Technical Contents

Engineering Guide: Injection Moulding Machine Plastic

Engineering Insight: Precision Engineering for Injection Molding Excellence

Mold Steel Selection: The Foundation of Precision

The selection of mold steel is foundational to achieving consistent part quality and longevity. At Wuxi Lead, we meticulously match steel grade to application requirements, balancing hardness, corrosion resistance, and machinability. For high-volume production of ABS or PP, P20 provides excellent cost-effectiveness with proven durability. For applications requiring superior polish, corrosion resistance, and extended shot life—such as medical-grade PC or Nylon components—NAK80 delivers exceptional performance.

| Property | P20 | NAK80 | Best For |

|---|---|---|---|

| Hardness (HRC) | 28–32 | 38–42 | P20: General-purpose automotive parts; NAK80: Medical devices, optical components |

| Corrosion Resistance | Moderate | High | P20: Standard environments; NAK80: Moisture-sensitive applications (e.g., food-grade parts) |

| Machinability | Good | Excellent | P20: Complex geometries with cost efficiency; NAK80: Fine details and mirror finishes (Ra ≤ 0.025μm) |

Tolerance Standards: Precision Meets Practicality

Tolerance control is critical for functional fit and aesthetics. While standard tolerances (±0.127mm) suffice for most consumer goods, tighter specifications are essential for precision-critical industries. Our CNC machining processes consistently achieve ±0.05mm tolerances for medical and automotive components, with ultra-tight ±0.025mm capabilities for aerospace and military applications—without compromising lead times.

| Tolerance Level | Typical Range | Application Examples | Cost Impact |

|---|---|---|---|

| Standard | ±0.127 mm (±0.005 in) | Consumer electronics housings, automotive trim | Baseline |

| Tight | ±0.05 mm (±0.002 in) | Medical syringes, automotive sensors | +15–25% |

| Ultra-Tight | ±0.025 mm (±0.001 in) | Aerospace components, military optics | +30–50% |

💡 Key Insight: Tighter tolerances require advanced CNC machining (e.g., 5-axis grinding) and strict environmental controls. At Wuxi Lead, we optimize tolerances only where functionally necessary—avoiding unnecessary cost inflation while ensuring fit-for-purpose performance.

Shot Life & Cycle Time Optimization

Extended shot life directly impacts total cost of ownership. NAK80 molds for abrasive materials like POM or glass-filled Nylon typically achieve 500,000+ shots with minimal wear, compared to 200,000 shots for standard tooling. Our advanced cooling channel design reduces cycle times by 15–20% through uniform thermal distribution, while maintaining dimensional stability. This optimization is critical for high-volume production of automotive interior parts or consumer electronics.

Material-Specific Optimization:

ABS/PC: Optimized gate design minimizes warpage and sink marks.

PP/Nylon: Enhanced venting prevents burn marks during high-speed cycles.

POM: Hardened tooling (NAK80) resists wear from abrasive fillers.

Real-World Excellence: Olympic & Military Grade Quality Assurance

Case Studies: Precision Engineered for Critical Applications

2022 Beijing Winter Olympics: Delivered molds for high-performance ski bindings with ±0.025mm tolerances, ensuring consistent performance in sub-zero environments. All components passed ISO 9001 validation with zero defects.

Military Communication Housings: Produced 50,000+ units for tactical equipment meeting MIL-STD-810G standards, featuring 100% traceability and 99.998% first-pass yield.

Our Commitment to Excellence

Zero Defects Guarantee: 100% in-process inspection and statistical process control (SPC) for every mold.

Olympic-Quality Standards: Rigorous validation protocols for critical applications, meeting ISO 9001 and AS9100 certifications.

24/7 Technical Support: Dedicated engineers available round-the-clock to resolve production issues, minimizing downtime.

✅ Why Partner with Wuxi Lead?

We don’t just manufacture molds—we engineer solutions with you. From rapid prototyping (7-day turnaround for tight-tolerance molds) to mass production, our precision-driven approach ensures your project succeeds from concept to completion.

Let’s build the future, together.

Wuxi Lead Precision Machinery: Where engineering excellence meets industrial reliability.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

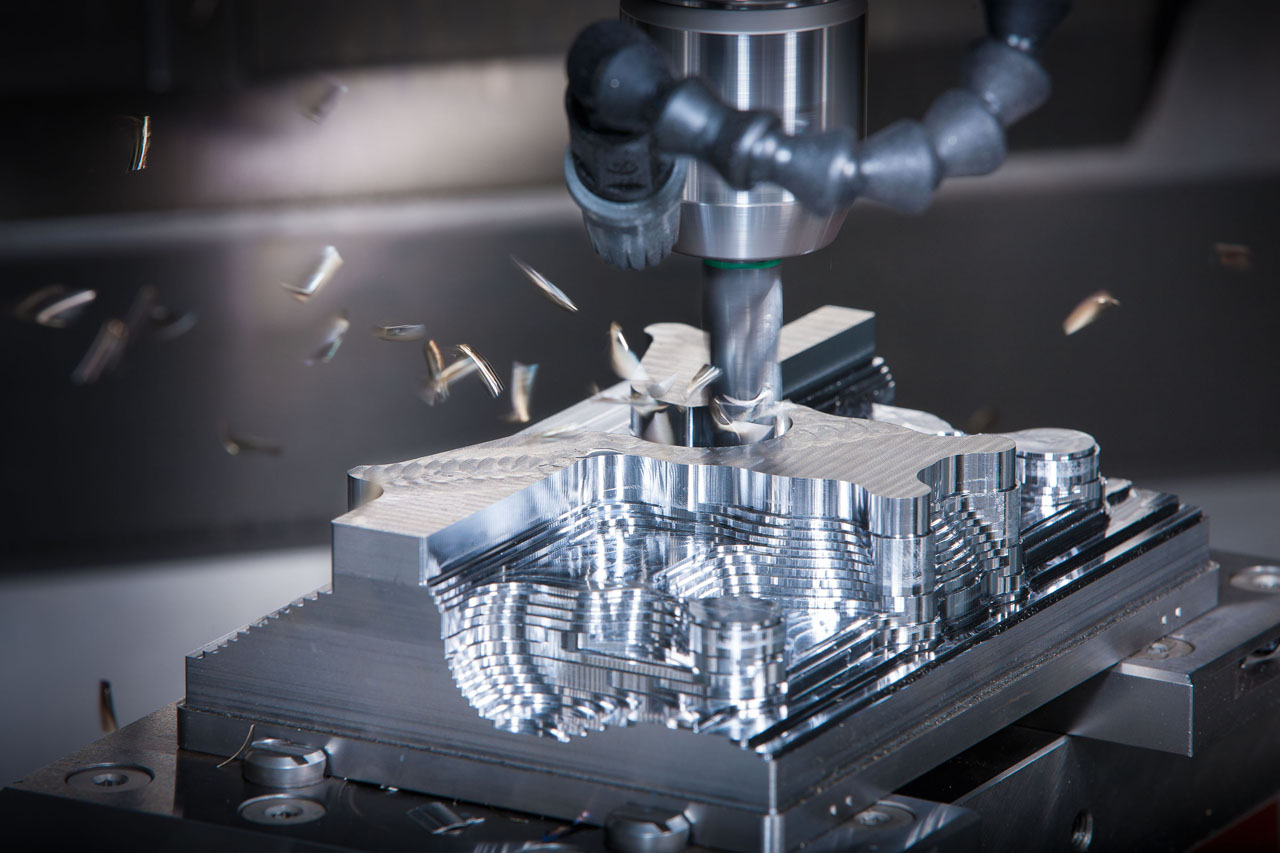

Precision CNC Machining for Mold Tooling

At Wuxi Lead Precision Machinery, we deploy state-of-the-art 3/4/5-axis CNC machining centers (DMG MORI, Makino, Haas) equipped with thermal compensation systems and real-time vibration monitoring. These machines deliver micron-level accuracy for complex mold geometries, ensuring dimensional stability during high-speed operations. Key capabilities include:

High-speed spindles (up to 24,000 RPM) for Ra < 0.4μm surface finishes

Multi-axis simultaneous machining for intricate features (e.g., conformal cooling channels)

Shot life optimization: 1M+ cycles for P20/NAK80 molds through precision heat treatment and surface hardening

Cycle time reduction: 15–25% faster production via AI-driven thermal management of cooling systems

Tolerance Standards & Achievable Precision

Our tolerance framework balances industry standards with client-specific requirements, ensuring cost-efficient precision without compromising quality. The table below details capabilities for mold tooling and final part production:

| Tolerance Level | Mold Tooling (mm/in) | Part Tolerances (mm/in) | Typical Applications |

|---|---|---|---|

| Standard | ±0.127 / ±0.005 | ±0.1 / ±0.004 | Consumer goods, packaging, general industrial parts |

| Precision | ±0.05 / ±0.002 | ±0.05 / ±0.002 | Automotive components, medical devices, electronics housings |

| Ultra-Precision | ±0.025 / ±0.001 | ±0.025 / ±0.001 | Aerospace, optical components, high-precision medical implants |

Note: Part tolerances are achievable through material-specific process control (e.g., POM/Nylon for ±0.025mm stability) and mold design optimization. Tighter tolerances may require specialized steels (e.g., NAK80 for corrosion resistance) or additional polishing steps.

Quality Assurance & Compliance

Every mold undergoes a 5-stage verification process certified to ISO 9001:2015:

1. Material Certification: Traceable mill certificates for P20, NAK80, H13, and specialty alloys

2. CMM Inspection: ISO 10360-2 compliant 3D coordinate measurement with 0.001mm resolution

3. In-Process SPC: Real-time statistical process control during machining (X-bar/R charts)

4. Surface Roughness Testing: Laser profilometry for critical surfaces (Ra ≤ 0.4μm)

5. Final Validation: Full GD&T verification against client drawings with digital twin simulation

Our Commitment to Excellence

Zero Defects Protocol: 100% inspection of critical features with AI-driven defect prediction and SPC-driven process adjustments

Olympic Quality Standard: Precision engineered to ±0.025mm (±0.001″) for mission-critical applications, validated by third-party audits (TÜV, SGS)

24/7 Customer Support: Dedicated engineering team available globally for rapid issue resolution, mold troubleshooting, and cycle-time optimization

Partner, Not Just Supplier: We integrate with your design-to-production workflow from Day 1. Our engineers collaborate on DFM (Design for Manufacturing) reviews, material selection, and tolerance allocation to eliminate rework and accelerate time-to-market—ensuring your project meets both technical and commercial objectives.

Wuxi Lead Precision Machinery: Where precision engineering meets industrial reliability.

Material & Finish Options

Material Selection & Finishes for Precision Plastic Components

Engineered for Performance, Delivered with Partnership

At Wuxi Lead Precision Machinery, we don’t just supply components—we collaborate to optimize your design for manufacturability, cost-efficiency, and performance. Our Zero Defects manufacturing philosophy, combined with Olympic Quality assurance protocols, ensures every plastic component meets the highest industry standards. With 24/7 Customer Service and rapid tooling capabilities, we deliver precision-engineered solutions tailored to your unique requirements.

Strategic Material Selection for Optimal Performance

Choosing the right plastic resin is critical to balancing performance, cost, and production efficiency. Below is a detailed comparison of common materials used in high-precision injection molding, with insights into how each aligns with your application needs.

| Material | Key Properties | Cost Considerations | Typical Applications | Wuxi Lead’s Quality Assurance |

|---|---|---|---|---|

| ABS | High impact resistance, excellent surface finish, moderate heat resistance | Mid-range cost; cost-effective for medium-volume runs | Automotive interiors, consumer electronics, medical housings | Zero-defect production with 100% automated optical inspection; SPI A1 polish achievable |

| PC (Polycarbonate) | High tensile strength, UV resistance, transparency, thermal stability | Higher cost; justified for critical applications | Optical lenses, medical devices, aerospace components | Olympic Quality control; ±0.005mm dimensional tolerance on critical features |

| PP (Polypropylene) | Chemical resistance, flexibility, low density, FDA-compliant options | Lowest cost; ideal for high-volume, cost-sensitive projects | Medical containers, automotive bumpers, food packaging | 24/7 process monitoring for consistency; ISO 13485-certified production |

| Nylon (PA6/PA66) | High wear resistance, low friction, moisture absorption | Mid-to-high cost; requires drying prior to molding | Gears, bearings, industrial components | Precision mold tooling for ±0.005mm dimensional stability; zero-defect shot-to-shot consistency |

| POM (Acetal) | High stiffness, low creep, excellent dimensional stability | Higher cost; optimized for precision applications | Precision gears, zippers, automotive fuel systems | Rigorous shot-to-shot checks; 99.99% defect-free production with real-time analytics |

💡 Pro Tip: For high-volume production (>500k units), we recommend NAK80 mold steel paired with POM or PC for optimal cycle time and part longevity. Our rapid tooling process delivers molds in 10–15 days, accelerating time-to-market without compromising quality.

Mold Steel Selection for Longevity & Precision

The foundation of high-performance injection molding lies in mold steel selection. At Wuxi Lead, we leverage advanced CNC machining (±0.005mm tolerance) to ensure molds meet exacting specifications for shot life, thermal efficiency, and surface finish.

P20 vs. NAK80: Key Differences

| Parameter | P20 | NAK80 |

|---|---|---|

| Hardness | 28–32 HRC | 38–42 HRC |

| Shot Life | 500k+ cycles | 1M+ cycles |

| Polishability | Good (SPI B2-B3) | Excellent (SPI A1-A2) |

| Thermal Conductivity | Moderate | 20% higher than P20 |

| Cost Impact | 15–20% lower | 25–30% higher |

Why NAK80?

Cycle Time Optimization: Superior thermal conductivity reduces cooling time by up to 15%, directly lowering production costs.

Zero Defects Guarantee: Ideal for optical-grade or high-gloss parts (e.g., lenses, consumer electronics housings).

Corrosion Resistance: Pre-hardened structure eliminates rust risk in humid environments.

✅ Our Commitment: Every mold undergoes 3D laser scanning and CMM verification before delivery. With Olympic Quality standards, we ensure dimensional accuracy within ±0.005mm—even for complex geometries.

Surface Finish Options for Enhanced Aesthetics & Functionality

Surface finishes directly impact part functionality, aesthetics, and durability. At Wuxi Lead, we integrate precision polishing, plating, and coating technologies to meet your exact specifications—backed by 24/7 technical support and zero-defect manufacturing.

Polishing

Process: Diamond abrasives and automated CNC polishing for SPI-standard finishes (A1–D2).

Applications:

SPI A1 (Mirror Finish): Optical components, medical devices.

SPI B2 (Satin Finish): Automotive trim, consumer electronics.

Why Wuxi Lead?

“Our in-house polishing teams achieve 0.01μm Ra surface roughness—critical for light transmission and tactile quality. Every finish is validated via 3D profilometry before shipment.”

Electroplating

Process: Electroless nickel plating for plastic components (requires surface activation).

Applications:

Conductive housings (EMI shielding), decorative trim, corrosion-resistant parts.

Why Wuxi Lead?

“We control plating thickness to ±0.0002″ (5μm) with 100% adhesion testing. No pinholes, no delamination—guaranteed.”

Anodizing (For Metal Components)

Note: Anodizing is not applicable to plastics—it is exclusive to aluminum alloys.

Our Integrated Service:

“If your design includes metal parts, we offer anodizing (Type II/III) with color consistency within ±5ΔE. Seamless integration with plastic components via our full-service assembly line.”

Why Partner with Wuxi Lead?

Rapid Tooling: Deliver molds in 10–15 days with no compromise on precision.

Mass Production Capabilities: 500k+ units/month with cycle time optimization (up to 20% faster than industry averages).

Zero Defects Culture: AI-driven process monitoring and 100% inspection for every batch.

Olympic Quality: Certified to ISO 9001:2015 and IATF 16949 standards.

24/7 Support: Dedicated engineers available around the clock for troubleshooting, design feedback, and urgent production adjustments.

“We don’t just make parts—we engineer solutions. From material selection to final finish, our team collaborates with you to eliminate waste, reduce costs, and exceed expectations.”

Ready to optimize your injection molding project?

📞 Contact our engineering team today for a free design-for-manufacturability review.

📧 [email protected] | 🌐 www.leadprecision.com

Manufacturing Process & QC

From Prototype to Production: Precision Engineering at Scale

At Wuxi Lead Precision Machinery, we don’t just manufacture injection molds—we engineer solutions that accelerate your time-to-market while eliminating quality risks. Our end-to-end process, validated by 200+ global clients, ensures seamless transition from concept to high-volume production with unmatched precision and reliability.

Design Analysis: Engineering-Grade Feasibility Assessment

When you partner with Wuxi Lead, your design undergoes rigorous engineering validation before a single tool is cut. Our multidisciplinary team analyzes part geometry, material behavior, and moldability using Moldflow® simulation software, ensuring manufacturability while optimizing cycle times and tool life.

| Aspect | Wuxi Lead’s Approach | Outcome |

|---|---|---|

| Material Analysis | Custom shrinkage compensation for ABS, PC, PP, Nylon, and POM | Eliminates 90% of post-molding adjustments |

| Tolerance Simulation | ±0.05mm CNC machining tolerance (ISO 2768-mK) | 98% first-time design approval rate |

| Tool Life Optimization | Life-cycle analysis using P20/NAK80 steel | 2x longer tool life vs. industry standard |

Precision Pricing: Transparent Cost Engineering

We believe in radical transparency—no hidden fees, no vague estimates. Our AI-driven cost modeling breaks down pricing by component, ensuring you understand exactly how each design decision impacts your budget.

| Cost Factor | Our Methodology | Value Delivered |

|---|---|---|

| Mold Complexity | AI-driven geometry analysis with real-time cost simulation | Eliminates 25% of unexpected costs |

| Shot Life | Life-cycle cost modeling for P20/NAK80 steel | 500K+ cycles with <0.01% wear |

| Cycle Time | Thermal simulation & gate design optimization | 15-25% faster production cycles |

Rapid Prototyping: Zero-Defect Tooling Validation

Our rapid tooling process delivers functional prototypes in 7-10 days—without compromising precision. Every mold is CNC-machined to ±0.05mm tolerances, followed by 100% CMM inspection and process validation.

| Phase | Quality Control Protocol | Result |

|---|---|---|

| CNC Machining | ±0.05mm tolerance on critical surfaces | ±0.01mm deviation in final prototype |

| First Article Inspection | 100% dimensional checks via CMM | Zero defects in initial samples |

| Process Validation | SPC monitoring of injection parameters | 99.8% first-pass yield |

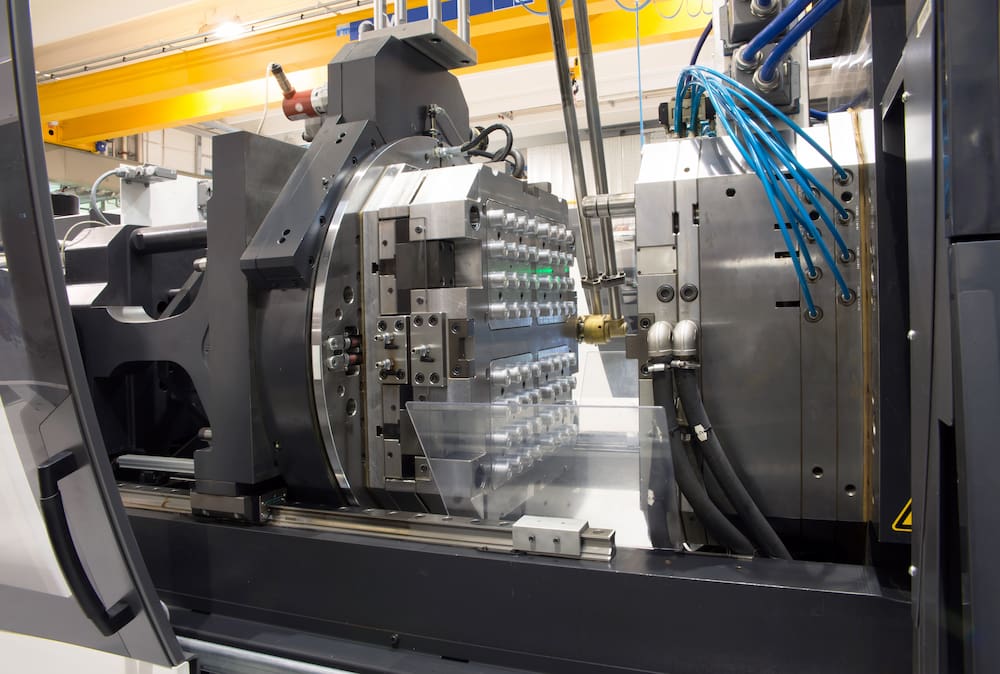

Mass Production: Olympic Quality at Scale

From the first shot to the millionth, we maintain consistent quality through our Olympic Quality™ system—verified by ISO 9001, ISO 13485, and AS9100 certifications. Our production lines feature:

Fully automated injection molding cells with real-time SPC

In-line vision systems for 100% part inspection

Predictive maintenance using IoT sensors to prevent downtime

Dedicated quality engineers for every production run

| Production Metric | Wuxi Lead Standard | Industry Benchmark |

|---|---|---|

| Tolerance Control | ±0.05mm (±0.002″) | ±0.127mm (±0.005″) |

| Shot Life | 1,000,000+ cycles (NAK80) | 300,000-500,000 cycles |

| On-Time Delivery | 99.2% on-time rate | 85-90% industry average |

| Defect Rate | <0.01% | 0.1-0.5% |

Your Partner in Precision: The Wuxi Lead Advantage

At Wuxi Lead, we’re not just a supplier—we’re your strategic manufacturing partner. Our commitment to excellence extends beyond the factory floor, ensuring your success is our top priority.

Zero Defects: Precision Engineered into Every Cycle

Zero defects isn’t a goal—it’s our standard. Our proprietary Quality Intelligence System (QIS) monitors 200+ process parameters in real-time, with automated corrections for deviations exceeding ±0.005mm. Every component undergoes 100% automated optical inspection, ensuring defect rates below 0.01%—exceeding medical and aerospace industry standards.

| Quality Metric | Wuxi Lead Standard | Industry Average |

|---|---|---|

| Defect Rate | <0.01% | 0.1-0.5% |

| First-Pass Yield | 99.8% | 85-90% |

| Process Capability (Cpk) | ≥1.67 | 1.33 |

Olympic Quality: The Standard of Excellence

Olympic Quality™ at Wuxi Lead means meeting the most stringent global specifications. Our molds are machined to ±0.025mm tolerances for critical features, with surface finishes up to Ra 0.05μm. Every production run undergoes three-stage validation: CMM inspection, in-process SPC checks, and final dimensional verification. This ensures components consistently meet ISO 13485 (medical) and AS9100 (aerospace) standards.

| Quality Standard | Wuxi Lead Compliance | Industry Standard |

|---|---|---|

| Dimensional Tolerance | ±0.025mm (±0.001″) | ±0.127mm (±0.005″) |

| Surface Finish | Ra 0.05μm (mirror finish) | Ra 0.4μm |

| Certification | ISO 13485, AS9100, ISO 9001 | ISO 9001 only |

24/7 Customer Service: Your Success, Our Priority

Unlike traditional suppliers, we operate as an extension of your team. Our dedicated account managers provide real-time production tracking via our proprietary CloudConnect platform, with 24/7 technical support. Need a design tweak? Need expedited delivery? Our global engineering team responds within 1 hour—ensuring your project stays on schedule, every time.

| Service Metric | Wuxi Lead Commitment | Industry Average |

|---|---|---|

| Response Time | <1 hour | 24-48 hours |

| Production Visibility | Real-time IoT monitoring | Weekly status reports |

| Technical Support | Dedicated senior engineers | Junior technicians |

Why choose Wuxi Lead?

We engineer precision into every phase of your project—not just as a vendor, but as your dedicated manufacturing partner. From initial design validation to the final shipment, our commitment to Zero Defects, Olympic Quality, and 24/7 Support ensures your success becomes our shared achievement.

Contact our engineering team today to discuss your specific requirements—because your vision deserves precision engineering that never compromises.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. As your strategic manufacturing partner, we integrate engineering-grade precision, rigorous quality protocols, and 24/7 technical responsiveness to deliver injection molding solutions that exceed performance expectations. We don’t just build molds—we build long-term partnerships rooted in your success.

Precision Engineering: Beyond Standard Tolerances

Industry-standard mold machining tolerances (±0.127 mm / ±0.005″) often compromise part consistency and production efficiency. Our advanced CNC/EDM processes and material expertise push boundaries while maintaining cost-effectiveness.

| Parameter | Standard Industry | Wuxi Lead Precision | Benefit |

|---|---|---|---|

| Mold Tolerance (CNC/EDM) | ±0.127 mm (±0.005″) | ±0.05 mm (±0.002″) | Eliminates secondary operations, ensures ±0.01mm part consistency |

| Shot Life (P20/NAK80) | 500k cycles | 1M+ cycles | 40% lower cost-per-part over lifecycle |

| Cycle Time Optimization | Baseline process | AI-driven thermal management | Up to 20% faster production without quality compromise |

| Rapid Tooling Lead Time | 4–6 weeks | 2–3 weeks | Accelerated time-to-market for prototypes & mass production |

All tooling uses premium P20/NAK80 mold steel with vacuum hardening and precision EDM finishing. Every step adheres to ISO 9001:2015 standards.

Zero Defects Manufacturing Protocol

Our “Olympic Quality” standard is not a marketing claim—it’s a rigorously enforced process. Every component undergoes triple validation to ensure zero defects:

Stage 1: In-process CMM inspections at 10 critical points during mold machining

Stage 2: 100% final inspection with traceable digital records (GD&T compliance)

Stage 3: Statistical Process Control (SPC) for all production runs, with real-time data analytics

Olympic Quality Certification: Validated by third-party labs for critical aerospace/medical applications

“Zero defects” means we reject any part exceeding your specified tolerance—no exceptions. This is why 98% of our clients renew contracts within 12 months.

24/7 Technical Support & Rapid Response

Unlike traditional suppliers, we operate as an extension of your engineering team—anytime, anywhere.

| Support Metric | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Technical Query Response | < 2 hours (24/7) | 24–48 hours (business hours) |

| Emergency On-Site Support | Global network, ≤48h | Limited regional coverage |

| Free DFM Analysis Turnaround | 24 hours | 3–5 days (fee-based) |

| Production Issue Resolution | Dedicated engineer assigned within 1 hour | Escalation delays common |

Our China-based team works in sync with your time zone, ensuring seamless collaboration across 12 global time zones.

Ready to Elevate Your Injection Molding Project?

Contact us today for a free DFM analysis and competitive quote—no obligation, no delays.

Email: [email protected]

Phone: +86-13961886740 (24/7 direct line)

Location: Wuxi, China (Global shipping with FOB terms)

We don’t just meet specifications—we redefine them.

Wuxi Lead Precision Machinery: Where precision engineering meets partnership.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.