Technical Contents

Engineering Guide: Injection Mould Tools

Engineering Insight Injection Mould Tools

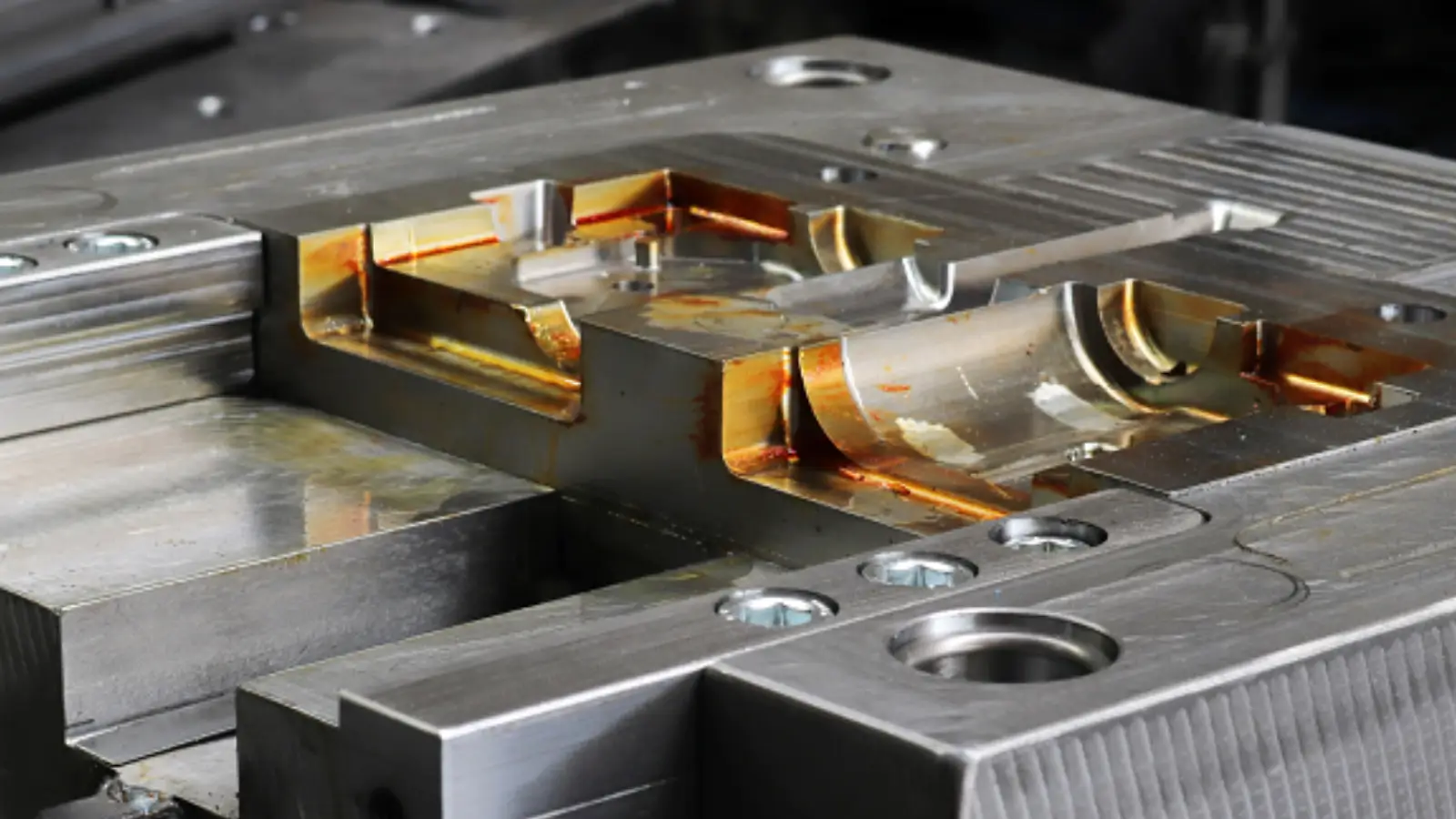

Precision in injection mould tool manufacturing is non-negotiable for high-performance industrial applications. Minute deviations in cavity geometry, core alignment, or cooling channel placement directly translate to part defects, inconsistent cycle times, and accelerated tool wear. In sectors like medical device production or aerospace components, tolerances below ±0.005mm are often mandatory to ensure functional integrity and regulatory compliance. Substandard tooling introduces hidden costs through rejected parts, production downtime for adjustments, and premature tool replacement. The foundation of a successful mould lies not just in the final product specification, but in the microscopic accuracy engineered into every mating surface, vent, and ejection mechanism during fabrication.

At Wuxi Lead Precision Machinery, we engineer this critical precision into every custom mould tool through a rigorous, integrated process. Our approach begins with advanced simulation-driven design validation, identifying potential stress points and flow imbalances before metal is cut. We leverage multi-axis CNC machining centres with sub-micron repeatability, coupled with stringent in-process metrology using coordinate measuring machines (CMMs) and optical comparators at defined checkpoints. Material selection is equally precise, utilizing premium pre-hardened steels like NAK80 or H13, heat-treated and stress-relieved to exacting standards, ensuring dimensional stability under high-cycle production demands. This systematic control over the entire manufacturing chain guarantees that the as-machined tool geometry matches the digital model, eliminating costly trial-and-error during mould commissioning.

Our capability to deliver this level of precision is proven in mission-critical applications. We have manufactured complex, high-cavitation mould tools for components used in Beijing Winter Olympics venue infrastructure, where environmental resilience and absolute dimensional consistency were paramount. Furthermore, we consistently produce defence-grade tooling meeting stringent MIL-STD requirements for aerospace and military hardware, where failure is not an option. This experience underscores our commitment to exceeding the most demanding precision benchmarks.

The table below outlines key precision parameters achievable with our advanced manufacturing platform, reflecting capabilities honed through these high-stakes projects:

| Parameter | Standard Industry Tolerance | High-Precision Requirement | Wuxi Lead Precision Capability |

|---|---|---|---|

| Cavity/Core Tolerance | ±0.025mm | ±0.005mm to ±0.010mm | ±0.002mm to ±0.005mm |

| Surface Finish (Cavity) | SPI-A2 (6-8 Ra µm) | SPI-A1 (1-4 Ra µm) | SPI-A1 / <0.8 Ra µm |

| Core Pin Alignment | ±0.05mm | ±0.02mm | ±0.008mm |

| Cooling Channel Pos. | ±0.10mm | ±0.05mm | ±0.02mm |

| Tool Life (Cycles) | 100,000 – 500,000 | 500,000 – 1,000,000+ | 1,000,000+ (Verified) |

Investing in precision-engineered mould tools from Wuxi Lead Precision Machinery delivers immediate and long-term value. It minimizes scrap rates, maximizes production uptime, extends tool service life significantly, and ensures consistent part quality batch after batch. For applications where performance and reliability are critical, our proven expertise in delivering Olympic and military-grade precision provides the assurance your manufacturing process demands. Partner with us to transform your injection moulding challenges into competitive advantages through uncompromising accuracy.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the design and production of high-precision injection mould tools, serving global industries that demand reliability, repeatability, and micron-level accuracy. Our facility in Wuxi, China, is engineered for excellence in custom metal manufacturing, integrating state-of-the-art 5-axis CNC machining systems with comprehensive quality control protocols to ensure every component meets or exceeds client specifications.

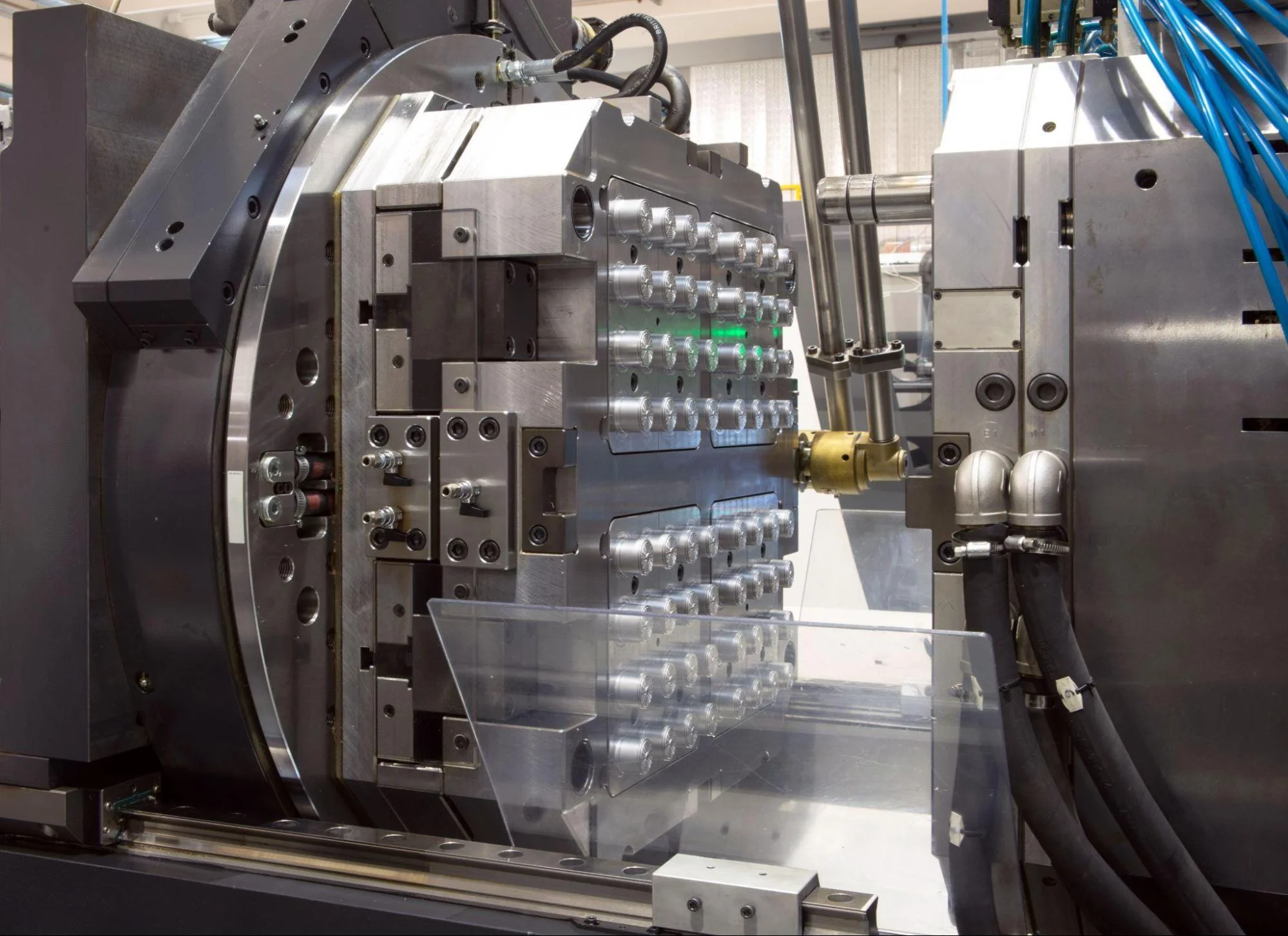

At the core of our machining operations is a fleet of high-performance 5-axis CNC machines, enabling complex geometries and tight-tolerance features that are unattainable with conventional 3-axis systems. These machines allow simultaneous multi-axis movement, offering superior surface finish, reduced setup times, and enhanced dimensional accuracy. This capability is particularly critical in injection mould tooling, where intricate cooling channels, undercuts, and contoured cavities require precise, continuous tool paths. Our skilled programmers and machinists utilize advanced CAM software to optimize tool motion, minimize cycle times, and maintain consistency across production batches.

All critical dimensions and form features undergo rigorous inspection using a Coordinate Measuring Machine (CMM), ensuring full compliance with engineering drawings and international standards. Our CMM system operates in a temperature-controlled environment to eliminate thermal drift, providing repeatable and traceable measurement data. Each inspection report is documented and archived, supporting full process traceability for aerospace, medical, and automotive clients where regulatory compliance is mandatory.

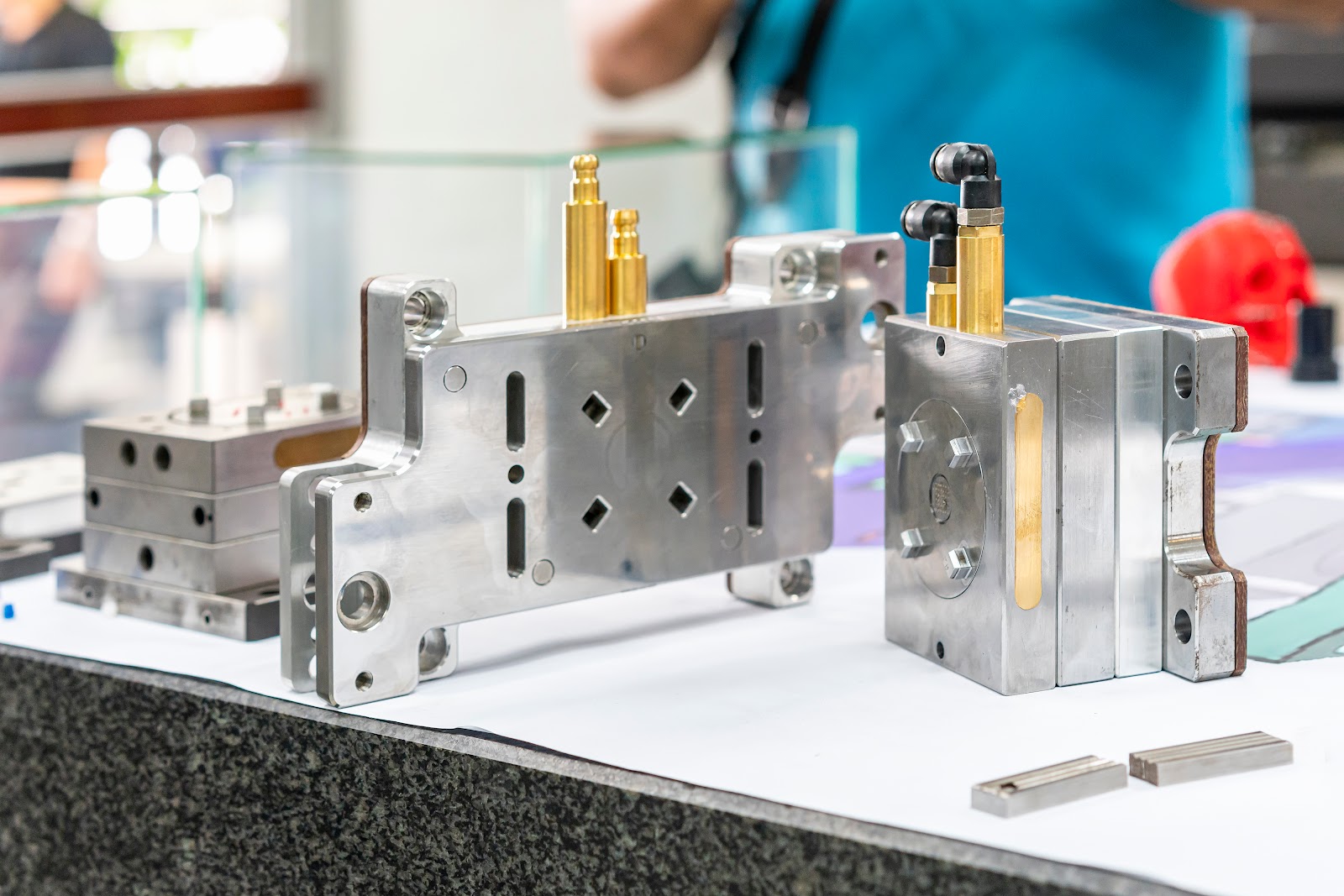

Our technical team works closely with clients during the design-for-manufacturability (DFM) phase to identify potential challenges early, optimize tool steel selection, and recommend modifications that enhance part longevity and reduce maintenance cycles. We specialize in tooling for high-volume production environments, where wear resistance, thermal stability, and ejection precision directly impact part quality and cycle efficiency.

The following table outlines the typical tolerances we achieve on injection mould tools using our 5-axis CNC and CMM inspection processes:

| Feature Type | Typical Tolerance | Measurement Method |

|---|---|---|

| Linear Dimensions | ±0.005 mm | CMM |

| Bore Diameter | +0.010 / +0.002 mm | CMM, Air Plug Gages |

| Flatness | 0.008 mm per 100 mm | CMM, Precision Granite |

| Parallelism | 0.010 mm | CMM |

| Perpendicularity | 0.012 mm | CMM |

| Surface Finish (Ra) | 0.2 – 0.8 µm | Surface Roughness Tester |

| Radius/Internal Corner | ±0.01 mm | CMM, Optical Comparator |

These capabilities are supported by robust project management and engineering review cycles, ensuring on-time delivery without compromise to quality. Wuxi Lead Precision Machinery is committed to being a technical extension of our clients’ engineering teams, delivering injection mould tools that perform under the most demanding production conditions.

Material & Finish Options

Material Selection for High-Performance Injection Mould Tools

Selecting the optimal material for injection mould tools is critical to balancing production volume, part complexity, cost efficiency, and tool longevity. At Wuxi Lead Precision Machinery, we prioritize engineering-driven decisions based on your specific application requirements. Aluminum offers rapid prototyping and low-volume production advantages due to its superior machinability and thermal conductivity, reducing cycle times. However, its lower hardness limits use in high-wear applications or abrasive polymers. Steel remains the industry standard for high-volume production, providing exceptional wear resistance, dimensional stability, and durability under repeated thermal cycling. Premium tool steels like H13 or S136 deliver extended service life for complex geometries and demanding resins. Titanium, while less common, excels in highly corrosive environments or ultra-high-precision applications requiring extreme rigidity and minimal thermal expansion, though its cost and machining complexity necessitate rigorous justification.

The following table summarizes key comparative specifications for common mould tool materials:

| Material | Hardness (HRC) | Corrosion Resistance | Thermal Conductivity (W/m·K) | Typical Use Case | Relative Cost |

|---|---|---|---|---|---|

| Aluminum | 45-60 | Low | 120-180 | Prototypes, low-volume | Low |

| Tool Steel | 50-58 | Moderate to High | 25-40 | High-volume production | Medium |

| Titanium | 30-40 | Very High | 6-10 | Corrosive/precision niche | High |

Surface finishing, particularly anodizing for aluminum tools, significantly enhances performance. Hard anodizing (Type III) creates a dense, wear-resistant oxide layer up to 50–100µm thick, improving surface hardness to 60–70 HRC and drastically increasing abrasion resistance. This process also seals the surface against moisture ingress, mitigating corrosion in humid environments or when processing hygroscopic resins. For steel tools, nitriding or PVD coatings are typically preferred, but anodizing remains indispensable for maximizing aluminum tool lifespan in production scenarios exceeding initial prototyping phases.

Material choice directly impacts your total cost of ownership. While aluminum reduces upfront tooling costs, premature wear in high-volume runs incurs replacement expenses and downtime. Steel’s higher initial investment yields lower per-part costs over millions of cycles. Titanium’s niche applicability demands careful ROI analysis. Our engineering team evaluates resin type, part geometry, expected volume, and environmental factors to prescribe the optimal material-finish combination. At Wuxi Lead, we leverage advanced CNC machining and metallurgical partnerships to ensure every material specification translates into reliable, precision tool performance—proving Chinese manufacturing excellence meets global industrial standards. Trust our data-driven approach to elevate your injection moulding efficiency.

Manufacturing Process & QC

The production process for high-precision injection mould tools at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase is engineered to ensure zero defects, dimensional accuracy, and long-term performance under industrial conditions. Our methodology integrates advanced simulation, precision machining, and real-time quality verification to deliver tooling solutions that meet the most demanding international standards.

Design begins with a comprehensive analysis of the client’s part geometry, material specifications, and production volume requirements. Our engineering team utilizes 3D CAD software—SolidWorks, UG NX, and CATIA—to develop optimized mould structures with precise gating, cooling, and ejection systems. Finite Element Analysis (FEA) and Moldflow simulation are applied to predict filling behavior, warpage, and stress distribution, ensuring the design is robust before any metal is cut. This virtual validation reduces physical trial iterations and accelerates time-to-market.

Prototyping follows design approval and serves as a functional validation step. We fabricate a pilot mould using the same hardened tool steels and machining processes as the final production tool. This allows us to produce sample parts under real injection conditions, verifying part dimensions, surface finish, and structural integrity. All prototypes undergo full metrological inspection using coordinate measuring machines (CMM) and 3D scanning, with results compared against the original CAD model. Any deviations trigger immediate design or process adjustments, ensuring the final tool will perform flawlessly.

Mass Production commences only after prototype approval and process validation. Our CNC machining centers—equipped with high-speed milling, wire EDM, and micro-drilling capabilities—manufacture the final mould components to tolerances as tight as ±0.002 mm. All critical surfaces are polished or textured according to customer specifications, and hardened to 50–54 HRC for wear resistance. The complete mould is then assembled, tested on our in-house injection machines, and subjected to a 48-hour continuous run to confirm stability and repeatability.

Throughout the process, our quality management system—certified to ISO 9001:2015—ensures traceability, process control, and zero-defect delivery. Every tool is documented with inspection reports, material certifications, and performance data.

| Specification | Detail |

|---|---|

| Material Options | P20, 718, 2738, H13, S136, 420 Stainless Steel |

| Tolerance | ±0.002 mm |

| Surface Finish | Mirror polish (Ra ≤ 0.05 µm) to textured (VDI 3400) |

| Mould Life | 500,000 to 1,000,000 cycles |

| Cooling System | Conformal cooling channels (optimized via simulation) |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP Level 3 |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Tool) | 30–50 days |

This end-to-end process ensures that every injection mould tool delivered by Wuxi Lead Precision Machinery meets the highest standards of precision, durability, and performance.

Why Choose Wuxi Lead Precision

Why Partner With Lead Precision for Injection Mould Tools

Securing a reliable, technically advanced manufacturing partner for high-precision injection mould tools is non-negotiable in competitive global markets. At Wuxi Lead Precision Machinery, we transcend the role of a standard supplier. We function as your dedicated engineering extension, committed to transforming complex design challenges into robust, high-yield production realities. Our integrated approach combines deep metallurgical expertise with cutting-edge CNC technology, ensuring your mould tools deliver exceptional part consistency, extended service life, and minimized downtime from day one. We understand that tool failure is not an option; it directly impacts your production schedule, quality output, and bottom line. Partnering with Lead Precision means investing in proactive engineering collaboration, not just a transactional purchase.

Our technical foundation rests on state-of-the-art equipment operating under stringent quality protocols. We specialize in the complete lifecycle of precision mould bases, cavities, cores, and intricate inserts, utilizing premium materials like H13, S136, and NAK80. Every process, from initial material certification through final polishing and assembly, adheres to international standards, including ISO 9001:2015. This rigorous discipline guarantees dimensional stability and surface integrity critical for demanding applications in automotive, medical, and consumer electronics. The table below outlines our core manufacturing capabilities relevant to injection mould tool production.

| Capability Category | Specification Detail | Relevance to Injection Mould Tools |

|---|---|---|

| CNC Machining | 5-Axis Milling Centers (Makino, DMG MORI) | Complex core/cavity geometries, tight internal features |

| Precision Level | ±0.005 mm (±0.0002″) Tolerances | Ensures part fit, function, and dimensional repeatability |

| Surface Finish | Ra 0.05 µm to Ra 0.8 µm (as required) | Critical for part ejection, aesthetics, and sealing |

| Material Expertise | Tool Steels (H13, S136, P20), Aluminum | Optimized selection for wear resistance, corrosion, cycle life |

| Lead Time Efficiency | Prototype: 15-25 Days; Production: 30-45 Days | Accelerated time-to-market without compromising quality |

Beyond specifications, our value lies in responsive engineering partnership. Our team engages early in your design phase, providing actionable DFM feedback to optimize manufacturability, reduce costs, and prevent costly revisions later. We implement rigorous in-process inspections using CMMs and optical comparators, providing full traceability documentation. This commitment to transparency and technical collaboration minimizes risk and ensures your tool performs predictably at scale. We view every project as a strategic investment in your success, supported by responsive project management and post-delivery technical support.

The cost of mould tool failure extends far beyond the initial investment. It encompasses production line stoppages, scrap, rework, and lost market opportunities. Partnering with Wuxi Lead Precision Machinery mitigates these risks through engineering excellence and unwavering reliability. We are prepared to become your trusted source for mission-critical injection mould tools that consistently exceed performance expectations. Initiate the conversation that transforms your manufacturing challenges into competitive advantages. Contact our engineering sales team directly at [email protected] to discuss your specific requirements and receive a tailored capability assessment. Let Lead Precision deliver the precision foundation your production demands. Wuxi Lead Precision Machinery: Engineered Precision, Guaranteed Performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.