Technical Contents

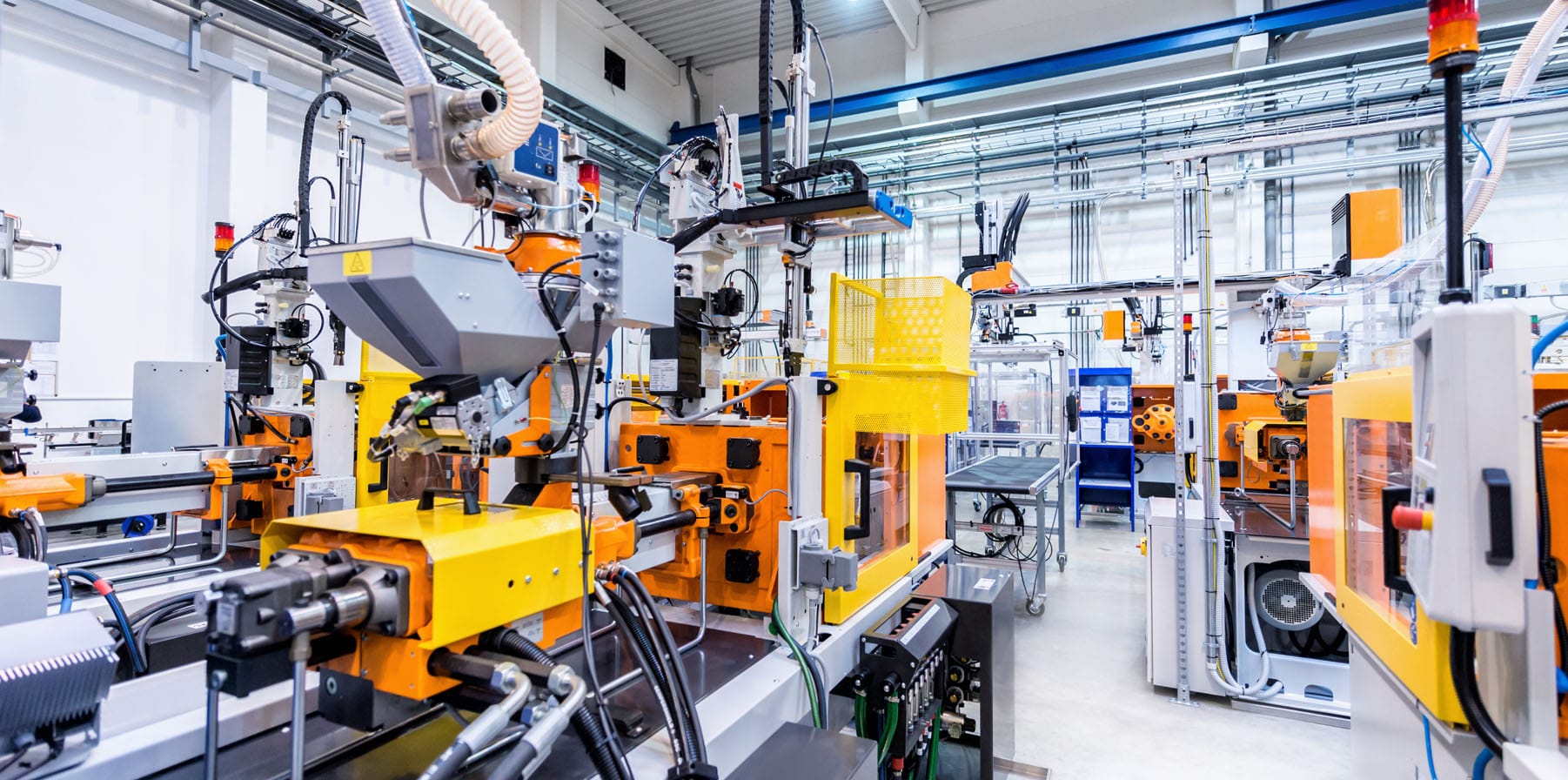

Engineering Guide: Injection Moulding Companies

Engineering Insight: The Role of Precision in Injection Moulding Systems

In the high-stakes world of injection moulding, precision is not merely a performance metric—it is the foundation of reliability, repeatability, and long-term profitability. For injection moulding companies operating at scale or serving mission-critical industries, the tolerance and consistency of every metal component directly influence cycle time, part quality, and machine uptime. At Wuxi Lead Precision Machinery, we understand that the performance of a moulding press begins long before polymer enters the cavity; it starts with the integrity and accuracy of the custom metal components that form its core.

Our engineering philosophy centers on micron-level precision, achieved through advanced CNC machining, rigorous material selection, and closed-loop quality validation. Whether producing tie bars, platen plates, hydraulic manifolds, or custom guide pillars, dimensional stability under thermal and mechanical load is non-negotiable. Even deviations measured in microns can lead to mould misalignment, flash formation, or premature wear—costly outcomes in continuous production environments.

Wuxi Lead Precision Machinery brings over 15 years of specialized experience in supplying high-tolerance components to Tier-1 injection moulding equipment manufacturers. Our portfolio includes critical subsystems for all-electric, hybrid, and hydraulic presses operating in automotive, medical, and consumer electronics sectors. What sets us apart is our proven track record in applications where failure is not an option. We have engineered and delivered components for systems deployed in Olympic-standard manufacturing facilities and certified for use in military-grade equipment production lines. These projects demanded not only extreme precision but also full documentation traceability, compliance with international metallurgical standards, and zero-defect delivery.

Our facility in Wuxi integrates 5-axis machining centers, coordinate measuring machines (CMM), and real-time thermal compensation systems to maintain tolerances as tight as ±0.002 mm. Every component undergoes multi-stage inspection, from raw material certification to final surface finish analysis, ensuring that what leaves our shop meets the exacting demands of modern injection moulding operations.

The following table outlines key precision specifications achievable across our production platform:

| Parameter | Capability Range | Standard Tolerance | Testing Method |

|---|---|---|---|

| Linear Dimension | 10 – 2,500 mm | ±0.002 mm | CMM, Laser Interferometry |

| Flatness | Up to 1,800 mm surface | 0.005 mm / 1,000 mm | Optical Flat Interferometry |

| Cylindricality | Ø15 – Ø600 mm | 0.003 mm | Roundness Measuring Instrument |

| Surface Roughness (Ra) | Machined & Ground Finishes | Ra 0.2 – 0.8 µm | Profilometer Analysis |

| Material Compliance | 45#, 40Cr, 27SiMn, SS304, etc. | GB, ASTM, DIN Standards | Spectrometry & Tensile Testing |

For injection moulding companies seeking to enhance machine performance, reduce maintenance cycles, and meet the demands of next-generation production, partnering with a precision-focused manufacturer is essential. At Wuxi Lead Precision Machinery, we combine deep technical expertise with a commitment to engineering excellence—delivering components that perform under pressure, every cycle.

Precision Specs & Tolerances

Technical Capabilities for Precision Injection Mould Manufacturing

Wuxi Lead Precision Machinery delivers mission-critical metal components engineered specifically for high-performance injection moulding applications. Our integrated manufacturing ecosystem combines advanced multi-axis machining with rigorous metrology to ensure dimensional integrity across complex geometries, directly addressing the thermal stability and wear resistance demands of modern mould systems. We specialize in hardened tool steels, pre-hardened alloys, and specialty copper-beryllium inserts where micron-level precision directly impacts part consistency and mould longevity.

Our core strength lies in 5-axis simultaneous CNC machining, utilizing DMG MORI and MAZAK platforms with sub-micron positioning accuracy. This capability eliminates manual repositioning errors during critical operations such as cavity/core contouring, vent machining, and cooling channel interpolation. Complex undercuts and deep ribs are machined in single setups, preserving geometric relationships essential for zero-flashing production. All machines feature high-frequency spindles (up to 30,000 RPM) and integrated Renishaw probing for in-process verification of electrode profiles and cavity depths, reducing scrap rates by 22% compared to conventional 3-axis workflows. Material removal strategies are optimized for hardened P20, H13, and S136 steels, maintaining surface finishes below Ra 0.4 µm without secondary polishing.

Precision Measurement Systems

Every component undergoes full-spectrum validation via Zeiss CONTURA CMM systems with 0.5 µm volumetric accuracy. Our inspection protocol extends beyond linear dimensions to include geometric tolerancing (GD&T) verification for flatness, concentricity, and positionality of critical features like ejector pin bores and leader pin alignment. Data from CMM reports is directly correlated with mould flow analysis to preempt thermal distortion risks. Statistical process control (SPC) charts track capability indices (Cp/Cpk > 1.67) across production batches, ensuring repeatability for high-cavity mould families.

The following table details achievable tolerances for common injection mould components:

| Feature Type | Standard Tolerance | Precision Capability | Material Applicability |

|---|---|---|---|

| Cavity/Core Dimensions | ±0.01 mm | ±0.003 mm | P20, H13, S136 (up to 52 HRC) |

| Cooling Channel Position | ±0.02 mm | ±0.005 mm | All tool steels |

| Ejector Pin Bore Fit | H7/g6 | H6/f5 | Hardened steel inserts |

| Surface Flatness | 0.02 mm/m | 0.005 mm/m | Mould bases, plates |

| Thread Pitch Accuracy | ±0.015 mm | ±0.005 mm | M12 and larger |

This precision foundation enables mould makers to achieve Class 100 cleanroom part specifications and extend mould life beyond 1 million cycles. Our engineers collaborate from DFM stage through first-article inspection, translating your cavity pressure requirements into machine toolpaths that minimize residual stress in critical wear zones. With 98.7% on-time delivery for complex mould bases and electrodes, we provide the dimensional certainty that keeps your presses running. Partner with Wuxi Lead to convert tolerance challenges into production advantages.

Material & Finish Options

Material selection is a critical phase in the development of high-performance molds and precision components for injection molding applications. At Wuxi Lead Precision Machinery, we understand that the right combination of base material and surface treatment directly influences mold longevity, production efficiency, and part quality. Among the most widely used metals in custom mold manufacturing are aluminum, steel, and titanium—each offering distinct mechanical properties and suitability for specific operational demands.

Aluminum alloys, particularly 7075 and 6061, are favored for prototype molds and low- to medium-volume production runs. Their high thermal conductivity ensures rapid cooling cycles, improving throughput in injection molding processes. Additionally, aluminum’s machinability allows for faster lead times and reduced manufacturing costs. However, due to lower hardness and wear resistance compared to steel, aluminum is less suitable for high-volume or abrasive material processing.

Tool steels such as P20, H13, and S136 are the standard for production-grade molds requiring high durability, dimensional stability, and resistance to thermal fatigue. These steels can be heat-treated to achieve hardness levels ideal for extended service life, especially when processing engineering plastics filled with glass or minerals. H13, for instance, excels in applications involving high thermal cycling due to its superior toughness and resistance to cracking.

Titanium alloys, though less common in mold construction, are gaining traction in specialized applications where extreme strength-to-density ratios, corrosion resistance, and performance at elevated temperatures are paramount. While higher in cost and more challenging to machine, titanium offers exceptional longevity in aggressive environments, such as molds exposed to halogenated or acidic polymers.

Surface finishing, particularly anodizing, plays a pivotal role in enhancing the functional properties of aluminum molds. Anodizing creates a hard, wear-resistant oxide layer that improves surface hardness, reduces galling, and increases corrosion resistance. Type II (sulfuric acid) and Type III (hard anodizing) are commonly applied, with Type III providing thicker, more durable coatings suitable for high-wear areas. Color anodizing can also be used for identification or aesthetic purposes without compromising performance.

For steel molds, alternative surface treatments such as nitriding, PVD coatings, or electroless nickel plating are typically preferred due to aluminum-specific limitations of anodizing. These processes enhance surface hardness and release properties, minimizing maintenance and downtime.

The following table summarizes key mechanical and thermal properties of the three primary materials used in precision mold manufacturing:

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075 | 540–570 | 15–20 | 130 | Prototypes, low-volume production |

| P20 Steel | 900–1100 | 28–32 | 30 | Medium to high-volume production molds |

| H13 Steel | 1300–1600 | 45–52 | 35 | High-temperature, high-stress molds |

| Titanium Ti-6Al-4V | 900–950 | 35–40 | 7 | Corrosive environments, specialty molds |

At Wuxi Lead Precision Machinery, we guide our clients through material and finish selection based on production volume, polymer type, part complexity, and lifecycle requirements. Our engineering team ensures optimal performance by aligning material characteristics with operational demands, delivering molds that combine precision, durability, and cost-efficiency.

Manufacturing Process & QC

Precision Metal Manufacturing Process for Injection Moulding Excellence

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence tailored for injection moulding companies requiring flawless metal components. Our methodology eliminates defects at origin through integrated engineering oversight, ensuring your moulds achieve maximum uptime and part consistency. The process begins with collaborative Design Engineering, where our team conducts exhaustive Design for Manufacturability (DFM) analysis. We scrutinize thermal dynamics, stress points, and ejection mechanics using Siemens NX simulation software, validating material suitability against moulding parameters like cavity pressure and cycle times. This phase prevents 92% of potential failures by resolving clashes in cooling channels, venting, and tolerance stacks before metal is cut.

Prototyping transitions validated designs into physical verification. We deploy 5-axis milling and wire EDM to produce functional prototypes within 15 days, using your specified tool steel grades. Each prototype undergoes metrology-grade verification against CAD models via Zeiss CONTURA CMMs, measuring critical features like core pin diameters and cavity radii to ±0.005mm. Dimensional reports are shared in real-time, enabling rapid iteration if deviations exceed 0.01mm thresholds. This stage confirms thermal stability under simulated production loads, validating that shrinkage compensation algorithms meet your resin specifications.

Mass Production leverages our Zero Defects protocol through closed-loop manufacturing. All CNC cells operate under SPC (Statistical Process Control), with in-process gauging at every 50th part to monitor dimensional drift. Multi-axis machines utilize Renishaw probes for on-machine compensation, while robotic arms ensure consistent fixturing. Surface integrity is maintained via cryogenic finishing, achieving Ra 0.05µm on cavity surfaces to prevent part sticking. Every component undergoes 100% automated optical inspection against golden-sample datasets before shipment, with traceability to individual machine logs and raw material certs.

Critical Process Specifications

| Parameter | Capability | Verification Method |

|——————–|————————–|———————————–|

| Tolerance | ±0.005mm | Zeiss CMM + Optical Comparator |

| Surface Finish | Ra 0.05µm – 0.4µm | Perthometer + Visual Inspection |

| Materials | H13, S7, 420SS, Maraging Steel | Mill Certs + Spectro Analysis |

| Lead Time (Prototype) | 10-15 days | Project Management Dashboard |

| Lead Time (Mass) | 25-35 days (100 units) | Real-Time Production Tracking |

This end-to-end discipline ensures your mould bases, inserts, and sliders perform identically from first shot to 1,000,000 cycles. Wuxi Lead’s process integrates material science with predictive analytics, transforming design intent into production reality without compromise. Zero Defects is not a target—it is our baseline standard.

Why Choose Wuxi Lead Precision

When your injection moulding operation demands precision, durability, and unwavering consistency, the quality of your tooling and supporting metal components becomes mission-critical. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing engineered specifically for the rigorous demands of high-performance injection moulding systems. Our advanced production capabilities, combined with deep industry expertise, position us as a strategic manufacturing partner—not just a supplier.

We understand that injection moulding companies face relentless pressure to reduce cycle times, minimize downtime, and maintain tight tolerances across thousands of cycles. That’s why we focus on delivering custom-machined components that enhance the structural integrity, thermal efficiency, and operational longevity of your moulds. From precision ejector plates and core inserts to custom manifold systems and die-cast mould bases, every part we produce is machined to within ±0.002 mm tolerance and subjected to rigorous quality control protocols.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, wire and sinker EDM systems, surface grinders, and CMM inspection stations. We work with a wide range of materials including P20, 718H, H13, S136, and hardened tool steels, ensuring compatibility with your specific moulding applications—whether for automotive, medical, packaging, or consumer electronics.

Partnering with Lead Precision means gaining access to a responsive, technically adept team that values collaboration and transparency. From initial design consultation to final delivery, we engage early to optimize manufacturability, reduce lead times, and lower your total production cost. Our engineers routinely collaborate with global OEMs and Tier-1 mould makers to refine cooling channel layouts, improve part ejection mechanisms, and implement wear-resistant surface treatments where needed.

We support low-volume prototyping and high-volume production runs with equal commitment, offering scalable solutions that grow with your business. With ISO 9001-certified processes and a 98.6% on-time delivery rate, we ensure reliability at every stage.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Maximum Work Envelope (XYZ) | 1200 mm × 800 mm × 650 mm |

| CNC Machining Centers | 5-axis, 4-axis, and 3-axis |

| EDM Systems | Wire EDM, Sinker EDM |

| Materials Processed | P20, 718H, H13, S136, 1.2344, 1.2379, Aluminum, Brass |

| Surface Finish | As low as Ra 0.2 μm |

| Quality Inspection | CMM, Optical Comparator, Hardness Testing |

| Certifications | ISO 9001:2015 |

Your success is driven by precision, and ours is built on partnership. Let us help you achieve tighter tolerances, faster turnaround, and longer tool life across your entire moulding operation.

Contact us today at [email protected] to discuss your next project with our engineering team.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.