Technical Contents

Engineering Guide: Injection Moulding Plastic

Engineering Insight: Precision in Injection Moulding Plastic

In the realm of custom metal manufacturing, the integration of injection moulding plastic components demands an uncompromising standard of precision. At Wuxi Lead Precision Machinery, we recognize that the performance, durability, and functionality of end-use parts—especially in high-stakes sectors such as aerospace, defense, and advanced automation—are directly influenced by the accuracy of both metal tooling and the plastic elements produced. Injection moulding is not merely a process of shaping molten polymer; it is a tightly controlled engineering operation where micron-level deviations can cascade into functional failure.

The foundation of precision injection moulding lies in the design and construction of the mould itself. As a custom metal manufacturer with over a decade of specialized experience, Lead Precision excels in crafting high-tolerance steel and aluminum moulds that ensure repeatable part geometry, consistent wall thickness, and minimal warpage. Our engineering team employs advanced simulation software to predict flow behavior, cooling rates, and potential stress points, allowing for preemptive optimization before any metal is cut.

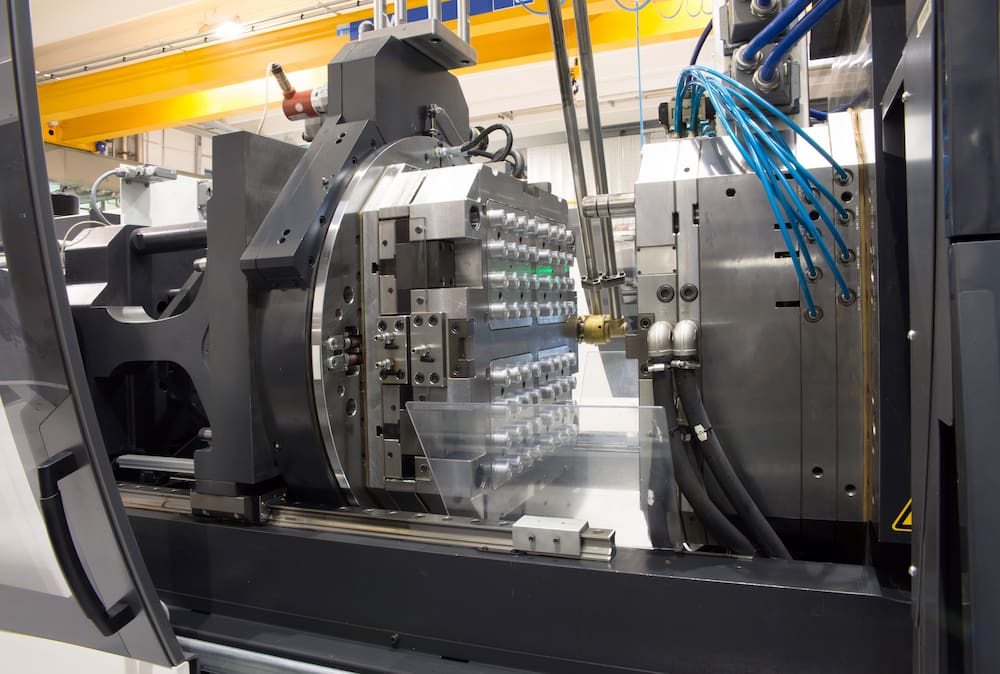

Precision extends beyond the mould. Process control parameters—such as injection pressure, temperature profiles, cooling time, and clamping force—must be calibrated to the specific resin and part geometry. At Lead Precision, we utilize closed-loop control systems and real-time monitoring to maintain process stability across production runs, ensuring that each component meets exact dimensional and mechanical specifications.

Our commitment to precision is validated through rigorous quality assurance protocols. Every mould undergoes comprehensive metrological verification using coordinate measuring machines (CMM) and optical inspection systems. Plastic components are tested for dimensional accuracy, surface finish, and mechanical integrity, ensuring compliance with international standards such as ISO 9001 and customer-specific requirements.

Wuxi Lead Precision Machinery has applied this disciplined approach to projects of the highest caliber, including components used in Olympic-grade sporting equipment and mission-critical military hardware. These applications demand not only flawless part consistency but also traceability, material certification, and long-term reliability under extreme conditions—benchmarks we consistently meet.

Our expertise in integrating precision metal fabrication with advanced plastic injection processes positions us as a trusted partner for clients requiring complex, multi-material solutions. Whether producing high-volume consumer components or low-volume, high-complexity industrial parts, Lead Precision delivers engineered accuracy at every stage.

| Specification | Detail |

|---|---|

| Mould Tolerance | ±0.002 mm |

| Clamping Force Range | 50–2000 Tons |

| Material Compatibility | ABS, PC, POM, PEEK, PP, PA (Nylon), PMMA |

| Process Control | Closed-loop injection, Real-time monitoring |

| Quality Standards | ISO 9001, ISO 13485 (medical), RoHS compliant |

| Surface Finish Options | SPI A1 (Polished), SPI B1 (Satin), Textured, EDM |

| Lead Time (Standard) | 25–40 days (based on complexity) |

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for Injection Moulding Excellence

Wuxi Lead Precision Machinery delivers the critical metal foundation required for high-performance plastic injection moulding. Our expertise lies in manufacturing the precision metal components—mold bases, cavities, cores, inserts, and ejector systems—that directly determine the quality, consistency, and longevity of your plastic parts. We bridge the gap between advanced plastic processing requirements and the uncompromising dimensional accuracy demanded in modern mold tooling. Our integrated manufacturing and quality control processes ensure every metal component meets the exacting standards necessary for successful, high-volume plastic production.

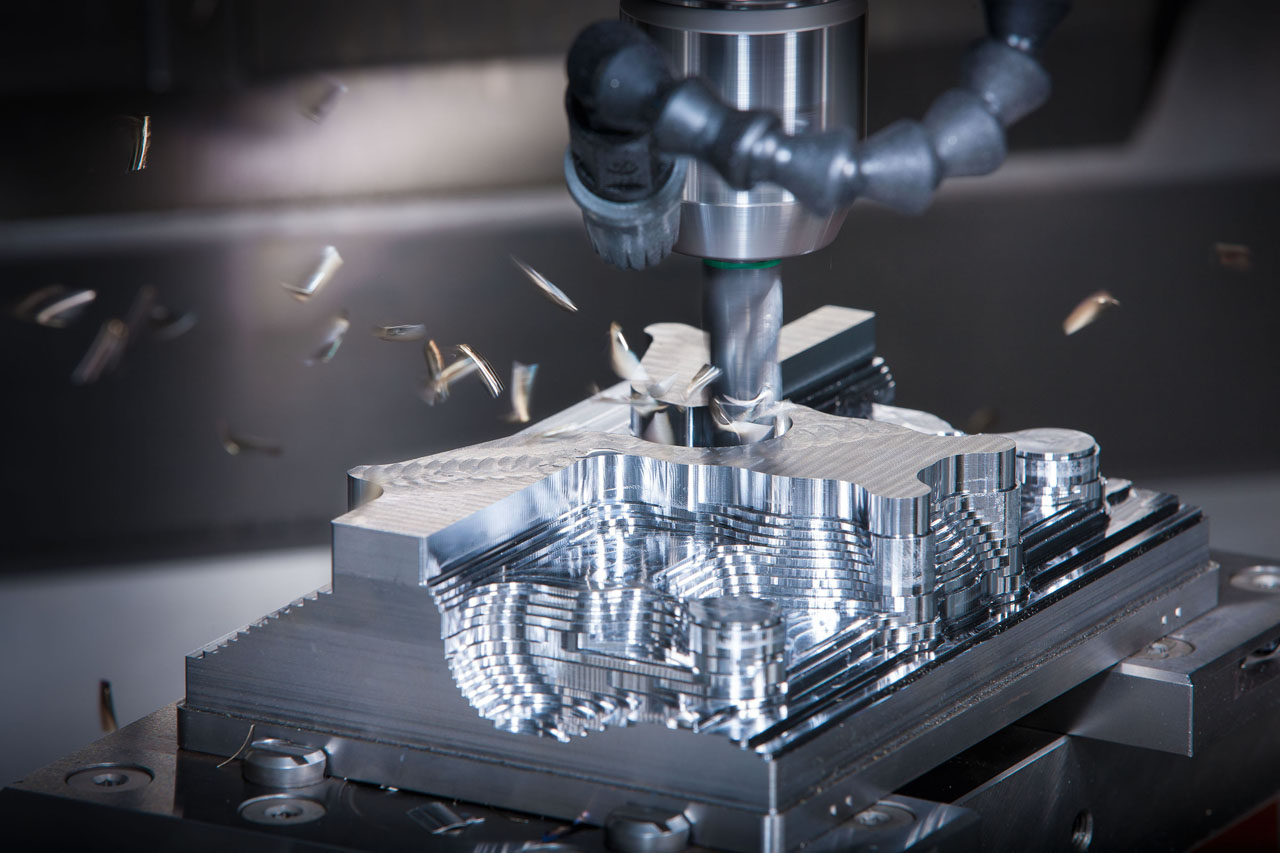

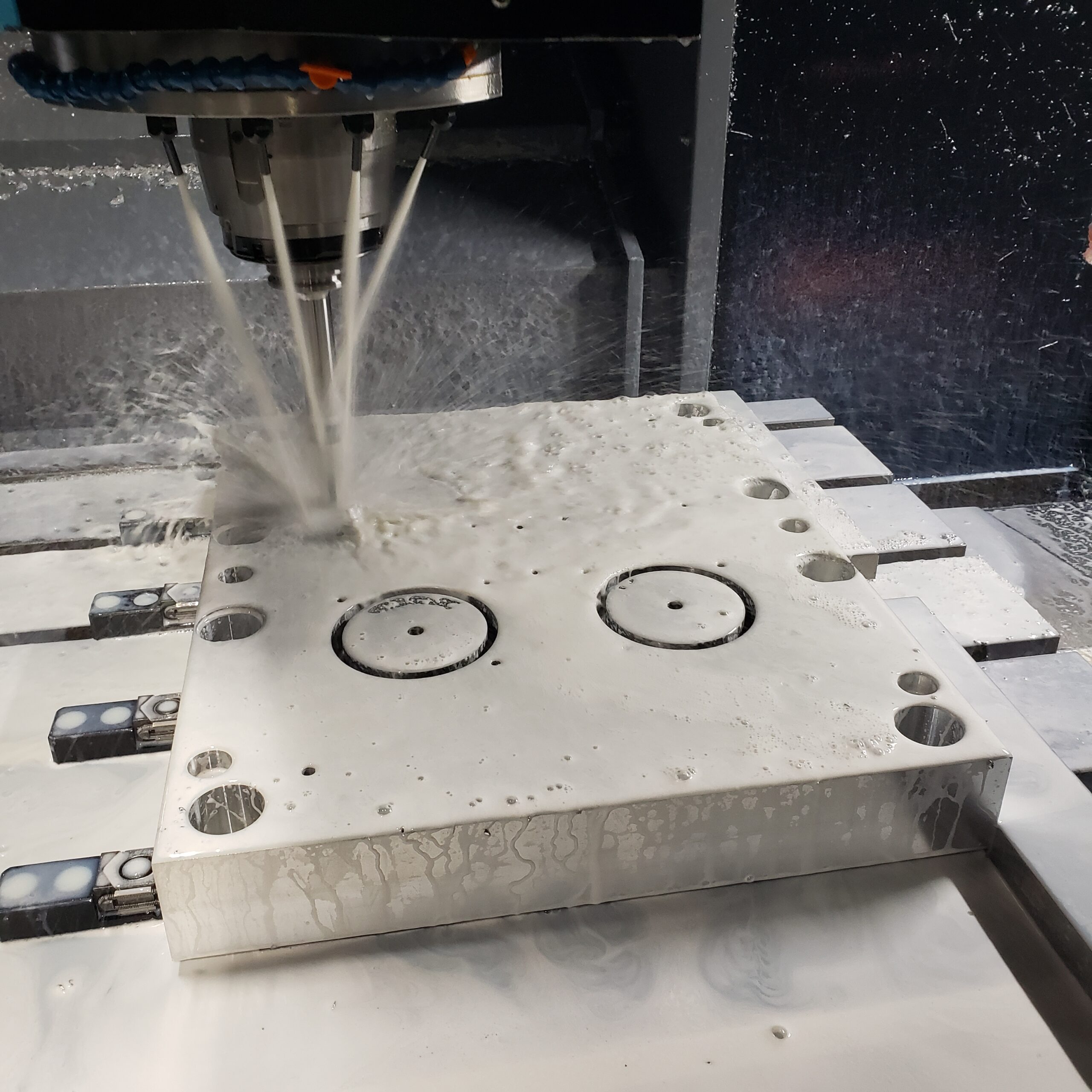

Our core manufacturing capability centers on state-of-the-art 5-axis CNC machining centers. This technology is fundamental for producing the complex, contoured geometries inherent in modern injection molds, particularly for multi-cavity layouts, intricate part features, and conformal cooling channels. 5-axis simultaneous machining eliminates the need for multiple setups, significantly reducing cumulative error and ensuring superior geometric relationships between critical mold features. We machine a wide range of mold-grade tool steels, pre-hardened alloys, and specialty materials to achieve the tight tolerances and fine surface finishes essential for optimal plastic flow, part ejection, and extended mold life. This capability directly translates to reduced cycle times, minimized part defects like flash or sink marks, and consistent plastic part replication over millions of cycles.

Rigorous quality control is non-negotiable in mold manufacturing. Every critical component undergoes comprehensive verification using our Zeiss and Hexagon Coordinate Measuring Machines (CMM). This metrology-grade inspection provides full geometric dimensioning and tolerancing (GD&T) validation, generating detailed inspection reports traceable to international standards. We measure complex 3D profiles, positional tolerances, flatness, parallelism, and critical diameters with micron-level precision. This data-driven QC process guarantees that the metal components arriving at your mold assembly floor conform precisely to the engineering intent, preventing costly assembly delays, mold rework, or production downtime due to dimensional discrepancies.

The following table details the standard precision capabilities we consistently achieve for critical injection mold components:

| Feature Category | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM |

| Geometric Tolerances | ±0.015 mm | ±0.008 mm | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

| Hole Position | ±0.012 mm | ±0.006 mm | CMM |

| Flatness | 0.015 mm | 0.008 mm | CMM / Optical Flat |

These capabilities are not theoretical targets but proven standards achieved daily within our ISO-certified facility. By providing mold makers with metal components manufactured to these precise tolerances and rigorously verified, Wuxi Lead Precision Machinery ensures your injection molding process starts with a foundation built for reliability, efficiency, and exceptional plastic part quality. Partner with us to eliminate the metal-related variables that compromise your plastic production outcomes.

Material & Finish Options

Material Selection for High-Precision Injection Moulding Tools

In the realm of high-end injection moulding for plastic components, the choice of tooling material is a critical determinant of production efficiency, part quality, and tool longevity. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for precision mould tools, leveraging advanced material science to meet the demanding requirements of aerospace, medical, and automotive industries. The primary materials used in our injection mould construction—aluminum, steel, and titanium—each offer distinct mechanical properties, thermal performance, and cost-efficiency profiles.

Aluminum alloys, particularly 7075 and 6061, are favored for prototype and low-to-medium volume production runs. Their high thermal conductivity ensures rapid cooling cycles, reducing cycle times and increasing throughput. Aluminum is also easier to machine, allowing for faster tool fabrication and design iteration. However, its lower hardness and wear resistance make it less suitable for high-volume or abrasive plastic resins.

Tool steels such as P20, H13, and S136 dominate high-volume injection moulding applications. These steels provide excellent hardness, wear resistance, and dimensional stability under repeated thermal cycling. Stainless variants like S136 offer superior corrosion resistance, making them ideal for medical-grade or transparent plastic components where surface purity is paramount. While steel tools require longer machining and heat treatment processes, their extended service life justifies the investment in mass production environments.

Titanium alloys, though less common due to cost and machining complexity, are employed in highly specialized applications requiring exceptional strength-to-density ratios and corrosion resistance. Titanium mould components are typically reserved for aerospace or defense applications where weight reduction and performance under extreme conditions are critical.

Surface finishing, particularly hard anodizing, plays a pivotal role in enhancing mould performance. Anodizing increases surface hardness, improves wear resistance, and reduces friction—key factors in part ejection and surface finish replication. For aluminum tools, hard anodizing (Type III) is standard, providing a durable, non-conductive oxide layer up to 50–75 µm thick. This treatment significantly extends tool life and maintains dimensional accuracy over thousands of cycles.

Below is a comparative overview of key material properties relevant to injection mould tooling.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Use Case | Anodizing Compatibility |

|---|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 500–570 | 130 | Prototypes, low-volume runs | Excellent (Type III) |

| P20 Steel | 28–32 | 900–1100 | 30 | Medium-to-high volume moulds | Not applicable |

| H13 Steel | 48–52 | 1300–1600 | 35 | High-stress, high-temp tools | Not applicable |

| S136 Steel | 50–54 | 1400–1700 | 25 | Corrosion-resistant moulds | Not applicable |

| Titanium Ti-6Al-4V | 35–40 | 900–1000 | 7 | Aerospace, specialized tools | Limited (special process) |

Selecting the optimal material and finish requires a holistic assessment of production volume, part geometry, resin type, and performance requirements. At Wuxi Lead Precision Machinery, we collaborate closely with clients to engineer mould solutions that balance performance, durability, and cost-effectiveness.

Manufacturing Process & QC

Injection Moulding Production Process: Achieving Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, our injection moulding process for plastic components is engineered for uncompromising quality and repeatability, starting with rigorous design validation. The journey begins with comprehensive geometric and flow analysis using advanced CAD/CAE tools. Our engineering team scrutinizes part geometry, wall thickness transitions, and gate locations to eliminate potential defects like sink marks, warpage, or knit lines before tool fabrication. Material selection is precisely matched to functional requirements and processing parameters, ensuring optimal flow and structural integrity. This proactive design phase establishes the critical foundation for Zero Defects, preventing costly revisions later.

Prototyping is not a mere formality but a vital validation checkpoint. Utilizing high-precision CNC-machined prototype moulds or rapid tooling, we produce functional parts under near-production conditions. Every parameter—melt temperature, injection speed, packing pressure, and cooling time—is meticulously optimized and documented. Parts undergo rigorous dimensional inspection against GD&T callouts and functional testing. Any micro-defect identified here triggers immediate process or tooling adjustment. This iterative phase ensures the final mould design and process window are perfected, guaranteeing that mass production starts with validated, defect-free capability.

Mass production leverages fully automated, closed-loop control systems on our state-of-the-art presses to maintain the validated process window with extreme precision. Real-time monitoring of cavity pressure, temperature, and cycle time feeds into Statistical Process Control (SPC) systems, instantly detecting any deviation beyond micron-level tolerances. Automated vision inspection systems perform 100% in-line checking for surface defects, dimensional accuracy, and critical features. Our integrated quality management system, certified to ISO 9001:2015, mandates traceability for every component batch, linking material lots, machine parameters, and inspection data. This closed-loop approach, combining precision engineering, real-time analytics, and stringent procedural controls, is how we consistently deliver Zero Defects at scale for demanding industrial applications.

Critical process parameters maintained throughout production are detailed below:

| Parameter | Control Range | Measurement Tolerance | Impact on Zero Defects Target |

|---|---|---|---|

| Melt Temperature | 180°C – 320°C | ±0.5°C | Prevents material degradation & flow issues |

| Cavity Pressure | 500 – 2000 bar | ±5 bar | Ensures complete fill & minimizes sink |

| Nozzle Temp Stability | Setpoint ±1.0°C | ±0.1°C | Eliminates viscosity fluctuations |

| Cooling Time | 15s – 120s (part dep) | ±0.2s | Controls warpage & dimensional stability |

| Clamping Force | 50 – 2500 Tons | ±1% | Prevents flash & ensures part integrity |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Injection Moulding Plastic Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal manufacturing solutions engineered to elevate your injection moulding plastic operations. With over a decade of experience serving global industrial clients, we have perfected the integration of advanced CNC machining, die-casting, and mold base fabrication to support the demanding requirements of modern plastic injection systems. Our commitment to engineering excellence ensures that every component we produce meets the highest standards of durability, accuracy, and performance.

Our strategic focus lies in supporting OEMs, automation integrators, and large-scale manufacturers who demand reliability and repeatability in their production environments. Whether you are developing high-cavitation molds, hot runner systems, or precision ejector mechanisms, our engineering team collaborates closely with your design staff to optimize manufacturability, reduce cycle times, and extend tool life. We utilize premium-grade materials such as P20, 718H, NAK80, and H13, all processed through state-of-the-art 5-axis CNC centers, EDM, and surface grinding equipment to achieve tolerances within ±0.002 mm.

We understand that in injection moulding, even the smallest dimensional deviation can lead to part defects, downtime, or costly rework. That is why every project at Lead Precision begins with a comprehensive design review, followed by rigorous quality inspection using Zeiss CMMs and 3D metrology systems. Our ISO 9001:2015-certified processes ensure full traceability, from raw material sourcing to final packaging, giving you confidence in every component we deliver.

Our clients span the automotive, medical device, consumer electronics, and industrial equipment sectors—industries where performance under pressure is non-negotiable. By partnering with us, you gain more than a supplier; you gain a long-term engineering ally committed to innovation, on-time delivery, and total customer satisfaction.

Below are key technical capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Maximum Machining Size | 2,500 mm × 1,800 mm × 1,200 mm |

| Tolerance Control | ±0.002 mm |

| Surface Finish | Ra 0.1 – 0.8 μm (polished & machined) |

| Materials Processed | P20, 718H, NAK80, H13, S136, 420SS, Aluminum 7075 |

| CNC Equipment | 5-Axis Machining Centers, High-Speed Mills |

| Quality Assurance | Zeiss CMM, 3D Scanning, Hardness Testing |

| Lead Time | 15–35 days (varies by complexity) |

| Certifications | ISO 9001:2015, RoHS Compliant |

We invite you to experience the Lead Precision difference. Contact us today at [email protected] to discuss your next injection moulding project. Let our engineers help you achieve tighter tolerances, faster cycles, and superior mold performance—engineered in China, trusted worldwide.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.