Technical Contents

Engineering Guide: Injection Moulding Machine Parts

Engineering Insight: Precision in Injection Moulding Machine Parts

In the high-stakes world of industrial manufacturing, the performance of injection moulding machinery hinges on the precision and durability of its core components. These machines operate under extreme pressures, temperatures, and cyclic loads, demanding parts that maintain dimensional stability and functional reliability over millions of cycles. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations in critical components can lead to part defects, machine downtime, or catastrophic failure. This is why our engineering philosophy centers on uncompromising precision, advanced material science, and rigorous quality control.

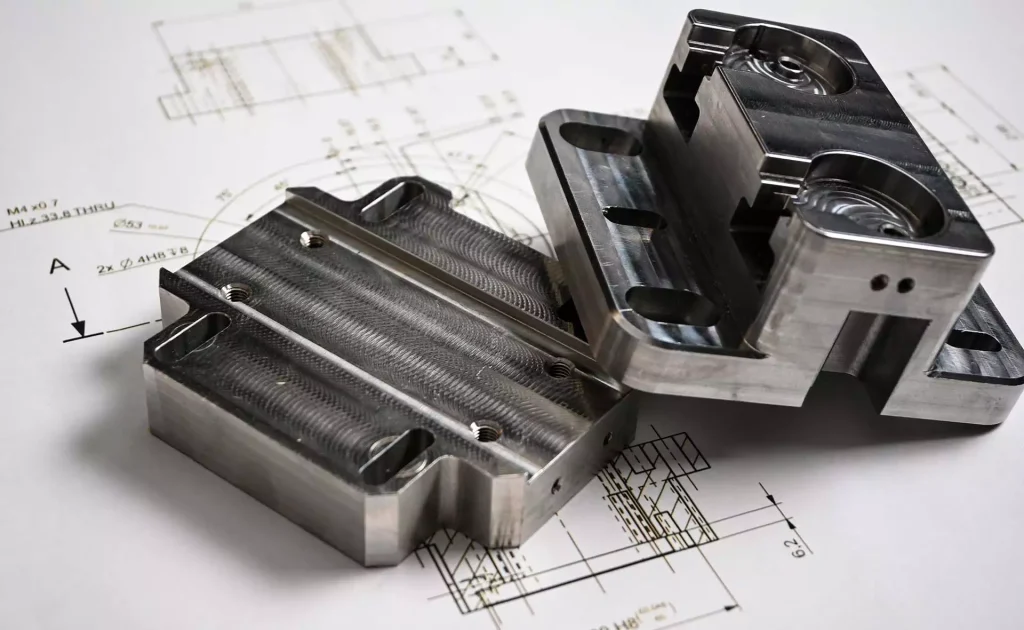

Injection moulding machine parts such as tie bars, toggle joints, ejector plates, and platen components must be manufactured to exacting tolerances. These elements endure repeated stress and must align perfectly to ensure consistent mould closure, optimal clamping force distribution, and uniform part quality. Any misalignment or deformation due to poor machining or substandard materials can result in flash, short shots, or wear that compromises machine lifespan. Our CNC machining processes, supported by multi-axis milling and grinding technologies, ensure geometric accuracy within ±0.002 mm, with surface finishes tailored to functional requirements.

What sets Wuxi Lead apart is not just our technical capability, but our proven track record in mission-critical applications. Our precision components have been integrated into systems used in Olympic-grade sports equipment manufacturing and specialized military hardware, where failure is not an option. These projects demanded not only extreme accuracy but also full traceability, material certification, and compliance with international standards—capabilities we bring to every injection moulding machine component we produce.

We specialize in custom metal manufacturing for OEMs and Tier-1 suppliers worldwide, delivering parts in hardened steels, alloy steels, and wear-resistant materials such as 27CrMoV55 and 42CrMo4. Each component undergoes comprehensive quality assurance, including CMM inspection, hardness testing, and ultrasonic flaw detection, ensuring reliability under real-world operating conditions.

Below are typical specifications for key injection moulding machine components manufactured at our facility:

| Component | Material | Tolerance (mm) | Surface Finish (Ra µm) | Hardness (HRC) | Key Process |

|---|---|---|---|---|---|

| Tie Bars | 42CrMo4 | ±0.003 | 0.8 | 38–42 | CNC Turning, Grinding |

| Platen Plates | S45C + Hard Chrome | ±0.01 | 1.6 | 28–32 | Milling, Boring |

| Toggle Links | 27CrMoV55 | ±0.005 | 1.2 | 40–45 | CNC Milling, Heat Treatment |

| Ejector Pins | SKD61 | ±0.002 | 0.4 | 48–52 | Precision Grinding |

| Guide Columns | GCr15 | ±0.003 | 0.6 | 58–62 | Cylindrical Grinding |

At Wuxi Lead Precision Machinery, we combine decades of metallurgical expertise with state-of-the-art manufacturing to deliver components that ensure the longevity and efficiency of injection moulding systems. When precision is non-negotiable, our experience in high-reliability sectors stands as a testament to our capability.

Precision Specs & Tolerances

Technical Capabilities for Precision Injection Moulding Machine Components

Wuxi Lead Precision Machinery delivers uncompromising precision in the manufacture of critical injection moulding machine parts. Our core strength lies in advanced multi-axis machining integrated with rigorous metrology, ensuring components meet the exacting demands of high-speed, high-pressure moulding environments. We specialize in complex geometries requiring tight tolerances, superior surface finishes, and exceptional material integrity across tool steel, stainless steel, and hardened alloys. This capability is essential for mould bases, tie bars, ejector systems, hot runner manifolds, and intricate cavity/core inserts where dimensional stability directly impacts mould performance and part quality.

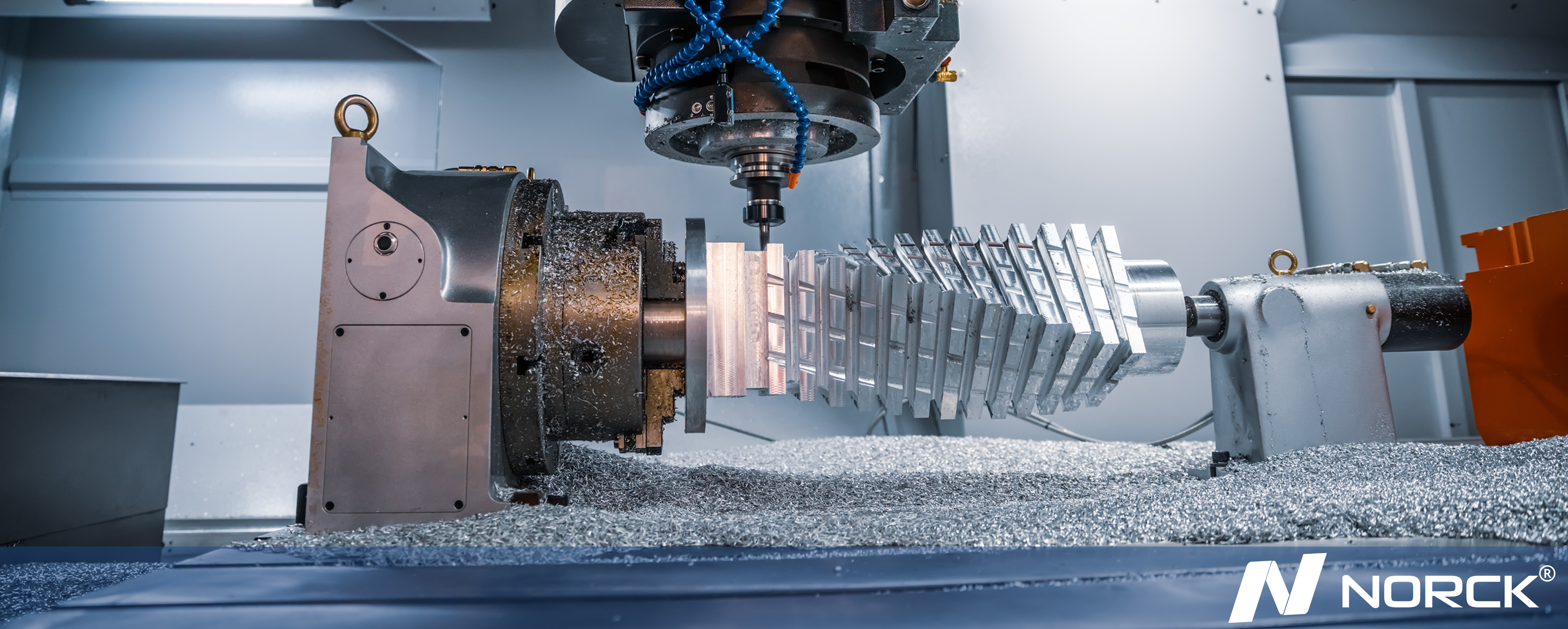

Our primary manufacturing platform centers on state-of-the-art 5-axis CNC machining centers. This technology enables the complete machining of highly complex components in a single setup, eliminating cumulative errors inherent in multi-operation processes. We achieve exceptional geometric accuracy and surface integrity on deep cavities, undercuts, and contoured profiles typical in modern mould construction. The simultaneous 5-axis motion allows optimal tool orientation, minimizing tool deflection and maximizing material removal rates while maintaining micron-level precision. This capability is critical for producing monolithic structures and reducing assembly points, enhancing the overall rigidity and longevity of the moulding machine assembly.

Dimensional validation is non-negotiable. Every critical feature undergoes comprehensive inspection using calibrated Coordinate Measuring Machines (CMM). Our CMM protocols follow ISO 10360 standards, providing traceable, objective verification of complex geometries against the original CAD model. This includes full 3D profile analysis, positional tolerancing, flatness, parallelism, and true position verification. CMM reporting delivers actionable data, ensuring not only that parts meet print specifications but also confirming their functional compatibility within the larger mould assembly. This systematic approach guarantees dimensional integrity before components leave our facility.

The following table details our standard achievable tolerances for machined features on injection moulding machine components, validated through our CMM process. These specifications represent our routine production capability for critical features under controlled environmental conditions using hardened tool steels and stainless alloys.

| Feature Type | Standard Tolerance | Critical Feature Tolerance | Surface Roughness (Ra) |

|---|---|---|---|

| Linear Dimensions | ±0.02 mm | ±0.005 mm | 0.8 μm |

| Geometric Form (Flatness, Roundness) | 0.02 mm | 0.005 mm | 0.4 μm |

| Positional Tolerance | ±0.015 mm | ±0.003 mm | 0.8 μm |

| Angular Dimensions | ±0.05° | ±0.01° | 1.6 μm |

This combination of advanced 5-axis CNC machining and stringent CMM-based quality control forms the foundation of Wuxi Lead’s commitment to precision. We understand that the performance and uptime of your injection moulding operation depend on the absolute reliability of every machined component. Our technical capabilities are engineered to deliver that reliability consistently, ensuring your moulds operate at peak efficiency with minimal maintenance downtime. Partner with us for components where precision is not just a specification, but a functional requirement.

Material & Finish Options

Material selection is a critical decision in the design and production of injection moulding machine parts, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-demand industrial applications, offering expert guidance in selecting the optimal material and surface treatment for your specific requirements. The most commonly used materials in this domain are aluminum, steel, and titanium, each presenting unique mechanical properties and suitability for different operational environments.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly suitable for mould components requiring rapid heat dissipation and reduced cycle times, such as mould bases and inserts in low-volume production. While not as hard as steel, aluminum offers significant cost and time savings during machining, making it ideal for prototyping and short-run manufacturing. When enhanced with anodizing, aluminum gains improved surface hardness, wear resistance, and corrosion protection—essential for maintaining dimensional accuracy and prolonging service life.

Steel remains the standard for high-volume injection moulding due to its superior hardness, wear resistance, and dimensional stability under prolonged stress. Tool steels such as P20, H13, and S136 are commonly selected based on factors like cavity complexity, required polish, and exposure to corrosive materials. Hardened and tempered steel components ensure long tool life and consistent part quality, especially in aggressive production cycles. While heavier and more challenging to machine than aluminum, steel’s longevity often justifies the higher initial investment.

Titanium is used selectively in high-performance applications where extreme strength, corrosion resistance, and lightweight properties are paramount. Though significantly more expensive and difficult to machine, titanium excels in environments involving high temperatures, aggressive chemicals, or where weight reduction is critical. Its use in injection moulding is typically limited to specialized cores, ejector pins, or wear components exposed to harsh conditions.

Surface finishing plays an equally important role in component performance. Anodizing, particularly for aluminum, creates a controlled oxide layer that enhances surface durability and supports secondary treatments like sealing or coloring. Hard anodizing (Type III) can achieve surface hardness approaching that of tool steel, making it a strategic upgrade for high-wear areas.

Below is a comparative overview of key material properties and performance characteristics.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Common Applications in Moulding |

|---|---|---|---|---|---|

| Aluminum (6061-T6) | 2.7 | 310 | 95 | 167 | Mould bases, inserts, prototypes |

| Steel (P20) | 7.8 | 950 | 290 | 36 | Cavity plates, core blocks |

| Steel (H13) | 7.8 | 1,500 | 450 | 30 | Hot runner components, high-wear areas |

| Titanium (Grade 5) | 4.5 | 900 | 360 | 7.2 | Ejector pins, high-corrosion zones |

At Wuxi Lead Precision Machinery, we combine material science expertise with advanced CNC machining to deliver injection moulding components that meet exacting industrial standards. Our engineering team supports clients in selecting the right material and finish to balance performance, cost, and production efficiency.

Manufacturing Process & QC

Precision Execution: From Concept to Zero-Defect Injection Moulding Components

Precision begins long before metal cutting commences. At Wuxi Lead Precision Machinery, our production process for critical injection moulding machine parts—such as tie bars, platens, and ejector plates—is engineered for uncompromising quality. Every component undergoes a rigorously controlled sequence: Design Validation, Prototyping Verification, and Zero-Defect Mass Production. This methodology eliminates costly field failures and ensures seamless integration into high-pressure moulding systems.

The Design phase integrates advanced DFM (Design for Manufacturability) analysis using CATIA and SolidWorks. Our engineering team collaborates with clients to optimize geometry, material selection (typically 2714H, 1.2344, or custom tool steels), and thermal management. Finite Element Analysis (FEA) simulates stress points under 2000+ ton clamping forces, preempting fatigue risks. Critical tolerances—such as platen flatness within 0.02mm over 1000mm—are locked before prototyping. This phase reduces downstream rework by 70% through proactive error elimination.

Prototyping transforms validated designs into physical benchmarks. We produce 1-3 functional units using the same CNC machining centers (DMG MORI, Makino) and heat-treatment protocols slated for mass production. Each prototype undergoes destructive and non-destructive testing: CMM verification of all critical dimensions, ultrasonic testing for internal integrity, and pressure cycling to 150% of operational load. Client engineers review test data and fitment reports. Only after sign-off—confirming zero deviations from performance specifications—does the project advance. This stage catches 95% of potential defects before volume manufacturing begins.

Mass Production deploys our Zero-Defect framework. Machining occurs in climate-controlled cells with real-time SPC (Statistical Process Control) monitoring. Each part is traced via laser-etched serial numbers through every operation: rough milling, precision grinding, hardening (to HRC 50-52), and mirror polishing. In-process inspections at defined checkpoints use automated optical comparators and 3D scanning. Final validation requires 100% dimensional certification against the approved prototype, with hardness and metallurgical reports. Non-conforming units are quarantined before leaving the cell—never entering client inventory. This closed-loop system achieves <50 PPM defect rates, exceeding ISO 9001 standards.

Our commitment to perfection is quantifiable. The table below compares critical specifications for mould bases, demonstrating how Wuxi Lead exceeds industry baselines:

| Parameter | Industry Standard | Wuxi Lead Specification |

|---|---|---|

| Platen Flatness | ≤0.05mm / m² | ≤0.02mm / m² |

| Parallelism (Tie Bars) | ≤0.03mm | ≤0.01mm |

| Surface Roughness (Ra) | 0.8µm | 0.4µm |

| Hardness Uniformity | ±3 HRC | ±1.5 HRC |

This disciplined approach—from virtual validation to metrology-backed production—ensures your injection moulding systems deliver maximum uptime and part consistency. Wuxi Lead transforms engineering intent into flawless metal reality, safeguarding your productivity and reputation.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Injection Moulding Machine Parts

At Wuxi Lead Precision Machinery, we specialize in the custom manufacturing of high-precision metal components engineered specifically for injection moulding machines. With over a decade of experience serving global industrial clients, we have built a reputation for delivering parts that meet the most stringent performance, durability, and dimensional accuracy requirements. Our advanced CNC machining capabilities, combined with rigorous quality control protocols, ensure that every component we produce contributes directly to the efficiency and reliability of your injection moulding operations.

Our engineering team works closely with OEMs, system integrators, and machine builders to develop tailor-made solutions that address exact functional demands. Whether you require tie bars, platen plates, injection units, or custom guide columns, our in-house design and manufacturing processes allow for rapid prototyping, short lead times, and full traceability. We utilize premium-grade materials such as 45# steel, P20, 718H, and other alloy tool steels, all treated with precise heat treatment processes to ensure optimal hardness, wear resistance, and structural integrity.

We understand that downtime in injection moulding systems can be costly. That’s why every part we manufacture is designed not only to meet original equipment specifications but to exceed them in longevity and performance. Our ISO 9001-certified production facility integrates CAD/CAM design, 5-axis CNC machining, surface grinding, and CMM inspection to maintain tolerances as tight as ±0.002 mm. This level of precision ensures seamless integration into existing machine platforms and reduces maintenance frequency.

Below are key technical capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Maximum Machining Size | 2000 mm × 1200 mm × 800 mm |

| Tolerance Control | ±0.002 mm |

| Surface Finish | Ra 0.4 μm (standard), down to Ra 0.1 μm (precision grinding) |

| Materials Processed | 45#, P20, 718H, H13, S136, 42CrMo, and custom alloys |

| Heat Treatment | Quenching & Tempering, Nitriding, Induction Hardening |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Reports, PPAP available |

| Equipment | 5-Axis CNC Centers, CNC Lathes, Surface & Cylindrical Grinders, CMM |

We are committed to being more than a supplier—we are a strategic manufacturing partner. From concept validation to volume production, our engineers provide technical consultation, DFM analysis, and continuous improvement support to help you optimize performance and reduce total cost of ownership.

For inquiries about custom injection moulding machine parts or to request a quote, contact us today at [email protected]. Let Wuxi Lead Precision Machinery be the precision behind your production.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.