Technical Contents

Engineering Guide: Injection Moulding Quote

Engineering Insight: The Critical Role of Precision in Injection Moulding Quotes

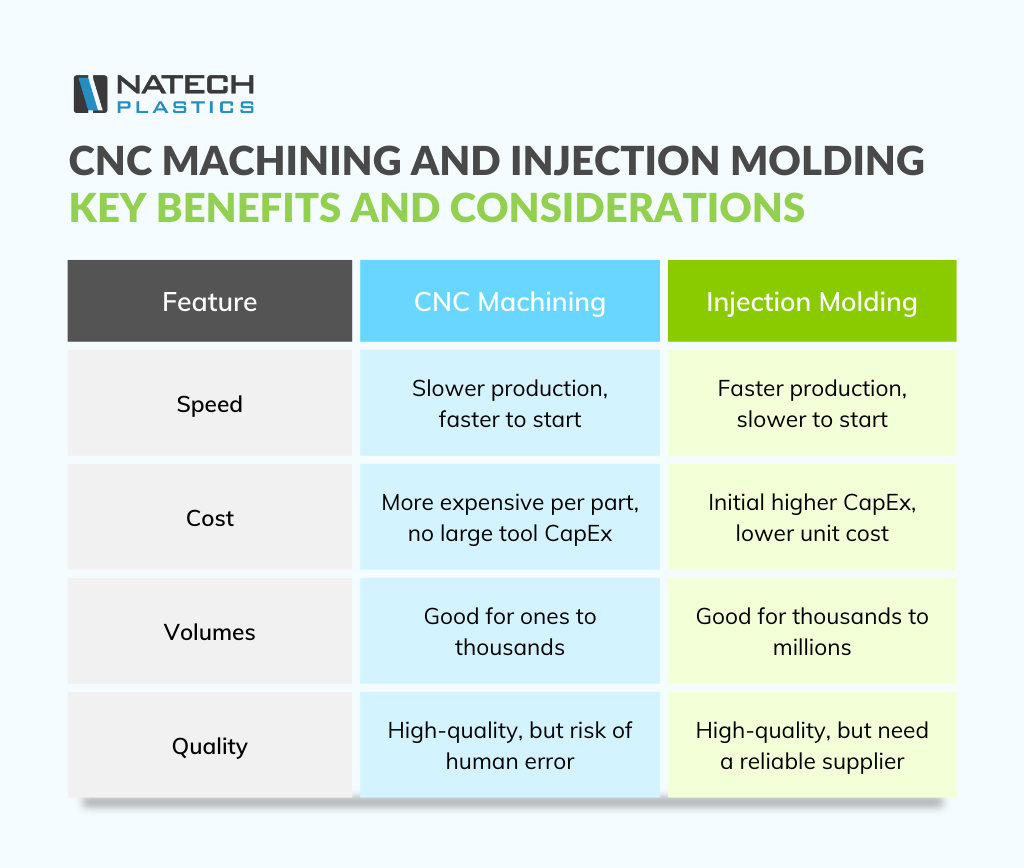

In high-end custom metal manufacturing, the injection moulding quote is far more than a cost estimate—it is a technical commitment rooted in precision, material science, and engineering integrity. At Wuxi Lead Precision Machinery, we understand that every component produced through injection moulding must meet exacting dimensional tolerances, surface finish requirements, and functional performance standards. This level of consistency begins not with production, but with the quotation phase, where engineering insight determines feasibility, material selection, tooling design, and long-term repeatability.

Precision in injection moulding is non-negotiable, particularly for industries such as aerospace, defense, and high-performance automotive—sectors where Lead Precision has delivered mission-critical components. Our involvement in projects supporting Olympic-grade equipment and military-grade systems underscores our capability to meet the most stringent quality benchmarks. These applications demand tolerances within ±0.002 mm, exceptional material homogeneity, and zero-defect production runs. Achieving such results requires a quotation process that integrates deep material knowledge, advanced simulation tools, and decades of hands-on experience in mold flow analysis and thermal management.

A well-structured injection moulding quote from Lead Precision includes not only cost and lead time but also a detailed engineering assessment of part geometry, gate location optimization, ejection strategy, and cooling channel design. Our engineers evaluate potential stress points, warpage risks, and cycle time efficiency before finalizing the proposal. This proactive approach ensures that the tooling produced is not only accurate but also durable, capable of sustaining high-volume production without degradation in part quality.

We utilize premium-grade tool steels such as P20, 718H, and H13, selected based on production volume and material aggressiveness. Surface treatments including nitriding and chrome plating are incorporated when necessary to extend mold life and resist corrosion. All molds are built with modular designs for ease of maintenance and future scalability.

Our clients benefit from a transparent, technically grounded quotation process that mitigates risk, reduces time-to-market, and ensures first-time-right manufacturing. Whether producing small-batch prototypes or full-scale production molds, Lead Precision applies the same level of engineering rigor.

Below are key specifications that define our injection moulding capabilities:

| Parameter | Specification |

|---|---|

| Maximum Mold Size | 2000 mm × 1500 mm × 1200 mm |

| Maximum Part Weight | 5 kg (plastic), 3 kg (metal insert molding) |

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Tool Steel Options | P20, 718H, H13, S136, NAK80 |

| Surface Finishes | SPI #A1, #A2, #B1, #B2, EDM textures |

| Lead Time (Average) | 25–45 days (depending on complexity) |

| Production Volume Capacity | 10,000 to 1,000,000+ cycles per mold |

| Industries Served | Aerospace, Military, Medical, Automotive |

At Wuxi Lead Precision Machinery, every injection moulding quote reflects our engineering philosophy: precision is not an outcome—it is the foundation.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Injection Moulding Excellence

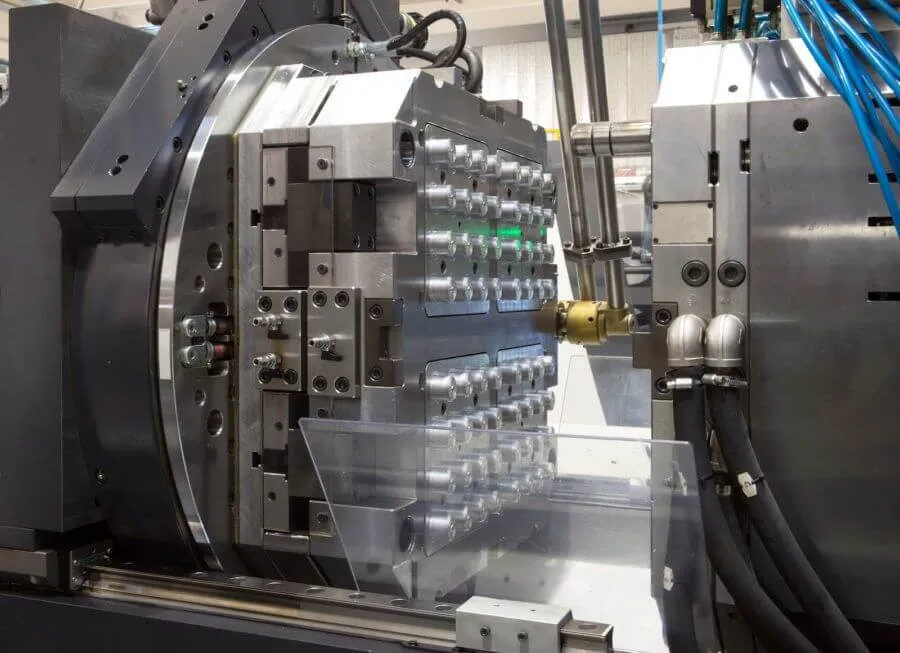

Wuxi Lead Precision Machinery delivers unmatched technical execution for complex injection moulding applications through integrated advanced manufacturing and metrology systems. Our core strength lies in transforming demanding design specifications into high-integrity tooling and components, directly influencing quote accuracy and project success. Central to this capability is our fleet of state-of-the-art 5-axis CNC machining centers, operating under stringent environmental controls to ensure thermal stability. These systems enable simultaneous multi-axis movement, eliminating secondary setups and achieving intricate geometries—such as deep cavities, undercuts, and organic cooling channels—with micron-level repeatability. This precision directly translates to reduced mould assembly time, superior part consistency, and extended tool life, factors critically evaluated during our quoting process to provide realistic cost and timeline projections.

Complementing our machining prowess is a comprehensive Coordinate Measuring Machine (CMM) inspection protocol integrated into every production phase. All critical features undergo 100% verification against CAD nominal data using calibrated Zeiss and Mitutoyo CMMs, supported by advanced GD&T analysis software. This is not a final-stage check but a continuous feedback loop; in-process measurements during roughing, semi-finishing, and finishing stages allow immediate corrective action, preventing costly rework. Our QC technicians are certified to ISO 10360 standards, ensuring measurement uncertainty is maintained below 1.5µm. This rigorous validation guarantees that every component meets the exacting tolerances required for zero-defect mould performance, a non-negotiable element reflected in our detailed technical quotations.

The following table defines our standard and precision tolerance capabilities for machined mould bases, inserts, and electrodes. These values represent achievable performance under controlled production conditions and form the technical foundation for our quoting methodology. Tolerances beyond the Precision tier require specific design collaboration and are assessed during the Request for Quotation (RFQ) review.

| Feature Type | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | CMM |

| Angular Dimensions | ±0.005° | ±0.001° | CMM / Optical Comparator |

| Positional (Holes) | ±0.008 mm | ±0.003 mm | CMM |

| Flatness | 0.005 mm / 100 mm | 0.002 mm / 100 mm | CMM / Granite Surface |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

Our quoting process rigorously cross-references client CAD data against these capability thresholds. When specifications approach or exceed standard tolerances, we proactively propose design-for-manufacturability (DFM) adjustments or precision-tier execution paths, clearly itemizing cost and lead time implications. This transparent technical assessment—rooted in verifiable machine performance and metrology—ensures quotes are not merely price points but engineered commitments to quality. Wuxi Lead’s integrated approach eliminates tolerance-related surprises, delivering moulds that perform consistently from first article to end-of-life production.

Material & Finish Options

Material Selection for Injection Moulding Tools and Components

Selecting the appropriate material for injection moulding tools and related components is critical to achieving optimal performance, longevity, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision manufacturing using high-grade metals tailored to meet the rigorous demands of industrial applications. The most commonly used materials in our custom metal manufacturing processes are aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum alloys, such as 7075 and 6061, are widely favored for prototype and low-to-medium volume production runs. Their excellent machinability allows for faster tool fabrication, reducing lead times significantly. Additionally, aluminum’s superior thermal conductivity enhances cooling efficiency during the injection cycle, improving part consistency. While not as durable as steel, aluminum tools are ideal for applications where rapid iteration and cost control are priorities.

Steel, particularly tool steels like P20, H13, and S136, remains the standard for high-volume injection moulding operations. These alloys offer exceptional hardness, wear resistance, and dimensional stability under repeated thermal cycling. Pre-hardened steels like P20 are often used for medium-run tools, while hardened steels such as H13 are selected for long production runs involving abrasive or high-temperature resins. Stainless variants like S136 provide added corrosion resistance, making them suitable for medical and food-grade applications.

Titanium alloys, though less common due to higher costs, are employed in specialized scenarios requiring extreme strength-to-density ratios and resistance to corrosion and high temperatures. While not typically used for full-scale mould bases, titanium may be integrated into critical wear components or used in high-performance environments such as aerospace or defense applications.

Surface finish selection further enhances the functional and aesthetic qualities of moulded parts. Anodizing is one of the most effective post-processing treatments for aluminum components. This electrochemical process creates a durable, corrosion-resistant oxide layer that can be dyed in various colors for identification or branding. Hard anodizing, in particular, increases surface hardness, making it suitable for wear-prone areas. For steel tools, alternatives such as nitriding or chrome plating are often recommended to improve surface durability and release properties.

Below is a comparative overview of key material properties relevant to injection moulding applications.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 570 | 130 | Prototypes, low-volume production |

| P20 Steel | 28–32 | 900 | 30 | Medium-volume tooling |

| H13 Steel | 48–52 | 1,600 | 25 | High-volume, high-heat applications |

| S136 Steel | 50–54 | 1,700 | 22 | Corrosion-resistant tooling |

| Titanium Gr5 | 35–40 | 900 | 7 | Aerospace, specialty components |

Understanding the interplay between material properties and production requirements ensures the selection of the most suitable option for your injection moulding needs. Wuxi Lead Precision Machinery supports clients in making informed decisions based on technical specifications, operational demands, and lifecycle costs.

Manufacturing Process & QC

Precision Metal Injection Moulding: From Concept to Zero Defects Production

Achieving flawless metal components demands a rigorously controlled production process, not merely sequential steps. At Wuxi Lead Precision Machinery, our Zero Defects mandate begins at the earliest design interaction and permeates every stage through mass production. We integrate deep metallurgical expertise with advanced process validation to eliminate waste and ensure absolute reliability for critical applications in aerospace, medical, and automotive sectors. This systematic approach transforms your injection moulding quote into a guaranteed delivery of precision-engineered metal parts.

The Design phase is foundational. Our engineering team conducts intensive Design for Manufacturability (DFM) analysis, scrutinizing your CAD model for optimal material flow, uniform wall thickness, and strategic gate placement specific to Metal Injection Moulding (MIM). We simulate the entire process—feedstock injection, debinding, and sintering—to predict and mitigate potential defects like sink marks, warpage, or density variations before tooling begins. This proactive collaboration ensures the design is not just feasible but inherently robust, setting the stage for zero rework.

Prototyping transitions validated design into tangible proof. We fabricate high-precision steel mould tools using multi-axis CNC machining and electrical discharge machining (EDM), achieving micron-level accuracy critical for MIM. Initial runs utilize production-intent parameters on our state-of-the-art presses. Every prototype undergoes exhaustive dimensional verification against the original CAD model and rigorous material property testing, including density, tensile strength, and microstructure analysis. This stage is not merely about form and fit; it is a comprehensive validation of the process window required for defect-free mass production. Critical parameters are locked based on empirical data, not assumptions.

Mass Production executes with unwavering adherence to the validated process. Our fully automated production cells maintain strict environmental controls for feedstock handling, injection, and thermal processing. Real-time monitoring of pressure, temperature, and cycle time ensures consistency. Crucially, every lot undergoes 100% critical dimension inspection via Coordinate Measuring Machines (CMM) and statistical process control (SPC) on key characteristics. Non-destructive testing (NDT) like X-ray or ultrasound verifies internal integrity. This relentless focus on process stability and verification, backed by our ISO 9001 and IATF 16949 certified systems, guarantees parts meet specifications consistently, eliminating scrap and downstream failure costs.

The following table outlines core process specifications underpinning our Zero Defects commitment for MIM production:

| Parameter | Specification | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.05 mm (part size dependent) | CMM, Optical Comparator, Gauging |

| Material Density | ≥ 98% Theoretical Density | Archimedes’ Principle, Microscopy |

| Surface Roughness (Ra) | 0.8 µm to 3.2 µm | Profilometer |

| Critical Dimension SPC | Cp/Cpk ≥ 1.67 | Real-time SPC Charts, Statistical Analysis |

| Material Certification | Full Mill Test Reports (MTRs) | Traceable MTRs, In-house Chemical Analysis |

| Non-Destructive Testing | 100% on critical internal features | X-ray Radiography, Ultrasonic Testing |

This integrated Design-Prototyping-Production workflow, governed by stringent specifications and continuous verification, transforms the injection moulding quote from a simple cost estimate into a binding assurance of precision and performance. Partner with Wuxi Lead for MIM solutions where zero defects is the operational standard, not an aspiration.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Moulding Excellence

When precision, reliability, and performance define your manufacturing standards, choosing the right partner is not just important—it’s critical. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions engineered to meet the exacting demands of global industries, from automotive and aerospace to medical devices and consumer electronics. Our expertise in injection moulding goes beyond standard production; we deliver fully optimized, high-precision tooling and components tailored to your unique specifications.

Our advanced manufacturing facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, EDM systems, and automated quality inspection stations. Every injection mould we produce is built with tight tolerances, superior surface finishes, and extended service life in mind. We work with a wide range of tool steels and alloys—including P20, 718H, NAK80, and H13—ensuring optimal material performance under high-pressure, high-cycle production environments. From concept validation to final delivery, our engineering team collaborates closely with clients to streamline design for manufacturability, reduce cycle times, and minimize total cost of ownership.

Whether you require single-cavity prototypes or multi-cavity production moulds capable of millions of cycles, our integrated approach guarantees consistency and repeatability. We support hot runner and cold runner systems, stack and family mould configurations, and complex side-action mechanisms. Our in-house project management ensures transparent communication, real-time updates, and on-time delivery—no matter the complexity.

To illustrate our technical capabilities, here are key specifications we consistently achieve:

| Specification | Capability |

|---|---|

| Mould Weight Range | 50 kg – 15,000 kg |

| Maximum Mould Size | 2,000 mm × 1,500 mm × 1,200 mm |

| Tolerance | ±0.005 mm (critical dimensions) |

| Surface Finish | Ra 0.05 µm to Ra 1.6 µm (polished, textured, or as-machined) |

| Steel Types | P20, 718H, NAK80, H13, S136, 2316 |

| Lead Time (Standard) | 25–45 days (based on complexity) |

| Annual Production Capacity | 600+ custom moulds |

| Quality Standards | ISO 9001:2015 certified, full first article inspection (FAI) reports |

We understand that your injection moulding quote is more than a price—it’s a commitment to quality, timeline, and technical partnership. At Wuxi Lead Precision Machinery, we provide detailed, transparent quotations that reflect true manufacturability, material efficiency, and long-term value. Our team of application engineers is ready to review your 3D CAD models, suggest design improvements, and deliver a precise quote tailored to your production goals.

Take the next step toward manufacturing excellence. Contact us today at [email protected] to request your injection moulding quote. Let Lead Precision become your trusted partner in high-performance metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.