Technical Contents

Engineering Guide: Injection Moulding Uk

Engineering Insight Precision as the Non-Negotiable Foundation for UK Injection Moulding

The competitive landscape of UK injection moulding demands absolute precision as a baseline requirement, not merely an aspiration. In sectors like medical devices, aerospace components, and high-end consumer electronics – key markets for UK manufacturers – tolerances often fall below ±0.02mm. Achieving this consistently requires far more than standard machinery; it necessitates a holistic engineering approach where machine rigidity, thermal stability, and control system fidelity converge. Material behavior under high pressure and rapid cycling introduces microscopic variables; only systems engineered for micron-level repeatability can mitigate these, ensuring part conformity across million-shot runs. For UK moulders serving global supply chains, dimensional inconsistency translates directly to rejected batches, costly rework, and eroded client trust. Precision is the critical enabler of yield, efficiency, and market reputation.

Lead Precision’s engineering philosophy is forged in environments where failure is not an option. Our CNC-machined mould bases and hydraulic/pneumatic manifolds undergo validation in zero-failure contexts, including components for Olympic-standard sporting equipment and certified military hardware. This experience instills a non-negotiable standard: every tolerance stack-up, every surface finish specification, every thermal expansion coefficient is rigorously modelled and verified. We understand that UK manufacturers require partners who speak the language of ISO 13084 and VDI 2005 standards, delivering not just parts, but documented process capability (CpK > 1.67) essential for automotive and medical audits.

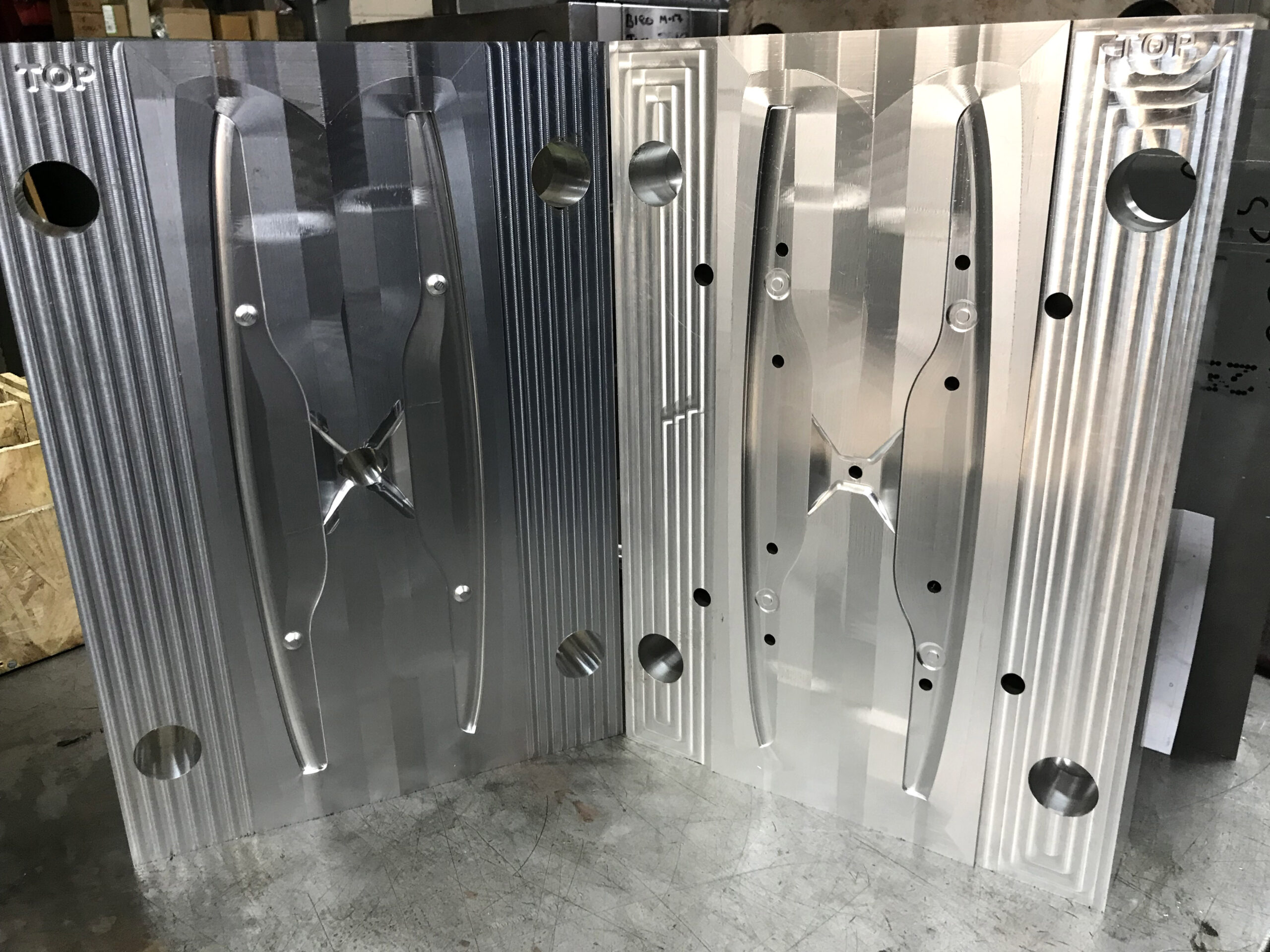

Our custom mould manufacturing leverages this precision heritage. Core and cavity inserts are machined on sub-micron capable VMCs with in-process probing, ensuring geometric accuracy before assembly. Critical sealing surfaces achieve Ra < 0.2µm, eliminating flash at parting lines even with aggressive cycle times. This level of control is embedded in the machine specifications we provide to UK partners:

| Critical Specification | Lead Precision Standard | Industry Typical | Impact on UK Moulding |

|---|---|---|---|

| Clamping Force Repeatability | ±0.05% | ±0.25% | Eliminates flash variation across long runs |

| Tie-Bar Parallelism | ≤ 0.02mm/m | ≤ 0.08mm/m | Prevents uneven wear, extends mould life |

| Shot Weight Repeatability | ±0.15g | ±0.5g | Critical for thin-wall medical containers |

| Platen Flatness (Under Load) | ≤ 0.01mm | ≤ 0.03mm | Ensures uniform cavity pressure distribution |

| Material Compatibility | PEEK, PEI, Medical PP | Standard Engineering Plastics | Meets UK regulatory demands for specialty polymers |

UK injection moulders face intense pressure to reduce costs while meeting escalating quality demands. Partnering with a manufacturer whose precision engineering is battle-tested in elite applications provides a decisive advantage. Lead Precision delivers the dimensional integrity and process stability that allow UK factories to operate at peak efficiency, confidently bidding for high-value contracts requiring certified consistency. This is not just machining; it is the assurance of performance where tolerances define success.

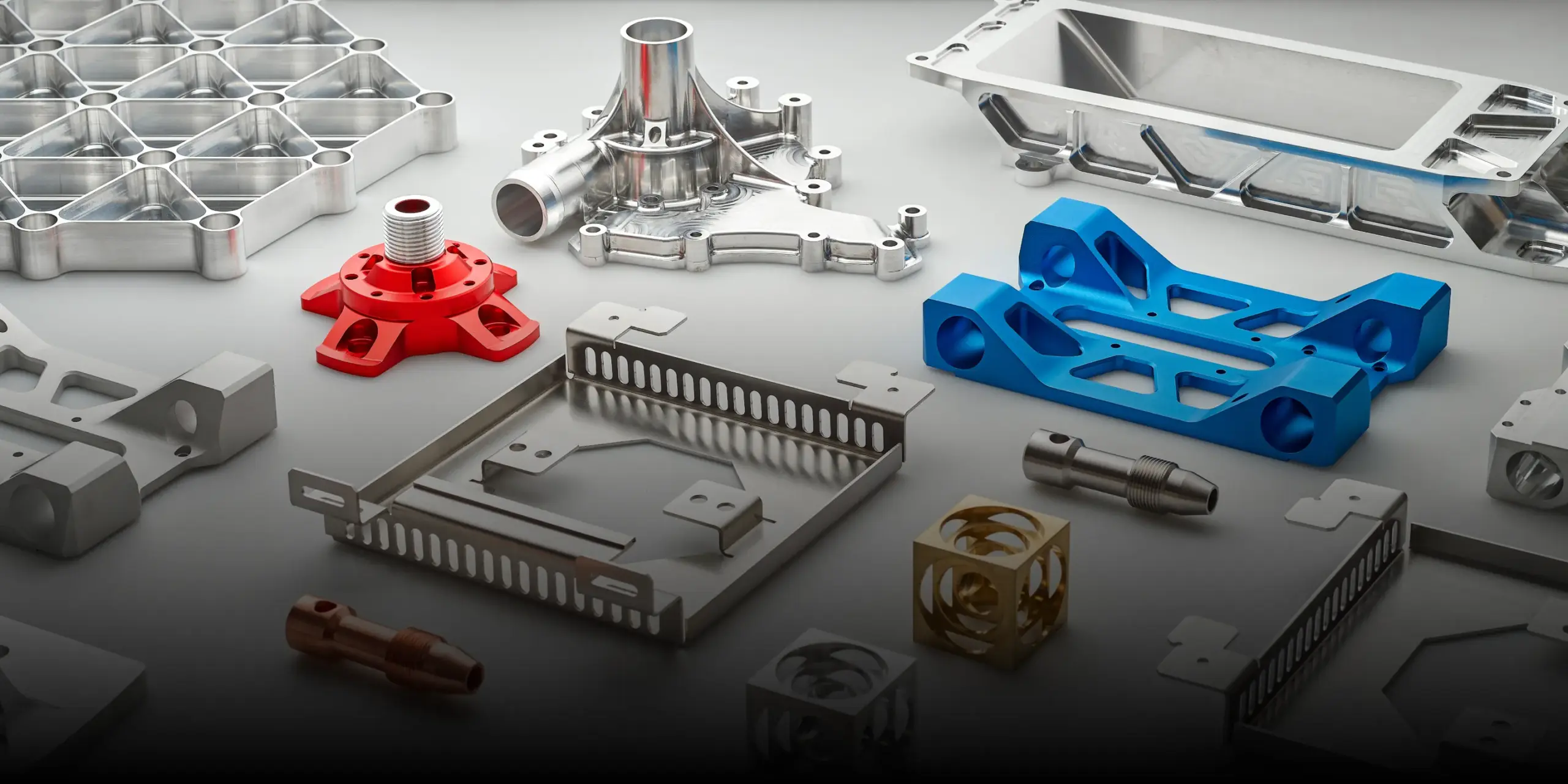

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered to meet the demanding requirements of high-performance industries such as automotive, aerospace, medical, and industrial automation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex, high-precision components with superior surface finish and dimensional accuracy. This advanced machining platform allows for simultaneous multi-axis movement, reducing setup times and ensuring tight tolerances across intricate geometries that would be unachievable with conventional 3-axis systems.

Our 5-axis CNC machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure consistent part quality and process efficiency. These machines support a wide range of metallic materials, including aluminum alloys, stainless steel, titanium, tool steels, and specialty alloys commonly used in injection moulding applications. Whether producing mould cores, cavities, ejector components, or precision inserts, our machining process ensures optimal thermal stability, wear resistance, and long service life—critical attributes for injection moulding tooling subjected to high pressure and repetitive cycles.

To guarantee adherence to exacting specifications, every component undergoes rigorous quality control through our coordinate measuring machine (CMM) inspection system. The CMM provides full 3D metrology validation, capturing critical dimensions, form deviations, and positional tolerances with micron-level precision. This data-driven inspection process ensures full traceability and compliance with international standards such as ISO 9001 and IATF 16949. Additionally, inspection reports are provided with each batch, offering customers complete transparency and confidence in part consistency.

Our integrated manufacturing and quality assurance workflow supports both low-volume prototyping and high-volume production runs, with rapid turnaround times and seamless scalability. The combination of advanced 5-axis CNC technology and CMM-based inspection allows us to deliver components that meet the most stringent performance criteria required in modern injection moulding systems.

The following table outlines the standard technical specifications and tolerances achievable through our manufacturing process:

| Parameter | Specification |

|---|---|

| Machining Type | 5-Axis CNC Milling and Turning |

| Positional Tolerance | ±0.005 mm |

| Dimensional Tolerance | ±0.01 mm (standard), down to ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.4 μm (polished finishes available) |

| Maximum Work Envelope | 1200 mm × 800 mm × 750 mm |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Tool Steel, P20, 718, S136, etc. |

| Inspection Method | Zeiss or Mitutoyo CMM, full 3D reporting |

| Quality Standards | ISO 9001, IATF 16949 compliant |

Wuxi Lead Precision Machinery is committed to technical excellence, precision consistency, and on-time delivery, serving as a trusted partner for UK and European injection moulding manufacturers seeking high-integrity metal components.

Material & Finish Options

Strategic Material Selection for Injection Moulding Tooling in the UK Market

Material choice critically impacts mould longevity, production efficiency, and part quality in high-volume injection moulding. For UK manufacturers facing stringent quality demands and cost pressures, selecting the optimal base material ensures maximum return on investment. Aluminum, steel, and titanium each offer distinct advantages depending on production volume, part complexity, and environmental exposure. Aluminum 7075-T6 excels in rapid prototyping and low-to-medium volume runs due to its exceptional machinability and thermal conductivity, reducing cycle times. However, its lower hardness limits use in abrasive polymers or extended production. Tool steels like P20 and H13 dominate high-volume applications, providing superior wear resistance and dimensional stability under repeated thermal cycling. Titanium Grade 5 (Ti-6Al-4V) is reserved for highly corrosive environments or extreme weight-sensitive aerospace components, though its high cost and machining complexity restrict widespread adoption.

Critical performance metrics must guide selection. The following table compares key properties for common mould materials:

| Material | Hardness (HRC) | Tensile Strength (MPa) | Corrosion Resistance | Thermal Conductivity (W/m·K) | Typical UK Application |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | 503-572 | Moderate | 130 | Prototypes, short-run consumer goods |

| P20 Tool Steel | 28-32 | 950-1100 | Low (uncoated) | 28-36 | High-volume automotive, medical housings |

| H13 Tool Steel | 46-52 | 1200-1600 | Moderate | 25-30 | Long-run engineering plastics, hot-runner systems |

| Titanium Grade 5 | 33-38 | 900-1000 | Excellent | 7-10 | Chemical processing, aerospace components |

Surface finishing, particularly anodizing, significantly enhances mould performance. Hard anodizing (Type III) applied to aluminum moulds increases surface hardness to 50-70 HRC, improving abrasion resistance by 300% and extending tool life in glass-filled polymer applications. For steel moulds, nitriding or PVD coatings are preferred, but anodizing remains vital for aluminum-based inserts or cooling cores where thermal management is critical. UK manufacturers operating in regulated sectors like medical or automotive must validate finish compatibility with polymer chemistry to prevent part contamination.

Wuxi Lead Precision Machinery advises UK partners to prioritize material-finish synergy based on annual production volumes. For runs exceeding 500,000 cycles, H13 steel with nitriding delivers optimal durability. Aluminum 7075-T6 with hard anodizing remains cost-effective for 50,000-200,000 cycles, especially where rapid heat dissipation is needed. Titanium’s niche applicability requires rigorous cost-benefit analysis. Our UK clients achieve 22% longer tool life by aligning material specifications with polymer abrasiveness and cycle stress profiles—leveraging our metrology-certified QC processes to ensure zero deviations from ISO 2768-mK standards. Strategic material engineering mitigates supply chain volatility while guaranteeing precision repeatability in demanding European manufacturing environments.

Manufacturing Process & QC

From Concept to Consistent Quality: The Wuxi Lead Precision Manufacturing Process

At Wuxi Lead Precision Machinery, we specialize in delivering custom metal components for advanced manufacturing applications, including high-precision parts used in injection moulding systems across the UK and Europe. Our production process is engineered for zero defects, ensuring reliability, repeatability, and performance under demanding industrial conditions. We follow a disciplined three-phase approach: Design, Prototyping, and Mass Production—each stage rigorously controlled to meet the highest standards of precision engineering.

The process begins with Design, where our engineering team collaborates closely with clients to interpret technical requirements, functional needs, and integration parameters. Using advanced CAD/CAM software and finite element analysis (FEA), we develop 3D models optimized for manufacturability, thermal performance, and structural integrity. This phase includes material selection—typically high-grade tool steels such as P20, 718H, or H13—based on mould life, corrosion resistance, and processing temperatures. Tolerances are defined to ±0.002 mm, ensuring seamless fit and function within complex mould assemblies.

Next is Prototyping, a critical validation step before full-scale production. We fabricate a limited set of components using the same CNC machining, EDM, and surface treatment processes intended for mass production. This ensures process fidelity and allows for dimensional inspection, hardness testing, and functional trials within actual mould setups. Any deviations are corrected through iterative refinement, with full traceability and documentation. Our metrology lab employs coordinate measuring machines (CMM) and optical profilometers to verify geometric accuracy and surface finish, minimizing risk before tooling commitment.

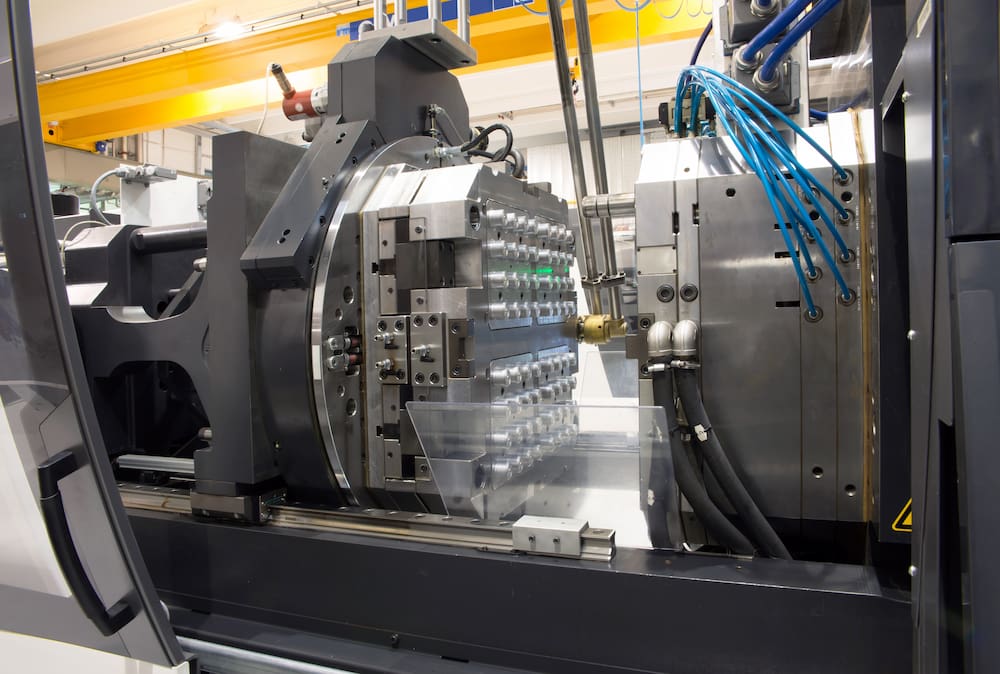

Once the prototype is approved, we transition to Mass Production under a fully documented quality management system compliant with ISO 9001 standards. Each component is manufactured using high-speed CNC machining centers with real-time tool monitoring and automated in-process gauging. Our production cells operate under strict environmental controls, and every batch undergoes 100% visual inspection and random sampling for dimensional conformance. We implement Six Sigma methodologies and root cause analysis to eliminate variability, achieving a defect rate below 50 PPM (parts per million).

Throughout the process, traceability is maintained via laser marking and digital work orders, enabling full audit trails from raw material to final shipment. Our clients in the UK injection moulding sector rely on this disciplined approach to reduce downtime, extend mould life, and ensure consistent part quality.

Key Manufacturing Specifications

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.2 – 0.8 µm (polished to mirror finish) |

| Materials Used | P20, 718H, H13, S136, Stainless Steel 316 |

| Hardness Range | 28–52 HRC (custom heat treatment available) |

| Maximum Part Size | 800 × 600 × 500 mm |

| Production Capacity | 50,000+ units annually |

| Quality Standard | ISO 9001:2015, 100% inspection, CMM reports |

This end-to-end process ensures that every component we deliver meets the exacting demands of modern injection moulding applications—precision, durability, and zero-defect performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your UK Injection Moulding Precision Engineering Solution

For UK injection moulding enterprises demanding uncompromising quality and reliability in critical metal components, Wuxi Lead Precision Machinery delivers engineered excellence from the heart of China’s advanced manufacturing sector. We understand the stringent tolerances, complex geometries, and rapid turnaround times essential for high-performance moulds, inserts, and ancillary tooling in the competitive UK market. Our dedicated focus on custom metal manufacturing for the global plastics industry ensures your production lines run with maximum uptime and part consistency. Partnering with Lead Precision means accessing European-grade precision engineering capabilities backed by rigorous quality control systems designed to meet and exceed the expectations of discerning UK manufacturers. We navigate the complexities of international supply chains, providing a seamless, Brexit-resilient source for mission-critical components without sacrificing speed or technical support.

Our advanced CNC machining centre, featuring state-of-the-art multi-axis milling, turning, and grinding equipment, is purpose-built for the demanding requirements of injection mould manufacturing. We specialise in processing challenging materials including hardened tool steels (H13, S136, 2738), stainless steels, and aluminium alloys to exacting specifications. Every component undergoes comprehensive metrology using CMMs, optical comparators, and surface roughness testers, ensuring dimensional integrity and surface finishes critical for mould longevity and part quality. Our engineers collaborate closely with your technical team from initial concept through to final inspection, offering value engineering insights to optimise manufacturability and reduce total cost of ownership. We operate under ISO 9001:2015 certification, guaranteeing consistent processes and documentation traceability demanded by UK automotive, medical, and consumer goods sectors.

Technical Capabilities for Injection Mould Manufacturing

| Parameter | Specification |

|---|---|

| Material Range | Tool Steels (H13, S136, P20, 718), Stainless Steels (304, 316), Aluminium Alloys, Brass |

| Tolerance Capability | ±0.001 mm (Sub-Micron Precision) |

| Max Workpiece Size | 1200 x 800 x 600 mm |

| Surface Finish (Ra) | As low as 0.05 µm (Mirror Polish) |

| Key Processes | 5-Axis Milling, Precision Turning, Wire EDM, Surface/ID Grinding, Hard Milling |

| Quality Certification | ISO 9001:2015, Full First Article Inspection Reports, Material Certificates |

Choosing Lead Precision eliminates the risk of production delays caused by inconsistent component quality or unreliable suppliers. We offer transparent project management, real-time progress updates, and flexible logistics solutions tailored for efficient delivery to UK ports. Our commitment extends beyond delivery; our engineering support team provides responsive troubleshooting assistance, ensuring your moulds perform optimally throughout their lifecycle. There are no minimum order quantities, making our precision accessible to both large-scale producers and agile UK SMEs requiring high-mix, low-volume specialist components.

Elevate your injection moulding capability with a manufacturing partner proven in the global arena. Contact us today to discuss your specific project requirements and discover how Lead Precision Machinery delivers the precision, reliability, and partnership your UK operation demands. Specify your application details for a tailored capability assessment and competitive quotation.

Contact [email protected] to initiate your precision engineering partnership. Let our expertise become your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.