Technical Contents

Engineering Guide: Injection Moulding Gates

Engineering Insight: Injection Moulding Gates – The Precision That Defines Performance

In high-end custom metal manufacturing, particularly within industries demanding zero tolerance for error, the design and execution of injection moulding gates are far more than a procedural detail—they are a critical determinant of part integrity, consistency, and functionality. At Wuxi Lead Precision Machinery, we understand that the gate is not merely an entry point for molten material; it is the control center of flow dynamics, influencing fill rate, pressure distribution, cooling behavior, and ultimately, the structural quality of the final component.

Precision in gate design directly impacts part warpage, surface finish, internal stress, and dimensional accuracy. Even minor deviations in gate geometry—such as width, depth, or positioning—can cascade into part rejection, increased scrap rates, and production delays. This is especially critical when manufacturing for sectors such as aerospace, defense, and high-performance automotive, where component failure is not an option. Our engineering team applies advanced simulation software and empirical data to optimize gate location and type, ensuring balanced filling, minimized shear stress, and uniform shrinkage across complex geometries.

Wuxi Lead Precision Machinery brings over a decade of specialized experience in high-precision metal injection moulding, serving clients with mission-critical requirements. Our work has supported components used in Olympic-grade sporting equipment and precision subsystems for military applications—environments where mechanical reliability under extreme conditions is non-negotiable. These projects demand not only technical mastery but also a culture of precision that permeates every stage of development and production.

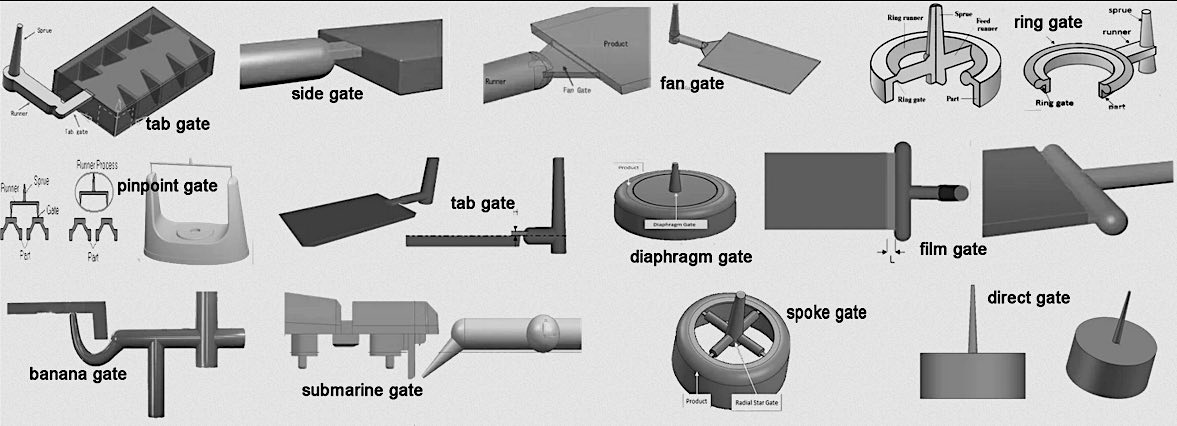

Our approach integrates material science, thermal analysis, and precision tooling to tailor gate solutions that match the exact performance criteria of the end-use application. Whether utilizing edge gates, tunnel gates, or hot runner systems, we ensure each gate is engineered to eliminate flow hesitation, reduce weld lines, and maintain repeatability across high-volume runs. This level of control is achieved through tight tolerance machining—down to ±0.002 mm—and rigorous in-process inspection using coordinate measuring machines (CMM) and 3D scanning.

The following table outlines key gate specifications and performance parameters routinely managed in our custom manufacturing process:

| Parameter | Typical Range | Tolerance Control | Application Impact |

|---|---|---|---|

| Gate Width | 0.5 – 3.0 mm | ±0.01 mm | Controls fill rate and pressure drop |

| Gate Depth | 0.3 – 1.5 mm | ±0.005 mm | Influences shear heating and flow stability |

| Gate Land Length | 0.3 – 1.0 mm | ±0.02 mm | Affects gate seal time and drool control |

| Gate Angle (Tunnel) | 15° – 45° | ±1° | Determines automatic degating efficiency |

| Surface Finish (Gate) | Ra 0.1 – 0.4 µm | Class A | Minimizes stress concentration and cracking |

| Tool Steel Hardness | HRC 48 – 52 | Verified per batch | Ensures wear resistance and longevity |

At Wuxi Lead, every gate is a testament to engineered excellence—reflecting our commitment to delivering not just parts, but performance assurance. In the world of precision manufacturing, the smallest details carry the greatest responsibility.

Precision Specs & Tolerances

Precision Gate Fabrication for Injection Moulding Systems

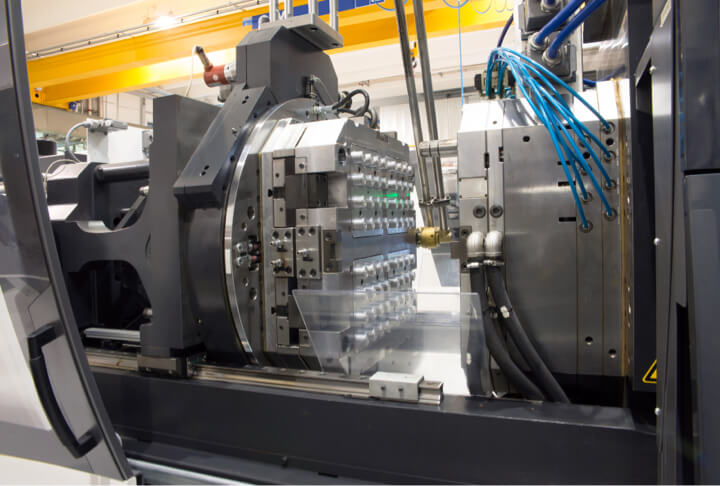

At Wuxi Lead Precision Machinery, we engineer injection moulding gates to exacting standards where dimensional accuracy directly dictates part quality, material flow, and production efficiency. Our specialized metal manufacturing process leverages advanced 5-axis CNC machining to produce gates with complex geometries and micron-level tolerances, eliminating common defects like jetting, hesitation, or sink marks. This precision ensures consistent cavity filling, optimal pressure distribution, and minimized residual stress in final plastic components.

Our HAAS and DMG MORI 5-axis CNC platforms enable simultaneous multi-directional machining of gate profiles—including pinpoint, submarine, fan, and tab styles—from hardened tool steels (H13, S136) and premium alloys. This capability allows us to achieve undercuts, radii, and tapered passages in a single setup, reducing cumulative error and ensuring seamless integration with core/cavity inserts. All gate features are machined with sub-micron surface finishes to prevent material hang-up and facilitate clean part ejection.

Rigorous quality control is embedded at every stage. Each gate undergoes 100% inspection via Zeiss CONTURA CMM systems, verifying critical dimensions against 3D CAD models with traceable NIST-certified accuracy. We measure linear dimensions, angular alignments, positional deviations, and surface integrity to validate conformity to ISO 2768-mK and client-specific standards. Statistical process control (SPC) data is documented for full traceability, ensuring repeatability across production runs.

The following table details our standard and enhanced tolerance capabilities for gate fabrication:

| Parameter | Standard Tolerance | Enhanced Capability |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm |

| Angular Features | ±0.1° | ±0.05° |

| Surface Roughness (Ra) | 0.4 µm | 0.2 µm |

| Positional Accuracy | ±0.015 mm | ±0.008 mm |

| Profile Deviation | ±0.020 mm | ±0.010 mm |

These tolerances are achievable across gate diameters ranging from 0.3 mm to 8.0 mm and depths up to 50 mm, supporting applications in medical, automotive, and electronics moulding. Our process reduces gate vestige height to <0.05 mm, eliminating secondary finishing operations and accelerating time-to-market. By controlling thermal deformation through stress-relieved substrates and optimized toolpaths, we guarantee gate longevity exceeding 500,000 cycles in high-volume production.

Wuxi Lead’s technical execution transforms gate design from a potential failure point into a reliability asset. Clients gain defect-free part replication, reduced scrap rates, and extended mould service life—proving that precision in the smallest features delivers the largest operational advantages. Partner with us to convert your gate specifications into measurable production gains.

Material & Finish Options

Material selection is a critical factor in the performance, durability, and cost-efficiency of injection moulding gates, especially in high-precision custom metal manufacturing applications. At Wuxi Lead Precision Machinery, we specialize in engineering gate systems tailored to the specific thermal, mechanical, and chemical demands of your production environment. The choice between aluminum, steel, and titanium directly impacts cycle life, thermal response, and resistance to wear and corrosion. Each material offers distinct advantages depending on production volume, part complexity, and operating conditions.

Aluminum is often selected for prototyping and low-to-medium volume production due to its excellent thermal conductivity and machinability. It allows for rapid heat dissipation, reducing cycle times during initial trials. However, aluminum’s lower hardness makes it less suitable for extended production runs or abrasive resins. For applications requiring surface enhancement, aluminum responds exceptionally well to anodizing. Anodized finishes increase surface hardness, improve wear resistance, and provide electrical insulation, making them ideal for gates in sensitive electronic or medical applications.

Steel, particularly tool steel grades such as H13 or P20, is the standard for high-volume injection moulding operations. Its superior hardness and thermal stability ensure long service life even under repeated thermal cycling and high injection pressures. Steel gates maintain dimensional accuracy over thousands of cycles and are highly resistant to erosion from glass-filled or mineral-reinforced polymers. While steel does not anodize like aluminum, it can be treated with nitriding, chrome plating, or PVD coatings to enhance surface properties. These finishes improve release characteristics and protect against corrosion in aggressive environments.

Titanium represents the premium choice for extreme durability and lightweight performance. With a high strength-to-density ratio and exceptional resistance to corrosion and galling, titanium gates are ideal for aerospace, defense, and high-performance automotive applications. Titanium maintains structural integrity at elevated temperatures and resists wear far beyond aluminum and standard steels. However, its high cost and challenging machinability typically limit its use to specialized, mission-critical components.

The following table summarizes key mechanical and thermal properties of these materials as they relate to injection moulding gate performance.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Typical Use Case | Surface Treatment Options |

|---|---|---|---|---|---|

| Aluminum | 40–50 (T6) | 160–200 | 310–350 | Prototyping, low-volume runs | Anodizing (Type II & III) |

| Steel (H13) | 48–52 | 30–35 | 1,500–1,800 | High-volume production | Nitriding, Chrome Plating, PVD |

| Titanium (Grade 5) | 35–40 (surface treated) | 7–8 | 900–1,000 | Aerospace, defense, high-stress | PVD, Nitriding, Oxidation Resistant Coatings |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination based on resin type, cycle requirements, and environmental exposure. Our engineering team integrates material science with precision manufacturing to deliver gates that maximize efficiency and longevity in your injection moulding process.

Manufacturing Process & QC

Injection Moulding Gates: Precision Engineering for Zero Defect Production

Gate design dictates the foundational integrity of every injection moulded component. At Wuxi Lead Precision Machinery, our integrated process ensures gate geometry, location, and type are optimized during the Design phase to eliminate flow imbalances, weld lines, and stress concentrations before metal is cut. We utilize advanced Moldflow simulation to model polymer behavior, predicting fill patterns and optimizing gate size for specific resins and part geometries. This computational rigor prevents common defects like jetting or short shots at the source. Critical parameters including shear rate, pressure drop, and cooling uniformity are validated against stringent aerospace and medical industry standards, ensuring the gate design inherently supports dimensional stability and surface perfection.

Prototyping transitions simulation into physical validation using our high-precision CNC machining centers. We fabricate mould inserts with micron-level accuracy, directly implementing the simulated gate design. Each prototype gate undergoes rigorous metrological analysis using Zeiss CMM systems and in-mould pressure sensors. We measure actual flow front progression, gate seal time, and residual stress distribution against simulation predictions. Any deviation triggers immediate design iteration within our closed-loop system. This phase is non-negotiable; we validate gate performance across multiple material batches and processing windows to guarantee robustness before committing to production tooling. Defect root causes are identified and resolved here, never on the production floor.

Mass Production executes the validated process with absolute repeatability. Our automated moulding cells integrate real-time monitoring of gate-specific parameters: melt temperature at the nozzle tip, injection velocity profiles, and precise gate freeze-off timing. Closed-loop control systems dynamically adjust to material viscosity fluctuations, maintaining consistent gate shear conditions. Every production cycle undergoes 100% automated visual inspection focused on gate vestige, sink, and surface defects. Statistical process control (SPC) charts for gate-related metrics are continuously analyzed. This relentless focus on process stability and immediate corrective action ensures Zero Defect output. Wuxi Lead’s end-to-end ownership of design, prototyping, and production guarantees gate performance translates directly into flawless part quality at scale.

Critical Gate Specification Parameters at Wuxi Lead

| Parameter | Standard Capability | High-Precision Capability | Validation Method |

|---|---|---|---|

| Positional Tolerance | ±0.02 mm | ±0.005 mm | CMM (Zeiss Contura) |

| Gate Vestige Height | ≤ 0.10 mm | ≤ 0.03 mm | Optical Comparator / Profilometer |

| Surface Roughness (Ra) | ≤ 0.8 µm | ≤ 0.2 µm | Stylus Profilometer |

| Material Compatibility | P20, 718, NAK80, H13 | Maraging Steel, Stainless | ISO 20753 Testing |

| Gate Types Supported | Pin, Tunnel, Edge, Fan | Hot Tip, Valve, Submarine | Moldflow Analysis + Physical Test |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Moulding Gate Excellence

At Wuxi Lead Precision Machinery, we understand that precision in injection moulding begins at the gate. As a leading custom metal manufacturing partner based in China, we specialize in engineering high-performance injection moulding systems where every detail—from gate design to material flow dynamics—impacts final part quality. Our expertise in gate optimization ensures consistent filling, minimized defects, and superior surface finishes across high-volume production runs. When you partner with us, you’re not just sourcing components—you’re gaining a strategic engineering ally committed to manufacturing excellence.

Our team of seasoned CNC engineers and tooling specialists applies decades of industrial experience to design and produce custom moulds with precision-engineered gates tailored to your specific resin type, part geometry, and production requirements. Whether you require hot runner systems with needle valve gates or cold runner solutions with edge or tab gates, we deliver solutions that enhance cycle efficiency, reduce waste, and improve part repeatability. Every gate profile is machined to micron-level tolerances using advanced CNC milling, wire EDM, and surface grinding technologies, ensuring flawless integration within your mould assembly.

We serve global OEMs and tier-one suppliers in automotive, medical device, and consumer electronics industries, where consistency and reliability are non-negotiable. Our ISO 9001-certified facility in Wuxi integrates full in-house capabilities—from initial design validation to final inspection—enabling rapid prototyping and scalable production. With a focus on lean manufacturing and continuous improvement, we maintain strict process controls and utilize real-time monitoring to guarantee every component meets the highest standards of dimensional accuracy and surface integrity.

Below are key technical specifications that define our manufacturing capabilities for injection moulding gate systems:

| Specification | Detail |

|---|---|

| Material Options | P20, 718H, NAK80, S136, H13, Stainless Steel, Tool Steel, Aluminum |

| Tolerance Range | ±0.002 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished or textured as required) |

| Maximum Part Size | 1200 mm × 800 mm × 600 mm |

| Machining Equipment | 3-axis to 5-axis CNC, Wire EDM, CNC Grinding, High-Speed Milling |

| Gate Types Supported | Edge, Submarine, Pinpoint, Fan, Diaphragm, Valve-Gated (hot runner) |

| Quality Assurance | CMM, Optical Comparator, Roughness Tester, 100% First-Art Inspection |

Partnering with Wuxi Lead Precision Machinery means access to end-to-end technical support, from DFM analysis and gate location simulation to final validation and after-sales service. We collaborate closely with your engineering team to optimize gate design for balanced flow, reduced shear, and minimal residual stress—critical factors in high-integrity plastic components.

For precision you can trust and engineering partnership you can rely on, contact us today. Send your inquiries to [email protected] and let our experts help you achieve flawless mould performance through intelligent gate design and precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.