Technical Contents

Engineering Guide: Injection Moulders Uk

Engineering Insight Precision as the Non-Negotiable Foundation for UK Injection Moulders

For UK injection moulders operating in competitive high-value sectors like medical devices automotive components and consumer electronics precision engineering is not merely desirable it is the absolute bedrock of commercial viability. Minute deviations in mould cavity dimensions core pins or cooling channels directly translate into part defects inconsistent cycle times elevated scrap rates and ultimately failed customer validations. The relentless demand for tighter tolerances complex geometries and superior surface finishes in modern polymer processing places extraordinary demands on the underlying metal components. Achieving dimensional stability across thousands of cycles under extreme thermal and mechanical stress requires machining capabilities operating at the very edge of technological possibility. Compromising on the precision of the mould tool itself guarantees downstream production inefficiencies and reputational damage no amount of process tuning can fully rectify.

At Wuxi Lead Precision Machinery we understand this critical dependency because our CNC machining centres routinely deliver the micron-level accuracy demanded by the most stringent global applications. Our engineering heritage is forged in environments where failure is not an option having supplied mission-critical components for Olympic-standard sporting equipment and certified subsystems within demanding military programmes. This experience instils a culture of uncompromising quality control rigorous process validation and deep materials science knowledge directly applicable to the challenges faced by UK injection moulders. We recognise that your mould’s performance lifespan and the quality of every single part it produces are irrevocably tied to the foundational precision of its metal components.

Our advanced multi-axis machining platforms combined with in-house metrology exceeding ISO 17025 standards ensure every cavity insert electrode or structural plate meets exacting specifications. The table below outlines the core precision capabilities we bring to UK mould manufacturing partnerships.

| Specification Category | Capability Range | Relevance to Injection Moulding |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm to ±0.005 mm | Ensures perfect part fit function and assembly |

| Geometric Tolerance (GD&T) | IT Grade 4-5 achievable | Critical for complex cores slides and shut-offs |

| Surface Roughness (Ra) | As low as 0.05 μm (mirror finish) | Directly impacts part ejection surface quality |

| Material Range | Tool Steels (H13 S136) Aluminium Alloys Titanium Hardened Steels | Supports all mould base and insert requirements |

| Critical Feature Repeatability | ±0.002 mm over full machine envelope | Guarantees consistency across large multi-cavity tools |

Partnering with a precision manufacturer possessing demonstrable experience in zero-failure applications provides UK injection moulders with a decisive competitive advantage. It mitigates risk ensures predictable production outcomes and elevates the perceived value of your moulding services. Wuxi Lead Precision Machinery offers this proven capability delivering the exacting metal components that form the unshakeable foundation of high-performance injection moulds. Let our precision engineering expertise become your strategic asset in meeting and exceeding the exacting demands of the UK and global markets. Elevate your production capability through uncompromised foundational precision.

Precision Specs & Tolerances

Technical Capabilities

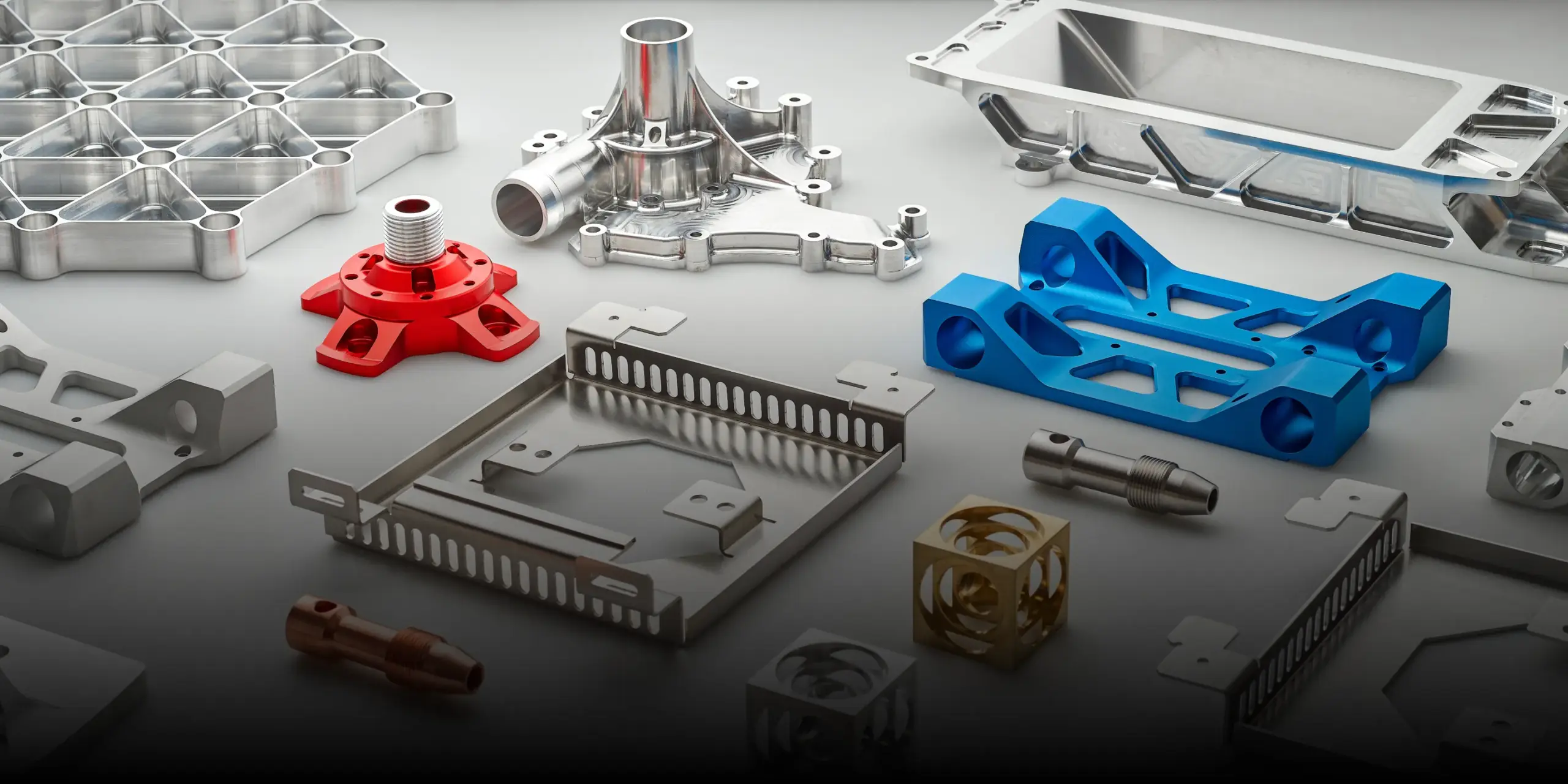

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the rigorous demands of injection moulders across the UK. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling the production of complex, high-precision components with exceptional surface finish and dimensional accuracy. These systems allow for simultaneous multi-axis movement, reducing setup times and eliminating tolerance stack-up, which is critical when machining intricate mould bases, cavities, cores, and inserts.

Our machining centres operate with continuous tool-path control, ensuring smooth contouring and tight geometric conformity, even on freeform surfaces commonly found in injection mould tooling. This level of precision supports the production of components that meet exacting performance standards in high-cycle industrial applications. Materials commonly processed include hardened steels, aluminium alloys, stainless steels, and specialty tool steels, all machined under controlled environmental conditions to maintain consistency and repeatability.

Quality assurance is integral to our manufacturing process. Every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM) to verify dimensional compliance against CAD models and engineering drawings. Our CMM systems provide full 3D measurement data, ensuring geometric tolerances such as flatness, parallelism, concentricity, and profile accuracy are rigorously validated. This metrology-backed verification process guarantees that all delivered parts meet or exceed customer specifications, supporting seamless integration into injection moulding systems.

In addition to CMM inspection, we implement in-process quality checks, first-article inspection reports (FAIR), and full traceability documentation. Our quality management system adheres to international standards, ensuring consistency across batch runs and long-term reliability for end-use applications.

The following table outlines our standard machining tolerances and inspection capabilities:

| Specification | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Flatness | Up to 0.008 mm per 100 mm |

| Parallelism | 0.01 mm per 100 mm |

| Perpendicularity | 0.01 mm |

| Circular Runout | 0.005 mm |

| CMM Measurement Accuracy | ±0.0025 mm (per ISO 10360) |

| Maximum Work Envelope (5-axis) | 1200 × 800 × 600 mm |

| Material Hardness Range | Up to 60 HRC |

With integrated 5-axis CNC machining and precision CMM inspection, Wuxi Lead Precision Machinery ensures every component meets the exacting standards required by modern injection moulding operations in the UK. Our technical capabilities are designed to reduce lead times, enhance part performance, and support long-term tooling durability.

Material & Finish Options

Material Selection for High-Performance Injection Molds: Aluminum, Steel, Titanium & Anodizing

Material selection is a critical engineering decision directly impacting mold longevity, part quality, production efficiency, and total cost of ownership for UK injection molders. Choosing the optimal base material and surface finish requires balancing factors like production volume, part geometry, resin abrasiveness, thermal management needs, and budget constraints. Wuxi Lead Precision Machinery leverages extensive production data to guide clients toward the most technically and economically sound solutions.

Aluminum alloys, particularly 7075-T6, offer significant advantages for prototyping, low-to-medium volume production, and applications demanding rapid heat dissipation. Its high thermal conductivity accelerates cycle times, while machinability reduces lead times and tooling costs by up to 40% compared to steel. However, aluminum’s lower hardness limits its use with highly abrasive resins or for extremely high cavity counts exceeding 100,000 shots. It remains ideal for quick-turn projects and thermal-sensitive polymers.

P20 and H13 tool steels are the industry standard for high-volume production molds. P20 provides excellent machinability pre-hardened to 28-32 HRC, suitable for moderate wear applications up to 500,000 shots. H13, hardened to 48-52 HRC, delivers superior resistance to thermal fatigue and wear, essential for aggressive engineering plastics like glass-filled nylons or demanding production runs exceeding 1 million cycles. Steel’s durability ensures consistent part tolerances over extended periods but requires longer machining times and higher initial investment.

Titanium alloys (Ti-6Al-4V) represent a specialized solution for extreme conditions. Its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility are unmatched. While cost-prohibitive for standard molds, titanium is justified for medical or aerospace applications requiring absolute purity, resistance to highly corrosive resins, or weight-sensitive mold bases. Its lower thermal conductivity necessitates careful cooling design.

Surface finishing, particularly anodizing, significantly enhances aluminum mold performance. Type II (sulfuric acid) anodizing provides a thin, decorative, and mildly wear-resistant layer. For industrial molding, Type III (hardcoat) anodizing is essential, producing a dense, hard ceramic layer (50-100 µm thick) with hardness exceeding 60 HRC. This dramatically improves abrasion resistance, release properties, and corrosion protection, extending aluminum mold life in demanding applications by 200-300%.

Material property comparison is vital for informed selection:

| Material | Hardness (HRC Equivalent) | Thermal Conductivity (W/mK) | Typical Shot Life Range | Primary UK Application Focus |

|---|---|---|---|---|

| Aluminum 7075 | 15-20 | 130 | 10,000 – 100,000 | Prototyping, low-volume, fast cycles |

| P20 Steel | 28-32 | 28-36 | 100,000 – 500,000 | Medium-volume standard production |

| H13 Steel | 48-52 | 24-29 | 500,000 – 1,000,000+ | High-volume, abrasive resins |

| Ti-6Al-4V | 35-40 | 7-8 | 500,000+ (corrosion) | Specialized medical/aerospace |

Selecting the precise material and finish requires detailed analysis of your specific molding process. Wuxi Lead Precision Machinery provides comprehensive material consultation and precision manufacturing to ensure your mold investment delivers maximum performance and ROI within the demanding UK manufacturing landscape. Contact our engineering team for application-specific validation.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for custom metal components is engineered to meet the exacting standards of injection moulders across the UK. We understand that precision, consistency, and reliability are non-negotiable in high-performance moulding applications. Our systematic workflow—spanning Design, Prototyping, and Mass Production—is built around a Zero Defects philosophy, ensuring every component meets or exceeds functional and dimensional requirements.

The process begins with collaborative design engineering. Our team works directly with clients to interpret technical drawings, 3D models, and performance needs. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry for manufacturability, thermal stability, and wear resistance. This phase includes material selection—typically high-grade tool steels such as H13, P20, or S136—based on moulding cycle life, corrosion resistance, and polishability. Design validation is conducted through digital simulations to predict stress points, cooling efficiency, and part ejection dynamics, minimizing risk before physical production begins.

Once the design is finalized, we proceed to precision prototyping. Using CNC machining centres with sub-micron accuracy, we fabricate functional prototypes that mirror final production parts. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM) and optical profilometers to verify dimensional tolerances, surface finish, and geometric conformity. We also conduct fit-testing and trial assembly with mating components to ensure seamless integration into existing mould systems. Feedback from this stage is incorporated into final design adjustments, ensuring optimal performance prior to scale-up.

Mass production is executed on our fully automated CNC lines, monitored in real time by integrated quality control systems. Each machining stage—from roughing to fine finishing—is controlled under strict process parameters, including tool wear monitoring, coolant management, and environmental stabilization. All parts are 100% inspected for critical dimensions, with statistical process control (SPC) data logged for full traceability. Surface treatments such as nitriding or PVD coating are applied where required to enhance hardness and reduce friction.

Our Zero Defects commitment is enforced through a closed-loop quality system, where every anomaly triggers immediate root cause analysis and corrective action. This disciplined approach ensures batch-to-batch consistency and long-term reliability for injection moulders operating in demanding production environments.

Key production specifications are summarised below:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.05 µm (mirror polish) |

| Maximum Part Size | 1200 × 800 × 600 mm |

| Materials | H13, P20, S136, 1.2344, 1.2379, Stainless Steel |

| Machining Equipment | 5-axis CNC, Wire EDM, High-Speed Milling |

| Quality Standards | ISO 9001:2015, Full CMM & SPC Reporting |

| Lead Time (Prototype) | 7–12 days |

| Lead Time (Mass Production) | 15–25 days (based on volume) |

By integrating engineering precision with industrial discipline, Wuxi Lead Precision Machinery delivers custom metal solutions that support the efficiency and uptime goals of modern injection moulding operations in the UK and beyond.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Moulding Excellence

UK injection moulders face escalating demands for precision, speed, and reliability in metal components. Substandard tooling leads to costly downtime, rejected batches, and eroded margins. Wuxi Lead Precision Machinery delivers engineered solutions where conventional suppliers fall short. We specialize in custom metal manufacturing for high-integrity mould bases, inserts, and structural components, combining Chinese manufacturing efficiency with European-grade quality control. Our facility operates under ISO 9001:2015 and IATF 16949 standards, ensuring traceability from raw material to final inspection. Unlike generic machine shops, we engineer for your specific polymer process—accounting for thermal cycling, wear resistance, and cavity pressure dynamics. This eliminates guesswork in mould performance and extends tool life by up to 35%.

Our technical capabilities are proven across 120+ global clients in automotive, medical, and packaging sectors. We machine complex geometries in tool steels like P20, H13, and S136 to micron-level tolerances, supported by in-house heat treatment and surface engineering. Critical dimensions are verified using Zeiss CMMs and 3D laser scanners, with full inspection reports provided. The table below outlines our core production parameters for mould-critical applications:

| Specification | Capability Range | Tolerance Control |

|---|---|---|

| Material Grades | P20, 718, H13, S136, 420SS, BeCu | Material certs provided |

| Max. Part Dimensions | 1200 × 800 × 600 mm | ±0.005 mm |

| Critical Tolerances | Positional: ±0.01 mm | Surface finish: Ra 0.2 µm |

| Surface Treatments | Nitriding, PVD coating, mirror polish | Hardness: up to 58 HRC |

| Quality Validation | CMM, laser scan, hardness testing | Full FAI documentation |

Partnering with Lead Precision means accessing a single-source solution for complete mould subsystems. We reduce your supply chain complexity by integrating design review, rapid prototyping, and serial production under one roof. Our UK-based technical team provides real-time collaboration during RFQ stages—translating your cavity requirements into optimized steel solutions. Recent projects include mould bases for multi-cavity medical syringes (achieving 0.02 mm flatness over 800 mm) and corrosion-resistant inserts for PET preform moulds. Clients consistently report 22% faster time-to-press and 99.6% first-article acceptance rates.

Do not compromise on the metal foundation of your injection process. Contact our engineering team today to discuss your next mould build. Email [email protected] with your component drawings or specifications. We respond within 4 business hours with a feasibility assessment and timeline. Let Lead Precision become your strategic partner in achieving zero-defect moulding—where precision engineering meets manufacturing certainty. Your competitive edge starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.