Technical Contents

Engineering Guide: Injection Moulding Large Parts

Engineering Insight: Injection Moulding Large Parts with Precision

Injection moulding of large-scale components presents unique engineering challenges that extend far beyond the capabilities of standard production systems. When manufacturing large parts—such as structural enclosures, industrial housings, or aerospace panels—maintaining dimensional accuracy, material consistency, and long-term repeatability becomes exponentially more critical. At Wuxi Lead Precision Machinery, we understand that precision in large-part injection moulding is not a secondary benefit but a foundational requirement for performance, safety, and integration into complex assemblies.

The scale of large moulded components amplifies even minor deviations. A tolerance shift of just 0.1 mm can result in misalignment, compromised sealing, or failure during final assembly—especially when interfacing with machined metal parts or high-tolerance systems. This is why our approach integrates precision engineering at every phase: from mould design and material flow analysis to cavity pressure control and cooling uniformity. We utilize advanced simulation software to predict warpage and stress points, enabling proactive corrections before tooling begins.

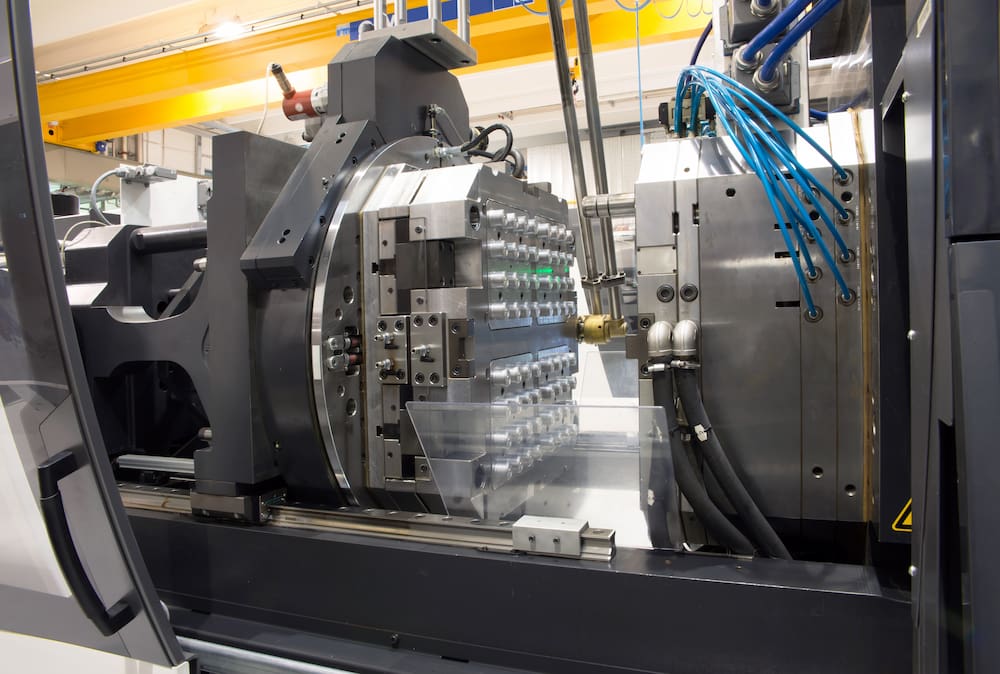

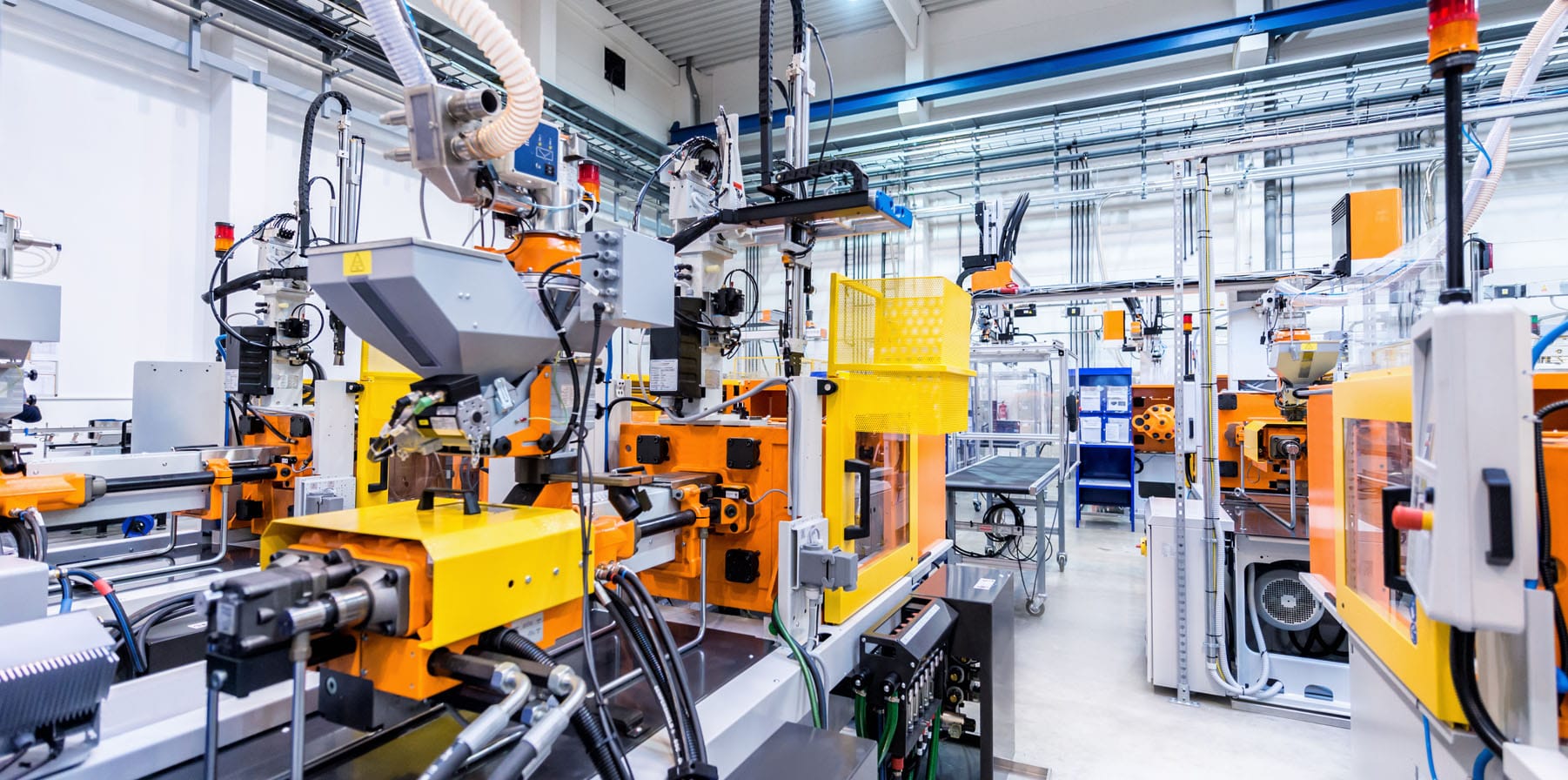

Our facility is equipped with high-tonnage hydraulic and hybrid presses, capable of delivering consistent clamp forces up to 4,500 tons. These machines are paired with real-time monitoring systems that track injection speed, pressure, and temperature with sub-millisecond response times. This level of control ensures that even parts exceeding 1,200 mm in length maintain tight tolerances and uniform wall thickness across the entire geometry.

Wuxi Lead Precision Machinery has applied this precision-driven methodology in mission-critical applications. We have supported projects for Olympic-grade sports infrastructure, where structural panels required both aesthetic perfection and mechanical resilience under dynamic loads. Additionally, our work in defense and military logistics has involved producing large, durable enclosures for field-deployable equipment—components that must endure extreme environments while maintaining exact dimensional stability.

Our experience underscores a fundamental truth: large-part injection moulding cannot rely solely on machine power. It demands a holistic engineering strategy that balances material science, thermal management, and process control. At Lead Precision, we combine decades of metallurgical expertise with state-of-the-art automation to deliver parts that meet the most stringent industrial standards.

The following table outlines key specifications that define our large-part injection moulding capabilities:

| Parameter | Capability |

|---|---|

| Maximum Part Dimensions | 1,800 mm × 1,200 mm × 800 mm |

| Maximum Clamp Force | 4,500 tons |

| Tolerance Range | ±0.05 mm to ±0.1 mm (depending on geometry) |

| Material Compatibility | Engineering-grade ABS, PC, PP, PPS, PEEK |

| Mould Steel Types | H13, S136, 2738HH, 718H |

| Cycle Time Monitoring | Real-time, closed-loop control |

| Production Environment | ISO 9001-certified, climate-controlled |

Precision at scale is not an aspiration—it is our standard. For industries where failure is not an option, Wuxi Lead Precision Machinery delivers large-part injection moulding solutions engineered for excellence.

Precision Specs & Tolerances

Technical Capabilities for Large-Part Injection Mould Manufacturing

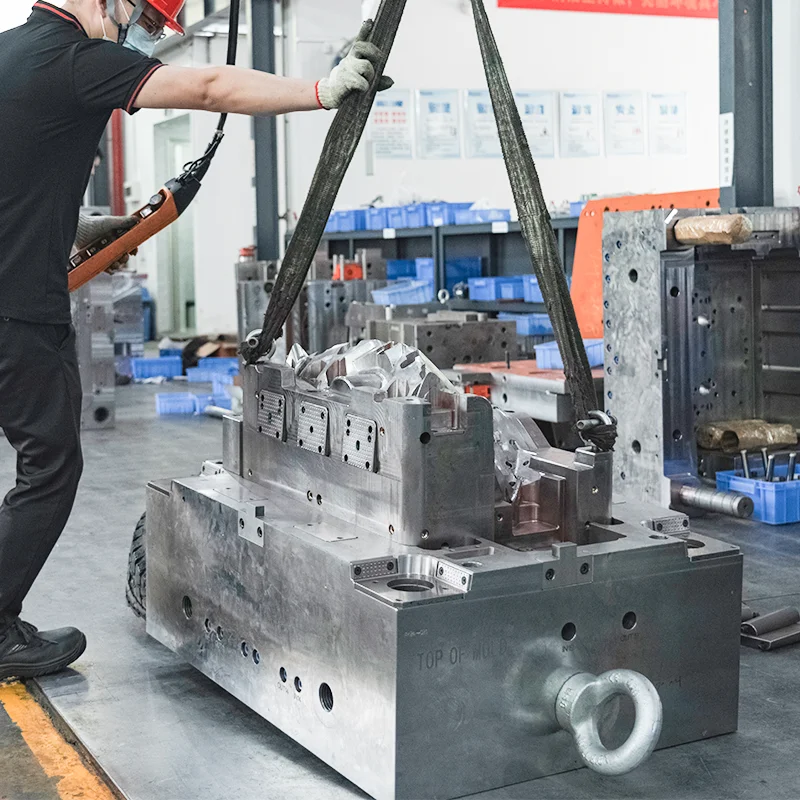

Wuxi Lead Precision Machinery delivers uncompromising precision in the production of injection moulds for large-scale plastic components, addressing the stringent demands of automotive, aerospace, and industrial equipment sectors. Our core strength lies in mastering the geometric complexity and dimensional stability required for parts exceeding 1500mm in critical dimensions. This capability is fundamentally enabled by our advanced 5-axis CNC machining infrastructure. We operate a dedicated fleet of high-torque, high-travel 5-axis machining centers, including models from DMG MORI and Makino, featuring work envelopes exceeding 2000mm x 1500mm x 1000mm with rapid traverse rates optimized for large-part efficiency. These systems eliminate the need for multiple setups, ensuring monolithic structural integrity and critical feature alignment across vast surfaces through simultaneous five-axis contouring. This is essential for achieving the complex undercuts, smooth flow paths, and precise cavity/core matching demanded by large mould applications, directly translating to consistent part quality and reduced cycle times for our clients.

Rigorous quality control is non-negotiable in large-part mould manufacturing, where minor deviations have amplified consequences. Every critical feature undergoes comprehensive validation via our coordinate measuring machine (CMM) inspection protocol. We utilize multiple high-accuracy CMMs, including a 3000mm x 2000mm x 1000mm system with sub-micron probing resolution, specifically calibrated for large-scale metrology. Inspection routines are developed directly from CAD models, focusing on critical gating locations, parting line flatness, ejector pin alignment, cooling channel positioning, and overall cavity/core conformity. This systematic approach, combined with in-process probing during machining, ensures dimensional accuracy is maintained throughout production, providing documented evidence of conformance before mould assembly and testing. Our QC process is certified to ISO 9001:2015, with all inspection reports traceable to international standards.

The following table details our standard achievable tolerance ranges for large-part injection mould components, validated through our integrated machining and CMM inspection processes. These specifications reflect our commitment to delivering moulds capable of producing high-precision large plastic parts consistently.

| Feature Type | Tolerance Range | Measurement Method |

|---|---|---|

| Critical Cavity/Core Dimensions | ±0.005 mm | CMM with certified probes |

| Parting Line Flatness (per 300mm) | ≤ 0.010 mm | CMM / Precision Straight Edge |

| Ejector Pin Bore Location | ±0.010 mm | CMM |

| General Machined Surfaces | ±0.020 mm | CMM / Calibrated Micrometers |

| Cooling Channel Position | ±0.025 mm | CMM / Bore Gauges |

| Overall Mould Base Flatness | ≤ 0.030 mm/m | Laser Tracker / Surface Plate |

Wuxi Lead Precision Machinery combines substantial 5-axis machining capacity with metrology-grade inspection to solve the unique challenges of large-part injection mould manufacturing. We transform complex design requirements into production-ready tooling, ensuring dimensional fidelity, extended mould life, and optimal part quality for the most demanding large-scale applications. Partner with us for precision engineered at scale.

Material & Finish Options

Material Selection for Injection Moulding Large Parts: A Precision Engineering Guide

When manufacturing large-scale injection moulds for industrial applications, material selection is a critical determinant of performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the demanding requirements of large-part injection moulding. The choice between aluminum, steel, and titanium depends on production volume, part complexity, thermal management needs, and environmental exposure.

Aluminum alloys, particularly 7075 and 6061-T6, offer excellent machinability and thermal conductivity, making them ideal for prototypes and low-to-medium volume production runs. Their lightweight nature reduces mould handling stress and accelerates cycle times due to faster cooling. However, aluminum’s lower hardness and wear resistance limit its use in high-volume or abrasive material processing.

Steel, especially P20, H13, and 420 stainless, remains the standard for high-volume injection moulding. These alloys provide superior hardness, dimensional stability, and resistance to wear and deformation under prolonged thermal cycling. P20 is widely used for large mould bases due to its good machinability and through-hardening properties. H13 offers enhanced toughness and thermal fatigue resistance, making it suitable for hot runner systems and cores in large moulds. For corrosive environments or medical-grade applications, 420 stainless steel provides excellent resistance to rust and chemical exposure.

Titanium alloys, while less common due to high cost and machining complexity, are selected for niche applications requiring exceptional strength-to-density ratios and corrosion resistance. In aerospace or defence-related large moulds exposed to extreme conditions, titanium’s performance justifies its premium. However, its low thermal conductivity and high reactivity during machining demand specialized tooling and process control.

Surface finish plays a pivotal role in part ejection, surface quality, and mould maintenance. Anodizing is a widely adopted finish for aluminum moulds, significantly enhancing surface hardness and corrosion resistance. Type II (sulfuric acid) anodizing provides a decorative and protective layer, while Type III (hardcoat anodizing) delivers a wear-resistant surface capable of withstanding thousands of cycles. For steel moulds, alternatives such as nitriding, chrome plating, or PVD coatings are more common, though anodizing is not applicable.

Below is a comparative overview of key material properties relevant to large-part injection moulding:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | Moderate | Prototypes, low-volume production |

| P20 Steel | 28–32 | 30 | Low | High-volume mould bases |

| H13 Steel | 45–50 | 35 | Moderate | Cores, cavities, hot runner systems |

| 420 Stainless | 50–54 | 25 | High | Corrosive environments, medical |

| Titanium Grade 5 | 35–40 | 7 | Very High | Aerospace, extreme condition moulds |

Selecting the right material and finish ensures optimal cycle life, part quality, and return on investment. At Wuxi Lead Precision Machinery, we support clients in matching material properties to application demands, leveraging decades of precision engineering expertise in large-part injection mould manufacturing.

Manufacturing Process & QC

Precision Injection Molding Process for Large-Scale Metal Components

At Wuxi Lead Precision Machinery, our large-part injection molding process is engineered for uncompromising quality and geometric integrity from initial concept through high-volume output. We integrate advanced engineering with rigorous validation protocols to eliminate defects inherent in scaling production. The journey begins with collaborative Design for Manufacturing (DFM) analysis. Our engineering team works directly with client CAD models, utilizing Moldflow simulation to predict material flow, cooling dynamics, and potential warpage specific to large geometries exceeding 2000mm in critical dimensions. This phase identifies stress concentrations, optimizes gate placement for uniform cavity filling, and ensures thermal equilibrium across the mold – critical factors often overlooked that lead to sink marks or dimensional drift in oversized parts. Material selection undergoes stringent vetting against mechanical, thermal, and environmental requirements, with full traceability documentation provided.

Prototyping transitions seamlessly using production-intent hardened steel molds, not soft tooling. This critical step validates the DFM outcomes under actual process parameters. We conduct iterative trials measuring first-article dimensions against nominal CAD data using CMM verification, assessing surface finish consistency, and confirming structural performance under simulated load conditions. Each prototype cycle refines cooling channel efficiency, clamp pressure profiles, and ejection sequences to achieve part stability before committing to mass production. This phase is non-negotiable for mitigating risk; skipping it guarantees costly rework during volume runs.

Mass production operates under our Zero Defects Protocol, a closed-loop system combining real-time process monitoring with statistical process control (SPC). Every cycle is tracked via cavity pressure transducers and temperature sensors, feeding data to our central control system which instantly flags deviations beyond ±0.5% tolerance bands. Automated vision inspection systems perform 100% surface defect screening, while in-line metrology stations verify critical dimensions at defined intervals. Our dedicated process engineers continuously analyze SPC charts, adjusting parameters proactively rather than reactively. This systematic approach ensures consistent output where geometric accuracy and material properties meet aerospace and heavy industrial standards, eliminating scrap and rework costs associated with latent defects.

Large-Part Injection Molding Capabilities at Wuxi Lead

| Parameter | Specification | Zero Defects Protocol Integration |

|---|---|---|

| Max Part Dimensions | 4000mm x 2500mm x 1200mm | Real-time warpage monitoring via thermal imaging |

| Max Shot Weight | 35,000 grams | Cavity pressure control within ±0.3% |

| Press Tonnage Range | 2500 to 6500 tons | Automated clamp force adjustment |

| Material Compatibility | Engineering thermoplastics, LFT, GMT | Full material lot traceability & testing |

| Typical Tolerance Range | ±0.05mm per 100mm (as-molded) | SPC-driven process correction every 15 min |

| Production Validation | ISO 17025 accredited CMM lab | 100% automated surface inspection |

This end-to-end methodology transforms large-part molding from a high-risk operation into a predictable, high-yield process. By embedding quality at every phase – design validation, true-process prototyping, and intelligent production control – Wuxi Lead delivers components where dimensional precision and structural reliability are non-negotiable outcomes, not aspirations. The result is reduced total cost of ownership through eliminated waste and guaranteed on-time delivery for mission-critical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision Injection Moulding of Large-Scale Metal Components

When manufacturing large, high-integrity metal parts through injection moulding, precision, repeatability, and material consistency are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions engineered to meet the exacting demands of aerospace, heavy machinery, energy, and transportation sectors. Our advanced capabilities in large-part injection moulding combine proprietary tooling design, high-tonnage presses, and real-time process monitoring to deliver components that meet tight tolerances and rigorous performance standards.

Our facility in Wuxi, China, is equipped with state-of-the-art machinery capable of handling complex geometries and oversized parts—components exceeding typical industry size limits without sacrificing dimensional accuracy. We understand that scaling up introduces unique challenges in thermal distribution, material flow, and ejection dynamics. That’s why we integrate finite element analysis (FEA) and mold flow simulation into every project, ensuring optimal mold design and process parameters before a single pellet is melted.

We serve global OEMs and Tier-1 suppliers who demand more than just production—they require a technical partner with deep metallurgical expertise, scalable capacity, and full traceability. From prototype development to high-volume production, our team collaborates closely with clients to refine designs, select appropriate alloys, and validate performance through rigorous in-house testing. Our ISO 9001-certified quality management system ensures every batch meets international standards for consistency and reliability.

Below are key technical specifications that define our large-part injection moulding capabilities:

| Parameter | Specification |

|---|---|

| Maximum Clamping Force | 6,800 Tons |

| Maximum Shot Weight (Steel) | 42 kg |

| Largest Mold Footprint | 2,200 mm × 1,800 mm |

| Tolerance Control | ±0.02 mm (depending on geometry and material) |

| Material Compatibility | Stainless Steel (316L, 17-4PH), Low-Alloy Steels, Tool Steels |

| Process Monitoring | Real-time cavity pressure and temperature sensors |

| Secondary Operations | CNC Machining, Heat Treatment, Surface Finishing, CMM Inspection |

Our engineering team is fluent in English and German, enabling seamless collaboration across time zones and technical disciplines. We provide full digital reporting, including mold validation data, process capability (Cp/Cpk) analysis, and material certifications, ensuring complete transparency from design to delivery.

For manufacturers facing the challenge of producing large, complex metal components with minimal defects and maximum repeatability, Wuxi Lead Precision Machinery offers a proven, scalable solution. We don’t just manufacture parts—we engineer performance.

Contact us today to discuss your next large-part injection moulding project. Email us at [email protected] and let our engineers help you turn demanding designs into precision reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.