Technical Contents

Engineering Guide: Injection Molding Tools

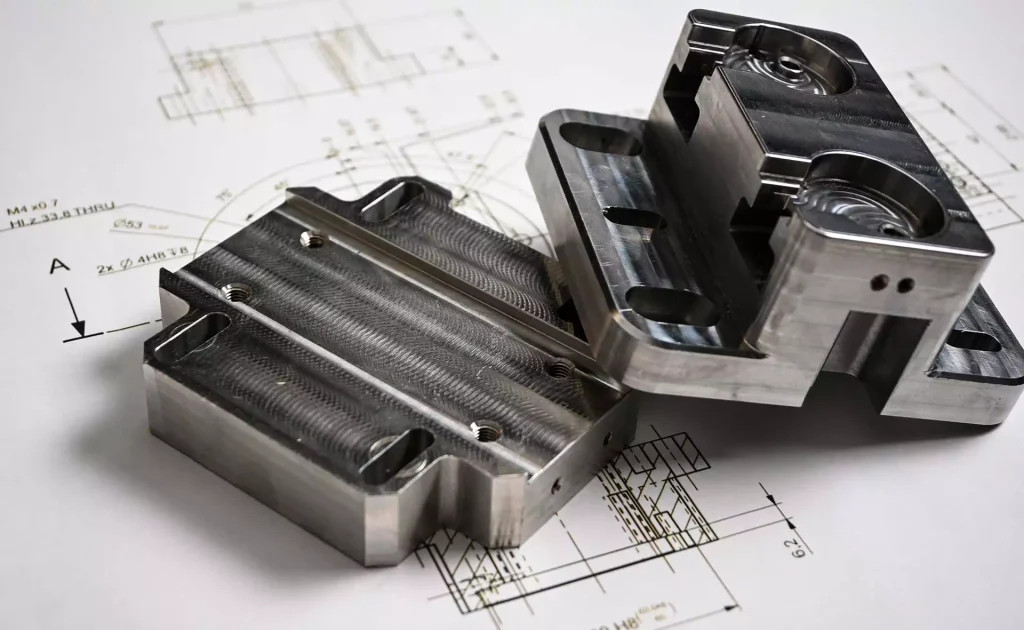

Engineering Insight Precision as the Non-Negotiable Foundation of Injection Molding Tools

In the high-stakes realm of injection molding, the tool is not merely a component; it is the absolute determinant of part quality, production efficiency, and ultimately, product success. The relentless pursuit of micron-level precision in mold fabrication is not an engineering luxury—it is a fundamental economic and technical imperative. A deviation of mere microns within the mold cavity or core translates directly into dimensional instability, surface defects, flash, or part warpage in the final component. This cascades into costly scrap, production downtime for adjustments, secondary operations, and potential failure in critical applications. For industries like medical devices, aerospace, automotive safety systems, and consumer electronics, where tolerances are unforgiving and regulatory scrutiny is intense, the initial precision of the mold tool is the bedrock upon which consistent, high-yield manufacturing is built. Compromising on tool accuracy guarantees downstream headaches and erodes the total cost of ownership, far outweighing any perceived savings in mold acquisition.

Wuxi Lead Precision Machinery operates at this pinnacle of precision demand. Our engineering philosophy is forged in environments where failure is not an option. We have engineered and manufactured injection molding tools for components used in Olympic Winter Games equipment, where performance under extreme conditions is non-negotiable, and for specialized military applications demanding absolute reliability and adherence to stringent mil-spec standards. These projects are not merely credentials; they are daily validation of our capability to deliver molds operating consistently within the tightest tolerances, under the most demanding material and production cycle requirements. Our CNC machining centers, operated by master craftspeople and supported by advanced metrology labs featuring CMMs and optical comparators, are calibrated to achieve and verify tolerances that push the boundaries of conventional manufacturing. We understand that the mold’s thermal management, steel selection, surface finish, and dimensional stability are intricately linked, and our process controls ensure every element converges to produce a tool capable of millions of flawless cycles.

The technical specifications below reflect the baseline capabilities we consistently achieve for our clients in high-precision sectors. This level of control is not accidental; it is the result of rigorous process discipline, advanced technology investment, and decades of specialized experience focused solely on critical metal components and tooling.

| Specification Category | Typical Capability Range | Advanced Capability (Olympic/Military Grade) |

|---|---|---|

| Linear Dimensional Tolerance | ±0.005 mm | ±0.002 mm |

| Geometric Tolerance (GD&T) | ±0.010 mm | ±0.003 mm |

| Surface Roughness (Cavity) | Ra 0.2 µm | Ra 0.05 µm |

| Core/Cavity Steel Hardness | HRC 48-52 | HRC 52-56 (Pre-Hardened/Tool Steel) |

| Thermal Control Precision | ±1.0°C | ±0.5°C |

| Expected Tool Life (Cycles) | 500,000 – 1,000,000 | 1,000,000+ |

Precision in injection molding tools is the invisible force ensuring visible success downstream. At Wuxi Lead Precision Machinery, we engineer this precision into every mold, leveraging proven expertise from the most demanding global projects to deliver tools that guarantee your production excellence and component integrity from cycle one to the end of life. Partner with us for molds where accuracy is engineered, not assumed. Contact our engineering team to discuss your critical application requirements.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision injection molding tools for demanding industrial applications. Our engineering expertise is anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex mold geometries with exceptional accuracy and surface finish. This multi-axis capability allows simultaneous cutting from five different angles, minimizing setup changes and ensuring tight alignment across intricate features. As a result, we achieve superior part consistency and reduced lead times, critical for clients in automotive, medical, and consumer electronics sectors where precision and repeatability are paramount.

All machining operations are supported by a rigorous quality control framework, with every component undergoing comprehensive inspection via Coordinate Measuring Machine (CMM) technology. Our CMM systems provide micron-level verification of dimensional accuracy, geometric tolerances, and surface profiles, ensuring complete compliance with client specifications and international standards. Data from each inspection is documented and traceable, supporting full quality reporting for audit and production validation purposes. This closed-loop quality process guarantees that every injection molding tool meets the highest standards of performance and durability.

Our manufacturing floor integrates advanced simulation software with real-time tool monitoring, enabling predictive maintenance and optimized machining strategies. This digital approach enhances process stability and extends tool life, directly benefiting long-term mold performance. Materials are carefully selected based on application requirements, including hardened tool steels, stainless alloys, and aluminum for prototype tooling, all processed under controlled environmental conditions to minimize thermal distortion.

The following table outlines the standard technical specifications and tolerances achievable across our production platform:

| Parameter | Specification |

|---|---|

| Machining Process | 5-Axis CNC Milling |

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Geometric Tolerance (GD&T) | ±0.012 mm |

| Surface Roughness (Ra) | 0.4 – 1.6 µm (adjustable per requirement) |

| Maximum Work Envelope | 1200 mm × 800 mm × 750 mm |

| Inspection Method | CMM (ZEISS CONTURA G2 Series) |

| Measurement Accuracy (CMM) | (1.9 + L/300) µm |

Wuxi Lead Precision Machinery maintains full in-house control from design support to final validation, ensuring seamless execution for custom injection molding tools. Our technical team collaborates closely with clients during the design-for-manufacturability phase, identifying opportunities to enhance mold functionality, reduce cycle times, and improve part ejection and cooling efficiency. This proactive engineering approach, combined with our advanced equipment and precision quality systems, positions us as a trusted partner for high-end mold manufacturing in global supply chains.

Material & Finish Options

Material Selection Fundamentals for Injection Molding Tools

Selecting the optimal material for injection molding tools directly impacts production efficiency, part quality, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your project’s volume, complexity, and end-use requirements. Misalignment here risks premature tool failure, inconsistent part tolerances, or inflated operational costs. Below we detail key material options and surface treatments essential for high-performance tooling.

Aluminum alloys like 7075-T6 offer rapid machinability and superior thermal conductivity, accelerating prototype development and low-volume production under 100,000 cycles. Its lower hardness limits use in abrasive polymers but excels for quick-turn applications where thermal management is critical. Steel remains the industry standard for high-volume runs exceeding 500,000 shots. Pre-hardened grades such as P20 (HRC 28-32) balance machinability and durability for mid-range production, while hardened tool steels like H13 (HRC 48-52) withstand extreme cavity pressures and thermal fatigue in demanding applications. Titanium alloys, though less common, provide exceptional corrosion resistance and strength-to-weight ratios for specialized medical or aerospace components involving aggressive resins, though higher costs necessitate rigorous ROI analysis.

Anodizing is the definitive surface treatment for aluminum tooling, transforming the outer layer into a hard, wear-resistant ceramic oxide. Type III hard anodizing achieves thicknesses of 50-75µm with hardness exceeding 600 HV, significantly extending tool life in abrasive polymer environments while maintaining dimensional stability. This process also enhances release properties, reducing cycle times and secondary finishing needs.

Critical material specifications are summarized below for direct comparison.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Application Range | Relative Cost |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | 503-572 | 130 | Prototypes, <100k shots | Low |

| P20 Steel | 28-32 | 950-1100 | 28-36 | Medium-volume, 100k-500k shots | Medium |

| H13 Tool Steel | 48-52 | 1300-1600 | 24-30 | High-volume, >500k shots | High |

| Titanium Ti-6Al-4V | 36-41 | 900-1000 | 7-8 | Specialized corrosion-resistant | Very High |

Material choice must integrate with your production strategy. For urgent prototyping or low-volume runs, aluminum with hard anodizing delivers speed without compromising initial part validation. Steel dominates sustained production, where its wear resistance justifies upfront investment through reduced downtime. Titanium warrants consideration only for niche applications justifying its premium. At Wuxi Lead, our engineers evaluate resin abrasiveness, cycle expectations, and surface finish requirements to prescribe the precise material-finish combination maximizing your tool’s service life and part consistency. Partner with us to transform material science into your competitive advantage.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our approach to manufacturing injection molding tools is engineered for precision, consistency, and zero-defect performance. We specialize in custom metal manufacturing solutions tailored to the most demanding industrial applications. Our production process follows a rigorously controlled sequence—Design, Prototyping, and Mass Production—ensuring every tool meets exact client specifications and exceeds industry standards.

The process begins with comprehensive Design engineering. Our team of senior CNC engineers collaborates directly with clients to analyze part geometry, material behavior, and production requirements. Utilizing advanced CAD/CAM software, we develop 3D models and perform mold flow analysis to predict and optimize filling, cooling, and ejection dynamics. This phase includes critical decisions on gate location, cooling channel layout, and steel selection, all aimed at maximizing tool life and minimizing cycle time. Every design is validated through simulation to preempt potential defects such as warpage, sink marks, or short shots.

Following design approval, we move into the Prototyping phase. A functional prototype mold is fabricated using high-precision CNC machining, wire EDM, and surface grinding technologies. This prototype is used to produce a limited run of sample parts under actual production conditions. These samples undergo rigorous dimensional inspection using coordinate measuring machines (CMM) and are evaluated for structural integrity, surface finish, and conformity to specifications. Any deviations are traced back to root causes, and iterative adjustments are made to the mold design or process parameters. This closed-loop validation ensures that all potential failure modes are eliminated before full-scale production begins.

Only after prototype sign-off do we transition to Mass Production. Our automated manufacturing cells, staffed by certified technicians and monitored by real-time quality control systems, produce injection molding tools with micron-level accuracy. Each tool is built from premium-grade tool steels such as P20, 718, H13, or S136, selected based on wear resistance, corrosion performance, and thermal stability. Throughout production, we implement in-process inspections and statistical process control (SPC) to maintain consistency. Final tools are polished, assembled, and subjected to dry runs and pressure testing to verify operational reliability.

Our zero-defect commitment is enforced through full traceability, documented process validation, and adherence to ISO 9001 standards. Every tool shipped from Wuxi Lead is a testament to precision engineering and uncompromised quality.

| Parameter | Specification |

|---|---|

| Tolerance | ±0.002 mm |

| Surface Finish (cavity) | Ra ≤ 0.05 µm (polished), Ra ≤ 1.6 µm (machined) |

| Tool Steel Options | P20, 718, H13, S136, 2344, 2738 |

| Mold Life | 500,000 to 1,000,000 cycles (depending on steel and part complexity) |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 30–60 days |

| Quality Standard | ISO 9001:2015, Full First Article Inspection (FAI) report provided |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Molding Tool Excellence

When sub-micron tolerances determine your production yield and tool longevity impacts your bottom line, selecting a precision metal manufacturing partner is not a procurement decision—it is a strategic imperative. At Wuxi Lead Precision Machinery, we engineer injection molding tools that transform design intent into repeatable, high-volume reality. Our ISO 9001:2015-certified facility in Wuxi integrates advanced CNC milling, wire EDM, and surface grinding with rigorous metrology protocols, ensuring every cavity plate, core, and ejector system meets the uncompromising standards demanded by automotive, medical, and consumer electronics sectors. We do not merely fabricate tools; we deliver production stability through metallurgical expertise, thermal analysis, and in-process validation that eliminates costly iterations.

Our technical capabilities are quantifiable. Below are core specifications defining our injection molding tool production:

| Parameter | Specification | Industry Benchmark |

|---|---|---|

| Tolerance Control | ±0.002 mm (78 µm) | ±0.01–0.02 mm |

| Steel Grades | NAK80, S136, H13, 2344 ESR, Custom PM | Standard H13 only |

| Surface Finish | Ra 0.05 µm (Mirror Polishing) | Ra 0.2–0.8 µm |

| Cavity Complexity | Up to 32 cavities, multi-shot capable | Typically 8 cavities |

| Lead Time (Prototype) | 25–35 days | 45–60 days |

| Validation Standard | 100% CMM inspection + Moldflow reports | Spot-check reports |

This precision translates directly to your operational efficiency. Tools manufactured to our specifications achieve 500,000+ cycles with zero dimensional drift, reducing scrap rates by 18–33% compared to industry averages. Our engineers collaborate from DFM review through first-article approval, embedding manufacturability into every contour. Unlike offshore suppliers relying on manual finishing, Lead Precision employs automated polishing cells and real-time cavity pressure monitoring to guarantee uniform wall thickness and gate integrity—critical for thin-wall medical components or optical lenses.

The true cost of injection molding lies not in initial tooling investment but in unplanned downtime and quality deviations. We mitigate this risk through proactive material certification, thermal stress simulation, and a zero-defect culture audited against IATF 16949 protocols. When your project requires tools that perform under 150+ tonnage cycles with zero flash generation, our process control systems ensure consistency where others compromise.

Initiate a technical consultation with our engineering team to validate your tooling requirements against our production capacity. Share your CAD files and quality targets with us, and we will deliver a comprehensive feasibility analysis within 72 hours—including material selection rationale, tolerance stack-up assessment, and a validated timeline. Do not settle for tools that merely meet specifications; demand tools engineered to exceed them. Contact [email protected] to schedule your precision review. Let Lead Precision become the silent partner ensuring your production line never misses a cycle.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.