Technical Contents

Engineering Guide: Injection Moulding Recruitment

Engineering Insight: The Critical Role of Precision in Injection Moulding Recruitment

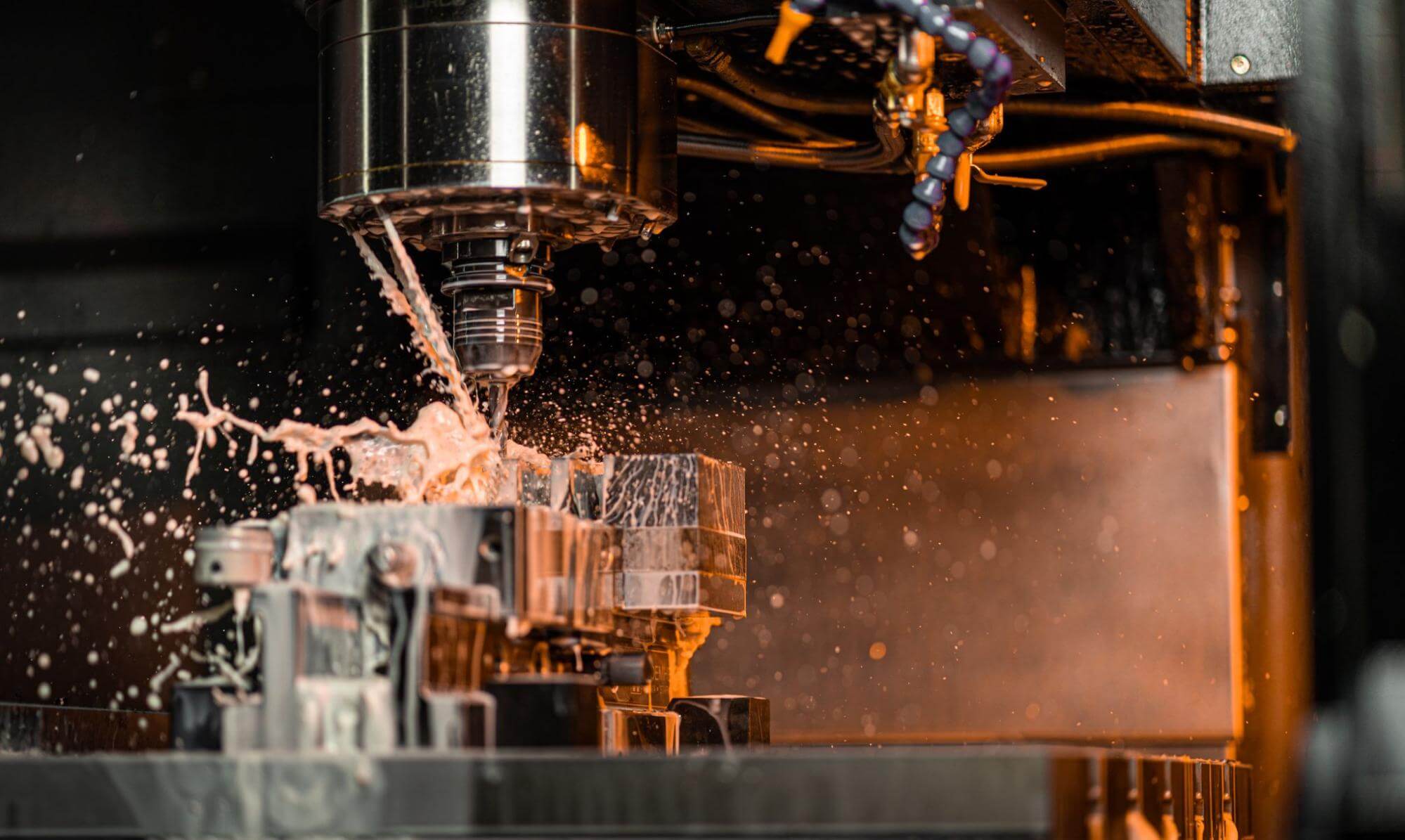

In the highly specialized field of custom metal manufacturing, particularly within injection moulding, the recruitment of skilled engineering personnel is not merely a human resources function—it is a strategic imperative. At Wuxi Lead Precision Machinery, we understand that precision begins not with machines, but with people. The engineers, toolmakers, and process specialists we bring into our organization directly influence the tolerances, repeatability, and reliability of every mould we produce. In industries where a deviation of a few microns can lead to system failure—such as aerospace, medical devices, or defense—the margin for error is effectively zero.

Injection moulding for high-performance applications demands more than technical proficiency. It requires a deep-rooted culture of precision, honed through experience and reinforced by rigorous standards. This is why our recruitment strategy emphasizes not only formal qualifications but also hands-on expertise in high-tolerance machining, material science, and thermodynamic process control. We seek individuals who have demonstrated success in environments where consistency under pressure is non-negotiable.

Our own track record reflects this commitment. Wuxi Lead Precision Machinery has supplied critical components for applications in Olympic-standard sports equipment and military-grade hardware—sectors where failure is not an option. These projects demanded not only state-of-the-art CNC and EDM capabilities but also a team capable of maintaining tolerances down to ±0.002 mm across complex geometries. Achieving such results requires engineers who are fluent in both the theoretical and practical aspects of injection mould design, from gate placement to cooling channel optimization.

Recruiting for precision also means investing in continuous development. At Lead Precision, we maintain an internal training framework that ensures all technical staff stay current with advancements in simulation software, multi-axis machining, and quality assurance protocols such as GD&T and ISO 13041 standards. This culture of excellence is embedded from day one, ensuring that every team member contributes to our reputation for delivering mission-critical components on time and to exacting specifications.

The following table outlines key precision specifications consistently achieved across our injection moulding projects:

| Specification | Standard Performance | Measurement Method |

|---|---|---|

| Linear Tolerance | ±0.002 mm | Laser Interferometry |

| Surface Roughness (Ra) | 0.05 – 0.2 µm | Profilometer Analysis |

| Parallelism | 0.003 mm over 100 mm | Coordinate Measuring Machine (CMM) |

| Mold Alignment | ≤ 0.005 mm shift | Optical Alignment System |

| Thermal Stability | ±0.5°C control | Infrared Thermography |

In high-end manufacturing, the right hire doesn’t just fill a position—they elevate the entire operation. At Wuxi Lead Precision Machinery, we recruit with the understanding that precision is a collective discipline, built one expert at a time.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Injection Mould Excellence

At Wuxi Lead Precision Machinery, our core strength in custom metal manufacturing for the injection moulding industry is built upon advanced technical capabilities that directly address the demanding precision requirements of modern mould production. We understand that the performance, longevity, and part quality of an injection mould are fundamentally determined by the accuracy and surface integrity of its critical metal components. Our dedicated facility leverages state-of-the-art equipment and rigorous quality protocols to consistently deliver mould bases, cavities, cores, inserts, and precision components meeting the most stringent specifications demanded by global automotive, medical, and consumer electronics manufacturers.

Central to our precision machining capability is our fleet of high-performance 5-axis CNC machining centers. These advanced systems enable us to manufacture complex geometries inherent in modern mould designs with exceptional efficiency and accuracy, eliminating multiple setups and minimizing cumulative error. This capability is essential for producing intricate cooling channels, undercuts, and freeform surfaces found in high-cavitation or family moulds, ensuring optimal thermal management and part ejection critical for production stability. Our skilled programmers and machinists utilize the latest CAD/CAM software to generate highly optimized toolpaths, maximizing material removal rates while maintaining micron-level control over critical features.

Quality assurance is not a final step but an integrated process throughout production. Every critical component undergoes comprehensive verification using Coordinate Measuring Machines (CMM) equipped with advanced probing systems and metrology software. This provides full geometric dimensioning and tolerancing (GD&T) validation against the original CAD model, ensuring dimensional integrity and form accuracy far beyond basic dimensional checks. Our CMM inspection protocols deliver traceable, data-driven verification reports, providing absolute confidence in component conformity before mould assembly. This level of metrology-grade verification is non-negotiable for achieving the tight tolerances required in high-precision injection moulding applications.

Our commitment to dimensional perfection is quantified in the achievable tolerances consistently delivered across common mould materials. The table below reflects our standard production capabilities under controlled environmental conditions, utilizing calibrated equipment and rigorous process control:

| Feature Type | Standard Tolerance (mm) | High-Precision Capability (mm) | Material Context |

|---|---|---|---|

| Linear Dimensions | ± 0.010 | ± 0.005 | P20, H13, S136, Aluminum |

| Geometric Form (Flatness, Roundness) | ± 0.010 | ± 0.003 | All Tool Steels |

| Positional Tolerance | ± 0.015 | ± 0.008 | Critical Alignment Points |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm (Polishable Base) | Cavity/ Core Finishing |

Why This Matters for Talent: Working within this environment of advanced machinery and uncompromising quality standards provides engineers and technicians with unparalleled opportunities to master complex 5-axis programming, precision measurement science, and rigorous process validation techniques. The ability to consistently achieve and verify micron-level tolerances on critical mould components is a hallmark of true precision manufacturing expertise, directly translating to superior mould performance and part quality for our clients. This technical depth defines the challenging and rewarding work our team engages in daily.

Material & Finish Options

Material selection is a critical factor in the design and manufacturing of high-performance injection moulds, directly influencing tool life, part quality, and production efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the exacting demands of precision injection moulding. Our expertise spans advanced materials such as aluminum, steel, and titanium, each offering distinct mechanical properties and performance characteristics. Selecting the optimal material depends on production volume, part complexity, thermal requirements, and cost targets.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype and low-to-medium volume production moulds. Their high thermal conductivity enables faster cooling cycles, reducing cycle times and increasing throughput. Aluminum is also easier to machine, allowing for complex geometries and tight tolerances with reduced lead times. However, its lower hardness and wear resistance make it less suitable for high-volume production runs involving abrasive materials.

Steel remains the dominant choice for high-volume injection moulding applications. Tool steels such as P20, H13, and S136 offer excellent hardness, wear resistance, and dimensional stability under repeated thermal cycling. These properties ensure long service life and consistent part quality over millions of cycles. While steel has lower thermal conductivity than aluminum, proper cooling channel design mitigates this limitation. Steel moulds are ideal for engineering-grade resins and applications requiring high surface finish and precision.

Titanium, though less common in standard mould construction, is gaining traction in specialized applications where extreme corrosion resistance, high strength-to-density ratio, and thermal stability are paramount. Its use is typically reserved for niche aerospace or medical components where performance outweighs cost considerations. Titanium’s low thermal conductivity and challenging machinability require advanced CNC capabilities and careful process planning.

Surface finishing further enhances mould performance and longevity. Anodizing is a key post-processing technique, particularly for aluminum moulds. This electrochemical process creates a durable, corrosion-resistant oxide layer that improves surface hardness and wear resistance. Type II (sulfuric acid) anodizing is commonly used for general protection and aesthetic finish, while Type III (hardcoat anodizing) provides a thicker, harder layer suitable for high-wear environments. Anodized surfaces also offer excellent adhesion for coatings and reduce friction during part ejection.

Understanding the interplay between material properties and finishing processes enables manufacturers to optimize mould performance and total cost of ownership. At Wuxi Lead Precision Machinery, we integrate material science with precision engineering to deliver mould solutions that meet the highest industrial standards.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Key Advantage |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | Prototypes, low-volume production | Fast machining, high thermal conductivity |

| P20 Steel | 28–32 | 30 | Medium to high-volume production | Balanced toughness and machinability |

| H13 Steel | 48–52 | 25 | High-stress, high-temperature moulds | Excellent thermal fatigue resistance |

| S136 Steel | 50–54 | 22 | Corrosion-resistant precision moulds | Superior polishability and durability |

| Titanium (Grade 5) | 35–40 (surface) | 7 | Specialized aerospace/medical tools | High strength-to-weight, corrosion resistance |

Manufacturing Process & QC

Process Rigor from Design to Delivery

At Wuxi Lead Precision Machinery, our precision metal component manufacturing follows a disciplined sequence ensuring zero defects from initial concept to final shipment. This methodology eliminates costly rework and guarantees compliance with aerospace, medical, and automotive sector standards. We integrate engineering expertise with real-time process control at every phase.

Design begins with collaborative CAD/CAM development using Siemens NX and Mastercam. Our engineers apply strict geometric dimensioning and tolerancing (GD&T) per ASME Y14.5, optimizing part geometry for CNC machinability while accounting for material behavior under stress. Finite element analysis (FEA) validates structural integrity early, preventing downstream failures. Critical factors like thermal expansion in titanium or aluminum alloys are modeled to ensure dimensional stability during machining. This phase concludes with a formal design for manufacturing (DFM) sign-off, confirming toolpath efficiency and fixture feasibility.

Prototyping transitions validated designs into physical components via 5-axis CNC milling and turning centers. We produce first-article samples within 72 hours using production-intent tooling and materials. Each prototype undergoes rigorous first-article inspection (FAI) per AS9102 standards, including CMM verification of all critical features, surface roughness testing, and metallurgical analysis. Dimensional data is compared against nominal CAD values, with deviations triggering immediate design or process adjustments. Only when prototypes meet 100% of specifications do we approve tooling for mass production.

Mass production leverages automated CNC cells with in-process probing and statistical process control (SPC). Every operation includes real-time tool wear monitoring and closed-loop dimensional feedback. Components undergo 100% critical feature inspection via automated optical comparators and coordinate measuring machines (CMMs), with data logged in our traceability system. Non-conforming parts are isolated before secondary operations, ensuring zero defective units reach clients. Production runs maintain CpK ≥1.67 through controlled environmental parameters and hourly SPC chart reviews.

Precision Manufacturing Specifications

| Phase | Tolerance Capability | Key Inspection Methods | Output Validation Standard |

|—————-|———————-|——————————|—————————-|

| Design | ±0.005 mm (critical) | FEA Simulation, DFM Audit | ASME Y14.5 Compliance |

| Prototyping | ±0.010 mm | CMM, Surface Profilometry | AS9102 FAI Report |

| Mass Production| ±0.008 mm | Automated CMM, SPC Charts | CpK ≥1.67, Zero Defects |

Zero defects are non-negotiable. Our integrated quality management system—certified to ISO 9001:2015 and IATF 16949—enforces traceability from raw material certs to final packaging. Each component’s machining history, inspection data, and operator logs are digitally archived for full lifecycle accountability. This end-to-end control delivers consistent yield rates above 99.8%, eliminating scrap costs and supply chain disruptions for global clients. Partner with Wuxi Lead to transform precision metal manufacturing from a production challenge into a competitive advantage.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Moulding Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and speed are non-negotiable in high-end injection moulding manufacturing. As a leading custom metal manufacturing partner based in China, we specialize in delivering engineered solutions that meet the exacting standards of global industries — from automotive and medical devices to consumer electronics and industrial automation. Our expertise in injection moulding, combined with advanced CNC machining and die-casting capabilities, positions us as a strategic extension of your engineering and production team.

We don’t just manufacture components — we engineer performance. Our integrated approach begins with collaborative design support, where our engineers work alongside yours to optimize part geometry, material selection, and manufacturability. This ensures faster time-to-market, reduced production costs, and superior part consistency. With state-of-the-art facilities and strict adherence to ISO 9001 quality standards, every product we deliver reflects our commitment to excellence.

Our injection moulding services are backed by in-house tooling development, allowing complete control over the entire production lifecycle. From prototype to high-volume production, we maintain tight tolerances, exceptional surface finishes, and full traceability. Whether you require micro-moulding for intricate medical components or large-scale structural parts, our advanced presses and automated systems ensure unmatched repeatability and efficiency.

Below are key technical capabilities that define our injection moulding and precision manufacturing services:

| Specification | Detail |

|---|---|

| Moulding Press Capacity | 50T – 1,200T |

| Maximum Part Size | 800 x 600 x 400 mm |

| Tolerance | Up to ±0.005 mm |

| Materials | ABS, PC, POM, PA (Nylon), PBT, PPS, PEEK, LCP, and filled variants |

| Secondary Operations | CNC machining, ultrasonic welding, insert moulding, surface finishing (polishing, texturing, painting) |

| Quality Standards | ISO 9001:2015 certified, full First Article Inspection (FAI), SPC process control |

| Lead Time (Prototype) | 2–4 weeks depending on complexity |

| Production Volume | Low-volume prototyping to high-volume mass production |

We pride ourselves on transparency, responsiveness, and technical depth. When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier — you gain a committed engineering ally focused on solving complex manufacturing challenges.

Contact us today to discuss your next injection moulding project. Our team is ready to support you with technical consultation, rapid quoting, and scalable production solutions tailored to your requirements.

Email us at [email protected] and discover how we can drive precision, performance, and value into your manufacturing outcomes.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.