Technical Contents

Engineering Guide: Injection Moulding Services

Engineering Insight: The Critical Role of Precision in Injection Moulding Services

In the realm of custom metal manufacturing, injection moulding services represent a convergence of material science, mechanical engineering, and ultra-precision tooling. At Wuxi Lead Precision Machinery, we recognize that the success of any injection moulding project hinges not only on the quality of raw materials or the speed of production but fundamentally on the precision achieved throughout the entire process. From initial design to final part inspection, tolerances measured in microns can determine the functionality, reliability, and longevity of a component—especially in high-stakes industries such as aerospace, defense, and advanced medical systems.

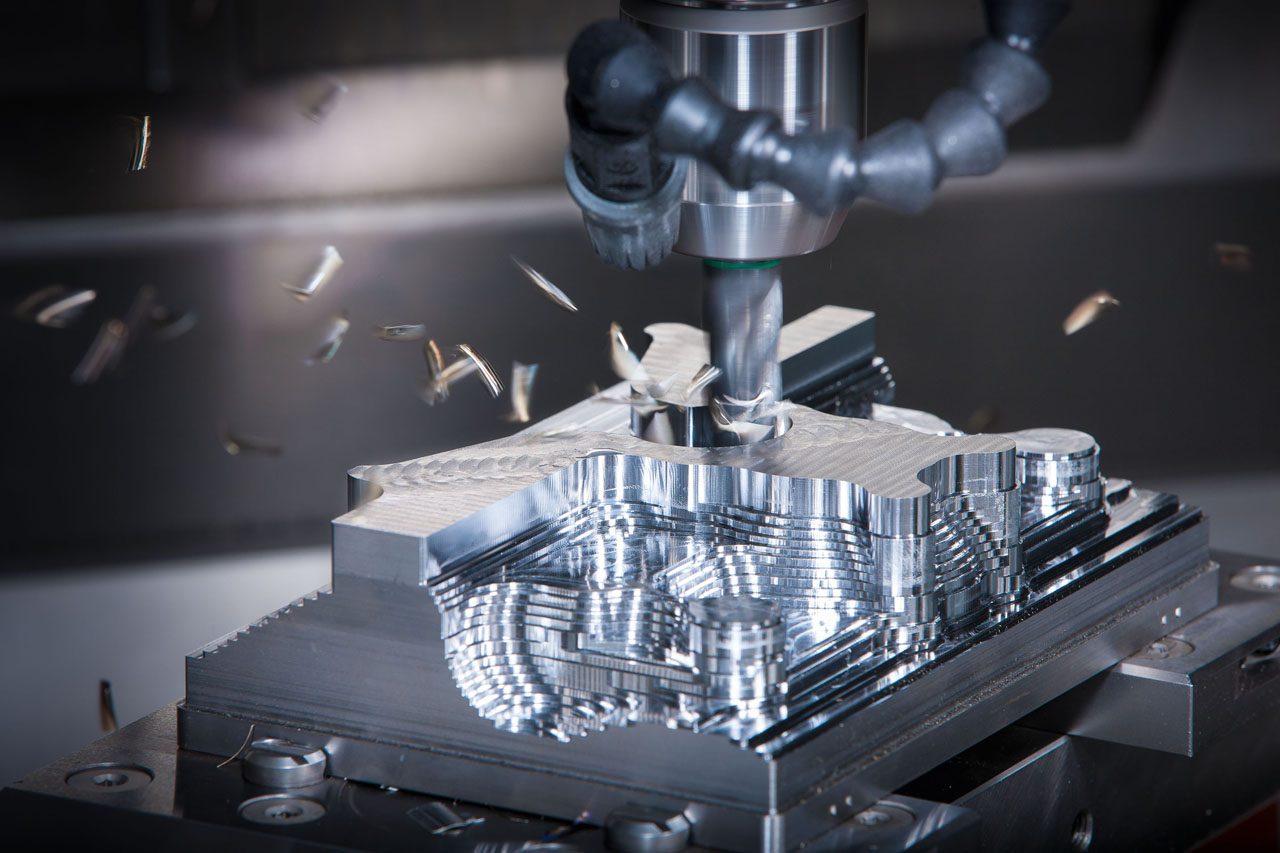

Precision in injection moulding begins with the creation of the mould itself. A high-performance mould must maintain dimensional stability under extreme thermal and mechanical stress, ensuring repeatable accuracy across thousands—or even millions—of cycles. At Lead Precision, our engineering team employs advanced CNC machining, electrical discharge machining (EDM), and laser measurement systems to fabricate moulds with tolerances as tight as ±0.002 mm. This level of control is not merely a technical achievement; it is a necessity for clients whose applications demand flawless performance under rigorous operational conditions.

Our experience in delivering precision components for Olympic-grade equipment and military-grade systems underscores our capability to meet the most exacting standards. These projects required not only adherence to strict dimensional specifications but also full traceability, rigorous material certification, and compliance with international quality protocols such as ISO 9001 and AS9100. The same engineering rigor is applied to every injection moulding service we provide, ensuring that each component performs exactly as designed, every time.

Beyond dimensional accuracy, precision also encompasses material consistency, gate placement, cooling channel design, and process control. At Lead Precision, we utilize real-time monitoring systems and statistical process control (SPC) to maintain optimal injection parameters, minimizing variability and preventing defects such as warping, sink marks, or short shots. This holistic approach to precision engineering ensures high yield rates and superior part quality, reducing total cost of ownership for our clients.

We support a wide range of engineering-grade thermoplastics and specialized alloys, enabling us to tailor material properties to specific environmental and mechanical demands. Whether producing lightweight structural components for unmanned systems or high-wear inserts for industrial tooling, our injection moulding services are engineered for performance and reliability.

Key Injection Moulding Specifications at Wuxi Lead Precision Machinery

| Parameter | Capability |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.025 mm |

| Mould Life | Up to 1,000,000 cycles (depending on material and design) |

| Part Weight Range | 0.1 g to 2,500 g |

| Clamping Force | Up to 3,500 tons |

| Materials Supported | ABS, PC, POM, PEEK, Nylon, Liquid Silicone, Metal Injection Moulding (MIM) |

| Secondary Operations | CNC finishing, ultrasonic welding, laser marking, assembly |

| Quality Standards | ISO 9001, ISO 13485, AS9100 (available on request) |

At Wuxi Lead Precision Machinery, precision is not a feature—it is the foundation. Our injection moulding services are engineered to deliver uncompromising quality, enabling our global partners to build better, perform higher, and innovate with confidence.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Injection Moulding Applications

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal manufacturing, specifically engineered to meet the stringent demands of high-performance injection moulding services. Our core strength lies in advanced multi-axis machining, forming the foundation for mould bases, cavities, cores, and intricate inserts that define mould longevity and part consistency. We deploy state-of-the-art 5-axis CNC machining centers, primarily Makino a500Z and similar high-rigidity platforms. This technology enables the complete machining of complex geometries in a single setup, eliminating cumulative errors inherent in multi-operation workflows. Critical benefits include superior surface integrity on contoured features, reduced lead times through minimized handling, and the ability to achieve tight tolerances on deep ribs, undercuts, and freeform surfaces essential for modern plastic part design. Material versatility spans hardened tool steels (H13, S7, 420SS), pre-hardened P20, aluminum alloys for prototypes, and specialty materials like beryllium copper for thermal management inserts.

Precision is non-negotiable in mould making. Our quality control protocol is anchored by comprehensive Coordinate Measuring Machine (CMM) inspection using Zeiss CONTURA G2 and similar metrology-grade systems. Every critical dimension, geometric feature, and positional relationship on mould components undergoes rigorous verification against the master CAD model. This systematic approach ensures dimensional accuracy, geometric conformity (flatness, roundness, profile), and precise feature alignment – directly translating to reduced mould tryout cycles, consistent cavity filling, and elimination of part warpage or flash issues in production. Surface finish verification is equally critical; we meticulously measure and control Ra values through a combination of precision milling, EDM finishing, and hand polishing protocols, tailored to the specific polymer and part aesthetic requirements.

Our commitment to dimensional excellence is quantifiable. The following table details the typical tolerance capabilities achievable across common mould component features and materials under controlled production conditions. These specifications represent our standard for critical mould elements; tighter tolerances are attainable for specific features upon engineering review.

| Feature Type | Material Condition | Dimensional Tolerance | Positional Tolerance | Surface Roughness (Ra) | Flatness (per 100mm) |

|---|---|---|---|---|---|

| Core/Cavity Features | Hardened Steel | ±0.005 mm | ±0.008 mm | 0.4 – 0.8 µm | 0.005 mm |

| Mold Base Components | Pre-hardened Steel | ±0.010 mm | ±0.015 mm | 1.6 – 3.2 µm | 0.010 mm |

| Precision Alignment | All Steels | – | ±0.003 mm | – | – |

| Cooling Channels | All Steels | ±0.020 mm (Dia) | ±0.05 mm (Location) | 3.2 µm | – |

| EDM Surfaces | Hardened Steel | ±0.005 mm | ±0.010 mm | 0.8 – 1.6 µm | 0.008 mm |

This disciplined integration of advanced 5-axis CNC machining, rigorous CMM-based metrology, and deep process expertise ensures that every mould component we produce meets the exacting standards required for high-cavitation, long-life injection moulding tools. We translate complex design intent into tangible, reliable manufacturing capability, providing our clients with moulds that deliver exceptional part quality, reduced cycle times, and maximum uptime throughout the production lifecycle. Precision isn’t just a specification; it’s the core of our manufacturing philosophy.

Material & Finish Options

Material Selection for High-Precision Injection Moulding Tools

Selecting the appropriate material for injection moulding tools is critical to ensuring durability, precision, and cost-efficiency in high-volume production environments. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for injection moulding applications, leveraging advanced CNC machining and metallurgical expertise to deliver tooling solutions tailored to your operational demands. The most commonly used materials in our tooling systems are aluminum, steel, and titanium, each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum is often the preferred choice for prototype tooling and low-to-medium volume production runs. Its excellent thermal conductivity allows for faster cooling cycles, reducing overall cycle times. Additionally, aluminum is easier to machine than steel or titanium, which translates into shorter lead times and lower tooling costs. However, due to its lower hardness and wear resistance, aluminum is less suitable for long production runs involving abrasive or glass-filled resins.

Steel, particularly pre-hardened and tool-grade steels such as P20, H13, and S136, is the standard for high-volume injection moulding. These steels offer superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. Steel moulds can withstand thousands to millions of cycles, making them ideal for automotive, medical, and consumer electronics applications where consistency and longevity are paramount. While initial tooling costs are higher and machining times longer, the extended service life of steel justifies the investment in high-throughput environments.

Titanium, though less common in standard mould construction, is utilized in specialized applications requiring exceptional strength-to-density ratio and corrosion resistance. Its use is typically limited to critical mould components such as inserts or cores exposed to aggressive environments or where weight reduction is essential. Titanium’s high cost and challenging machinability restrict its use to niche applications, but its performance in extreme conditions is unmatched.

Surface finishing plays a crucial role in part quality and mould maintenance. Anodizing is a widely adopted post-machining treatment, especially for aluminum moulds. This electrochemical process enhances surface hardness, improves wear resistance, and provides excellent corrosion protection. Decorative or functional anodized finishes can also be applied to control surface texture and reduce part adhesion, facilitating smoother ejection and reducing cycle times.

Below is a comparative overview of key material properties relevant to injection moulding tooling:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Machinability | Corrosion Resistance |

|---|---|---|---|---|---|

| Aluminum (7075) | 15–20 | 130–150 | Prototypes, low-volume production | Excellent | Moderate (improved with anodizing) |

| Steel (P20) | 28–32 | 28–30 | Medium to high-volume production | Good | Low to moderate |

| Steel (H13) | 48–52 | 25–28 | High-stress, high-temperature applications | Moderate | Moderate |

| Steel (S136) | 50–54 | 20–22 | Corrosion-resistant, precision moulds | Moderate | High |

| Titanium (Ti-6Al-4V) | 36–40 | 6–7 | Specialized inserts, corrosive environments | Poor | Excellent |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production goals, resin type, and environmental exposure, ensuring optimal performance and return on investment.

Manufacturing Process & QC

Precision Injection Moulding: The Wuxi Lead Zero-Defect Production Process

At Wuxi Lead Precision Machinery, our custom metal injection moulding services transcend standard manufacturing through a rigorously controlled, integrated production process designed for absolute quality assurance. We eliminate defects at the source, ensuring every component meets the most stringent aerospace, medical, and industrial specifications. This begins with deep collaborative engineering during the Design phase. Our team works directly with your CAD models, applying decades of metallurgical and flow dynamics expertise. We conduct advanced Moldflow simulations to predict material behavior, identify potential stress points, and optimize gate locations and cooling channels before tooling commences. This upfront virtual validation prevents costly physical iterations and guarantees the design is manufacturable to micron-level tolerances under real-world production conditions.

Prototyping is not merely a formality at Wuxi Lead; it is the critical validation checkpoint for Zero Defects. Using the same hardened steel production tooling intended for full-scale runs, we manufacture initial batches under actual process parameters. Every prototype undergoes comprehensive metrology: CMM verification against nominal CAD data, microstructural analysis for material integrity, and functional testing for critical features like thread engagement or sealing surfaces. We measure thermal stability and dimensional consistency across multiple cycles. Only when all prototypes consistently pass our multi-point inspection protocol – exceeding typical industry AQL standards – does the process advance. This phase confirms the tooling performs flawlessly and establishes the definitive process window for mass production.

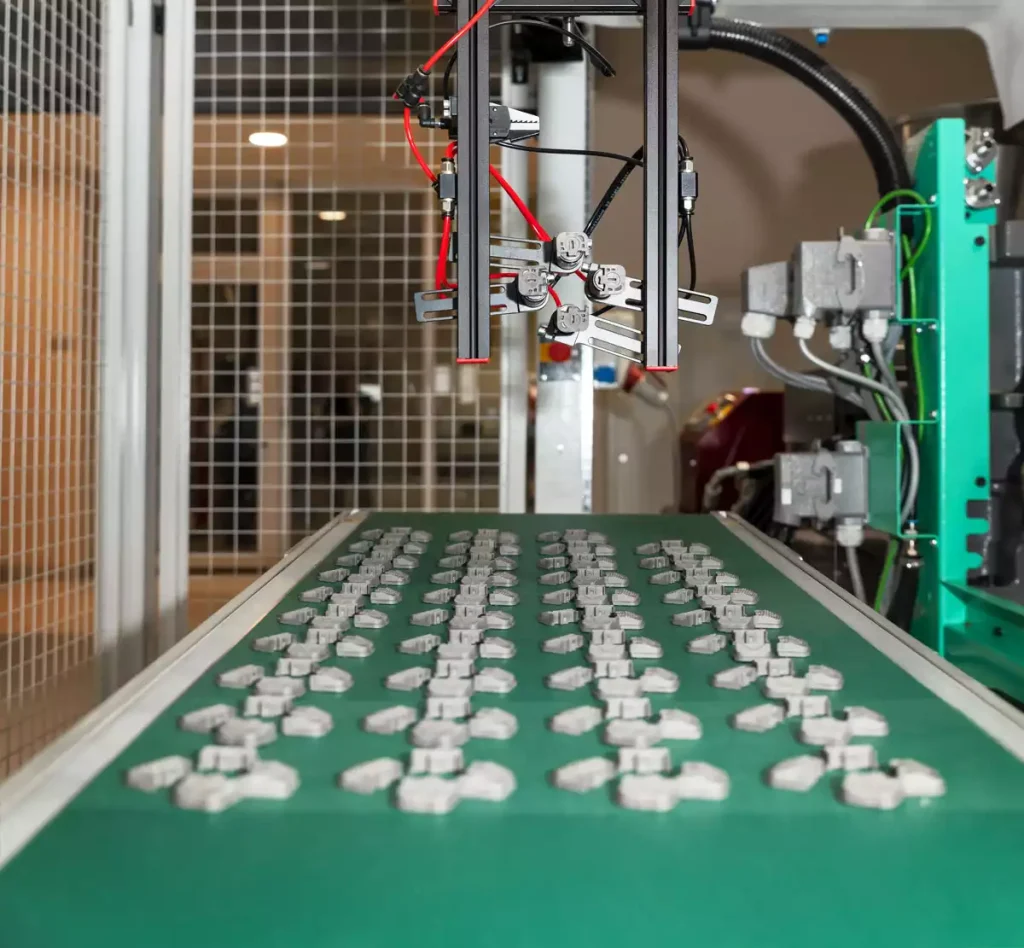

Mass Production executes with unwavering adherence to the validated parameters, underpinned by real-time process control. Our state-of-the-art presses integrate in-mold sensors monitoring cavity pressure, temperature, and fill time with millisecond precision. Data is continuously analyzed against the golden prototype baseline; any deviation triggers immediate corrective action, preventing non-conforming parts from progressing. Statistical Process Control (SPC) charts are maintained for every critical dimension, ensuring process capability (CpK > 1.67) is sustained. Final inspection employs automated vision systems alongside manual expert checks, with full traceability from raw material lot to finished part. This closed-loop system, combined with our ISO 9001 and IATF 16949 certified quality management, delivers true Zero Defects performance at scale.

Wuxi Lead Metal Injection Moulding Capabilities

| Parameter | Specification Detail | Quality Impact |

|---|---|---|

| Material Range | 17-4PH, 316L, 420F, Custom Alloys | Biocompatibility, Corrosion Resistance |

| Tolerance Capability | ±0.005 mm (critical features) | Precision Fit, Functional Reliability |

| Max Part Weight | 250 grams | Complex Geometry Support |

| Production Volume | 10,000 to 1,000,000+ parts | Scalable Zero-Defect Assurance |

| Process Monitoring | Real-time Cavity Pressure, Temp, Fill Time | Immediate Defect Prevention |

| Secondary Operations | CNC Machining, Laser Welding, Passivation | Integrated Precision Finishing |

This seamless transition from validated design through rigorously confirmed prototyping to tightly controlled mass production forms the cornerstone of Wuxi Lead’s commitment to defect-free delivery. We transform complex metal component requirements into manufactured reality with uncompromising quality and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Moulding Services That Deliver Precision, Reliability, and Speed

At Wuxi Lead Precision Machinery, we understand that in high-end manufacturing, consistency, precision, and on-time delivery are not just expectations—they are requirements. As a trusted leader in custom metal manufacturing based in Wuxi, China, we specialize in advanced injection moulding services tailored to meet the exacting standards of industries such as automotive, medical devices, aerospace, and industrial automation. When you partner with us, you’re not just outsourcing production—you’re gaining a strategic manufacturing ally with deep engineering expertise and a commitment to excellence.

Our injection moulding capabilities are built on state-of-the-art technology and decades of hands-on experience. We operate a fully integrated production floor equipped with high-precision electric and hybrid injection moulding machines, in-house tooling design, and real-time quality monitoring systems. From prototype development to high-volume production runs, we ensure every component meets tight tolerances, material specifications, and surface finish requirements. Our team of engineers works closely with clients from design validation through final delivery, providing DFM analysis, material selection guidance, and process optimization to reduce costs and accelerate time-to-market.

What sets Lead Precision apart is our end-to-end control over the manufacturing process. We design and build our own moulds using premium-grade steels and advanced CNC machining, ensuring longevity and repeatability. Our cleanroom-compatible production lines support medical-grade components, while our quality management system is aligned with ISO 9001 standards, with full traceability and inspection reporting available for every batch.

We serve global clients who demand more than just parts—they demand partnership, transparency, and performance. Whether you require micro-moulding for intricate components or large-scale production with multi-material overmoulding, our facility is equipped to handle complex challenges with agility and precision.

Below are key specifications that define our injection moulding capabilities:

| Specification | Detail |

|---|---|

| Clamping Force Range | 50 to 1,200 tons |

| Shot Weight Capacity | 1g to 3,500g |

| Tolerance Capability | ±0.005 mm |

| Materials Supported | ABS, PC, POM, PA (Nylon), PBT, PPS, PEEK, TPE, Liquid Silicone Rubber (LSR), and medical-grade resins |

| Mould Base Standards | HASCO, DME, or custom |

| Secondary Operations | Ultrasonic welding, insert moulding, heat staking, laser marking, assembly |

| Quality Standards | ISO 9001:2015, full first-article inspection (FAI), SPC process control |

Partnering with Lead Precision means gaining access to a manufacturing partner that combines technical mastery with responsive service. We communicate clearly, meet deadlines consistently, and prioritize continuous improvement in every project.

Contact us today at [email protected] to discuss your next injection moulding project. Let our team help you turn design intent into precision reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.