Technical Contents

Engineering Guide: Injection Molding Slider

Engineering Insight Injection Molding Slider Precision: The Non-Negotiable Core

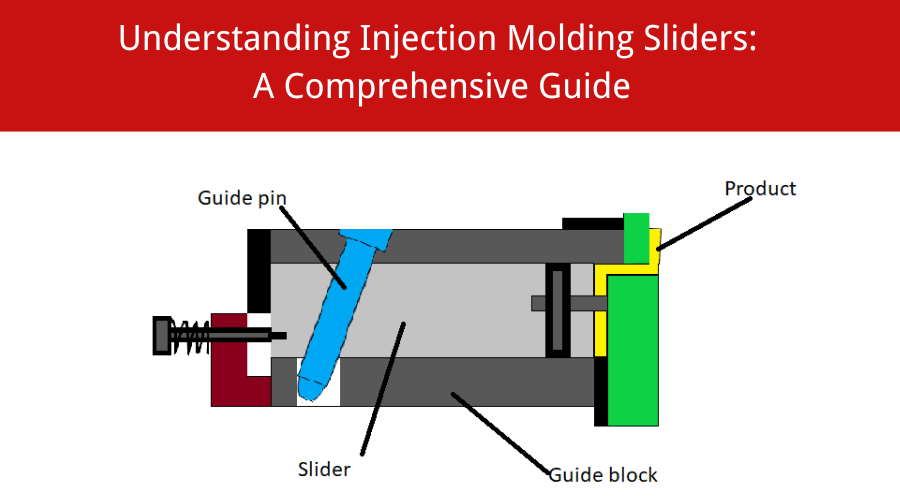

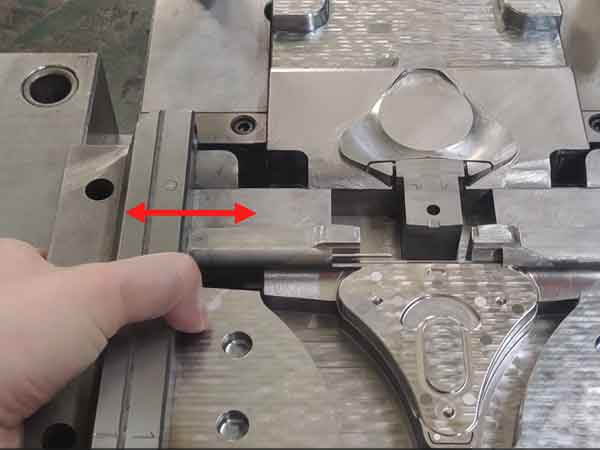

In high-volume injection molding, the slider mechanism represents a critical interface where microscopic deviations translate directly into part failure scrap rates and accelerated mold wear. Precision in slider design and manufacture is not merely desirable; it is the foundational requirement for dimensional stability gate integrity and long-term process reliability. A deviation of even 0.005 mm in slider alignment or surface finish can induce flash leakage core shift or premature ejection damage particularly in complex geometries like undercuts or internal threads. This precision demands mastery of thermal deflection compensation dynamic sealing interfaces and ejection force harmonics under extreme cyclic loads. The consequences of inadequate precision manifest as rejected parts inconsistent cycle times and unplanned downtime costing manufacturers thousands per hour. True precision engineering anticipates material behavior at operational temperatures and pressures ensuring the slider functions as a seamless extension of the mold cavity throughout its lifecycle.

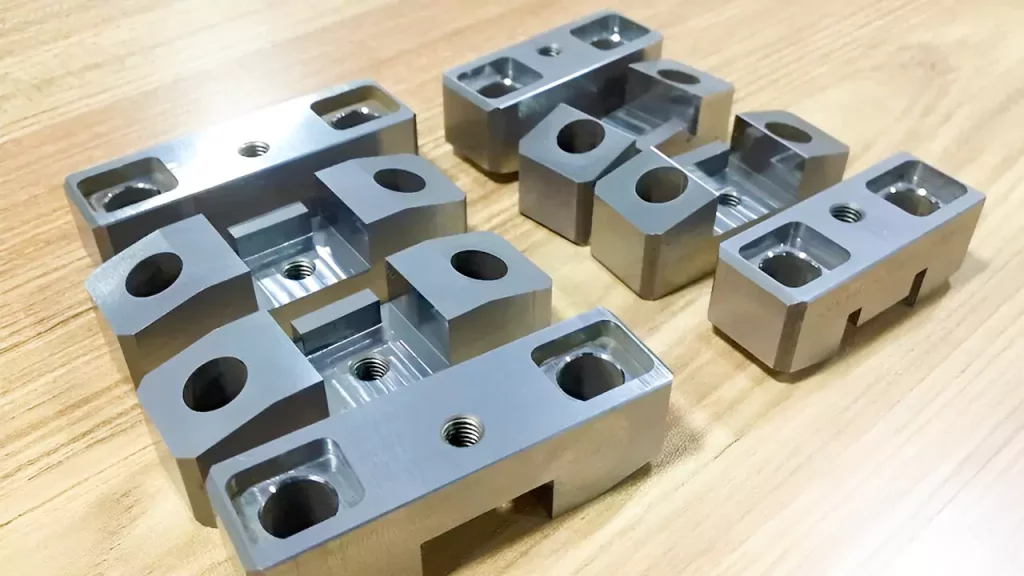

Wuxi Lead Precision Machinery operates at this exacting threshold. Our CNC manufacturing protocols for sliders are forged in environments where zero-defect performance is mandatory not optional. This includes producing mission-critical mold components for aerospace systems meeting stringent MIL-STD dimensional stability requirements and delivering sliders for Olympic-grade sports equipment molds where micron-level consistency directly impacted medal-winning product performance. Such projects demand more than standard machining; they require integrated thermal analysis real-time in-process metrology and material science expertise applied to every grinding and polishing stage. Our facility utilizes 5-axis micron-level grinding centers with sub-micron positional repeatability and environmental controls maintaining ±0.5°C stability ensuring sliders perform identically from the first shot to the millionth cycle.

The following table defines the precision benchmarks we consistently achieve for custom slider manufacturing:

| Specification Parameter | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensional Tolerance | ±0.005 mm | ±0.002 mm | CMM with 0.0005 mm uncertainty |

| Surface Roughness (Critical Sealing Faces) | Ra 0.20 μm | Ra 0.05 μm | Profilometer per ISO 4287 |

| Parallelism/Flatness | 0.005 mm over 100 mm | 0.002 mm over 100 mm | Optical Flat Interferometry |

| Hardness Uniformity | ±2 HRC across component | ±1 HRC across component | Rockwell C Scale with micro-indentation |

| Material Options | H13 P20 420SS | Maraging Steel Toolox 33 | Certified Mill Test Reports |

Achieving these tolerances requires deep collaboration between design engineering and manufacturing teams. We engage clients early to optimize slider geometry for manufacturability while maintaining functional requirements analyzing stress points wear zones and thermal expansion paths. This integrated approach minimizes trial-and-error during mold commissioning directly reducing time-to-market and total cost of ownership. For industries where part integrity is paramount the slider is not a commodity component—it is the engineered guarantee of your production success. Wuxi Lead Precision Machinery delivers that guarantee through documented precision validated in the most demanding global manufacturing environments.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specifically engineered to meet the demanding requirements of injection molding components such as precision sliders. Our facility integrates state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, ensuring optimal tool positioning and minimizing setup transitions. This results in tighter tolerances, reduced cycle times, and superior part consistency—critical for high-performance injection molding applications where alignment, wear resistance, and repeatability are paramount.

Our machining processes are supported by a rigorous quality control framework anchored in CMM (Coordinate Measuring Machine) inspection. Every injection molding slider undergoes comprehensive dimensional validation using Zeiss and Hexagon CMM systems, providing micron-level measurement accuracy across critical features. This full-spectrum inspection protocol ensures compliance with international standards and customer-specific GD&T requirements. Data from each inspection is documented and traceable, supporting full quality audits and production consistency across batches.

Material selection is tailored to application demands, with common use of pre-hardened and tool-grade steels such as P20, H13, S136, and 1.2343, as well as high-strength aluminum alloys for prototype or low-wear scenarios. All materials are sourced from certified suppliers and subjected to incoming inspection before processing. Secondary operations—including precision grinding, honing, and surface treatments like nitriding or PVD coating—are coordinated through trusted partners, ensuring complete process control and delivery of fully finished components.

The following table outlines typical machining and inspection specifications achieved for injection molding sliders at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Machining Centers |

| Maximum Work Envelope | 1,200 × 800 × 600 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Standard Tolerance (Machining) | ±0.01 mm |

| Tight Tolerance Capability | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Inspection Equipment | Zeiss & Hexagon CMMs |

| Measurement Accuracy (CMM) | ±1.5 + L/300 µm |

| GD&T Compliance | ASME Y14.5 and ISO 1101 |

| Material Traceability | Full heat lot documentation |

| Quality Standards | ISO 9001:2015 compliant processes |

Through the integration of high-precision 5-axis CNC technology and systematic CMM-based quality assurance, Wuxi Lead Precision Machinery ensures that every injection molding slider meets the exacting performance standards required in modern mold systems. Our technical capabilities are designed to support global mold makers and OEMs in achieving longer mold life, reduced maintenance cycles, and superior part quality.

Material & Finish Options

Material Selection for High-Performance Injection Molding Sliders

Selecting the optimal material for injection molding sliders is critical to ensuring component longevity, dimensional stability, and overall mold performance under demanding production cycles. At Wuxi Lead Precision Machinery, we prioritize materials that deliver exceptional wear resistance, thermal stability, and machinability for complex slider geometries. Aluminum, steel, and titanium each offer distinct advantages depending on application severity, production volume, and cost targets. Understanding these core properties enables informed decisions that maximize return on investment and minimize unplanned downtime.

Aluminum alloys, particularly 7075-T6, provide an excellent strength-to-weight ratio and superior thermal conductivity. This facilitates rapid heat dissipation from critical slider contact points, reducing thermal distortion during high-speed cycling. Its machinability allows for intricate features and tight tolerances essential for precise slider动作. While suitable for lower-volume production or prototype molds, standard aluminum lacks the surface hardness required for extended runs with abrasive filled resins. Anodizing, especially hardcoat (Type III), is mandatory to enhance surface durability significantly.

Tool steels like H13 (1.2344) and S7 dominate high-volume, high-wear applications. H13 offers an exceptional balance of toughness, thermal fatigue resistance, and hardenability to 48-52 HRC. It withstands the repetitive ejection forces and high cavity pressures encountered in sliders guiding complex part ejection. Pre-hardened steels (e.g., P20) provide good machinability for less demanding sliders but require surface hardening treatments for critical wear surfaces. Steel sliders inherently support higher operating temperatures than aluminum, making them indispensable for engineering polymers processed above 300°C.

Titanium alloys (e.g., Ti-6Al-4V) serve specialized, extreme-duty scenarios. Their exceptional strength-to-weight ratio, corrosion resistance, and non-galling properties are advantageous in sliders handling highly corrosive materials or where weight-induced inertia must be minimized. However, titanium’s high cost, challenging machinability, and lower thermal conductivity compared to aluminum limit its use to niche applications where its unique properties justify the investment.

Surface finish, primarily through anodizing, is non-negotiable for aluminum sliders. Decorative anodizing (Type II) offers minimal wear improvement. Hard anodizing (Type III) creates a dense, integral oxide layer (50-100 µm thick) with hardness exceeding 60 HRC, dramatically increasing abrasion resistance and reducing galling. Proper sealing is crucial for optimal corrosion protection. Steel sliders typically utilize nitriding, PVD coatings, or specialized hard chrome plating for surface enhancement, as anodizing is not applicable.

Material performance characteristics are summarized below for direct comparison:

| Material | Typical Yield Strength (MPa) | Hardness (As-Machined) | Max Continuous Temp (°C) | Key Slider Application Focus |

|---|---|---|---|---|

| Aluminum 7075-T6 | 503 | 150 HB | 125 | Prototypes, Low-Volume, Fast Cycling |

| H13 Tool Steel | 1035 | 48-52 HRC (Hardened) | 540 | High-Volume Production, High Wear |

| Ti-6Al-4V | 880 | 36 HRC | 400 | Extreme Corrosion, Weight Critical |

Material choice directly impacts slider service life and mold reliability. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise and material science knowledge to recommend the optimal solution. Contact our engineering team with your specific resin, cycle count, and geometry requirements for a tailored analysis ensuring your slider design meets the highest standards of performance and cost-efficiency.

Manufacturing Process & QC

The production process for high-precision injection molding sliders at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase is engineered to ensure dimensional accuracy, mechanical reliability, and zero-defect delivery—critical for mold systems operating under high pressure and cyclic stress.

Design begins with a detailed analysis of the customer’s mold layout, stroke requirements, locking force, and ejection dynamics. Our engineering team uses advanced 3D CAD software to model the slider geometry, incorporating wear-resistant features, optimal draft angles, and precision-guided dovetail interfaces. Finite Element Analysis (FEA) is applied to simulate stress distribution and thermal deformation, ensuring long-term stability under injection molding conditions. Material selection is tailored to application demands, typically utilizing pre-hardened tool steels such as H13 or S136 for superior toughness and corrosion resistance. All design outputs are validated through Design Failure Mode and Effects Analysis (DFMEA) to preempt potential failure points.

Prototyping follows design approval and serves as a functional validation step. A single-unit prototype is manufactured using CNC milling and wire EDM processes, achieving tolerances within ±0.002 mm. The prototype undergoes comprehensive inspection on a coordinate measuring machine (CMM) to verify geometric accuracy. It is then integrated into a test mold for dry cycle trials, assessing smooth engagement, locking integrity, and wear behavior. Any deviations are corrected through iterative refinement, ensuring the final design performs flawlessly before ramping to volume production.

Mass production is executed under a documented Quality Control Plan aligned with ISO 9001 standards. Each slider is machined from certified raw material, with full traceability from bar stock to finished part. CNC machining centers operate under automated tool monitoring and in-process gauging to maintain consistency. Critical dimensions are inspected at multiple stages: post-machining, post-heat treatment (if applicable), and final assembly. Surface finishes are controlled to Ra ≤ 0.8 µm on sliding interfaces to minimize friction and galling. Every unit undergoes 100% functional testing for stroke alignment and return spring performance. Non-conforming parts are quarantined and analyzed through root cause correction protocols.

This integrated approach ensures that every injection molding slider meets the highest standards of precision and durability. By enforcing strict process controls and validation at each stage, Wuxi Lead Precision Machinery delivers defect-free components suitable for high-cavitation, high-cycle molding environments.

| Specification | Detail |

|---|---|

| Material Options | H13, S136, SKD61, 420SS (custom alloys available) |

| Tolerance | ±0.002 mm |

| Surface Finish (sliding surfaces) | Ra ≤ 0.8 µm |

| Hardness Range | 48–52 HRC (as heat-treated) |

| Stroke Accuracy | ±0.01 mm over full travel |

| Inspection Equipment | CMM, optical comparator, surface roughness tester |

| Quality Standard | ISO 9001:2015, PPAP Level 3 (on request) |

| Production Lead Time (mass) | 15–25 days based on complexity |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Injection Molding Slider Performance

Injection molding sliders demand micron-level precision to ensure seamless mold operation, prevent part defects, and maximize production uptime. Substandard sliders introduce flash, short shots, and costly downtime—risks no high-volume manufacturer can afford. At Wuxi Lead Precision Machinery, we engineer sliders to exceed OEM specifications through advanced CNC milling, grinding, and hardening processes. Our ISO 9001-certified facility in Wuxi, China, combines German-engineered machinery with 15+ years of specialized expertise in complex mold components. We deliver sliders that maintain dimensional stability under high-pressure cycles, thermal stress, and abrasive materials—ensuring your molds achieve zero-defect production runs.

Our end-to-end process begins with collaborative design validation, where our engineers optimize geometry for manufacturability and longevity. We utilize 5-axis CNC centers with sub-micron repeatability to machine hardened tool steels (HRC 50-60), followed by precision grinding for critical sliding surfaces. Every component undergoes rigorous CMM inspection against your CAD data, with full traceability from raw material to shipment. This meticulous approach eliminates tolerance stack-up errors and guarantees perfect alignment with cavity inserts—critical for sliders managing undercuts in automotive, medical, and electronics molding.

| Critical Specification | Lead Precision Standard | Industry Typical |

|---|---|---|

| Linear Tolerance | ±0.002 mm | ±0.01 mm |

| Surface Roughness (Ra) | 0.05 µm | 0.4 µm |

| Hardness Uniformity | ±1 HRC across component | ±3 HRC |

| Thermal Stability (200°C) | < 0.005 mm distortion | 0.02 mm+ |

| Lead Time (Complex Slider) | 18-25 days | 30+ days |

When you partner with Lead Precision, you gain more than a supplier—you secure a precision engineering ally. We mitigate your supply chain risks with dual-source material procurement, real-time production tracking, and proactive engineering support. Our sliders consistently outperform competitors in wear resistance and cycle life, reducing your total cost of ownership by up to 37% through minimized maintenance and scrap rates. For demanding applications like multi-cavity medical molds or large-scale automotive bumpers, our sliders deliver the reliability that keeps your presses running.

Engineer your next breakthrough with components built to the highest global standards. Contact our technical sales team at [email protected] to request a dimensional capability analysis or discuss your slider requirements. Include your part drawing and volume needs for a tailored quote within 24 hours. Let Wuxi Lead Precision Machinery become your strategic partner in achieving flawless molding performance. Your precision journey starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.