Technical Contents

Engineering Guide: Injection Mould Maker

Engineering Insight: The Non-Negotiable Imperative of Precision in Injection Mould Making

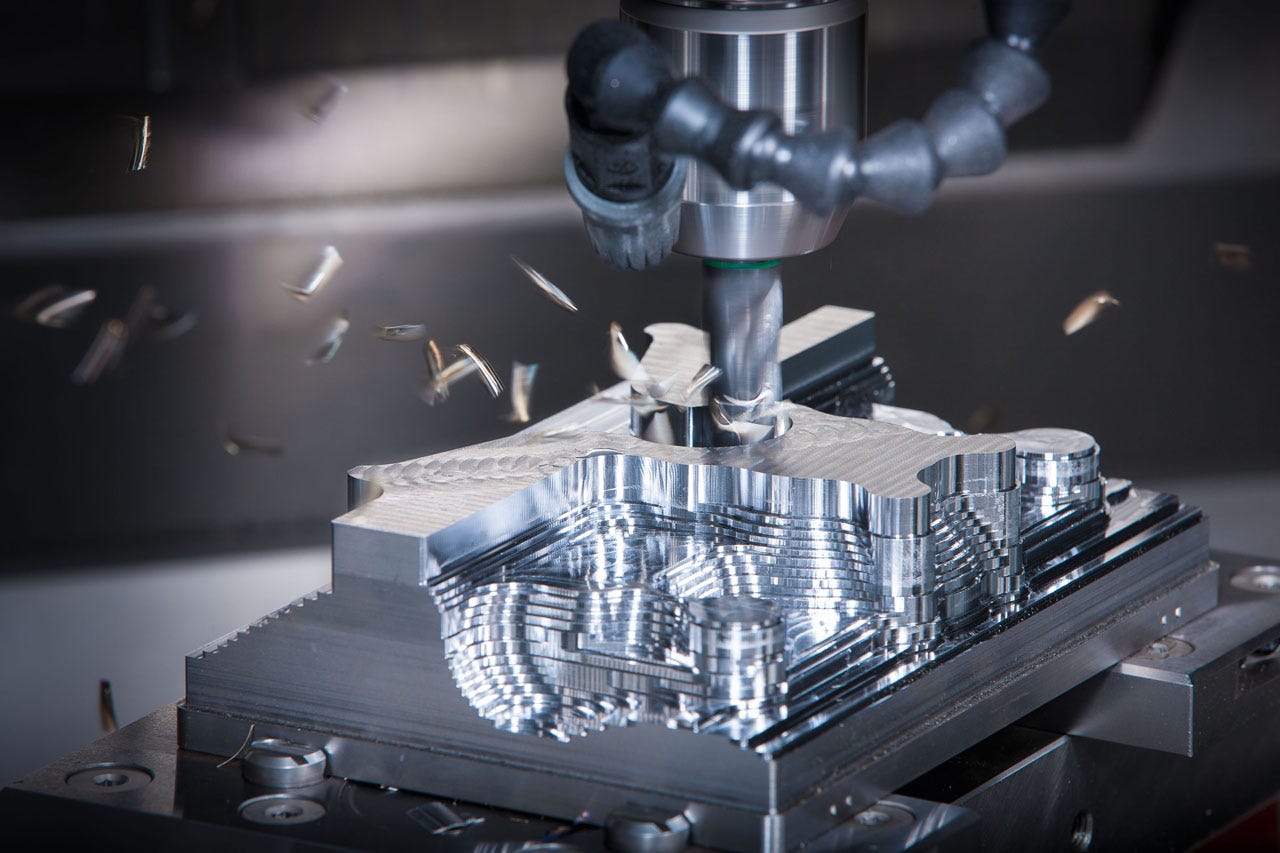

In high-volume injection moulding, micron-level deviations in the mould cavity translate directly into part inconsistency, scrap rates, and accelerated tool wear. Precision engineering is not merely desirable; it is the absolute foundation for profitability and product integrity. A mould lacking exact dimensional stability or thermal management control introduces variables that cascade through production—causing flash, sink marks, warpage, or dimensional drift. These defects compromise part functionality, especially in sectors like medical devices, aerospace, or automotive safety components where tolerances are unforgiving. The economic impact is severe: a single percentage point increase in scrap can erode margins significantly over a production run. True precision demands holistic control—from initial cavity design and material selection through CNC machining, electrode fabrication for EDM, and final polishing. It requires understanding how steel grade, heat treatment, and cooling channel geometry interact under cyclic thermal stress. Without this integrated approach, even advanced mould bases become unreliable.

At Wuxi Lead Precision Machinery, we engineer moulds to eliminate these failure points. Our process begins with finite element analysis (FEA) to predict thermal distribution and structural deflection, ensuring uniform cooling and minimal distortion during operation. Critical cavity and core features are machined using 5-axis CNC centres with sub-micron repeatability, followed by meticulous hand-finishing to achieve optical-grade surface integrity. This technical rigor is validated through stringent in-house metrology, including CMM inspection against 3D CAD models and cavity pressure monitoring during initial trials. The result is a mould that maintains dimensional fidelity over millions of cycles, delivering consistent part quality while maximizing uptime.

Our capability to achieve this level of precision is proven in applications where failure is not an option. We have manufactured critical mould components for systems used in Olympic timing equipment, where nanosecond accuracy in part formation is essential. Similarly, we support defence contractors with tooling for guided munitions components, adhering to MIL-STD specifications that demand zero-defect performance under extreme conditions. This experience underscores our commitment to precision as a core engineering discipline, not just a manufacturing target.

The following specifications represent the baseline capabilities we consistently achieve for high-cavitation, long-run production moulds:

| Specification Category | Performance Standard | Measurement Method |

|---|---|---|

| Linear Dimensional Tolerance | ±0.002 mm | CMM (Zeiss CONTURA) |

| Surface Roughness (Cavity) | Ra 0.025 µm (Mirror) | Profilometer (Taylor Hobson) |

| Flatness (Core Plates) | ≤ 0.003 mm over 300 mm | Laser Interferometry |

| Hole Concentricity | ≤ 0.005 mm | CMM with Rotary Table |

| Thermal Uniformity (Simulated) | ΔT ≤ 2°C across cavity | Moldflow Analysis |

This precision-centric methodology ensures our clients’ moulds deliver exceptional part consistency, extended service life, and reduced total cost of ownership. When tolerances are measured in microns, the margin for error vanishes—only uncompromising engineering discipline guarantees success. Wuxi Lead Precision Machinery delivers that discipline, proven in the world’s most demanding manufacturing environments.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers precision-driven custom metal manufacturing solutions tailored for high-performance industries, including automotive, aerospace, medical, and advanced consumer electronics. At the core of our technical capabilities is an advanced 5-axis CNC machining platform, enabling us to produce complex, high-accuracy components essential for injection mould making. Our multi-axis machining centers allow simultaneous movement across five axes, providing unparalleled flexibility in contouring intricate geometries with minimal setup changes. This results in tighter tolerances, superior surface finishes, and reduced lead times—critical factors in mould manufacturing where precision and repeatability are non-negotiable.

Our machining process supports a wide range of tool steels, stainless steels, aluminum alloys, and specialty metals, ensuring compatibility with diverse mould requirements. From cavity and core inserts to ejector systems and cooling channels, our 5-axis CNC technology ensures dimensional consistency and optimal part integrity. The integration of high-speed machining with adaptive toolpath strategies minimizes thermal deformation and tool wear, further enhancing the quality and longevity of the moulds we produce.

To maintain the highest standards of quality, every component undergoes comprehensive inspection using a state-of-the-art Coordinate Measuring Machine (CMM). Our CMM system provides full 3D metrology validation, verifying geometric dimensions, positional accuracy, and surface conformity against CAD models. This inspection protocol ensures that all machined parts meet or exceed international quality benchmarks such as ISO 2768 and ASME Y14.5. Real-time data from CMM reports are documented and traceable, offering full transparency for audit and compliance purposes.

Material handling, fixturing, and in-process gauging are seamlessly integrated into our production workflow, reducing human error and ensuring repeatable precision across batch runs. Our engineering team works closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, reduce complexity, and enhance tool life—adding value before the first cut is made.

All operations are conducted in a climate-controlled environment to minimize thermal variation, and our equipment is maintained under strict preventive maintenance schedules to ensure continuous peak performance. With over 15 years of experience in precision mould component manufacturing, Wuxi Lead Precision Machinery combines advanced technology with deep process expertise to deliver solutions that meet the most demanding specifications.

The following table outlines the standard tolerance capabilities achievable across common machining parameters:

| Feature | Capability |

|---|---|

| Linear Tolerance | ±0.005 mm |

| Geometric Tolerance (GD&T) | ±0.01 mm (per ASME Y14.5) |

| Surface Roughness (Ra) | 0.2 – 0.8 µm (standard), down to 0.1 µm (polished) |

| Positional Accuracy | ±0.008 mm |

| Angular Tolerance | ±0.05° |

| Minimum Wall Thickness (Steel) | 0.5 mm |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

These specifications reflect our commitment to precision and consistency, enabling us to support the most demanding injection mould applications with confidence and reliability.

Material & Finish Options

Material Selection for High-Performance Injection Moulds

Selecting the optimal material for injection mould cores, cavities, and critical inserts is fundamental to achieving part quality, production efficiency, and tool longevity. At Wuxi Lead Precision Machinery, our decades of precision machining experience with demanding global clients underscore that material choice must align precisely with production volume, part geometry, polymer characteristics, and surface finish requirements. Aluminum, steel, and titanium each offer distinct advantages and limitations in this high-stakes environment.

Aluminum alloys, particularly 7075-T6, excel in rapid prototyping and low-to-medium volume production. Their superior thermal conductivity significantly reduces cycle times compared to steel, accelerating time-to-market. Aluminum machines exceptionally fast, lowering initial tooling costs. However, its lower hardness and wear resistance make it unsuitable for abrasive polymers or extended high-volume runs. Steel remains the dominant choice for high-volume production. Pre-hardened steels like P20 offer good machinability and polishability for general applications. For demanding scenarios involving high wear, elevated temperatures, or corrosive materials, tool steels such as H13 (excellent heat resistance) or S136 (superior corrosion resistance for medical/optical parts) are essential. Steel provides the necessary hardness, durability, and dimensional stability for millions of cycles. Titanium alloys, while significantly more expensive and challenging to machine, offer unparalleled strength-to-weight ratio and exceptional corrosion resistance. Their primary application is in specialized, high-value sectors like aerospace or medical implants where weight savings or extreme chemical inertness are non-negotiable, though thermal conductivity limitations require careful thermal management design.

Surface finish, particularly anodizing for aluminum moulds, is critical for part ejection, surface replication, and wear resistance. Type II (sulfuric acid) anodizing provides good corrosion resistance and a base for dyeing, suitable for many applications. For moulds requiring maximum surface hardness and abrasion resistance – essential when processing glass-filled polymers or achieving ultra-smooth optical surfaces – Type III (hardcoat) anodizing is mandatory. This process creates a much thicker, denser, and harder ceramic layer significantly extending mould life in challenging conditions. Steel moulds typically utilize polishing, texturing, or specialized coatings like PVD/CVD for surface enhancement rather than anodizing.

The following table summarizes key material properties relevant to injection mould performance:

| Material | Hardness Range (HRC) | Thermal Conductivity (W/m·K) | Best For Applications | Machinability Rating |

|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | 130-150 | Prototypes, Low/Med volume, Fast cycle needs | Excellent |

| P20 Steel | 28-32 | 28-36 | General high-volume production | Good |

| H13 Tool Steel | 48-52 (Hardened) | 25-30 | High temp, High wear, Long run production | Moderate |

| Titanium Grade 5 | 32-36 (Equivalent) | 6-7 | Aerospace, Medical, Extreme corrosion scenarios | Poor |

Material and finish selection is not generic; it demands deep application understanding. Wuxi Lead Precision Machinery leverages advanced CNC capabilities and materials science expertise to match your specific polymer, volume, and quality targets with the optimal engineered solution. Consult our engineering team early in the design phase to maximize mould performance and ROI.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for custom injection mould making is engineered for precision, repeatability, and zero-defect outcomes. We integrate advanced design methodologies, rigorous prototyping, and tightly controlled mass production to deliver moulds that meet the highest standards of performance and durability. Every stage is optimized to ensure dimensional accuracy, material integrity, and long-term reliability in high-volume manufacturing environments.

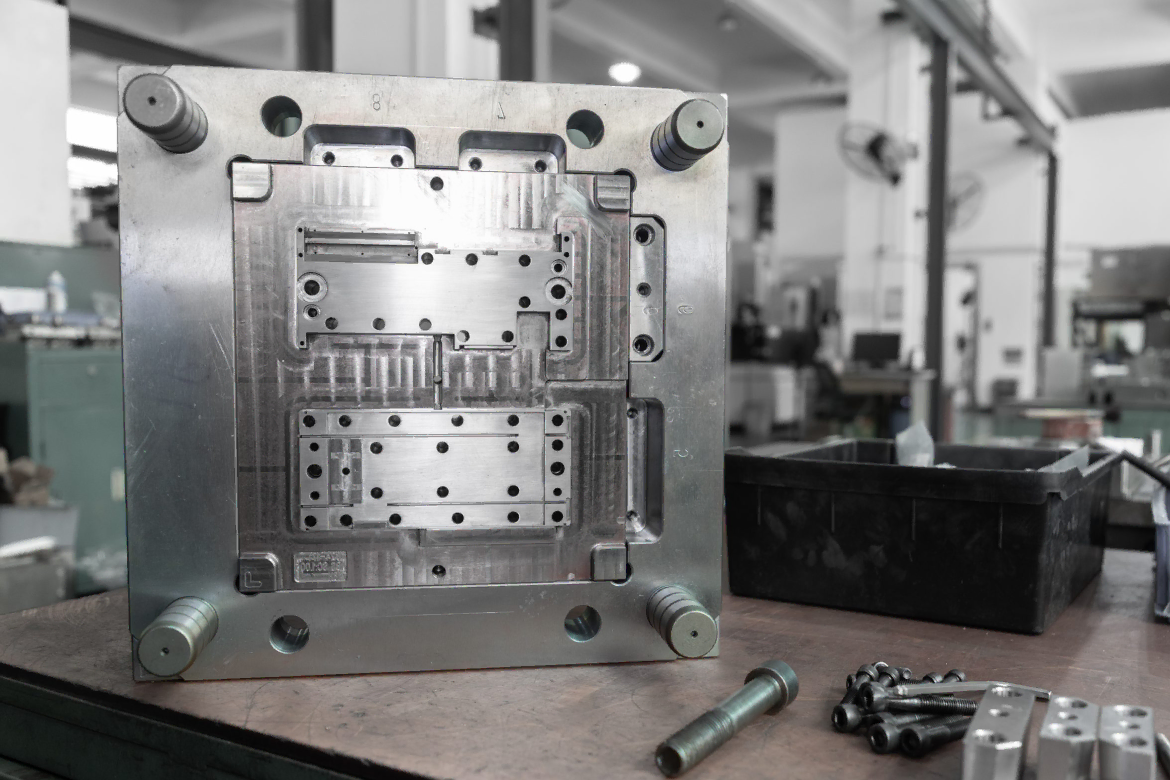

The process begins with comprehensive design engineering. Our team of experienced CNC engineers and tool designers collaborates closely with clients to interpret technical requirements, part geometry, and material specifications. Using industry-leading CAD/CAM software such as Siemens NX and SolidWorks, we develop 3D models and simulate mould flow dynamics to anticipate potential defects such as warpage, sink marks, or air traps. This virtual validation ensures optimal gate placement, cooling channel layout, and ejection mechanisms before any metal is cut.

Following design approval, we proceed to prototyping. A single-cavity prototype mould is manufactured using high-precision CNC machining, wire EDM, and surface grinding techniques. This prototype is used to produce initial test shots on our in-house injection moulding machines. Each sample part undergoes full dimensional inspection using coordinate measuring machines (CMM) and optical comparators. Material performance, cycle time, and surface finish are evaluated to validate the design. Any necessary adjustments are implemented digitally and re-verified before transitioning to full-scale production.

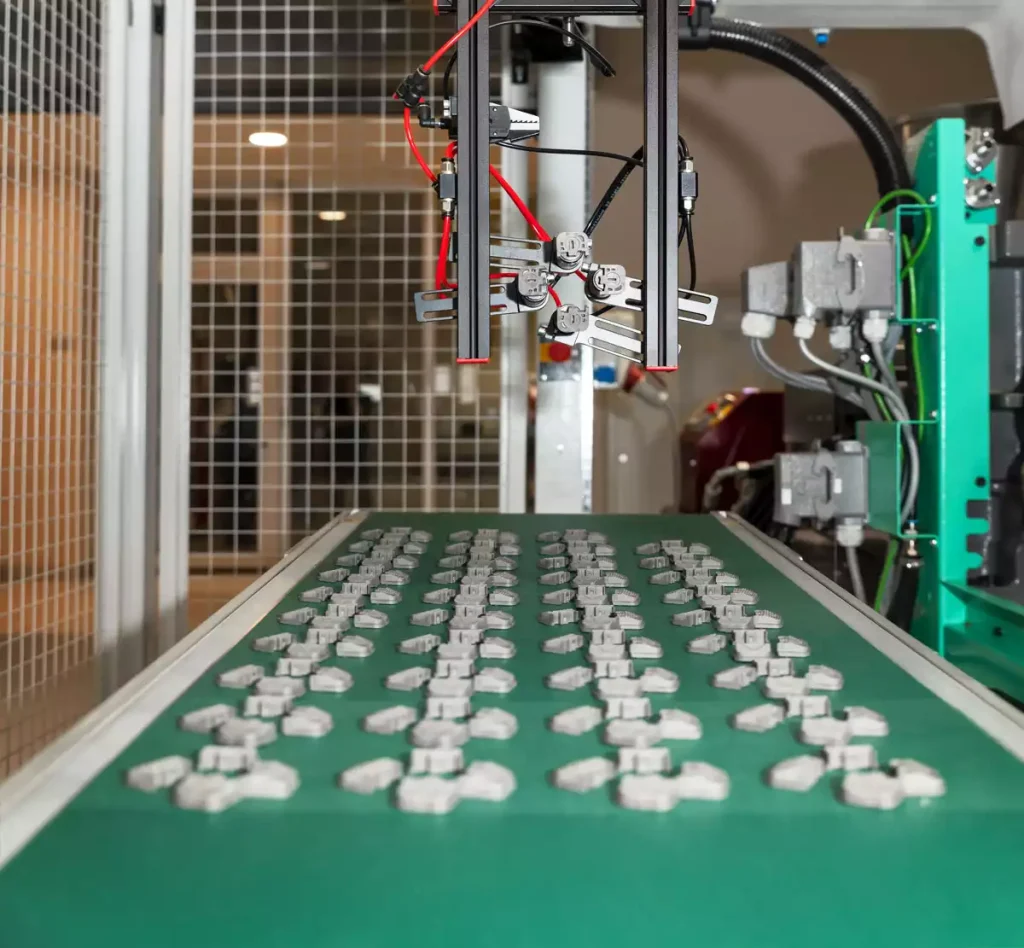

Mass production begins only after zero-defect validation. Our production floor is equipped with multi-cavity steel moulds built from pre-hardened or hardened tool steels such as P20, 718H, or H13, depending on application demands. Each mould is machined to tolerances as tight as ±0.002 mm and undergoes strict quality checkpoints including hardness testing, surface roughness analysis, and assembly verification. We utilize automated process monitoring systems to track injection pressure, temperature profiles, and cycle consistency in real time, ensuring every component produced meets exact specifications.

Throughout the entire process, Wuxi Lead enforces a zero-defect philosophy through statistical process control (SPC), first-article inspection reports (FAIR), and continuous feedback loops between production and engineering teams. This systematic approach minimizes variability and eliminates costly downstream failures in our clients’ manufacturing lines.

Below are key technical specifications maintained across our production workflow:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.1 – 0.8 µm (polished surfaces) |

| Tool Steel Options | P20, 718H, H13, S136, NAK80 |

| Mould Life Expectancy | 500,000 – 1,000,000 cycles (depending on steel and maintenance) |

| Cooling Channel Accuracy | ±0.01 mm positional tolerance |

| CMM Inspection Capability | Full 3D geometry reporting with GD&T |

| Production Lead Time | 4–8 weeks (prototype), 8–12 weeks (mass production) |

Our end-to-end control from design to mass production ensures injection moulds that deliver consistent quality, extended service life, and seamless integration into automated manufacturing cells.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Precision Foundation for Injection Mould Excellence

Injection mould makers operate at the absolute edge of dimensional accuracy and material science. A single micron of deviation in core, cavity, or intricate slide mechanism translates directly into part defects, costly rework, and production line stoppages. Wuxi Lead Precision Machinery exists to eliminate this critical risk. We are not merely a contract manufacturer; we are your dedicated precision engineering partner, focused exclusively on delivering the foundational metal components that define mould performance, longevity, and ultimate success. Our advanced CNC machining capabilities, stringent quality protocols, and deep understanding of mould dynamics ensure your tooling achieves the repeatability and stability demanded by modern high-volume production.

Our commitment begins with engineering validation and extends through final inspection. We specialize in machining the most demanding mould steels and alloys, including P20, 718H, H13, S136, and maraging steels, to the exacting tolerances required for flawless plastic flow and ejection. Every process step, from raw material certification through heat treatment oversight to final surface finishing, is controlled within our ISO 9001 certified facility. We understand that thermal stability under cyclic loading is non-negotiable; our processes are engineered to minimize residual stress and guarantee dimensional integrity throughout the mould’s operational life.

The technical specifications we consistently achieve form the bedrock of reliable mould performance. Our capabilities are rigorously validated for the most challenging applications.

| Critical Specification | Lead Precision Capability | Industry Standard Benchmark |

|---|---|---|

| Machining Tolerance | ±0.002 mm (0.00008″) | ±0.005 mm (0.0002″) |

| Surface Roughness (Ra) | 0.2 μm (8 μin) | 0.8 μm (32 μin) |

| Max Workpiece Size | 1200 x 800 x 600 mm | Typically 800 x 500 x 400 mm |

| Material Expertise | Tool Steels, Stainless, Aluminum Alloys, Copper Alloys | Common Tool Steels Only |

| Quality Control | 100% CMM Inspection, GD&T Reporting | Spot Checks, Basic Calipers |

Partnering with Lead Precision directly addresses the core challenges mould makers face: reducing lead times through optimized machining sequences, eliminating costly scrap from dimensional inaccuracies, and ensuring consistent first-article approval. Our proactive engineering collaboration identifies potential manufacturability issues early, saving weeks in the tool build schedule. When your mould components arrive from Lead Precision, you receive more than machined metal; you receive verified dimensional stability, guaranteed surface integrity, and the confidence that thermal performance will meet specification under real-world production conditions.

The next generation of injection moulding demands unprecedented precision in its foundation. Do not let substandard component manufacturing become the limiting factor in your mould’s performance or your client’s production efficiency. Contact our engineering team today to discuss your specific mould component requirements. We will provide a detailed capability assessment and a precise timeline for delivering components that meet the exacting standards your success depends upon. Initiate your precision partnership now. Email [email protected] to connect with our technical sales engineers and receive a project-specific quotation within 24 business hours. Let Lead Precision be the foundation of your next high-performance mould.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.