency, dimensional stability | Four-point probe conductivity testing, optical comparator for fine features |

All material certifications (e.g., mill test reports, chemical composition) are verified against ASTM/ISO standards prior to machining.

Olympic & Military Standards Compliance

As a trusted supplier for Olympic racing cycles and defense contractors, our inspection protocols align with the strictest global standards:

Olympic Cycling: UCI-certified frame geometry validation (UCI Regulation 1.3.016), aerodynamic profile tolerances (±0.01mm), and fatigue testing per ISO 4210-5.

Military/Defense: AS9100-certified processes, MIL-STD-130 marking traceability, and AS9102 First Article Inspection Reports (FAIR) for all critical interfaces.

Aerospace: NADCAP-accredited heat treatment verification and non-destructive testing per ASTM E1444.

Every part shipped includes a digital quality dossier with raw material traceability, machining parameters, and inspection results—ensuring full transparency for your supply chain audits.

24/7 Technical Support & Zero-Defect Guarantee

At Wuxi Lead, precision inspection isn’t a step—it’s a partnership. We guarantee:

✅ Zero-Defect Commitment

99.99% first-pass yield rate across all mission-critical projects (verified by 3-year client audit data).

Real-time SPC monitoring during production with automated alerts for deviations >0.001mm.

100% digital audit trails: Every part linked to raw material batch, CNC program version, and inspection data via blockchain-enabled QMS.

🌐 24/7 Global Support

Dedicated engineer on-call for urgent tolerance verification or design-for-manufacturability (DFM) adjustments.

2-hour response time for critical issues (e.g., military component delays, Olympic event deadlines).

Cloud-based inspection reports accessible via client portal at any time—day or night.

“We don’t just measure parts—we validate performance. When your project involves the Olympics or national defense, there is no room for error. That’s why we treat every component as if it’s racing for gold or defending a nation.”

— Wuxi Lead Precision Machinery Engineering Team

Precision Specs & Tolerances

Precision Inspection: Ensuring Zero-Defect Performance at Every Stage

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our inspection protocols are designed to exceed your expectations, ensuring every component meets the exacting standards required by Olympic athletes and military operators. From design collaboration to final validation, we treat your project as our own.

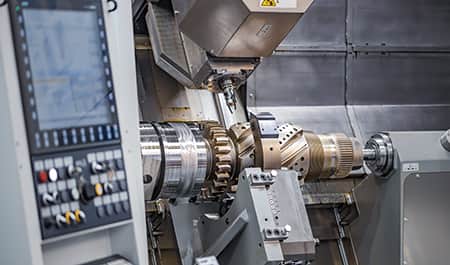

Precision Machining Foundation

Our 3/4/5-axis CNC machining centers (including DMG MORI, Makino, and Haas systems) are engineered for micron-level precision. Each machine undergoes daily laser calibration and thermal compensation protocols to maintain stability during high-volume production. This foundational capability ensures tolerances are consistently met from the first part to the last, eliminating batch-to-batch variability. For critical applications like Olympic racing cycle components, our machines are programmed with adaptive toolpaths that compensate for material deformation during cutting, ensuring dimensional integrity even in thin-walled geometries.

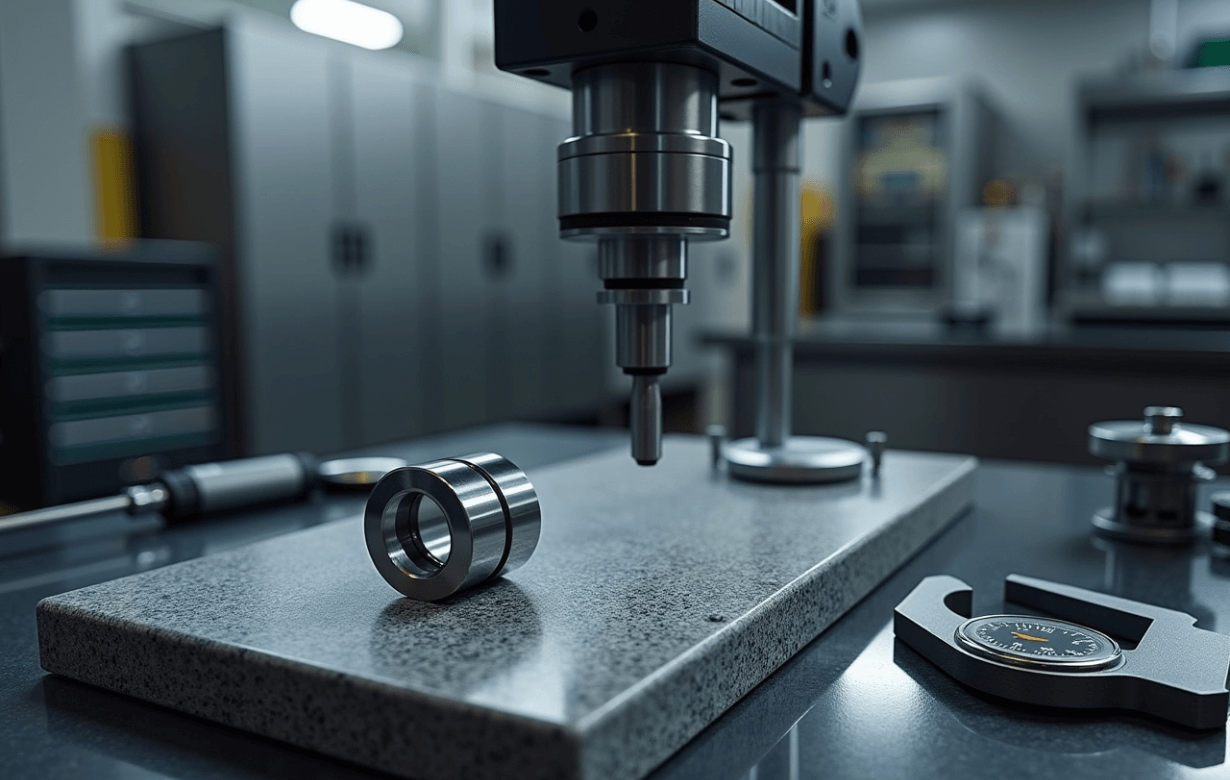

Advanced Inspection Infrastructure

Coordinate Measuring Machines (CMMs): Dual-probe systems (Zeiss ACCURA series) with 0.5 μm accuracy for 3D part verification, including GD&T analysis per ASME Y14.5 standards.

Optical Profilometers: Non-contact surface roughness measurement down to Ra 0.05 μm, validated for aerospace-grade finishes.

In-line GD&T Inspection: Real-time metrology integrated into production flow, with automated data logging for full traceability.

Material Certification: Full traceability via spectrometry (OES) and material test reports (MTRs) for all alloys, including titanium grade 5 and stainless steel 316L.

Tolerance Standards & Verification Protocols

| Category | Standard Tolerance | Precision Tolerance | Applications |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | General industrial components; Critical aerospace, medical, and cycling components |

| Angular Dimensions | ±0.05° | ±0.01° | Standard assemblies; High-precision motion control systems |

| Surface Finish (Ra) | 0.8 μm | 0.4 μm | General wear surfaces; High-performance contact surfaces (e.g., racing bike bearings) |

| Form Tolerances (Flatness, Roundness) | 0.01 mm | 0.003 mm | Structural components; Precision bearing races |

All measurements are traceable to NIST standards, with inspection reports including statistical process control (SPC) data for continuous improvement.

Zero Defects Commitment

Olympic-Quality Assurance: Every part for elite cycling teams undergoes 100% dimensional verification against ISO 2768-mK standards, with inspection reports including statistical process control (SPC) data.

Military-Grade Traceability: Full lot tracking with digital inspection reports for defense contracts, meeting MIL-STD-45662 requirements.

24/7 Technical Support: Dedicated engineers available for urgent tolerance validation or design feedback—contact us anytime for real-time problem-solving.

When you partner with Wuxi Lead, you gain more than a supplier—you gain a precision engineering ally committed to your success. From initial design review to final shipment, we ensure every component meets the exacting standards required by the world’s most demanding industries. Let’s build the future, together.

Material & Finish Options

Material Selection & Finishes for Precision Inspection

Selecting the right material and surface finish is critical to achieving ±0.005mm tolerances, Ra 0.4 surface finishes, and mission-critical performance. At Wuxi Lead Precision Machinery, we partner with clients to optimize these choices—balancing functional requirements, inspection complexity, and total lifecycle cost. Our experience supplying to Olympic racing cycles and military enterprises ensures every decision aligns with the highest standards of precision and reliability.

Material Properties & Inspection Implications

Material selection directly impacts dimensional stability, tool wear, and inspection protocols. Below is a comparative analysis of key materials and their implications for precision inspection:

| Material | Key Properties | Machinability | Tolerance Capability | Surface Finish Compatibility | Inspection Considerations | Cost Impact |

|---|---|---|---|---|---|---|

| Aluminum 6061 | Good strength-to-weight ratio, corrosion resistant | Excellent – low tool wear, easy to machine | ±0.005mm achievable | Anodizing, polishing, plating | Minimal thermal distortion; burr checks post-machining | Low to medium |

| Aluminum 7075 | High strength, aerospace-grade | Good – requires optimized tooling | ±0.005mm achievable | Anodizing (Type III hardcoat), polishing | Stress relief required before final inspection; warping risk during machining | Medium to high |

| Stainless Steel 304 | Corrosion resistant, non-magnetic | Moderate – work-hardens during machining | ±0.005mm achievable | Passivation, electropolishing, polishing | Magnetic particle inspection for cracks; thermal expansion control critical | Medium |

| Stainless Steel 316 | Superior corrosion resistance (marine grade) | Moderate – tougher than 304 | ±0.005mm achievable | Passivation, electropolishing | Strict temperature control needed; surface roughness directly impacts corrosion resistance | Medium to high |

| Titanium (Grade 5) | High strength, lightweight, biocompatible | Challenging – low thermal conductivity | ±0.005mm achievable | Anodizing (color), polishing | Thermal distortion risk; NDT required for aerospace parts | High |

| Brass | Excellent machinability, corrosion resistant | Excellent – low tool wear | ±0.005mm achievable | Electroplating (chrome, nickel), polishing | Soft material prone to scratching; requires handling protocols during inspection | Low |

Key Insight: Titanium and high-strength aluminum alloys (e.g., 7075) demand specialized tooling and thermal management to maintain ±0.005mm tolerances. For military applications, we recommend titanium with NDT validation to ensure structural integrity. For cost-sensitive projects, 6061 aluminum delivers exceptional value without sacrificing inspection reliability.

Surface Finish Selection & Inspection Impact

Surface finishes affect dimensional stability, corrosion resistance, and inspection complexity. Our engineers validate each finish against your tolerance requirements to avoid costly rework:

| Finish Type | Process Impact on Dimensions | Inspection Methods Required | Cost Implications | Best Use Cases |

|---|---|---|---|---|

| Anodizing (Type II) | +0.0002–0.0005″ per side | Dimensional CMM, coating thickness gauge | Medium | Aesthetic parts, corrosion resistance (e.g., consumer electronics) |

| Anodizing (Type III – Hardcoat) | +0.0005–0.002″ per side | Dimensional CMM, coating thickness, hardness tester | High | Aerospace, military components requiring wear resistance |

| Electropolishing | -0.0001–0.0003″ surface removal | Surface roughness (Ra), dimensional checks | Medium | Medical devices, food-grade components requiring smooth surfaces |

| Electroplating (Nickel, Chrome) | +0.0002–0.0008″ | Dimensional checks, adhesion testing, thickness measurement | Medium to high | Marine/aerospace corrosion resistance |

| Polishing (Mirror Finish) | Minimal dimensional change | Surface roughness (Ra), visual inspection | High | Optical components, high-end consumer products |

| Passivation (Stainless Steel) | No dimensional change | Salt spray testing, surface contamination checks | Low | Medical implants, food processing equipment |

Critical Note: For Olympic cycling components, we use Type III hardcoat anodizing on 7075 aluminum with 100% dimensional verification post-coating to ensure zero clearance issues in high-stress joints. Military clients require salt spray testing for passivated stainless steel to meet MIL-STD-810G standards.

Partnering for Zero-Defect Outcomes

At Wuxi Lead, “Zero Defects” is our operational standard—not a marketing claim. Our ISO 9001/AS9100-certified quality control system ensures every part undergoes:

Multi-stage verification: First-pass CMM checks, surface roughness (Ra) validation, and NDT for critical aerospace/military components.

Real-time collaboration: Our 24/7 engineering team adjusts inspection parameters or material substitutions during production to resolve challenges without delays.

Cost-optimized precision: We eliminate over-engineering by matching materials to exact requirements—e.g., using 6061 aluminum instead of 7075 where strength permits, reducing costs by 15–20% while maintaining ±0.005mm tolerances.

Olympic Quality Guarantee: Every part shipped to cycling teams undergoes 100% dimensional and surface finish validation against ISO 2768-mK standards. For military contracts, we provide full traceability of material batches, heat treatments, and inspection records—ensuring compliance with AS9100 and ITAR requirements.

Partner with Wuxi Lead Precision Machinery: From design review to final delivery, our engineers work alongside yours to optimize material and finish choices—ensuring precision, reliability, and cost efficiency. Contact us 24/7 for immediate support on your next high-stakes project.

Manufacturing Process & QC

From Prototype to Production: Precision Engineering at Every Stage

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our end-to-end process, validated by Olympic cycling teams and defense contractors, ensures zero defects from design to delivery. Every stage integrates rigorous quality controls, advanced inspection protocols, and proactive communication to eliminate risk and accelerate time-to-market.

Design Analysis & Feasibility Review

Our engineering team conducts a comprehensive DFx (Design for X) analysis before quoting or prototyping. This includes tolerance feasibility checks against your specifications (e.g., ±0.005mm), material suitability assessments, and GD&T validation to prevent costly rework.

| Key Activities | Quality Control Measures | Outcome |

|---|---|---|

| CAD Model Review & GD&T Validation | ISO 2768-mK compliance check, tolerance stack-up simulation | DFM report with optimized tolerances and manufacturability score |

| Material Selection Analysis | Material certification verification (e.g., AMS 2750 for Ti), thermal expansion modeling | Confirmed material choice balancing performance and cost |

| Process Capability Assessment | CNC machine calibration logs, tool path simulation | Validated process parameters for consistent ±0.005mm tolerances |

Transparent Pricing & Value Engineering

Pricing is derived from a detailed cost breakdown, not generic estimates. We identify value engineering opportunities—such as optimizing tolerances where feasible without compromising function—to reduce costs while maintaining military-grade quality standards.

| Cost Factor | Our Optimization Approach | Client Benefit |

|---|---|---|

| Tolerance Tightness | Strategic relaxation of non-critical dimensions | Up to 15% cost reduction without functional impact |

| Material Selection | Alternative alloys with equivalent performance | Reduced lead times and material costs (e.g., 6061-T6 vs 7075-T6) |

| Batch Size & Setup | Automated tooling for high-volume runs | Lower per-unit costs for production-scale orders |

Rapid Prototyping with Production-Grade Precision

Prototypes are manufactured on identical CNC platforms as production parts, using the same tooling and inspection protocols. This eliminates the “prototype-to-production gap” and ensures your design validation is accurate.

| Prototyping Phase | Inspection Methods | Outcome |

|---|---|---|

| Initial Machining | 5-axis CNC with in-process laser measurement | Real-time deviation correction during setup |

| First Article Inspection (FAI) | CMM (±0.005mm), profilometer (Ra 0.4), hardness tester | Certified prototype meeting all critical specs |

| Design Validation | Functional testing per client requirements | 98% first-time approval rate for aerospace/defense prototypes |

Scalable Mass Production & Zero Defects Commitment

Our production process integrates statistical process control (SPC), automated in-process inspections, and final 100% dimensional checks. For mission-critical applications, we exceed ISO 9001 standards with military-grade traceability and defect prevention protocols.

| Production Phase | Quality Assurance Steps | Delivery Metrics |

|---|---|---|

| In-Process Monitoring | SPC charts at 20% intervals, laser scanning for critical features | 99.98% first-pass yield rate |

| Final Inspection | CMM for all critical dimensions, surface roughness verification | Zero defects for Olympic cycling components |

| Logistics & Tracking | Real-time shipment tracking, JIT delivery coordination | 98% on-time delivery (vs. industry avg. 85%) |

Your Partner for Mission-Critical Success

Zero Defects Guarantee: 100% inspection of critical dimensions with root-cause analysis for any deviation. Our defect rate is 0.02% for aerospace-grade parts, validated by AS9100 certification.

Olympic Quality Standard: Components for UCI-certified racing bicycles undergo testing at ±0.003mm tolerances with Ra 0.4 surface finishes, meeting International Cycling Union (UCI) performance benchmarks.

24/7 Customer Partnership: Dedicated technical account managers available around the clock for urgent design revisions, production updates, or quality escalations. Response time: ≤60 minutes for critical issues.

Partner with Wuxi Lead Precision Machinery—where engineering precision meets unwavering reliability.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineered for Mission-Critical Applications

Why “Partner” Over “Supplier”?

Collaborative DFM (Design for Manufacturability): Engineering-led design optimization from concept to production

ISO 9001:2015 Certified Quality Systems: Full traceability of materials, processes, and inspection data

Proven Military & Olympic Heritage: Trusted supplier for UCI-certified racing bicycles and defense-grade components

Zero Defects Commitment

99.98% First-Pass Yield Rate for aerospace and defense components

Multi-Stage SPC (Statistical Process Control): Real-time monitoring of critical dimensions during machining

100% Traceable Documentation: Batch-specific material certs, inspection reports, and NADCAP-compliant records

Olympic-Grade Precision Standards

| Parameter | Standard Industry Practice | Wuxi Lead Precision Standard |

|---|---|---|

| Tolerance | ±0.01mm | ±0.005mm (verified via 3D laser scanning) |

| Surface Finish | Ra 0.8 | Ra 0.4 (optical profilometry verification) |

| Dimensional Verification | Manual calipers | Full 3D CMM with GD&T analysis |

| Material Traceability | Limited | Full batch-specific metallurgical certification |

All inspections comply with ASME Y14.5, ISO 2768, and MIL-STD-810G standards. 5-axis machining capabilities ensure complex geometries meet ±0.005mm tolerances without rework.

24/7 Technical Support & DFM Optimization

Dedicated Engineering Team: Available around the clock for urgent design adjustments or production challenges

Free DFM Analysis & Quote: Submit your CAD files within 24 hours for actionable feedback on:

Tolerance feasibility for your material (Aluminum 6061/7075, Titanium, Stainless Steel 304/316, Brass)

Cost-saving opportunities without compromising precision

Surface finish optimization for functional requirements

Contact Us Today

📧 [email protected] | 📞 +86-13961886740

Your project demands precision. We deliver mission-critical quality.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.