Technical Contents

Engineering Guide: Injection Molding Usa

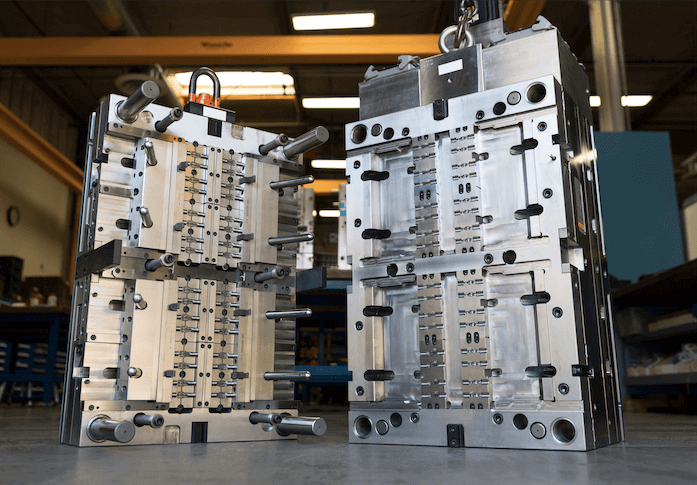

Engineering Insight Precision Imperatives in U.S. Injection Molding Tooling

Achieving consistent, high-integrity plastic components for the U.S. market demands far more than basic cavity replication. True precision in injection molding tooling centers on the intricate interplay of thermal management, micron-level dimensional stability, and rigorous process control – factors directly impacting part functionality, assembly yield, and end-product longevity. U.S. manufacturers face stringent requirements across aerospace, medical, and defense sectors where tolerances often reside below 0.001 inches. Variations in mold steel homogeneity, cooling channel placement accuracy, or even minute deflection under clamp force can propagate critical defects like warpage, sink, or flash. This necessitates tooling engineered not merely to hold dimension, but to maintain thermal equilibrium cycle after cycle, ensuring material flow and solidification behave predictably. The cost of imprecision manifests not just in scrap, but in delayed time-to-market, costly secondary operations, and potential field failures where performance is non-negotiable.

Wuxi Lead Precision Machinery operates at this demanding threshold. Our engineering philosophy treats the mold as a dynamic thermal system, not static metal. We integrate advanced simulation for cooling optimization and structural rigidity analysis before steel cutting, ensuring the physical tool mirrors the virtual model’s performance intent. This is validated through our ISO 9001-certified processes and direct experience meeting the uncompromising standards of U.S. defense contractors and major international sporting events. For the Tokyo 2020 Olympics, we delivered over 10,000 precision-machined mold components requiring sub-5-micron positional accuracy and flawless surface integrity for critical event infrastructure parts. Similarly, our work supporting Tier-1 aerospace suppliers involves molds certified to AS9100 standards, producing components where material traceability and process documentation are as vital as the physical dimensions.

Our capability stems from specialized infrastructure and disciplined execution. Below are core specifications underpinning our precision tooling for U.S. clients:

| Parameter | Specification | Relevance to U.S. Injection Molding |

|---|---|---|

| Positional Accuracy | ≤ ±0.0002 inches (5 microns) | Ensures core/cavity alignment critical for zero flash and part symmetry |

| Surface Finish | Ra 0.05 µm (Mirror) to Ra 0.8 µm | Meets medical/aerospace cosmetic and functional flow requirements |

| Thermal Stability | ±0.5°F (0.3°C) coolant control | Eliminates warpage by ensuring uniform mold temperature distribution |

| Process Capability | Cpk ≥ 1.67 sustained | Guarantees statistical process control for high-volume U.S. production |

| Material Certification | Full mill test reports (ASTM) | Mandatory for defense and medical traceability compliance |

Precision in U.S.-bound tooling transcends machining capability; it requires deep understanding of how microscopic tool behavior dictates macroscopic part performance. Lead Precision’s proven track record with elite global projects demonstrates our commitment to delivering tooling that performs reliably within the exacting operational frameworks of American manufacturing. When component failure is not an option, the mold’s foundational precision is the indispensable starting point. Consult our engineering team to discuss your specific U.S. project requirements and tolerance challenges.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the stringent demands of high-performance industries, including aerospace, medical, automotive, and industrial equipment. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex, high-precision components with superior surface finishes and dimensional accuracy. This advanced machining process allows simultaneous movement across five axes, ensuring exceptional geometric flexibility and reducing the need for multiple setups, which in turn enhances repeatability and reduces lead times.

Our 5-axis CNC systems are operated by experienced engineers who utilize industry-leading CAD/CAM software to optimize toolpaths and ensure precision in every cut. This integration of advanced hardware and intelligent programming allows us to machine intricate contours, deep cavities, and multi-faceted parts from a single workholding setup, minimizing human error and maximizing consistency. Materials commonly processed include aluminum alloys, stainless steel, titanium, tool steels, and high-temperature superalloys, all machined to meet exact customer specifications.

Quality control is integral to our manufacturing process. Every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM system provides highly accurate 3D measurements, capturing critical features with micron-level precision. Inspection reports are generated for each batch, offering full traceability and documentation for quality assurance. This metrology-backed approach guarantees that all parts meet or exceed customer expectations and industry standards such as ISO 9001 and AS9100.

We maintain strict environmental and process controls within our facility to ensure thermal stability and minimize variability during production. Our machining centers are housed in climate-controlled environments, and tool wear is continuously monitored and compensated for in real time. These measures, combined with our rigorous in-process inspections, ensure consistent output across both prototype and high-volume production runs.

The following table outlines our standard machining tolerances, reflecting our commitment to precision and repeatability:

| Feature | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 mm | ±0.010 mm |

| Hole Diameter | ±0.025 mm | ±0.005 mm |

| Positional Tolerance | ±0.025 mm | ±0.010 mm |

| Flatness | 0.025 mm | 0.010 mm |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm |

| Angular Tolerance | ±0.05° | ±0.02° |

| Profile Tolerance | ±0.025 mm | ±0.010 mm |

Wuxi Lead Precision Machinery is committed to delivering precision-engineered metal components that meet the exacting standards of U.S. and global markets. Our combination of 5-axis CNC machining, rigorous CMM-based quality assurance, and deep expertise in custom manufacturing makes us a trusted partner for injection molding OEMs and precision equipment manufacturers across North America.

Material & Finish Options

Material Selection for High-Performance Injection Molds

Material selection directly impacts mold longevity, part quality, and production economics in demanding US injection molding applications. Suboptimal choices accelerate wear, increase downtime, and compromise dimensional stability under thermal cycling and resin pressure. Wuxi Lead Precision Machinery leverages metallurgical expertise to match material properties to your specific resin type, volume, and geometric complexity. This section details critical considerations for aluminum, steel, and titanium alloys, alongside essential anodizing processes for aluminum tooling.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer rapid machining and excellent thermal conductivity. This enables faster cooling cycles, reducing part cycle times significantly for prototyping and low-to-medium volume production. However, aluminum’s lower hardness (150 HB) makes it susceptible to wear with abrasive resins or high-cavity-pressure applications. It is unsuitable for glass-filled polymers or sustained high-volume runs exceeding 100,000 shots. Aluminum excels where speed-to-market is paramount and resin abrasiveness is minimal.

Tool steels dominate high-volume production. P20 (AISI 4140 modified) provides a balanced solution for general-purpose molds up to 500,000 shots, offering good machinability and moderate wear resistance after heat treatment to 28-32 HRC. For demanding applications involving abrasive fillers, corrosive resins, or volumes exceeding 1 million shots, H13 (AISI H13) is essential. Hardened to 48-52 HRC, H13 delivers superior thermal fatigue resistance and wear performance. Pre-hardened steels like NAK80 offer mirror-polish capability for optical components but require careful handling to avoid surface damage during molding.

Titanium alloys (e.g., Ti-6Al-4V) present niche solutions for extreme corrosion resistance against PVC or flame-retardant resins. Their high strength-to-weight ratio benefits large mold bases. However, titanium’s low thermal conductivity impedes cooling efficiency, and machining complexity increases costs substantially. Use titanium only when corrosion resistance outweighs thermal and economic penalties.

Anodizing is critical for aluminum mold protection but requires precise specification. Type II sulfuric anodizing (5-25μm) provides basic corrosion resistance. For molding, Type III hardcoat anodizing (25-50μm, 50-70 HRC) is mandatory to withstand abrasive resins and ejection forces. Note that anodizing adds dimensionally significant coating thickness per side; this must be compensated in the CNC machining phase to maintain final cavity tolerances. NADCAP-certified anodizing ensures coating adhesion and uniformity meeting ASTM B580 standards.

Key Material Properties for Injection Mold Applications

| Material | Typical Hardness | Thermal Conductivity (W/m·K) | Max Shot Count (Est.) | Primary Use Case | Key Limitation |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 150 HB | 130 | 50,000 – 100,000 | Rapid prototyping, low-volume production | Low wear resistance |

| P20 Tool Steel | 28-32 HRC | 30 | 300,000 – 500,000 | General-purpose medium-volume production | Limited for abrasive resins |

| H13 Tool Steel | 48-52 HRC | 25 | 1,000,000+ | High-volume, abrasive/corrosive resins | Higher initial cost |

| Titanium Ti-6Al-4V | 36 HRC | 7 | 500,000+ (corrosion) | Extreme corrosion resistance applications | Poor thermal conductivity |

Material selection is not generic. Wuxi Lead Precision Machinery conducts resin compatibility analysis and thermal stress modeling to specify the optimal alloy and surface treatment for your USA-based production environment. Contact our engineering team to validate your material choice against actual molding parameters and avoid costly field failures.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, consistency, and zero-defect outcomes in custom metal manufacturing. Designed to meet the rigorous demands of high-end industrial clients—especially those sourcing from or operating within the injection molding USA sector—our workflow integrates advanced engineering with strict quality assurance at every stage. The journey begins with Design, transitions through Prototyping, and culminates in Mass Production, each phase calibrated to ensure seamless scalability and part integrity.

Design is the foundation of any successful manufacturing project. Our engineering team collaborates closely with clients to analyze part geometry, material selection, tolerances, and functional requirements. Utilizing 3D CAD modeling and simulation tools such as SolidWorks, AutoCAD, and Moldflow, we optimize designs for manufacturability, minimizing stress points, warpage risks, and assembly complications. Special attention is given to mold flow dynamics, gate positioning, and cooling channel layout—critical factors when producing metal components for integration with plastic injection molds. This stage ensures that every design is not only functional but also optimized for repeatable, high-precision production.

Once the design is finalized and approved, we move into Prototyping. This phase serves as a physical validation of the digital model. Using CNC machining, wire EDM, and precision grinding, we fabricate prototype tooling and initial sample parts in the actual production-grade materials. These prototypes undergo comprehensive inspection using CMM (Coordinate Measuring Machines), optical comparators, and surface roughness testers. We conduct fit, form, and function testing, often in collaboration with the client’s injection molding team to verify compatibility with existing systems. Any necessary adjustments are implemented before tooling release, ensuring full alignment with performance expectations.

Mass Production follows strict process controls under ISO 9001-certified protocols. Our automated CNC cells operate with real-time monitoring, enabling consistent output across large volumes. Each component is subject to in-process and final inspections, with full traceability maintained through batch numbering and digital quality logs. Preventive maintenance schedules and SPC (Statistical Process Control) ensure machine stability and dimensional accuracy throughout the production run. The result is a zero-defect manufacturing outcome, where every part meets or exceeds the original specifications.

The following table outlines key production capabilities and tolerances achieved across our facility:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.05 μm |

| Materials Supported | Stainless Steel, Tool Steel, Aluminum, Brass, Titanium |

| Max Workpiece Size | 1200 mm × 800 mm × 600 mm |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Level 3 |

From concept to completion, Wuxi Lead Precision Machinery delivers custom metal components with the precision and reliability required by advanced manufacturing sectors, ensuring seamless integration into injection molding systems across North American and global markets.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Injection Molding Excellence

For US injection molding operations demanding precision metal components that consistently exceed specifications, Wuxi Lead Precision Machinery stands as your strategic manufacturing partner. We bridge the gap between Chinese manufacturing scale and Western quality expectations, delivering the reliability and technical expertise essential for high-performance molds and critical tooling. Our ISO 9001:2015 and IATF 16949 certified facility in Wuxi, China, is engineered specifically for the rigorous demands of the North American market. We understand the critical impact of mold precision on cycle times, part quality, and overall production efficiency. Partnering with Lead Precision means gaining a dedicated extension of your engineering team, focused solely on eliminating the common pitfalls of offshore manufacturing: communication delays, inconsistent quality, and extended lead times. Our proven track record includes supplying Tier 1 automotive molders, medical device innovators, and consumer electronics leaders across the USA, where dimensional accuracy and material integrity are non-negotiable.

Lead Precision operates with a US-centric support model designed for seamless collaboration. A dedicated English-speaking project management team, available during EST business hours, provides single-point accountability from RFQ through final shipment. We implement rigorous in-process and final inspections using calibrated CMMs and optical comparators against your exact prints, with detailed reports provided pre-shipment. Our facility maintains strict material traceability and adheres to ASTM and SAE standards for all critical alloys. Crucially, we mitigate supply chain risks through strategic raw material inventory management and redundant machining capacity, ensuring your production schedules remain on track. This operational transparency and proactive communication are fundamental to our partnership philosophy, transforming the perceived complexity of offshore sourcing into a streamlined competitive advantage for your business.

Our technical capabilities are precisely aligned with the stringent requirements of modern injection molding applications. We specialize in complex mold bases, cavities, cores, ejector systems, and precision inserts requiring micron-level tolerances and superior surface finishes. The table below details our core manufacturing specifications relevant to mold component production.

| Specification Category | Capability Detail |

|---|---|

| Machining Tolerances | ±0.0001″ (2.5 µm) for critical features |

| Surface Finish | As low as Ra 0.05 µm (2 µin) mirror polish |

| Materials Expertise | P20, H13, S7, 420SS, 17-4PH, Aluminum 7075, Beryllium Copper |

| Maximum Part Size | 2000mm x 1200mm x 1000mm (78.7″ x 47.2″ x 39.4″) |

| Key Equipment | 5-Axis Milling Centers, High-Speed CNC Mills, Precision Grinding, Wire EDM, Laser Texturing |

| Quality Control | Full CMM Reporting, Material Certificates, First Article Inspection (FAI) to AS9102 |

Elevate your injection molding performance with components engineered and manufactured to the highest global standards, backed by responsive US-focused partnership. Do not compromise on the foundation of your molding success. Contact our US project team directly at [email protected] to discuss your specific requirements. Provide your drawings or specifications for a rapid, detailed technical and commercial quotation. Discover how Lead Precision Machinery delivers not just parts, but guaranteed performance and peace of mind for your critical molding applications. Initiate the conversation that secures your competitive edge today.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.