Technical Contents

Engineering Guide: Injection Molding Surface Finish

Engineering Insight: Injection Molding Surface Finish Precision

Surface finish in injection molding transcends mere aesthetics; it is a critical engineering parameter directly impacting part functionality, longevity, and performance. While visual appeal matters for consumer goods, the true significance lies in how finish influences friction coefficients, wear resistance, sealing integrity, light diffusion, and even biocompatibility in medical applications. An imprecise finish introduces microscopic inconsistencies that can accelerate part failure, compromise dimensional stability under load, or create nucleation points for stress cracks. Achieving the specified finish consistently demands absolute control over the entire manufacturing chain, starting with the mold tool itself. This is where ultra-precise metal fabrication becomes non-negotiable.

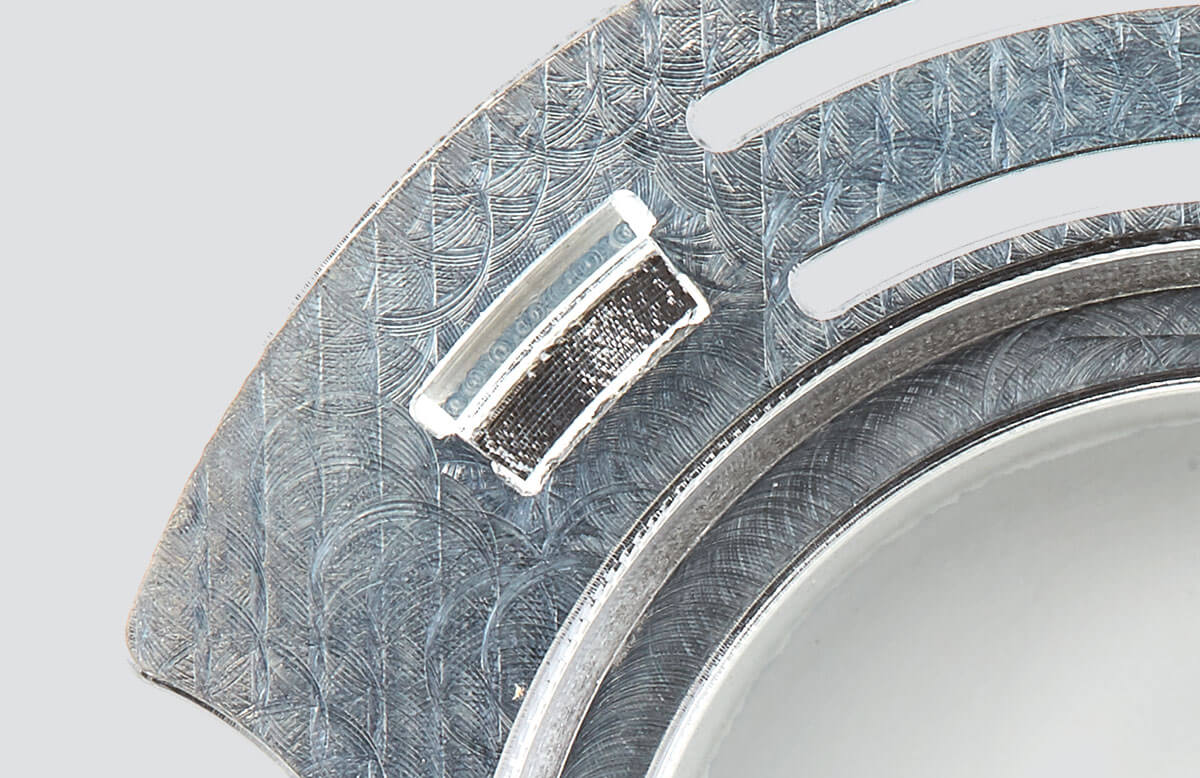

The mold cavity and core surfaces, typically crafted from hardened tool steels or specialized alloys, must replicate the desired finish at micron-level accuracy. Any deviation in the mold’s surface geometry – whether from inadequate machining, improper polishing, or thermal distortion – transfers directly onto every molded component. Standard machining processes often lack the repeatability required for high-specification finishes like SPI-A1 or VDI 3400-03. True precision requires advanced CNC milling, grinding, and EDM capabilities operating within sub-micron tolerances, coupled with master-level hand polishing protocols. At Wuxi Lead Precision Machinery, our decades of experience in custom metal manufacturing for mission-critical sectors form the bedrock of this capability. We have engineered mold components for Olympic-standard sporting equipment where surface friction dictates athlete performance, and supplied classified military hardware requiring finishes that ensure flawless operation in extreme environments. These projects demand zero-defect surface replication, validating our tolerance-driven approach under the most stringent conditions.

The table below outlines common injection molding surface finish specifications and the precision machining requirements essential for their consistent achievement.

| Finish Standard | Typical Ra Range (μm) | Common Applications | Precision Machining Requirement |

|---|---|---|---|

| SPI-A1 (Mirror) | 0.01 – 0.05 | Optical lenses, medical devices, high-gloss consumer goods | Sub-0.1μm grinding; diamond turning; multi-stage polishing |

| SPI-B2 (Satin) | 0.10 – 0.20 | Automotive interiors, appliance panels, technical housings | High-precision milling; controlled abrasive blasting; fine polishing |

| VDI 3400-21 (Fine Matte) | 0.40 – 0.80 | Structural components, hidden parts, wear surfaces | Precision milling with fine toolpaths; consistent EDM finishing |

| VDI 3400-27 (Coarse Matte) | 1.60 – 3.20 | Non-critical structural parts, under-hood automotive | Standard high-precision milling; controlled texturing processes |

Achieving the target finish reliably hinges on the mold maker’s ability to control surface topography at the micro-level during fabrication. This requires not only advanced equipment but deep metallurgical understanding to manage material behavior during heat treatment and finishing. Wuxi Lead integrates metrology-grade surface measurement – including profilometry and interferometry – directly into our production workflow, ensuring every mold cavity meets the exact Ra, Rz, and visual criteria before shipment. Surface finish is not an afterthought; it is engineered from the first machining pass. Partnering with a precision metal manufacturer possessing proven experience in high-stakes applications guarantees your injection molded parts perform as intended, every cycle.

Precision Specs & Tolerances

Surface Finish Precision in Injection Molding Components

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision metal components tailored for advanced injection molding applications. Our technical capabilities are engineered to meet the stringent surface finish requirements demanded by industries such as automotive, medical, and consumer electronics. Surface finish is a critical determinant of mold performance, affecting part release, cosmetic quality, and cycle time. We ensure optimal surface characteristics through a combination of advanced 5-axis CNC machining, rigorous process control, and post-machining refinement techniques.

Our 5-axis CNC machining centers provide exceptional geometric flexibility, enabling us to achieve complex contours and fine surface details with high repeatability. These machines operate with sub-micron precision and are equipped with high-speed spindles and advanced toolpath strategies that minimize tool marks and scalloping. By leveraging simultaneous multi-axis motion, we reduce the need for multiple setups, which in turn enhances surface consistency and dimensional accuracy across intricate mold geometries.

Material selection and tooling strategy are integral to our surface finishing process. We work with a wide range of mold-grade steels, including P20, H13, S136, and hardened tool steels up to 60 HRC. Using diamond-coated, polycrystalline cubic boron nitride (PCBN), and micro-grain carbide tools, we tailor the machining parameters to achieve the desired surface roughness without compromising structural integrity. Our in-house programming team utilizes high-efficiency machining (HEM) and fine finishing toolpaths to deliver surface finishes as fine as Ra 0.2 µm in machined surfaces, with the option for additional polishing or texturing upon request.

Quality assurance is maintained through comprehensive CMM (Coordinate Measuring Machine) inspection at multiple stages of production. Our Zeiss and Hexagon CMM systems provide full 3D verification of both form and surface geometry, ensuring that every component conforms to print specifications. Surface roughness is validated using calibrated profilometers, with documented reports provided for critical features.

We understand that surface finish directly impacts mold longevity and part quality. Our process integrates precision machining with metrological validation to deliver components that exceed industry standards. Whether producing core inserts, cavity plates, or ejector systems, Wuxi Lead ensures every surface is optimized for performance, durability, and aesthetic fidelity.

Tolerances and Surface Finish Specifications

| Parameter | Standard Capability | Precision Capability | Notes |

|---|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.005 mm | Based on ISO 2768-m |

| Surface Roughness (Ra) | Ra 0.8 µm | Ra 0.2 µm | Machined finish; polishing available |

| Flatness | 0.01 mm over 100 mm | 0.005 mm over 100 mm | Verified via CMM and optical flat |

| Parallelism | 0.01 mm | 0.005 mm | Across mating surfaces |

| Perpendicularity | 0.01 mm | 0.005 mm | Critical for mold alignment |

| Hole Position Tolerance | ±0.01 mm | ±0.005 mm | For cooling channels and fasteners |

| CMM Inspection Report | Full 3D deviation map | GD&T analysis included | Available per customer requirement |

Material & Finish Options

Strategic Material Selection for Injection Molding Surface Finishes

Material choice fundamentally dictates achievable surface finishes and long-term tool performance in high-precision injection molding. At Wuxi Lead Precision Machinery, we emphasize that optimal material-finish pairing is not cosmetic but a critical engineering decision impacting cycle life, part release, dimensional stability, and final product quality. Aluminum, steel, and titanium each present distinct advantages and limitations when subjected to demanding molding cycles and specific finish requirements like anodizing.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer rapid machining and excellent thermal conductivity, accelerating cycle times. They are cost-effective for prototyping and low-to-medium volume production. However, base aluminum lacks inherent wear resistance. Hardcoat anodizing (Type III) is essential, transforming the surface into a dense, hard aluminum oxide layer (typically 50-100µm thick) with hardness reaching 60-70 HRC. This significantly improves abrasion resistance and provides a non-stick surface, crucial for complex geometries or sticky resins. Standard sulfuric anodizing (Type II) offers corrosion resistance but less wear protection. Aluminum tools with hardcoat anodizing excel in applications requiring fast lead times and moderate production volumes where thermal management is paramount.

Tool steels, especially premium grades like H13, S7, and P20, form the backbone of high-volume production molds. Their superior hardness (typically 48-54 HRC after heat treatment) and toughness provide exceptional resistance to wear, deformation, and thermal fatigue. While anodizing is less common on steel due to its inherent properties, specialized steel surface treatments like nitriding, PVD coatings (e.g., TiN, CrN), or electroless nickel plating are standard for enhancing release, corrosion resistance, and wear life. Steel molds deliver the longevity and dimensional stability required for millions of cycles, making them indispensable for high-volume consumer goods and automotive components where consistency is non-negotiable.

Titanium alloys, such as Ti-6Al-4V, offer the highest strength-to-weight ratio and exceptional corrosion resistance, particularly against chlorides. They are significantly more expensive and challenging to machine than aluminum or steel. Anodizing titanium primarily serves decorative or enhanced corrosion purposes rather than wear resistance, producing vibrant colored finishes through voltage-controlled oxide layer growth. Its primary use in molding is for highly specialized, corrosive resin applications or aerospace components where weight savings and extreme environmental resistance justify the cost. Wear resistance remains inferior to properly treated tool steel.

The following table summarizes critical material and finish characteristics for injection mold applications:

| Material | Key Properties | Recommended Finishes | Primary Applications |

|---|---|---|---|

| Aluminum Alloys | High thermal conductivity, Machinability | Hardcoat Anodizing (Type III), Standard Anodizing (Type II) | Prototyping, Low/Medium volume, Thermal-critical molds |

| Tool Steels | High hardness, Toughness, Wear resistance | Nitriding, PVD Coatings, Electroless Nickel | High-volume production, Demanding resins, Long-life molds |

| Titanium Alloys | Exceptional corrosion resistance, Lightweight | Decorative Anodizing, Passivation | Specialized corrosive resins, Aerospace, Weight-sensitive parts |

Selecting the right material-finish combination requires balancing production volume, resin characteristics, part complexity, cosmetic requirements, and total cost of ownership. Wuxi Lead Precision Machinery leverages decades of CNC machining and surface treatment expertise to guide clients through this critical decision, ensuring molds deliver peak performance, extended service life, and flawless part finishes from the first shot to the last. Prioritize material properties aligned with your core operational demands before finalizing the surface treatment strategy.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the injection molding surface finish process begins with meticulous design engineering. Our team of senior CNC engineers and tooling specialists collaborate with clients to translate product requirements into manufacturable designs. Surface finish is not an afterthought—it is engineered from the outset. Using advanced CAD/CAM software and GD&T (Geometric Dimensioning and Tolerancing) principles, we define critical surface textures, draft angles, and gate locations to ensure optimal flow and replication. We analyze part geometry, material selection, and functional demands to determine the appropriate mold steel grade, heat treatment, and finishing method—whether it be mirror polishing, bead blasting, EDM texturing, or SPI/VDI-compliant finishes. Every design undergoes rigorous simulation using Moldflow analysis to predict shrinkage, warpage, and surface replication, ensuring the final part meets exact aesthetic and performance standards.

Prototyping: Validating Surface Integrity and Functionality

Once the mold design is finalized, we proceed to prototype tooling using high-precision CNC machining, wire EDM, and surface grinding. Prototyping at Wuxi Lead is not a simplified trial—it is a fully functional validation phase conducted with production-intent materials and processes. We produce initial sample batches under controlled conditions, inspecting each component for dimensional accuracy and surface consistency. Our metrology lab employs non-contact 3D scanning and profilometry to measure surface roughness (Ra, Rz) and compare against design specifications. Any deviations are traced through root cause analysis, and corrective actions are implemented in real time. This stage ensures that texture uniformity, gloss levels, and defect-free replication are achieved before committing to mass production. Client feedback is integrated efficiently, allowing for rapid iteration without compromising timeline integrity.

Mass Production: Zero Defects Through Process Control

Our transition to mass production is governed by a zero-defect philosophy. Molds are built from premium steels such as NAK80, S136, or 2738HH, hardened and polished to SPI-A1, A2, or B1 standards as required. Each production run is monitored using Statistical Process Control (SPC), with real-time data logging of temperature, pressure, and cycle time. Automated vision inspection systems and in-line metrology ensure 100% surface defect detection—excluding sink marks, flow lines, or texture inconsistencies. Preventive maintenance schedules and mold cleaning protocols are strictly enforced to sustain surface quality over high-volume runs. Our ISO 9001-certified production floor integrates full traceability, from raw material lot tracking to final inspection reports.

Surface Finish Specifications

| Finish Type | Standard | Surface Roughness (Ra, µm) | Typical Application |

|---|---|---|---|

| Mirror Polish | SPI-A1 | 0.01 – 0.02 | Optical lenses, medical devices |

| High Polish | SPI-A2 | 0.02 – 0.04 | Consumer electronics, cosmetics |

| Fine Satin | SPI-B1 | 0.04 – 0.10 | Automotive interiors |

| Medium Blast | VDI 3400 Gr. 18 | 0.20 – 0.32 | Industrial enclosures |

| Coarse Texture | VDI 3400 Gr. 24 | 0.40 – 0.63 | Handheld tools, rugged equipment |

Every stage—from design to delivery—is engineered for perfection. At Wuxi Lead Precision Machinery, surface finish is not just a specification. It is a standard of excellence.

Why Choose Wuxi Lead Precision

Elevate Your Injection Molding Surface Finish with Precision Engineering

Achieving flawless surface finishes in injection molding demands more than standard tooling—it requires micron-level precision in metal fabrication, thermal management, and texture replication. Subpar surface quality leads to part rejection, costly secondary operations, and compromised brand integrity, especially in automotive, medical, and consumer electronics applications. At Wuxi Lead Precision Machinery, we eliminate these risks through engineered metal solutions that guarantee consistency from prototype to high-volume production. Our CNC-machined molds and inserts leverage proprietary heat-treatment processes and diamond-polished cavities to achieve Class A finishes down to 0.025μm Ra, ensuring zero defects in critical cosmetic surfaces.

Our ISO 9001-certified facility integrates advanced metrology with every manufacturing phase. Each mold undergoes rigorous validation using Zeiss coordinate measuring machines (CMM) and white-light interferometers to verify surface topography against your exact specifications. We specialize in replicating complex textures—from subtle matte finishes to aggressive leather grains—with tolerances unattainable through conventional methods. This precision extends to thermal stability; our beryllium-copper inserts and conformal cooling channels maintain uniform temperature distribution, preventing sink marks and flow lines that degrade surface quality. Partnering with us means accessing a closed-loop production ecosystem where every parameter is traceable, repeatable, and optimized for your material’s rheological behavior.

Surface Finish Capabilities at a Glance

| Parameter | Capability Range | Industry Standard Equivalent | Verification Method |

|---|---|---|---|

| Surface Roughness | 0.025μm – 1.6μm Ra | SPI-SPE, VDI 3400 | White-light interferometry |

| Texture Depth | 0.005mm – 0.25mm | MT, EDM, Photo-etched | CMM + optical profilometry |

| Dimensional Stability | ±0.002mm over 300mm | ISO 2768-mK | Climate-controlled CMM lab |

| Lead Time (Texture) | 48 hours for samples | N/A | In-house EDM/texturing cell |

This technical rigor translates to tangible ROI: reduced cycle times, elimination of post-mold polishing, and 100% first-article approval rates for stringent OEM programs. We collaborate with your design team early in the process to optimize gate locations, material flow, and texture selection—preventing surface defects before steel is cut. Our engineers speak the language of polymers and physics, not just machining, ensuring your surface finish requirements are met without compromising part functionality or tool longevity.

Secure Your Competitive Edge Today

Surface finish is never an afterthought—it’s a strategic differentiator. Wuxi Lead Precision Machinery delivers the metallurgical expertise and process control to transform your most demanding surface specifications into manufacturing reality. Contact our engineering team directly to discuss texture replication, material-specific finish protocols, or rapid sample validation. Email [email protected] with your project requirements, and receive a detailed capability assessment within 24 hours. Let us prove how precision metal manufacturing elevates your injection molding outcomes. Your next breakthrough surface finish starts here.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.