Technical Contents

Engineering Guide: Injection Moulding Service

Engineering Insight: The Critical Role of Precision in Injection Moulding Services

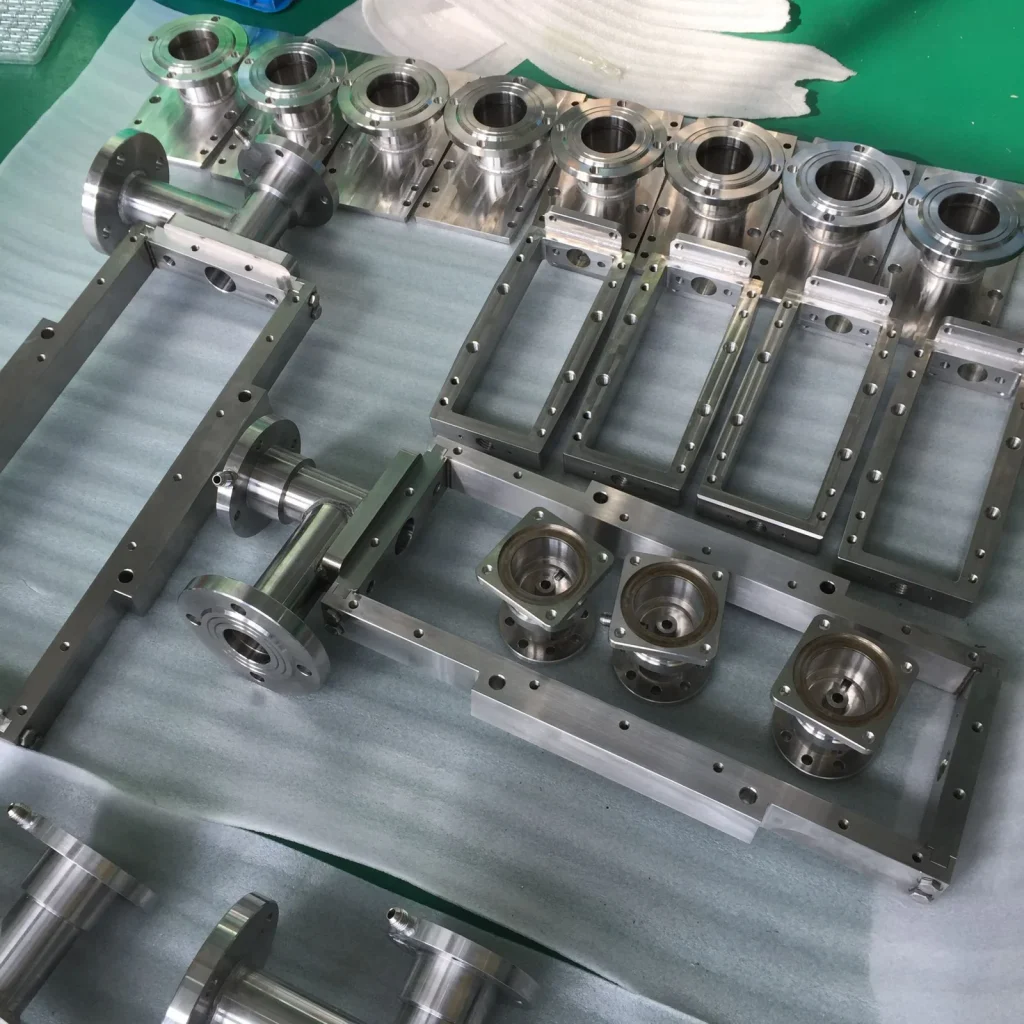

In high-end custom metal manufacturing, injection moulding services are not merely about shaping materials—they are a testament to engineering excellence, where micron-level tolerances define product integrity, performance, and longevity. At Wuxi Lead Precision Machinery, we understand that precision is not an outcome but a systematically engineered process, especially when serving sectors such as aerospace, defense, and high-performance industrial equipment. Our injection moulding services are built on decades of metallurgical expertise and advanced CNC-integrated tooling, ensuring that every component meets the most stringent quality benchmarks.

Precision in injection moulding begins with material science. The selection of high-grade alloys, combined with controlled thermal processing, ensures dimensional stability and resistance to mechanical stress. At Lead Precision, we utilize proprietary alloy blends tailored to specific application demands, from extreme temperature resilience to high-impact durability. This scientific approach is reinforced by real-time monitoring systems during the injection cycle, which regulate pressure, temperature, and cooling rates to eliminate warping, sink marks, or internal voids.

Our engineering team leverages finite element analysis (FEA) and mold flow simulation to predict and optimize material behavior before a single shot is molded. This predictive capability reduces prototyping cycles and accelerates time-to-market—critical advantages in defense logistics and Olympic-grade equipment manufacturing, where we have delivered mission-critical components under tight regulatory scrutiny.

Wuxi Lead Precision Machinery’s proven track record includes supplying precision-molded metal components for Chinese military-grade communication housings and structural elements in equipment used during the Beijing Winter Olympics. These projects demanded not only flawless repeatability but also full traceability, ISO 9001:2015 compliance, and third-party validation. Our facility operates under Class 10,000 cleanroom conditions for sensitive molding operations, ensuring particulate-free production environments.

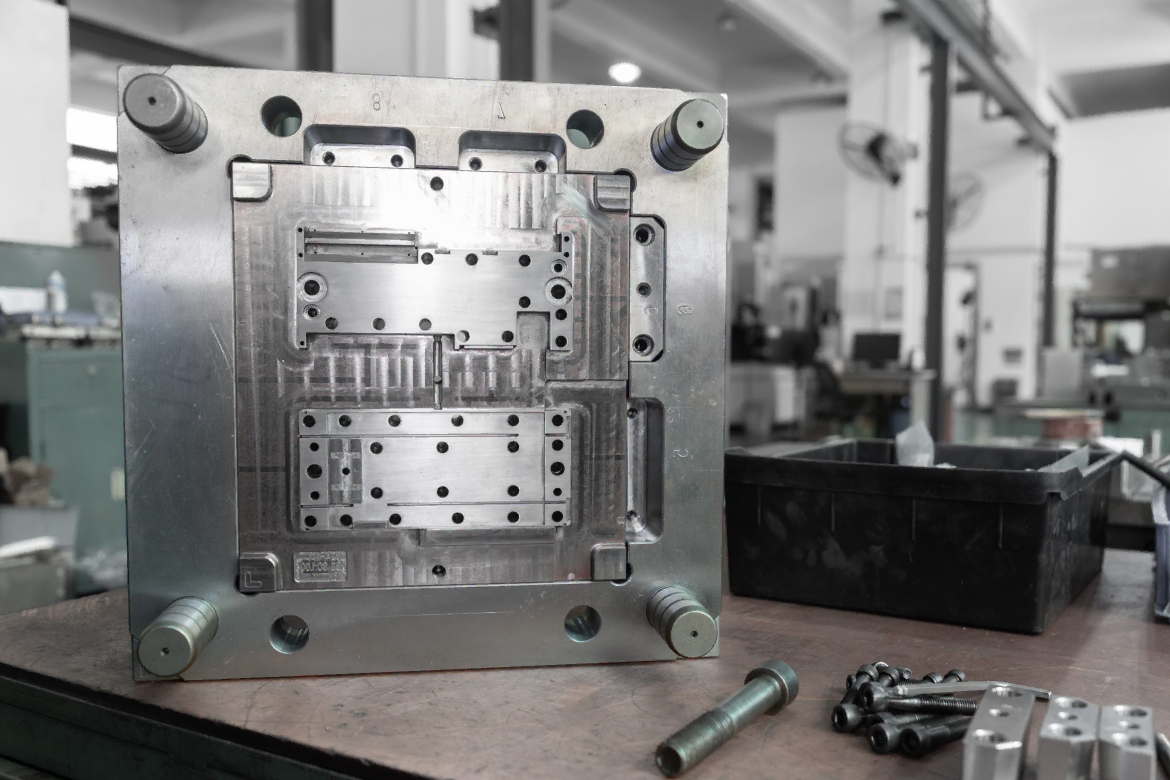

What sets our injection moulding service apart is the integration of custom tooling design with in-house CNC machining. Unlike standard service providers, we design and manufacture molds with hardened P20 and H13 steels, surface-treated via nitriding or chrome plating to extend mold life beyond 500,000 cycles. This vertical integration allows us to maintain full control over tolerances, surface finish, and production scalability.

The following table outlines the technical specifications achievable through our advanced injection moulding process:

| Parameter | Capability |

|---|---|

| Material Types | Stainless Steel (316L, 17-4PH), Titanium Alloys, Tool Steels |

| Tolerance Range | ±0.005 mm to ±0.02 mm |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm (polished/matte) |

| Part Weight Range | 1 g to 500 g |

| Mold Life | Up to 500,000 cycles |

| Production Capacity | 10,000 to 500,000 units/month |

| Standards Compliance | ISO 9001:2015, MIL-STD-810, RoHS |

Precision is not an option in critical applications—it is a requirement. At Wuxi Lead Precision Machinery, we engineer every injection moulded component as if it were destined for the front lines or the podium.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Injection Mould Applications

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal manufacturing for high-performance injection mould components. Our core strength lies in advanced multi-axis machining integrated with rigorous metrology, ensuring mould bases, cavities, cores, and intricate inserts meet the exacting demands of complex plastic part production. This capability directly translates to reduced cycle times, minimized part defects, and extended mould life for our clients.

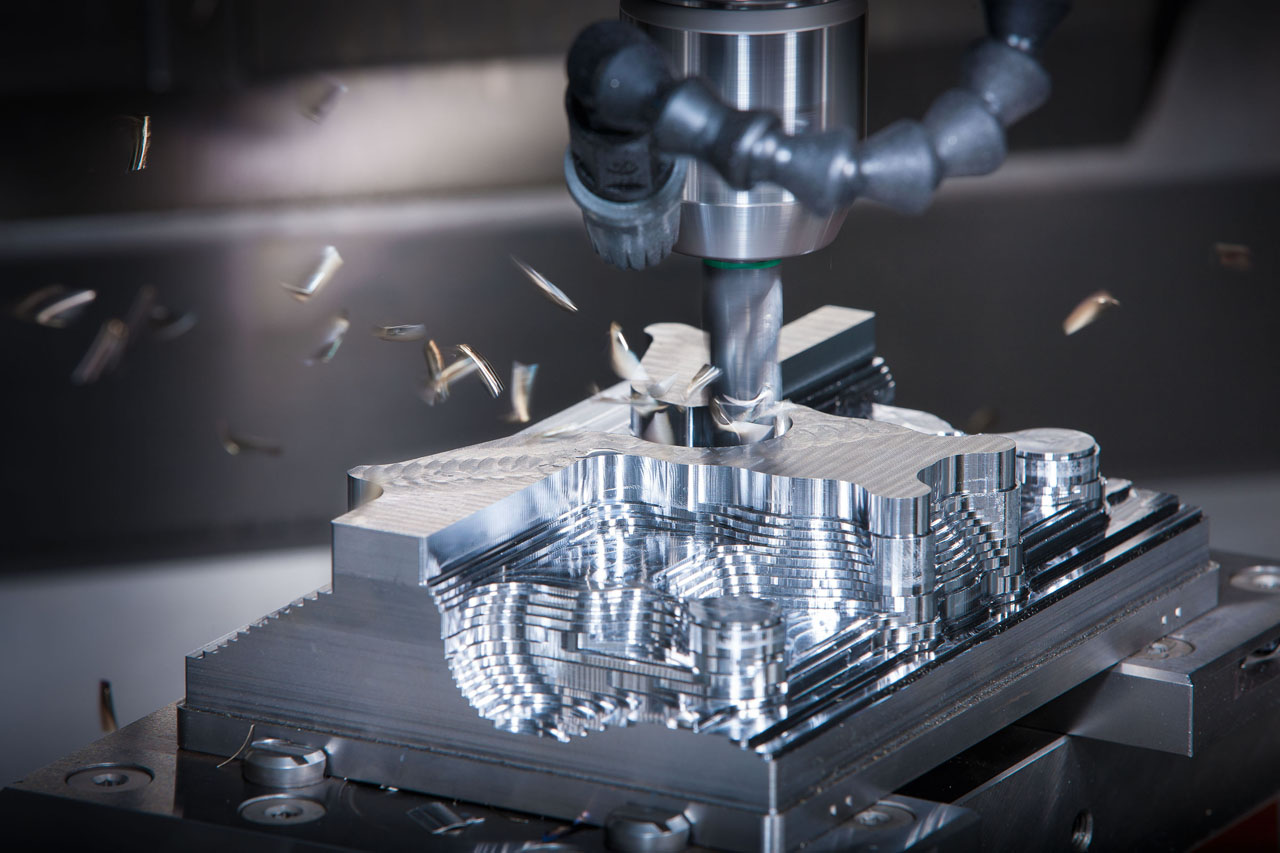

Central to our process is a dedicated fleet of state-of-the-art 5-axis CNC machining centers. These systems provide simultaneous multi-directional tool movement, enabling the efficient production of highly complex geometries within single setups. This eliminates cumulative errors from multiple fixturing operations, critical for maintaining tight positional relationships across intricate mould features like undercuts, conformal cooling channels, and organic surface contours. Our programming and machining protocols are optimized specifically for mould steel and pre-hardened alloys, ensuring superior surface finishes and dimensional stability essential for high-cavity-count and micro-moulding applications.

Quality verification is not a final step but an integrated process. Every critical dimension undergoes stringent inspection using calibrated Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMMs, operating in a climate-controlled metrology lab, provide traceable, sub-micron level measurement accuracy. We perform comprehensive GD&T analysis, full 3D surface comparison against CAD models, and detailed reporting for all critical features. This systematic approach guarantees that every component adheres precisely to the engineering specifications, significantly reducing assembly errors and in-mould fit issues.

The following table details our standard machining tolerances for injection mould components. These values represent achievable performance for typical part sizes and materials under controlled production conditions. Tighter tolerances are attainable for critical features through specialized processes and enhanced inspection protocols.

| Feature Type | Standard Tolerance | Critical Feature Tolerance |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm |

| Hole Position | ±0.015 mm | ±0.008 mm |

| Hole Diameter | H7 / h7 | H6 / h6 |

| Flatness | 0.020 mm / 100 mm | 0.010 mm / 100 mm |

| Perpendicularity | 0.020 mm | 0.010 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

Our technical capability extends beyond raw machine specs. It encompasses deep material science understanding, thermal stability management during machining, and proactive collaboration with mould designers to optimize manufacturability. By combining 5-axis precision, CMM-validated quality control, and process expertise, Wuxi Lead ensures your injection moulds achieve maximum productivity and part consistency from the first shot. Partner with us for mould components where dimensional integrity is non-negotiable.

Material & Finish Options

Material Selection for Injection Moulding Tools and Components

Selecting the appropriate material for injection moulding tools and precision components is critical to ensuring performance, durability, and cost-efficiency in high-volume manufacturing. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using advanced CNC machining and tooling techniques. Our expertise enables us to guide clients through optimal material choices based on application requirements, environmental exposure, mechanical loads, and surface finish needs.

Aluminum is frequently chosen for prototype moulds and low-to-medium volume production due to its excellent machinability, thermal conductivity, and lightweight properties. Grade 7075-T6 and 6061-T6 are commonly used for injection mould bases and inserts, offering good strength-to-weight ratios and ease of modification during design iterations. While not as wear-resistant as steel, aluminum significantly reduces lead time and machining costs, making it ideal for rapid development cycles.

Steel remains the standard for high-volume injection moulding applications where durability and wear resistance are paramount. Tool steels such as P20, H13, and S136 offer superior hardness, polishability, and resistance to thermal fatigue. P20 is widely used for mould cores and cavities in general-purpose applications, while H13 excels in hot environments due to its excellent heat resistance. For corrosive environments or clear optical parts requiring high surface clarity, stainless variants like S136 provide enhanced corrosion resistance and mirror-like polishability.

Titanium, though less common in standard mould construction, is selected for specialized applications requiring extreme strength-to-density ratios and resistance to corrosion. Grade 5 (Ti-6Al-4V) is often used in aerospace and medical components where weight savings and biocompatibility are essential. While titanium’s high cost and challenging machinability limit its use in large-scale tooling, it plays a vital role in high-performance end-use parts produced via insert moulding or overmoulding processes.

Surface finishing, particularly anodizing, plays a significant role in enhancing the functional and aesthetic qualities of aluminium components. Type II (sulfuric acid) anodizing improves corrosion and wear resistance while allowing for color dyeing, beneficial for consumer-facing parts. Type III (hardcoat) anodizing delivers a thicker, harder ceramic layer suitable for industrial components exposed to abrasion. Anodized surfaces also provide electrical insulation and better adhesion for paint primers.

Below is a comparative overview of key material properties relevant to injection moulding service applications.

| Material | Typical Grade | Hardness (HRC) | Tensile Strength (MPa) | Key Advantages | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 / 7075-T6 | 15–30 HB | 310–570 | Lightweight, high thermal conductivity | Prototype moulds, low-volume tools |

| Tool Steel | P20 / H13 / S136 | 28–52 HRC | 900–1,200 | High wear resistance, polishability | High-volume production moulds |

| Titanium | Ti-6Al-4V | 36–40 HRC | 900–1,000 | High strength-to-weight, corrosion resistance | Aerospace, medical components |

Material and finish selection directly impacts tool life, part quality, and production economics. At Wuxi Lead Precision Machinery, we collaborate closely with engineers to match material properties with project specifications, ensuring optimal performance and value.

Manufacturing Process & QC

Production Process Excellence: From Concept to Zero Defects Fulfillment

At Wuxi Lead Precision Machinery, our injection moulding service transcends basic manufacturing. We deliver mission-critical metal components through a rigorously controlled, three-phase production process engineered for absolute precision and Zero Defects outcomes. This integrated approach ensures your complex geometries meet the most demanding aerospace, medical, and industrial specifications, batch after batch.

Design Phase: Engineering Success from the Start

Success begins with flawless design integration. Our engineering team collaborates closely with your designers during the initial concept stage. Utilizing advanced 3D CAD/CAM software and sophisticated mould flow simulation tools, we conduct comprehensive Design for Manufacturability (DFM) analysis. This proactive step identifies potential challenges like material flow issues, weld lines, or sink marks before tooling commences. We optimize gate locations, cooling channel layouts, and part geometry to ensure structural integrity, dimensional stability, and seamless manufacturability. This deep engineering collaboration establishes the critical foundation for achieving micron-level tolerances and eliminating root causes of defects early in the cycle.

Prototyping Phase: Validating Precision Under Real Conditions

Moving beyond simple sample parts, our prototyping phase is a critical validation gate. We employ high-precision CNC-machined prototype tools or initial production moulds to create functional parts using your specified metal alloy under actual production parameters. Every prototype undergoes exhaustive metrology-grade inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers against the original CAD model and your stringent requirements. Material properties, dimensional accuracy, and surface finish are meticulously verified. This phase is not merely about producing a sample; it is a rigorous stress test of the entire process design, confirming that the proposed manufacturing solution will consistently yield defect-free components at scale. Any deviations trigger immediate engineering feedback loops for correction.

Mass Production Phase: Sustained Zero Defects Execution

Transitioning to volume production, our commitment to Zero Defects is operationalized through unparalleled process control. Each mould cavity is monitored in real-time using integrated cavity pressure sensors and temperature controls. Automated in-process inspection systems, including vision systems and laser micrometers, continuously verify critical dimensions during the cycle. Statistical Process Control (SPC) charts track key parameters like clamp force, injection speed, and cooling time, enabling predictive adjustments before drift occurs. Every production run adheres strictly to validated process windows established during prototyping. Final inspection employs AQL sampling plans aligned with ISO 13485 or AS9100 standards, utilizing our full metrology lab. This closed-loop system, combining cutting-edge automation with deep engineering oversight, guarantees consistent output where every part meets specification, eliminating scrap and rework.

The table below summarizes the critical specifications and controls defining each phase of our Zero Defects process:

| Phase | Key Activities | Tolerance Range (Typical) | Validation Method |

|---|---|---|---|

| Design | DFM Analysis, Mould Flow Simulation, Tool Design | N/A (Process Definition) | Simulation Reports, Engineering Sign-off |

| Prototyping | Functional Part Production, Material Testing | ±0.005 mm to ±0.025 mm | CMM, Optical Comparator, Material Certs |

| Mass Production | Real-time Cavity Monitoring, SPC, Automated Inspection | ±0.002 mm to ±0.015 mm | In-Process SPC, Final AQL Inspection |

Wuxi Lead Precision Machinery’s integrated process delivers more than parts; it delivers certainty. By embedding Zero Defects principles from initial design through high-volume production, we ensure your supply chain operates with unmatched reliability and quality. Partner with us for injection moulding where precision is non-negotiable.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Injection Moulding Excellence

At Wuxi Lead Precision Machinery, we don’t just provide injection moulding services—we deliver precision-engineered manufacturing solutions tailored to the exacting demands of high-performance industries. As a trusted leader in custom metal manufacturing based in China, we specialize in integrating advanced injection moulding capabilities with precision CNC machining, die casting, and comprehensive quality assurance protocols. Our clients span aerospace, medical devices, automotive, and industrial automation—sectors where tolerance, repeatability, and material integrity are non-negotiable.

When you partner with Lead Precision, you gain more than a supplier; you align with a team of engineering experts committed to your product’s success from concept to full-scale production. Our injection moulding services are designed for complexity and precision, supporting both low-volume prototyping and high-volume manufacturing runs with equal rigor. We utilize state-of-the-art electric and hybrid injection moulding machines, capable of handling engineering-grade thermoplastics with tight tolerances down to ±0.005 mm. Our in-house tooling department ensures rapid mold development, while our ISO 9001-certified processes guarantee consistency and traceability across every production batch.

Material selection is critical in injection moulding, and our engineering team collaborates closely with clients to choose resins that meet thermal, mechanical, and regulatory requirements—whether it’s PEEK for aerospace components, medical-grade polycarbonate for surgical devices, or reinforced nylon for automotive connectors. We also offer overmolding, insert molding, and two-shot molding solutions for complex multi-material assemblies.

Our facility is equipped with real-time process monitoring, automated quality inspection using CMM and optical measurement systems, and rigorous environmental testing to validate performance under extreme conditions. This end-to-end control ensures that every molded part meets the highest standards of dimensional accuracy, surface finish, and structural integrity.

Below are key technical specifications that define our injection moulding capabilities.

| Specification | Capability |

|---|---|

| Clamping Force Range | 50 to 1,200 tons |

| Shot Weight Capacity | Up to 3,500 grams |

| Tolerance | ±0.005 mm (typical) |

| Material Types | ABS, PC, POM, PEEK, PA6/PA66, PP, PE, PMMA, LCP, and filled variants |

| Mold Fabrication | In-house steel and aluminum molds, hardened and pre-hardened steels |

| Secondary Operations | CNC trimming, ultrasonic welding, pad printing, assembly |

| Quality Standards | ISO 9001, RoHS, REACH compliant |

We understand that your success depends on precision, reliability, and speed to market. At Wuxi Lead Precision Machinery, we are built to support your most demanding injection moulding challenges with engineering depth and manufacturing excellence.

Contact us today to discuss your next project. Reach out to our engineering team at [email protected] and discover how Lead Precision can become your strategic manufacturing partner in China.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.