Technical Contents

Engineering Guide: Injection Molding Production

Engineering Insight: The Critical Role of Precision in Injection Molding Production

In high-performance manufacturing, injection molding is far more than a process—it is a science where precision defines success. At Wuxi Lead Precision Machinery, we understand that the integrity of every molded component hinges on micron-level accuracy, consistent thermal control, and flawless tooling execution. Our decades of specialization in custom metal manufacturing have positioned us at the forefront of delivering injection molding solutions that meet the most stringent industrial demands.

Precision in injection molding is not optional—it is foundational. Even minor deviations in mold geometry, temperature distribution, or clamping force can result in part warpage, incomplete fills, or structural weaknesses. These defects are unacceptable in sectors such as aerospace, defense, and high-end consumer goods, where performance under stress is non-negotiable. Our engineering philosophy centers on eliminating variability through advanced CNC-machined tooling, real-time process monitoring, and rigorous material characterization.

Our experience extends to projects of national and international significance, including components used in Olympic-grade sporting equipment and mission-critical military hardware. These applications demand not only adherence to tight tolerances but also full traceability, durability under extreme conditions, and compliance with international quality standards. The trust placed in our systems by such high-stakes industries underscores our capability to deliver precision at scale.

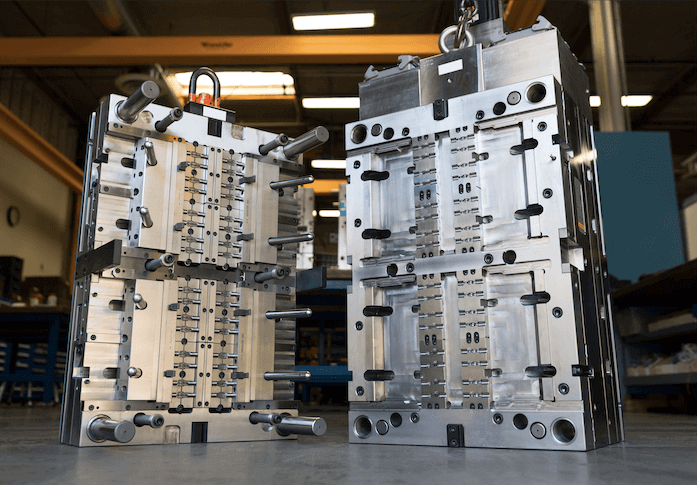

At the core of our injection molding production is a vertically integrated manufacturing ecosystem. We design and fabricate molds in-house using high-grade tool steels and advanced EDM (Electrical Discharge Machining) techniques, ensuring cavity accuracy within ±0.002 mm. Our molding presses are equipped with closed-loop control systems that adjust injection speed, pressure, and cooling cycles in real time, minimizing cycle-to-cycle variation. This level of control is essential when producing complex geometries or thin-walled components where material flow must be perfectly balanced.

We also prioritize material science in our process development. Whether working with engineering-grade thermoplastics like PEEK, PSU, or reinforced composites, our team conducts detailed flow analysis and mold filling simulations prior to production. This predictive modeling reduces trial-and-error, accelerates time-to-market, and ensures optimal gate placement and venting design.

The following table outlines key specifications that define our injection molding capabilities:

| Parameter | Specification |

|---|---|

| Clamping Force Range | 50 to 2,500 Tons |

| Shot Weight (PS) | 50 to 45,000 g |

| Tolerance Control | ±0.002 mm |

| Mold Materials | H13, S136, 2738, 718H, Custom Alloys |

| Process Monitoring | Real-time cavity pressure & temperature |

| Industries Served | Aerospace, Military, Medical, Automotive, Sports |

Precision is not achieved by equipment alone—it is engineered through experience, validated by performance, and proven in application. At Wuxi Lead Precision Machinery, we bring Olympic and military-grade discipline to every injection molding project, ensuring that form, function, and reliability are never compromised.

Precision Specs & Tolerances

Technical Capabilities: Precision Foundation for Injection Molding Excellence

At Wuxi Lead Precision Machinery, our technical capabilities are engineered specifically to deliver the uncompromising precision required for high-performance injection molding production tooling. We understand that mold longevity, part consistency, and production efficiency are directly tied to the dimensional accuracy and surface integrity of critical metal components. Our focus is not merely on manufacturing parts, but on providing the foundational precision that enables our clients’ molding success. This commitment is realized through advanced equipment, rigorous processes, and deep material expertise tailored to the demanding environment of injection molds.

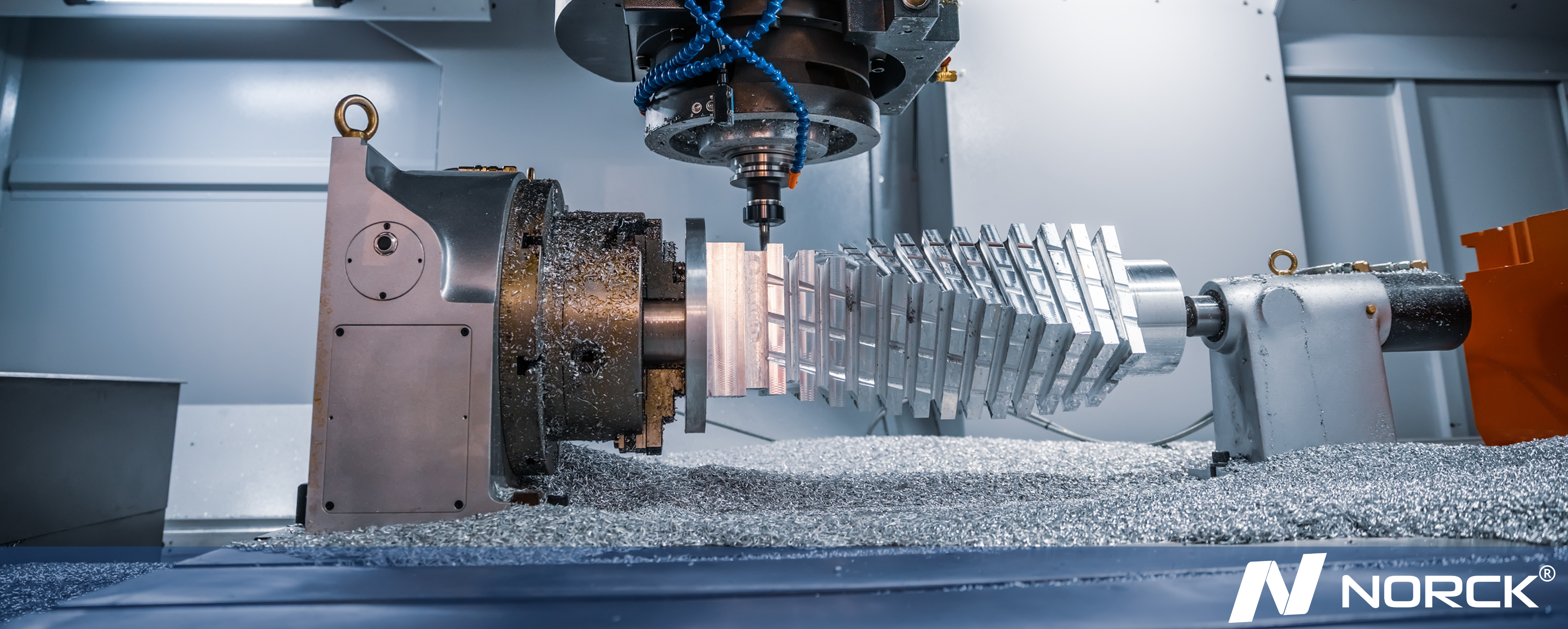

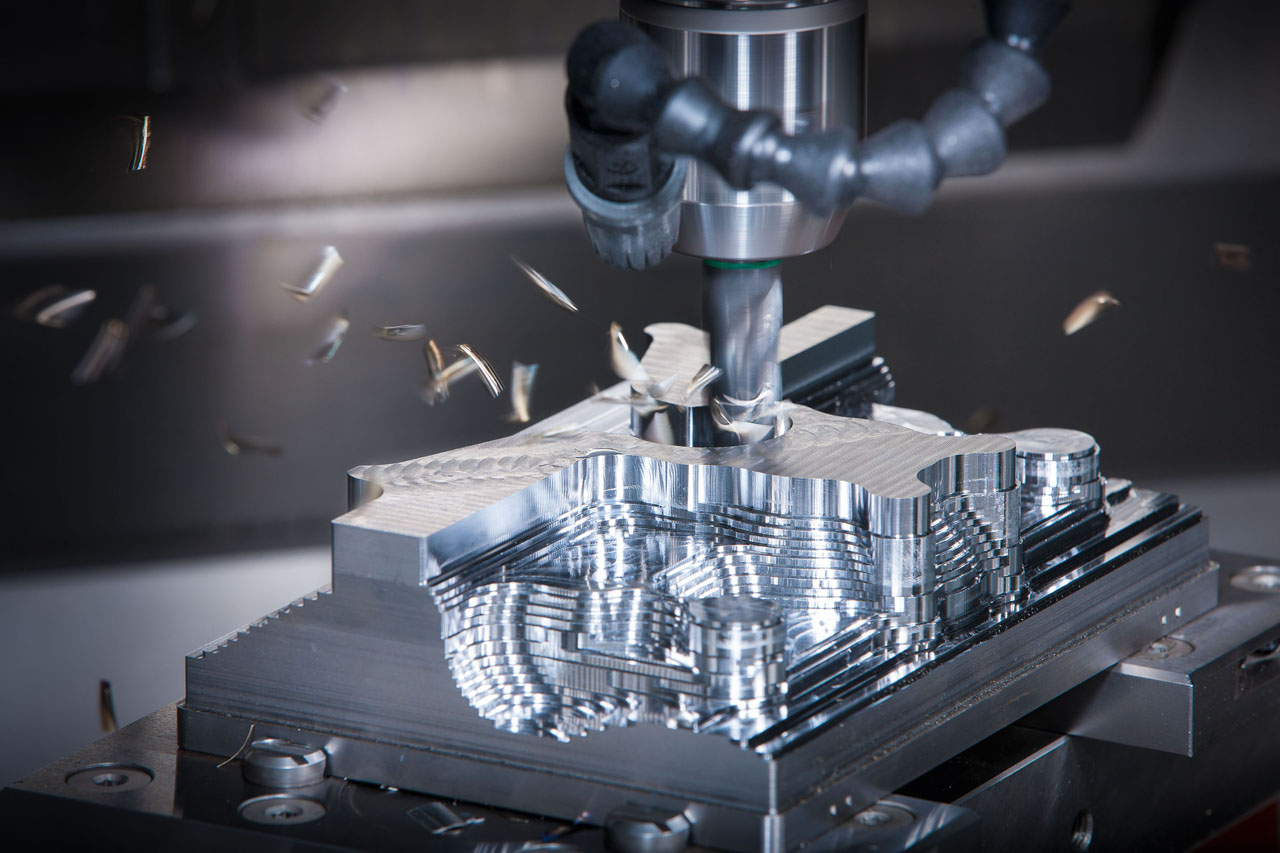

Central to our capability is our fleet of state-of-the-art 5-axis CNC machining centers. These systems are not just tools; they are strategic assets for complex mold component fabrication. The simultaneous multi-axis movement allows us to machine intricate core/cavity geometries, deep ribs, undercuts, and conformal cooling channels in a single setup. This eliminates cumulative errors inherent in multiple fixturing operations, significantly improving geometric accuracy and surface finish while reducing lead times. We leverage high-speed machining strategies with specialized tooling optimized for mold steels like P20, H13, S136, and hardened alloys, ensuring optimal material removal rates without compromising thermal stability or dimensional control. The result is mold components that fit perfectly, minimize wear, and facilitate consistent plastic flow during the molding cycle.

Precision is meaningless without verification. Our comprehensive Quality Control process is anchored by multiple Coordinate Measuring Machines (CMMs), including bridge and gantry types with probing systems calibrated to stringent international standards. Every critical dimension, geometric tolerance, and surface feature on mold bases, inserts, slides, and lifters undergoes systematic CMM inspection against the original CAD model and client specifications. This is not a final-step check; inspection points are integrated throughout the machining process to enable immediate correction and prevent scrap. Our QC technicians are trained mold specialists who understand the functional implications of tolerances within the molding process, ensuring measurements translate directly to mold performance.

The following table details the standard tolerance capabilities we consistently achieve and verify for injection mold components. These represent our typical production standards; tighter tolerances are achievable for critical features upon specific engineering review and process validation.

| Feature Type | Standard Tolerance (mm) | Measurement Method | Applicable Standards |

|---|---|---|---|

| Linear Dimensions | ±0.005 | CMM | ISO 2768-mK (Internal) |

| Geometric (Flatness) | 0.003 / 100mm | CMM, Optical Flat | ISO 1101 |

| Geometric (Parallelism) | 0.003 / 100mm | CMM | ISO 1101 |

| Geometric (Perpendicularity) | 0.005 / 100mm | CMM | ISO 1101 |

| Hole Diameter (Reamed) | H7 (+0.000 / +0.012) | CMM, Air Gage | ISO 286-2 |

| Surface Roughness (Ra) | 0.4 µm (Typical) | Profilometer | ISO 4287 |

This integrated approach—combining 5-axis CNC mastery with proactive CMM-driven quality assurance—ensures the dimensional integrity and functional reliability of every mold component we produce. We translate engineering intent into tangible precision, directly contributing to your mold’s performance, part quality, and ultimately, your production profitability. Wuxi Lead Precision Machinery provides the exacting metal foundation upon which successful injection molding operations are built.

Material & Finish Options

Material selection in injection molding production is a critical decision that directly impacts part performance, tool life, production efficiency, and overall cost. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-precision mold components, leveraging advanced metallurgy and finishing techniques to meet the rigorous demands of modern manufacturing. The choice between aluminum, steel, and titanium depends on application-specific factors such as production volume, part complexity, thermal performance, and environmental exposure.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype molds and low-volume production due to their excellent machinability and thermal conductivity. These properties allow for faster cooling cycles, reducing part cycle time during trials. However, aluminum’s lower hardness and wear resistance limit its use in high-volume applications. It is best suited for applications where rapid development and cost-effective tooling are priorities.

Steel, especially hardened tool steels like P20, H13, and S136, remains the standard for high-volume injection molding. These materials offer superior durability, wear resistance, and dimensional stability under prolonged thermal cycling. Pre-hardened steels provide a balance of machinability and strength, while hardened steels are ideal for corrosive environments or when optical surface finishes are required. Steel molds typically offer the longest service life, often exceeding hundreds of thousands of cycles with proper maintenance.

Titanium alloys, though less common, are gaining traction in specialized applications where extreme strength-to-density ratios and corrosion resistance are paramount. While titanium is not typically used for full mold bases due to cost and machining complexity, it is occasionally employed in core components exposed to aggressive chemicals or elevated temperatures. Its use is generally limited to niche aerospace or medical applications where performance outweighs cost considerations.

Surface finishing, particularly anodizing, plays a vital role in enhancing material performance. Anodizing aluminum increases surface hardness, improves wear resistance, and provides electrical insulation. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with Type III offering thicker, more durable coatings suitable for high-wear environments. While steel and titanium are not anodized in the traditional sense, they benefit from alternative surface treatments such as nitriding, chrome plating, or PVD coatings to achieve similar performance enhancements.

The following table summarizes key mechanical and thermal properties of these materials to aid in selection:

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Common Applications |

|---|---|---|---|---|---|

| Aluminum 7075 | 570 | 15–20 | 130 | 10,000–50,000 | Prototypes, low-volume production |

| P20 Steel | 900 | 28–32 | 30 | 100,000–500,000 | Medium to high-volume production |

| H13 Steel | 1,500 | 45–50 | 35 | 500,000+ | High-stress, high-temp molding |

| Titanium Ti-6Al-4V | 900 | 35–40 | 7 | Specialized components only | Aerospace, medical, corrosive env. |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on production goals, ensuring reliability, precision, and cost efficiency across the mold lifecycle.

Manufacturing Process & QC

Injection Molding Production: Precision Engineered from Concept to Volume

At Wuxi Lead Precision Machinery, our injection molding production process is engineered for uncompromising quality and efficiency, delivering true Zero Defects outcomes for demanding custom metal components. We integrate advanced engineering rigor with meticulous manufacturing control across three critical phases, ensuring every part meets exacting specifications before scaling to volume.

The Design phase is foundational to defect prevention. Our engineering team collaborates closely with clients during initial concept development, conducting comprehensive Design for Manufacturability (DFM) analysis. This proactive step identifies potential molding challenges—such as wall thickness inconsistencies, draft angle issues, or gate placement conflicts—long before tooling begins. We leverage sophisticated 3D simulation software to model material flow, cooling rates, and potential stress points under actual production conditions. Simultaneously, material science expertise guides optimal alloy selection, balancing mechanical properties, thermal stability, and flow characteristics for the specific application. This rigorous upfront engineering eliminates over 80% of potential defects at the source, significantly reducing downstream rework and accelerating time-to-market.

Prototyping transitions validated designs into tangible reality under production-intent conditions. Using high-precision rapid tooling or initial production molds, we manufacture functional prototype batches. These parts undergo exhaustive metrology, including CMM inspection, optical scanning, and application-specific performance testing. Critical dimensions, surface finishes, and mechanical properties are verified against the digital model and client requirements. Any deviations trigger immediate root cause analysis and iterative design or process adjustments. This phase is not merely validation; it is a critical learning loop where process parameters are fine-tuned and potential micro-defects are eradicated, ensuring the final process window is robust and repeatable.

Mass Production executes the perfected process with unwavering consistency. Our state-of-the-art molding cells operate under strict Statistical Process Control (SPC), with real-time monitoring of over 20 critical parameters—melt temperature, injection pressure, cooling time, and clamp force. Automated vision systems perform 100% in-line inspection for surface defects, while periodic destructive and non-destructive testing verifies internal integrity and material properties. Every batch is traceable via our integrated MES, linking raw material certs to machine logs and inspection data. This closed-loop system, combined with our zero-tolerance quality culture and rigorous operator training, guarantees sustained Zero Defects output. Continuous improvement protocols ensure process capability (Cpk) remains above 1.67, translating client specifications into flawless physical components.

Our precision capabilities are quantified in the specifications below, reflecting the core parameters enabling Zero Defects production for complex metal injection molded parts.

| Specification Category | Capability Range | Industry Standard Benchmark |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.05 mm | ±0.1 mm to ±0.2 mm |

| Surface Roughness (Ra) | 0.1 µm to 1.6 µm | 3.2 µm to 6.3 µm |

| Material Density | >98% Theoretical | 95% – 97% Theoretical |

| Feature Complexity | Micro-features < 0.1 mm | Features > 0.5 mm |

| Process Capability (Cpk) | ≥ 1.67 | ≥ 1.33 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Molding Production Excellence

When it comes to high-precision injection molding production, the foundation of success lies in the quality of your metal components and the reliability of your manufacturing partner. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing tailored to the exacting demands of modern injection molding operations. With decades of engineering expertise and a commitment to innovation, we deliver robust, high-performance components that ensure consistent output, extended tool life, and reduced downtime.

Our advanced CNC machining capabilities, combined with rigorous quality control protocols, enable us to produce mold bases, inserts, cores, cavities, and auxiliary systems to micron-level tolerances. Every component is manufactured using premium-grade materials and subjected to comprehensive inspection using coordinate measuring machines (CMM) and 3D scanning technology. Whether you require standard DME or HASCO-compliant systems or fully customized solutions, our team works closely with global OEMs and mold makers to meet exact specifications and tight deadlines.

We understand that injection molding environments demand durability under high pressure, thermal cycling, and continuous operation. That is why our components are engineered for superior wear resistance, dimensional stability, and thermal conductivity. From initial design consultation to final delivery, we integrate lean manufacturing principles to optimize efficiency and reduce lead times without compromising quality.

Our clients span industries where precision is non-negotiable—automotive, medical devices, consumer electronics, and industrial equipment. By partnering with Wuxi Lead Precision Machinery, you gain more than a supplier; you gain a strategic ally focused on your long-term operational success.

Below are key technical specifications that define our manufacturing capabilities:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.1 – 0.8 μm (polished to mirror finish) |

| Maximum Part Size | 1200 × 800 × 600 mm |

| Materials Supported | P20, 718, H13, S136, 420SS, Aluminum 7075 |

| CNC Equipment | 3-axis, 4-axis, 5-axis machining centers |

| Quality Standards | ISO 9001:2015, Full First Article Inspection |

| Lead Time (Average) | 15–25 days (depending on complexity) |

| Surface Treatments Available | Nitriding, Hard Chrome Plating, PVD Coating |

All projects are supported with full documentation, including CAD/CAM files, inspection reports, and material certifications. Our engineering team is available for technical collaboration at every stage—from mold flow analysis support to design for manufacturability (DFM) reviews.

To elevate your injection molding production with components built for precision and longevity, contact us today. Reach out to our team at [email protected] to discuss your requirements, request a quote, or schedule a virtual factory audit. Let Wuxi Lead Precision Machinery be the foundation of your next high-performance mold system.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.