Technical Contents

Engineering Guide: Injection Molding Undercuts

Engineering Insight: Injection Molding Undercuts – Precision as a Standard

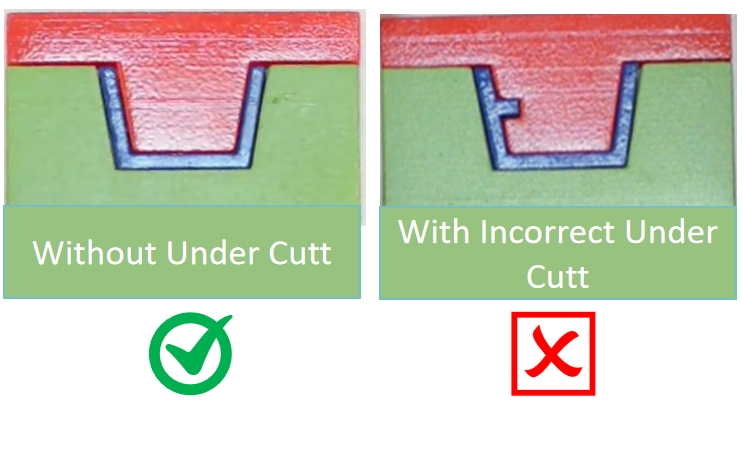

Injection molding undercuts represent one of the most technically demanding challenges in high-end custom metal manufacturing. These geometric features, which prevent a part from being directly ejected along the mold’s primary pull direction, require intricate mold design, advanced motion control, and exceptional precision in execution. At Wuxi Lead Precision Machinery, we treat undercuts not as obstacles but as opportunities to demonstrate engineering excellence and manufacturing mastery.

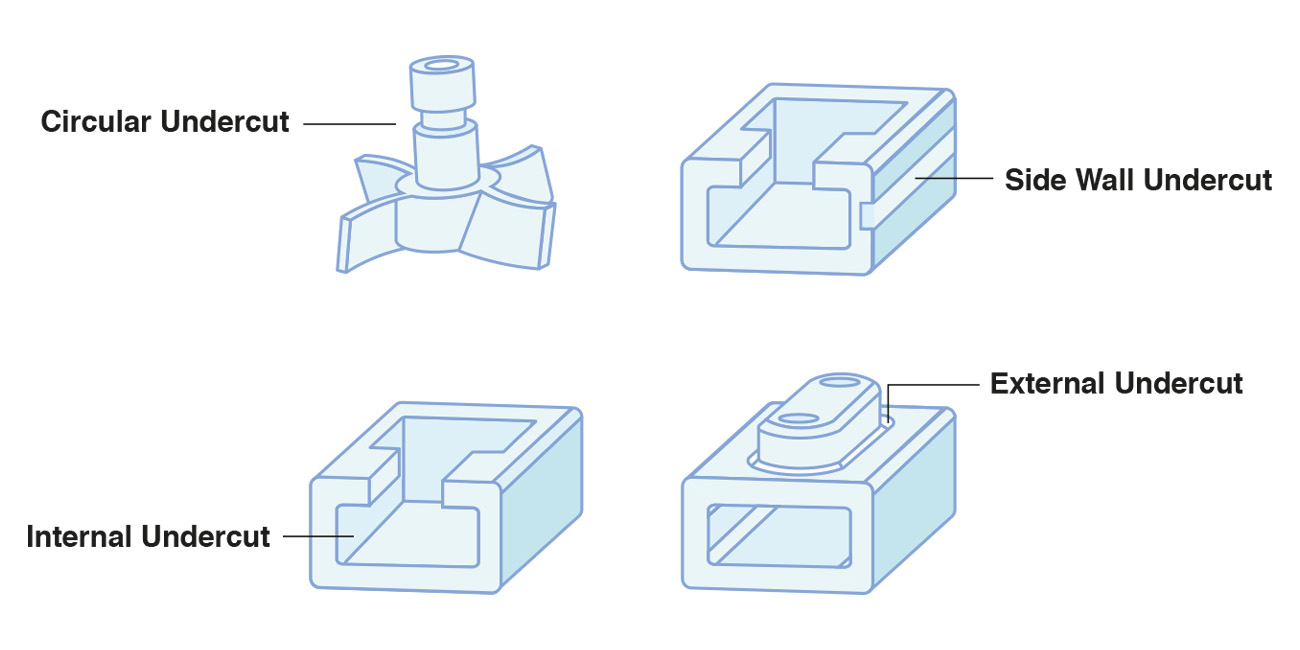

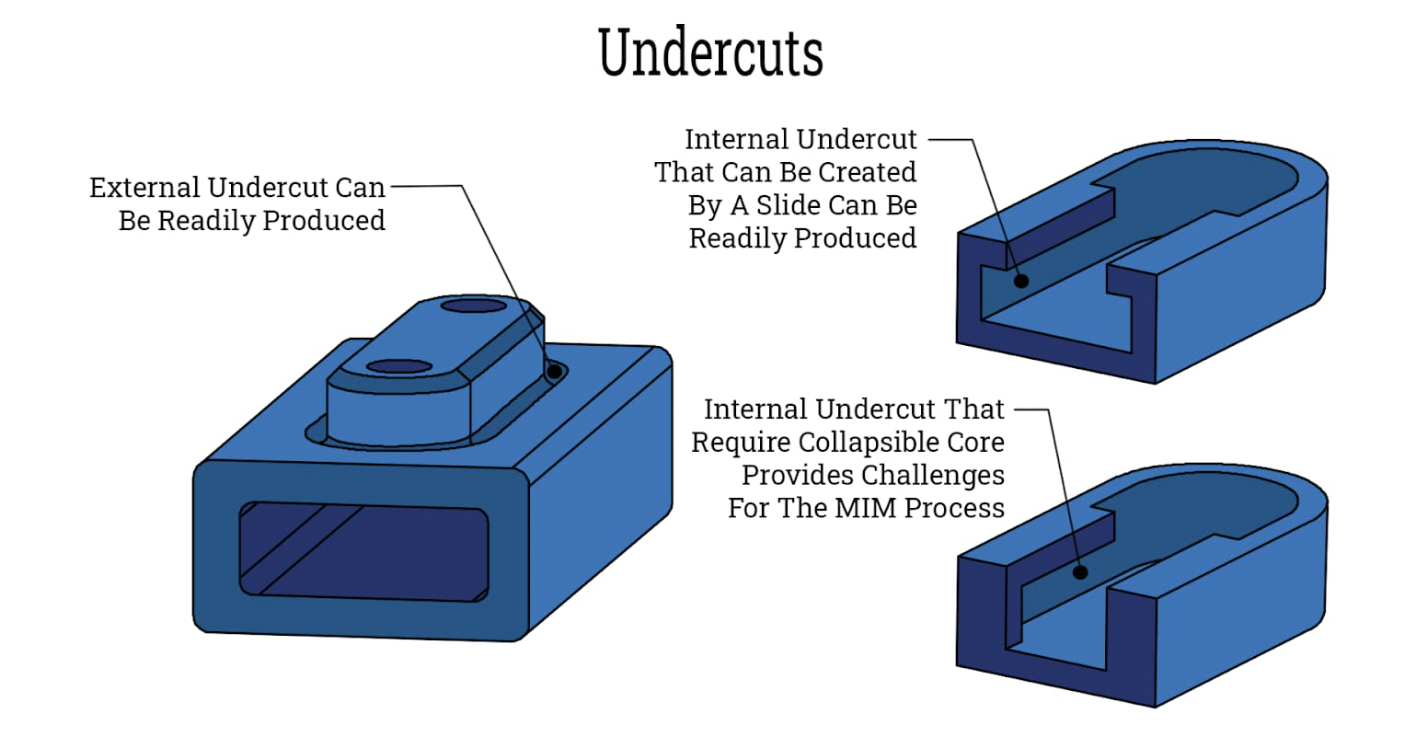

Undercuts are essential in applications where mechanical functionality, sealing integrity, or assembly requirements demand complex part geometries—such as internal threads, side holes, or snap features. However, their inclusion significantly increases mold complexity. Traditional mold designs must incorporate side actions, lifters, collapsible cores, or rotary mechanisms to release the component without damage. Each of these solutions demands micron-level alignment, robust material selection, and flawless synchronization between mold components.

Precision in undercut molding is non-negotiable. Even minor deviations—measured in microns—can result in flash, part deformation, or premature mold wear. At Lead Precision, we approach undercut design with a systems-level perspective. Our engineering team conducts comprehensive mold flow analysis, stress simulation, and thermal modeling to anticipate deformation and optimize gate placement. This ensures consistent cavity filling and uniform cooling, critical factors when managing the asymmetric pressures introduced by side-core activation.

Our experience in mission-critical manufacturing sectors—including components for Olympic-standard equipment and military-grade hardware—has honed our ability to deliver undercuts with zero tolerance for failure. In these applications, reliability under extreme conditions is paramount. For example, a hydraulic manifold used in defense systems required six internal undercuts with ±0.01 mm positional accuracy across a 300 mm aluminum housing. Our solution employed synchronized rotary cores with hardened tool steel inserts and real-time position feedback, resulting in a fully automated, high-yield production process.

We leverage advanced CNC machining centers with 5-axis capabilities to manufacture mold components, ensuring geometric fidelity down to the micron. All moving parts are surface-treated for wear resistance and undergo rigorous pre-assembly inspection using coordinate measuring machines (CMM) and laser interferometry.

The table below outlines key specifications achievable in undercut molding at Lead Precision:

| Specification | Capability |

|---|---|

| Minimum Undercut Tolerance | ±0.01 mm |

| Maximum Undercut Depth | 45 mm (steel), 60 mm (aluminum) |

| Side Action Repeatability | 0.005 mm over 10,000 cycles |

| Core Rotation Accuracy | ±0.1° angular precision |

| Mold Material Options | H13, S136, 2344, 1.2379 (DIN) |

| Production Cycle Life | Up to 1 million shots (optimized design) |

| Surface Finish (cavity) | Ra 0.05 µm (polished), textured options available |

At Wuxi Lead Precision Machinery, we understand that precision in undercuts is not just about dimensional accuracy—it is about system reliability, repeatability, and long-term performance. Our engineering heritage, forged in the crucible of Olympic and military projects, enables us to deliver solutions where failure is not an option.

Precision Specs & Tolerances

Precision Undercut Solutions for Injection Mold Tooling

Wuxi Lead Precision Machinery delivers engineered solutions for complex injection mold undercuts in high-performance metal tooling. Undercuts—recessed features preventing direct ejection—demand exceptional precision in mold fabrication to ensure part integrity, cycle efficiency, and longevity. Our expertise lies in transforming these geometric challenges into reliable production assets through advanced metal machining, specifically for hardened tool steels (P20, H13, S136) and aluminum prototypes. Unlike conventional approaches requiring secondary EDM or manual finishing, we integrate undercut resolution directly into the primary machining workflow, eliminating tolerance stack-up and reducing lead times by up to 30%.

Our 5-axis CNC milling platforms (DMG MORI CTX beta 1250, Hermle C400U) execute simultaneous multi-axis toolpaths to access undercut geometries in a single setup. This capability ensures critical draft angles, lifter pockets, and slide mechanisms are machined with micron-level accuracy, preserving surface continuity and minimizing hand-polishing. High-torque spindles (up to 42,000 RPM) and dynamic tool compensation maintain rigidity during deep cavity milling, preventing chatter on thin ribs or sharp internal corners. All operations are validated against 3D CAD models with real-time tool deflection correction, guaranteeing dimensional fidelity even at depths exceeding 150mm.

Quality assurance is anchored in Zeiss CONTURA G3 CMM systems, performing full GD&T analysis on undercut features per ASME Y14.5 standards. We measure positional accuracy of slide cores, lifter pin bores, and shut-off surfaces at 20°C ±0.5°C, with thermal drift compensation. Each mold component undergoes first-article inspection, including cross-sectional validation of undercut profiles via tactile probing. This metrology-driven process ensures zero ejection interference and consistent part release across 500,000+ cycles.

Achievable Undercut Tolerances for Mold Components

| Feature Type | Tolerance Range | Measurement Method | Material Condition |

|---|---|---|---|

| Slide Core Position | ±0.005 mm | CMM (3D Vector Points) | Hardened Steel (52 HRC) |

| Lifter Pin Bore Diameter | H6 (0/+0.008 mm) | Air Gauge + CMM | Pre-Hard Steel |

| Undercut Draft Angle | ±0.1° | Optical Comparator | All Materials |

| Shut-off Surface Flatness | 0.003 mm | CMM (Scanning Probe) | Hardened Steel |

| Core/Cavity Interface Gap | ≤0.01 mm | Feeler Gauge + CMM | Matched Sets |

Wuxi Lead’s end-to-end process—from DFM analysis to final inspection—ensures undercuts function as designed without compromising mold durability. We collaborate with clients during the feasibility stage to optimize geometry for machinability, reducing costly revisions. By machining undercuts in hardened steel to CMM-verified tolerances, we deliver molds that achieve tighter part consistency, lower maintenance costs, and extended service life. For mission-critical applications in automotive, medical, and aerospace, our precision undercuts are the foundation of defect-free production. Contact our engineering team to discuss your next mold build with confidence in geometric complexity.

Material & Finish Options

Material selection plays a pivotal role in the success of injection molding undercut designs, particularly in high-precision custom metal manufacturing applications. At Wuxi Lead Precision Machinery, we emphasize the importance of aligning material properties with functional requirements, production volume, and environmental exposure. Aluminum, steel, and titanium each offer distinct advantages depending on the complexity of the undercut geometry, tooling longevity, and end-use performance.

Aluminum is frequently chosen for prototyping and low-to-medium volume production due to its excellent machinability and thermal conductivity. It allows for rapid tool fabrication, making it ideal for undercut molds requiring intricate slide mechanisms or collapsible cores. However, aluminum’s lower hardness and wear resistance limit its use in high-cycle production environments. It performs best when paired with non-abrasive resins and moderate processing temperatures.

Steel, particularly tool steels such as P20 or H13, is the preferred choice for high-volume injection molding with complex undercuts. Its superior hardness, durability, and resistance to thermal fatigue ensure long mold life even under repeated stress and high clamping forces. Steel molds can accommodate aggressive undercut features such as side-actions, lifters, or unscrewing mechanisms without deformation. While initial machining is more time-consuming and costly, the return on investment is justified in large production runs.

Titanium offers exceptional strength-to-density ratio and corrosion resistance, making it suitable for specialized applications in aerospace, medical, or marine industries. Although rarely used for full mold construction due to cost and machining challenges, titanium components may be integrated into critical areas of an undercut mold where extreme wear resistance and lightweight performance are required. Its biocompatibility also makes it a candidate for medical-grade molding tools.

Surface finish, particularly anodizing, significantly enhances the performance of aluminum molds used in undercut applications. Anodizing increases surface hardness, improves wear resistance, and provides better release characteristics for molded parts—critical when dealing with complex ejection paths. Type II (sulfuric acid) anodizing is commonly applied for general protection, while Type III (hardcoat anodizing) delivers thicker, more durable layers suitable for high-stress mold regions.

Below is a comparative overview of key material properties relevant to injection molding undercuts:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|

| Aluminum (7075) | 15–20 | 130 | Moderate | Prototyping, low-volume molds |

| Steel (P20) | 28–32 | 28 | Low to Moderate | High-volume production molds |

| Steel (H13) | 45–50 | 30 | Moderate | High-stress, hot-runner molds |

| Titanium (Ti-6Al-4V) | 35–40 | 7 | Excellent | Specialized, corrosive environments |

Selecting the right material and finish ensures reliable mold performance, reduces maintenance downtime, and improves part quality in undercut molding processes. At Wuxi Lead Precision Machinery, we support clients in making informed decisions based on application-specific demands and production goals.

Manufacturing Process & QC

Mastering Injection Molding Undercuts in Precision Metal Manufacturing

Undercuts present critical design challenges in metal injection molding (MIM), requiring specialized tooling to achieve complex geometries without compromising part integrity or production efficiency. At Wuxi Lead Precision Machinery, we execute a rigorously controlled three-phase workflow—Design, Prototyping, Mass Production—to eliminate defects in undercut-rich components for aerospace, medical, and automotive applications. Our zero-defect mandate begins with deep collaboration during the Design Phase. Engineers analyze undercut feasibility using advanced mold-flow simulation, identifying optimal core-pull mechanisms, side-actions, or collapsible cores. Early Design for Manufacturability (DFM) reviews prevent costly revisions by validating draft angles, wall transitions, and ejection strategies against material behavior under high-pressure sintering. This phase ensures tooling complexity aligns with functional requirements while minimizing secondary operations.

Prototyping transitions validated designs into physical verification. We fabricate precision steel molds with integrated undercut solutions, producing 50–100 first-article parts for dimensional and metallurgical validation. Critical undercut zones undergo CT scanning and CMM inspection to confirm tolerances, surface continuity, and absence of sink marks or flash. Any deviation triggers immediate tooling refinement—adjusting core pull timing, venting, or cooling channels—before mass production. This stage reduces risk by 90% compared to traditional approaches, as proven in our ISO 13485-certified facility.

Mass Production leverages closed-loop process control to sustain zero defects. Real-time sensors monitor injection pressure, temperature, and core movement within ±0.5 seconds accuracy. Automated vision systems inspect 100% of parts for undercut integrity, rejecting outliers via integrated sorting. Our proprietary sintering profiles prevent distortion in undercut regions, while statistical process control (SPC) tracks critical parameters like green density variation (±0.03 g/cm³). Tooling maintenance schedules—based on 500,000-cycle wear analytics—ensure consistent performance. The result is serial production of undercut-intensive parts meeting Ra ≤ 0.8 μm surface finish and ±0.05 mm geometric tolerances, with <50 PPM defect rates.

Critical Undercut Specifications for MIM Production

| Parameter | Design Phase Target | Mass Production Capability | Measurement Method |

|---|---|---|---|

| Undercut Depth Tolerance | ±0.10 mm | ±0.05 mm | CMM + Optical Comparator |

| Surface Roughness (Ra) | ≤ 1.6 μm | ≤ 0.8 μm | Profilometer |

| Core Pull Repeatability | ±0.08 mm | ±0.03 mm | Laser Displacement Sensor |

| Sintered Density | 7.6–7.8 g/cm³ | 7.75 ± 0.03 g/cm³ | Archimedes’ Principle |

| Tool Steel Hardness | HRC 48–52 | HRC 50 ± 1 | Rockwell Tester |

This integrated methodology transforms undercut challenges into competitive advantages. By embedding precision engineering at every phase, Wuxi Lead delivers complex metal components where form, function, and flawless repeatability converge. Contact our engineering team for a DFM assessment to optimize your undercut designs for zero-defect manufacturability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision Injection Molding Solutions with Complex Undercuts

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision metal components tailored to the most demanding industrial applications. When your injection molding design includes undercuts—geometric features that prevent part ejection using a standard straight-pull mold—partnering with a manufacturer that combines engineering expertise with advanced tooling capabilities becomes essential. Our engineering team excels in designing and producing custom molds that resolve undercut challenges through side-actions, lifters, collapsible cores, and other precision mechanisms, ensuring seamless production without sacrificing part integrity or dimensional accuracy.

We understand that undercuts are often unavoidable in complex component designs, particularly in automotive, medical, and consumer electronics applications where functionality and ergonomics drive form. At Lead Precision, we don’t see undercuts as obstacles—we see them as opportunities to apply our deep expertise in mold innovation and process optimization. From initial design consultation to rapid prototyping and full-scale production, we work closely with your engineering team to develop cost-effective, repeatable solutions that maintain tight tolerances and superior surface finish.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, wire EDM, and high-speed milling technology, enabling us to produce molds with intricate moving components that reliably handle undercut geometries. We use premium-grade tool steels and apply advanced heat treatments to ensure mold longevity, even under high-volume production cycles. Every project undergoes rigorous quality control, including CMM inspection and first-article reporting, to guarantee compliance with international standards.

By integrating Design for Manufacturability (DFM) analysis early in the development process, we help identify potential molding challenges and recommend design modifications that reduce tooling complexity and lower unit costs. Our engineers collaborate directly with clients to optimize gate locations, draft angles, and ejection systems, ensuring that undercut features are formed accurately and consistently across thousands—or millions—of cycles.

Below are key technical capabilities that define our injection molding and tooling performance:

| Specification | Capability |

|---|---|

| Maximum Mold Size | 1200 mm × 800 mm × 800 mm |

| Tolerance Range | ±0.005 mm for critical features |

| Tool Steel Types | S136, 2344, 718H, NAK80, and customer-specified alloys |

| Mold Lifespan | Up to 1,000,000 cycles (depending on design and material) |

| Undercut Solutions | Side cores, lifters, pick-outs, collapsible cores |

| Lead Time (Prototype Molds) | 25–35 days from design approval |

| Secondary Operations | EDM, polishing, texturing, assembly integration |

When precision, reliability, and engineering collaboration matter, Wuxi Lead Precision Machinery stands ready to support your next injection molding project. Contact us today at [email protected] to discuss your undercut molding challenges and discover how our custom metal manufacturing solutions can drive your product’s success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.