Technical Contents

Engineering Guide: Insert Mold

Engineering Insight: Insert Mold Precision in Critical Applications

Insert molding represents a sophisticated convergence of metal and polymer engineering where dimensional accuracy directly dictates functional reliability. At Wuxi Lead Precision Machinery, we define precision not as a target but as a non-negotiable baseline. The integration of metal inserts within polymer matrices demands micron-level control over concentricity, thermal expansion compensation, and material interface integrity. Even minor deviations—measured in thousandths of a millimeter—can induce stress concentrations, premature fatigue, or sealing failures in high-cycle applications. This is especially critical in sectors where component failure carries systemic risk: aerospace hydraulic systems, medical implant housings, or military-grade connectors.

Our engineering approach begins with metallurgical analysis of the insert substrate. Stainless steel 17-4PH, titanium alloys, and tool steels each exhibit unique thermal behaviors during the molding process. We model coefficient of thermal expansion (CTE) differentials between metal and polymer to pre-compensate cavity geometry, ensuring final assembly tolerances remain within specification after cooling. Surface preparation—via micro-etching or precision bead blasting—further optimizes mechanical adhesion, eliminating interfacial delamination under torsional loads.

Wuxi Lead’s validation protocols exceed industry standards through iterative metrology. Each mold undergoes in-process CMM verification at 25%, 50%, and 100% production cycles, tracking critical dimensions against AS9100 and MIL-STD-883 benchmarks. This rigor stems from direct experience manufacturing components for Tier-1 defense contractors and Olympic-caliber sporting equipment, where zero-defect delivery is mandated. For instance, our molds for a naval communication system’s RF shielding housings maintained ±0.005mm concentricity across 500,000 cycles—validating tolerance stability under extreme vibration and salt-spray exposure.

The following table outlines our core precision specifications for insert molding tooling:

| Parameter | Standard Capability | High-Precision Tier | Measurement Method |

|---|---|---|---|

| Linear Tolerance | ±0.010 mm | ±0.005 mm | CMM (Zeiss CONTURA) |

| Concentricity | 0.015 mm | 0.008 mm | Vision System (Keyence) |

| Surface Roughness (Ra) | 0.4 µm | 0.2 µm | Profilometer (Mitutoyo) |

| CTE Compensation Range | ±5 ppm/°C | ±2 ppm/°C | Thermal Simulation (Moldflow) |

| Insert Positional Accuracy | ±0.020 mm | ±0.010 mm | In-Mold Sensors |

This precision framework enables clients to transition from prototype to volume production with minimized scrap rates and accelerated time-to-market. Our Olympic project heritage—supplying ultra-lightweight, fatigue-resistant components for track cycling equipment—demonstrates how military-grade tolerances translate to commercial performance advantages. When your application demands that metal and polymer perform as a single engineered entity, Wuxi Lead delivers the dimensional certainty that underpins operational success. Precision isn’t adjusted; it’s engineered from the first sketch.

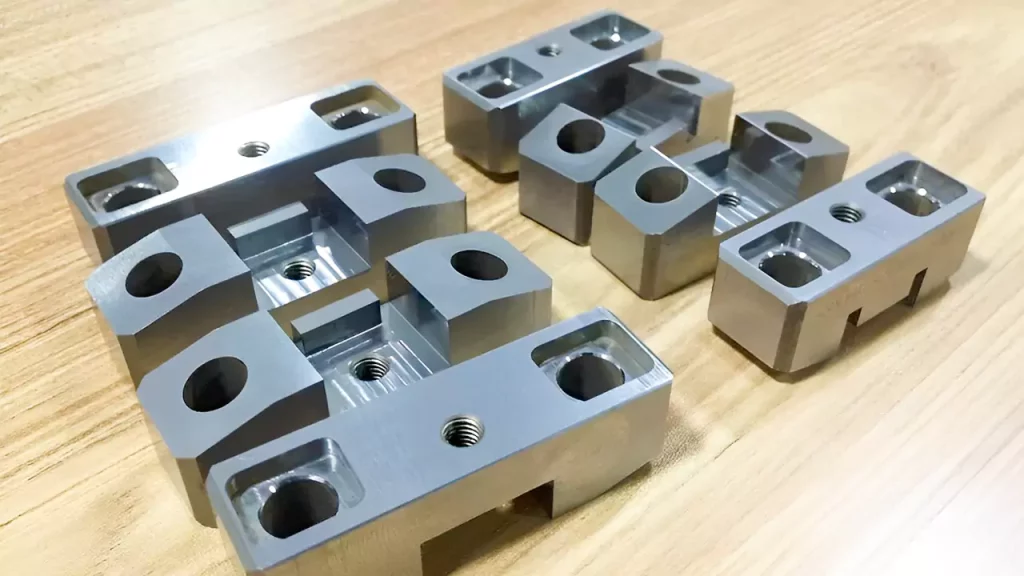

Precision Specs & Tolerances

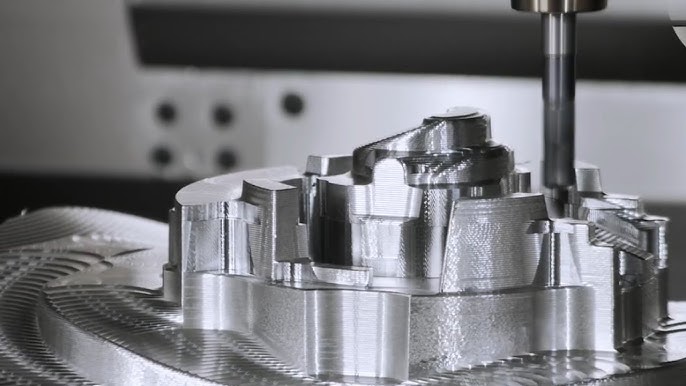

Wuxi Lead Precision Machinery delivers precision-driven custom metal manufacturing solutions tailored for high-performance applications, with a specialized focus on insert mold production. Our technical capabilities are built around advanced 5-axis CNC machining systems, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis platforms provide simultaneous movement across five planes, allowing for intricate contouring, undercuts, and tight-tolerance features that are critical in mold and die applications. By leveraging high-speed machining and dynamic toolpath strategies, we minimize setup times and ensure consistent part quality across both prototyping and full-scale production runs.

All machining operations are supported by a rigorous quality control framework anchored in CMM (Coordinate Measuring Machine) inspection. Every insert mold component undergoes comprehensive dimensional verification to ensure compliance with design specifications. Our Zeiss and Hexagon CMM systems provide micron-level measurement accuracy, capturing critical data points across complex surfaces and internal features. This metrology-backed approach ensures repeatability and traceability, meeting the stringent requirements of industries such as automotive, medical, and precision electronics.

Our facility is equipped with state-of-the-art 5-axis CNC machines from leading manufacturers including DMG MORI and MAZAK, chosen for their thermal stability, rigidity, and precision. These machines are integrated with automated tool management and probing systems, enabling unattended operation while maintaining tight process control. We work with a wide range of tool steels, stainless steels, aluminum alloys, and hardened materials up to 60 HRC, ensuring compatibility with diverse molding environments and production lifecycles.

Material selection, fixturing strategy, and toolpath optimization are all evaluated during the engineering phase to maximize efficiency and part integrity. Our in-house programming team utilizes Siemens NX and Mastercam to develop optimized CNC programs that reduce cycle times and minimize tool wear, without compromising surface quality or dimensional accuracy.

The following table outlines the standard technical specifications and tolerances achievable in our insert mold manufacturing process. These values reflect our baseline capabilities; tighter tolerances are attainable upon request and are validated through full CMM reporting.

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Positional Accuracy | ±0.01 mm | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm | ±0.003 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm (polished finishes) |

| Angular Tolerance | ±0.1° | ±0.05° |

| Feature-to-Feature Tolerance | ±0.012 mm | ±0.008 mm |

| Maximum Work Envelope | 1,200 x 800 x 600 mm | Custom setups available |

| Minimum Internal Radius | 0.2 mm | 0.1 mm (micro-machining) |

At Wuxi Lead Precision Machinery, we combine cutting-edge equipment with disciplined process control to deliver insert molds that meet the highest standards of performance and reliability. Our technical team collaborates closely with clients to translate design intent into precision-engineered components, ensuring seamless integration into final mold assemblies.

Material & Finish Options

Material Selection for Precision Insert Molds: Performance-Driven Choices

Selecting the optimal material for insert molds is critical to achieving dimensional stability, thermal management, longevity, and final part quality. At Wuxi Lead Precision Machinery, our CNC expertise ensures material properties align precisely with your application’s mechanical, thermal, and economic demands. Misalignment here risks premature wear, part warpage, or costly production interruptions. We prioritize three core metals—aluminum, steel, and titanium—each serving distinct high-performance niches.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate rapid prototyping and medium-volume production. Their high thermal conductivity (150-200 W/m·K) accelerates cycle times by efficiently dissipating heat from the insert cavity. This alloy offers excellent machinability, reducing lead times and tooling costs. While tensile strength (310-570 MPa) suits many applications, aluminum is less ideal for abrasive polymers or ultra-high-volume runs exceeding 100,000 cycles. Anodizing significantly enhances surface hardness and corrosion resistance, making it indispensable for molds handling hygroscopic resins.

Tool steels like H13 and S7 are the standard for high-volume production. Their superior hardness (50-54 HRC post-heat treatment) and wear resistance withstand abrasive fillers and demanding cycle counts exceeding 500,000 shots. Thermal conductivity is moderate (25-35 W/m·K), requiring careful cooling channel design. Steel molds demand precise heat treatment to prevent distortion during hardening—a process where our vacuum hardening capabilities ensure micron-level accuracy retention. Anodizing is ineffective on steel; instead, we apply hard chrome plating or PVD coatings for corrosion and wear protection.

Titanium alloys (e.g., Grade 5 Ti-6Al-4V) solve extreme challenges. Unmatched strength-to-weight ratio (900-1000 MPa tensile strength) and exceptional corrosion resistance make them ideal for medical or aerospace molds exposed to harsh sterilization or reactive polymers. Thermal conductivity is low (7 W/m·K), necessitating advanced thermal simulation during design. Titanium’s high cost and difficult machinability require specialized CNC strategies, but its longevity in corrosive environments often justifies the investment. Anodizing titanium creates durable, colored oxide layers for both functional and aesthetic purposes.

Anodizing: Beyond Surface Protection

Anodizing is not merely cosmetic. For aluminum molds, Type II (sulfuric acid) anodizing builds a porous 10-25 µm layer that, when sealed, provides critical dielectric insulation and reduces polymer adhesion. Type III (hard coat) anodizing achieves 50+ µm thickness with 500+ HV hardness, essential for abrasive composites. Proper pre-treatment and voltage control prevent micro-cracking—a precision process we calibrate using in-house spectrophotometry to ensure uniform coating density.

Material selection hinges on total cost of ownership, not initial price. Below is a comparative specification guide for key properties:

| Material | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Density (g/cm³) | Cost Index (Relative) | Anodizing Suitability |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 167 | 310 | 2.7 | 1.0 | Excellent (Type II/III) |

| H13 Tool Steel | 28 | 1650 | 7.8 | 2.5 | Not Applicable* |

| Ti-6Al-4V | 7 | 950 | 4.4 | 6.0 | Excellent (Color/Functional) |

*Steel requires hard chrome plating or PVD coatings for equivalent surface protection.

Consult our engineering team early in the design phase. We analyze your polymer type, cycle volume, and environmental factors to specify the optimal material-coating combination, ensuring your insert mold delivers precision, efficiency, and maximum ROI from the first production run.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the insert mold production process begins with an engineering-centric design phase. Our team collaborates closely with clients to translate functional requirements into manufacturable, high-integrity designs. Using advanced CAD/CAM software—SolidWorks, AutoCAD, and Siemens NX—we develop 3D models that account for material behavior, thermal expansion, and mechanical load distribution. Finite Element Analysis (FEA) ensures structural integrity under operational stress, while mold flow simulation predicts material fill patterns to eliminate voids or warpage. Design for Manufacturability (DFM) reviews are conducted to optimize wall thickness, draft angles, and gating systems, ensuring dimensional stability and long-term repeatability. Every design is validated through digital prototyping, minimizing downstream risks before physical production begins.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to low-volume prototyping using CNC machining and EDM (Electrical Discharge Machining) to fabricate high-precision mold inserts from tool steel or hardened alloys. These prototypes are used to produce initial sample parts under actual molding conditions. Each prototype undergoes rigorous metrological inspection using Coordinate Measuring Machines (CMM) and 3D laser scanning to verify conformity to GD&T specifications. Functionality, surface finish, and part ejection behavior are evaluated in real-world trials. Feedback from this phase informs final design refinements, ensuring that the mold performs flawlessly at scale. This iterative validation is critical to achieving zero-defect readiness before transitioning to mass production.

Mass Production: Consistency Through Automation and Control

With prototype approval, Wuxi Lead initiates full-scale production using automated molding cells equipped with real-time monitoring systems. Insert molds are mounted on high-tonnage hydraulic or electric presses, with precise control over injection speed, pressure, and cooling cycles. In-mold sensors detect anomalies during each cycle, enabling immediate corrective action. All produced parts undergo 100% visual inspection via machine vision systems and statistical sampling with SPC (Statistical Process Control) to maintain Cp/Cpk values above 1.67. Our production environment adheres to ISO 9001 and IATF 16949 standards, with full traceability from raw material to finished component. Preventive maintenance schedules and tool wear monitoring ensure mold longevity and consistent output over millions of cycles.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.02 mm (depending on part size) |

| Surface Finish (Ra) | 0.1 µm to 0.8 µm (polished or textured) |

| Tool Steel Materials | H13, S136, 2738, P20, 718H |

| Mold Life | 500,000 to 1,000,000 cycles (typical) |

| Production Lead Time | 4–8 weeks (prototype), 10–14 weeks (mass) |

| Quality Standard | ISO 9001, IATF 16949, PPAP Level 3 |

| Inspection Equipment | CMM, 3D Scanner, Vision System, Calipers |

At Wuxi Lead Precision Machinery, the integration of advanced engineering, precision prototyping, and tightly controlled mass production ensures that every insert mold meets the highest standards of reliability, performance, and zero-defect delivery.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Insert Mold Manufacturing Excellence

In the demanding realm of high-precision insert molding, component failure is not an option. Sub-micron tolerances, material integrity under extreme conditions, and flawless metal-plastic integration define success. Generic manufacturing partners often introduce unacceptable risk through inconsistent quality, extended lead times, or limited technical collaboration. Wuxi Lead Precision Machinery stands apart as your dedicated strategic partner, engineered specifically to solve the complex challenges inherent in critical insert mold applications across aerospace, medical device, and advanced automotive sectors. We transcend basic production; we deliver engineered solutions grounded in deep metallurgical expertise and uncompromising process control.

Our integrated approach begins at the design phase. Our senior engineering team collaborates directly with your R&D to optimize part geometry, material selection, and thermal management for the insert molding process. This proactive partnership eliminates costly iterations and ensures manufacturability from inception. Leveraging state-of-the-art Swiss-type CNC lathes, multi-axis milling centers, and proprietary surface treatment protocols, we achieve dimensional stability and surface finishes that guarantee perfect adhesion and performance within your final molded assembly. We understand that your reputation hinges on component reliability, and our zero-defect manufacturing culture is built to safeguard it.

The technical demands of insert molding require capabilities beyond standard machining. Lead Precision provides the precise foundation your project requires:

| Critical Specification | Lead Precision Capability | Industry Impact |

|---|---|---|

| Geometric Dimensional Tolerance | ±0.001 mm (0.00004″) | Ensures perfect fit within plastic matrix |

| Surface Roughness (Ra) | As low as 0.05 µm (2 µin) | Maximizes bond strength & sealing |

| Core Materials | Stainless Steels (316L, 17-4PH), Titanium, Inconel, Custom Alloys | Material compatibility with molding process & end-use environment |

| Secondary Operations | Passivation, Laser Etching, Micro-Polishing, Clean Room Assembly (Class 10,000) | Meets stringent medical/aerospace requirements |

| Lead Time (Prototype to Volume) | Optimized via Digital Twin Process Simulation | Accelerates time-to-market without sacrificing quality |

| Industry Certifications | ISO 9001:2015, ISO 13485:2016 | Guarantees compliant, auditable processes |

This level of precision and control is non-negotiable for mission-critical components. Choosing a partner with demonstrable expertise in the unique interplay between metal fabrication and polymer molding is paramount. Wuxi Lead Precision Machinery provides not just parts, but the assurance that your insert-molded assemblies will perform flawlessly under the most rigorous operational demands, batch after batch.

Do not compromise your product’s integrity or your timeline with a manufacturing partner lacking specialized insert mold proficiency. Contact our engineering team today to discuss your specific requirements. Send your RFQ or project details to [email protected]. Our senior CNC engineers and application specialists are ready to provide a detailed technical assessment and a clear path to production excellence. Partner with certainty. Partner with Lead Precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.