Technical Contents

Engineering Guide: Injection Molding Polyurethane

Engineering Insight: Precision Imperatives in Polyurethane Injection Molding

Polyurethane injection molding demands exceptional precision that transcends conventional thermoplastic processes. Unlike stable molten polymers, liquid polyurethane chemically reacts and expands during curing within the mold cavity. This inherent reactivity means dimensional accuracy is not solely determined by the mold geometry; it is critically dependent on the mold’s ability to consistently control temperature, pressure, and dwell time while accommodating material expansion. Minute variations in mold surface finish, thermal uniformity, or parting line alignment directly translate to unacceptable flash, voids, or dimensional drift in the final component. For mission-critical applications in aerospace, medical devices, or high-performance industrial equipment, where tolerances often fall below ±0.1 mm, these deviations compromise functionality, safety, and longevity. Precision engineering of the mold tooling – specifically the hardened steel cavities, cores, and intricate gating systems – is therefore non-negotiable. It is the foundation for achieving repeatable part integrity, optimal material flow, and controlled shrinkage compensation.

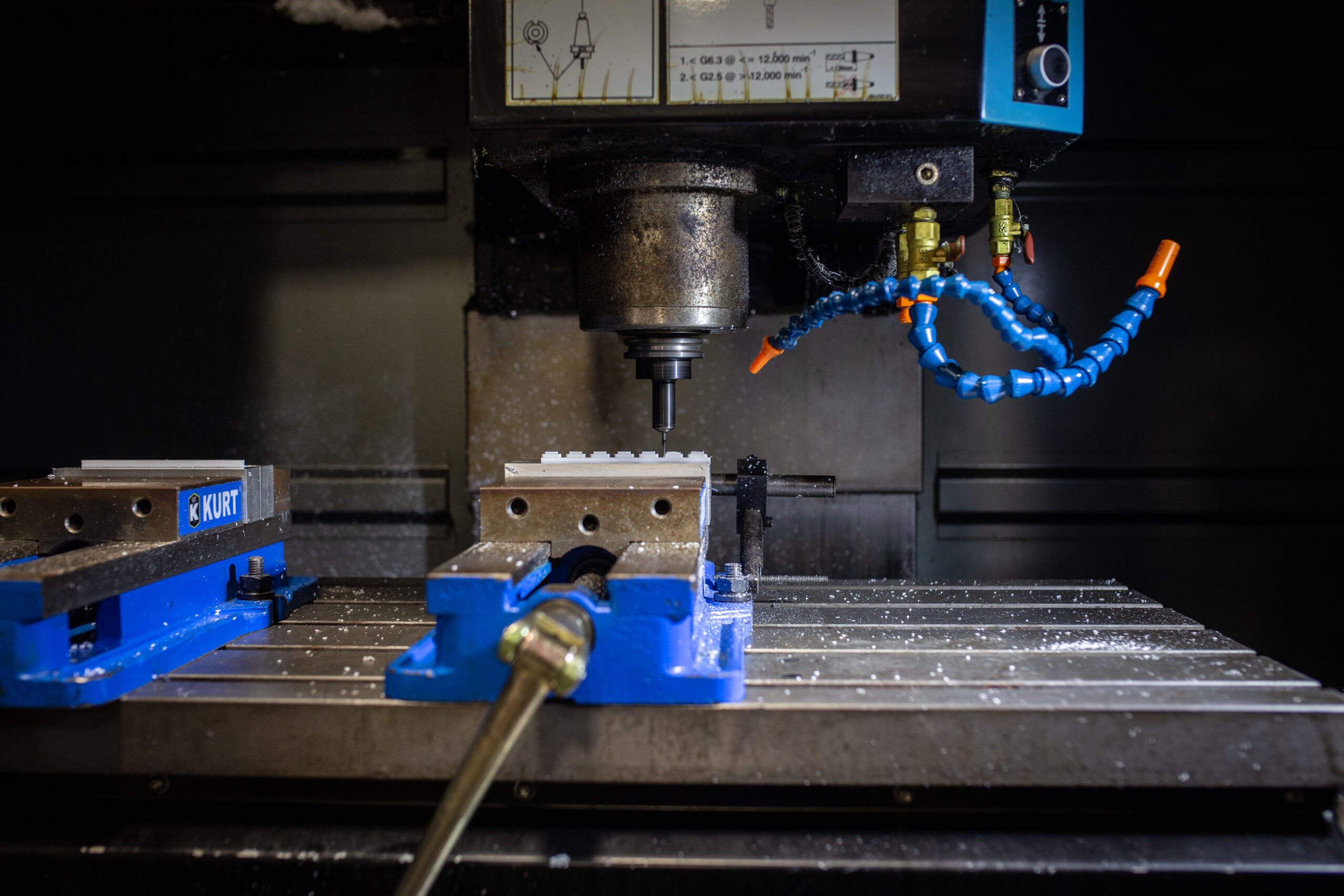

At Wuxi Lead Precision Machinery, our expertise in custom metal manufacturing for extreme environments directly addresses these challenges. We apply the same rigorous standards developed for Olympic-grade equipment and military specifications to polyurethane molding tooling. Our experience fabricating components for Beijing Olympic infrastructure demanded sub-0.02 mm tolerances under dynamic load conditions, while defense sector projects required absolute reliability in corrosive, high-vibration settings. This heritage informs every mold we produce. We utilize advanced multi-axis CNC machining centers with sub-micron positional accuracy to craft cavity and core inserts from premium tool steels like H13 or S136, ensuring thermal stability and wear resistance. Precision-ground parting lines and meticulously engineered venting systems prevent flash and air entrapment, critical for urethane’s expansion phase. Our process integrates real-time thermal mapping during mold trials to fine-tune cooling channels, guaranteeing uniform solidification and minimizing internal stresses that cause warpage.

The following specifications reflect our standard capabilities for high-precision polyurethane molding tooling, validated across demanding production environments:

| Parameter | Specification Range | Typical Capability (Production) |

|---|---|---|

| Linear Tolerance | ±0.01 mm – ±0.05 mm | ±0.025 mm |

| Surface Roughness (Cavity) | Ra 0.05 µm – Ra 0.4 µm | Ra 0.1 µm |

| Parting Line Flash Control | ≤ 0.03 mm | ≤ 0.015 mm |

| Tool Steel Hardness | 48 – 52 HRC | 50 ± 1 HRC |

| Thermal Uniformity | Δ ≤ 2°C across cavity | Δ ≤ 1°C |

Achieving excellence in polyurethane molding is a metallurgical and thermodynamic challenge as much as a molding one. Wuxi Lead Precision Machinery leverages its deep-rooted precision metal manufacturing discipline to deliver tooling that masters urethane’s complexities, ensuring your critical components meet the highest standards of performance and reliability. Our commitment to micron-level accuracy, forged in Olympic and military applications, provides the foundation for your success in demanding markets.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for injection molding applications involving polyurethane. Our expertise lies in producing tooling, molds, and support fixtures that meet the stringent demands of polyurethane processing, where thermal stability, surface finish, and dimensional accuracy are critical. Leveraging state-of-the-art 5-axis CNC machining technology, we ensure complex geometries and tight tolerances are achieved with repeatability and consistency across production runs.

Our 5-axis CNC machining centers provide simultaneous multi-directional cutting, enabling the fabrication of intricate mold cavities and cores with superior surface integrity. This capability is essential for polyurethane molding, where part ejection, flow dynamics, and final surface quality are directly influenced by mold precision. The use of high-rigidity machines with sub-micron positioning accuracy ensures minimal tool deflection and optimal contouring, even in hardened tool steels and high-performance alloys commonly used in long-life molds.

All components undergo comprehensive quality control protocols, anchored by CMM (Coordinate Measuring Machine) inspection. Our metrology lab is equipped with bridge-type and articulated-arm CMM systems, capable of full 3D geometric validation against CAD models. Each mold component is verified for dimensional conformity, form accuracy, and positional relationships, ensuring that assemblies meet design intent and function seamlessly in the molding environment. Data from CMM reports is traceable and provided with every shipment, supporting full compliance with ISO 9001 and customer-specific quality standards.

We maintain strict environmental controls in both machining and inspection areas to minimize thermal drift, ensuring measurement stability. In addition to dimensional accuracy, surface finishes are optimized for polyurethane release and aesthetic requirements, with polishing and texturing services available to customer specifications.

The following table outlines our standard machining tolerances and capabilities for mold components used in polyurethane injection applications.

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Positional Tolerance | ±0.01 mm | ±0.005 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Roundness | 0.008 mm | 0.003 mm |

| Surface Roughness (Ra) | 0.8 µm (machined) | 0.2 µm (polished) |

| Angular Accuracy | ±0.05° | ±0.02° |

| Feature Repeatability | ±0.01 mm | ±0.005 mm |

These specifications reflect our commitment to delivering mold components that ensure consistent polyurethane flow, minimal flash, and extended tool life. Wuxi Lead Precision Machinery combines advanced equipment, rigorous quality assurance, and deep process knowledge to serve industries including automotive, medical, and industrial equipment, where polyurethane molding performance is mission-critical.

Material & Finish Options

Material Selection for Polyurethane Injection Molding Tooling

Selecting the optimal mold material is critical for achieving precision, longevity, and cost efficiency in polyurethane (PU) injection molding. Unlike high-pressure thermoplastic processes, PU molding operates at significantly lower pressures but presents unique challenges including chemical reactivity of uncured resin, thermal cycling demands, and the need for exceptional surface replication. At Wuxi Lead Precision Machinery, we engineer molds using Aluminum, Steel, and Titanium alloys, each offering distinct advantages tailored to specific production volumes, part complexity, and resin formulations. Understanding these properties ensures your tooling investment aligns with operational goals and part quality requirements.

Aluminum alloys, particularly 7075-T6 and 6061-T6, are favored for rapid prototyping and low-to-medium volume production. Their superior thermal conductivity accelerates cycle times by enabling faster cooling of the PU part within the mold cavity. This responsiveness is advantageous for intricate geometries requiring precise thermal management. However, aluminum’s lower hardness necessitates protective surface treatments for extended service life against abrasive fillers or reactive PU chemistries. Steel molds, utilizing pre-hardened grades like NAK80 or hardened tool steels such as H13 and S136, provide the ultimate solution for high-volume production. Their exceptional hardness and wear resistance withstand thousands of cycles, maintaining tight tolerances and surface finish even with demanding PU formulations containing glass or mineral fillers. While initial cost and machining lead times are higher than aluminum, the longevity and dimensional stability of steel deliver superior long-term value for sustained production runs. Titanium alloys represent a specialized option, primarily selected for extreme chemical resistance against highly aggressive PU systems where even premium steels may corrode. Its use is typically justified only in niche applications due to significantly higher material and processing costs, as its thermal conductivity falls between aluminum and steel.

Surface finishing, particularly anodizing for aluminum molds, is non-negotiable for performance and durability. Type III hard anodizing creates a dense, wear-resistant ceramic layer that dramatically enhances surface hardness and corrosion resistance. This treatment effectively doubles or triples the service life of aluminum tooling in PU environments, preventing galling and maintaining the critical release properties needed for flawless part ejection. Neglecting this step severely compromises mold longevity and part quality consistency.

The following table summarizes key material properties relevant to PU injection molding tooling:

| Material | Typical Hardness (HB) | Thermal Conductivity (W/m·K) | Corrosion Resistance (PU) | Primary Application Volume |

|---|---|---|---|---|

| Aluminum 7075 | 150 | 130 | Low (Requires Anodizing) | Low to Medium |

| Steel NAK80 | 37-41 HRC | 30 | High | Medium to High |

| Steel H13 | 48-52 HRC | 28 | Very High | High Volume |

| Titanium Gr5 | 330 | 7.2 | Exceptional | Specialized Niche |

Material selection ultimately hinges on balancing upfront investment against total cost per part. For urgent prototypes or short runs under 5,000 cycles, anodized aluminum offers the fastest time-to-market. Volumes exceeding 10,000 parts almost always justify the investment in hardened steel for unmatched durability and consistency. Wuxi Lead Precision Machinery leverages decades of PU molding expertise to analyze your specific resin, part geometry, and production targets, ensuring the optimal material and finish selection for peak performance and maximum return on your tooling asset. Contact our engineering team for a tailored assessment.

Manufacturing Process & QC

Injection molding with polyurethane is a precision-driven manufacturing process tailored for high-performance components in aerospace, medical, automotive, and industrial sectors. At Wuxi Lead Precision Machinery, we integrate advanced engineering with stringent quality control to deliver zero-defect outcomes across every phase: Design, Prototyping, and Mass Production.

The process begins with Design, where our engineering team collaborates closely with clients to analyze part geometry, material behavior, and functional requirements. Finite Element Analysis (FEA) and mold flow simulation tools are employed to predict stress points, shrinkage rates, and fill patterns specific to polyurethane. This digital validation ensures optimal wall thickness, gate placement, and venting, minimizing defects such as voids or delamination. Design for Manufacturability (DFM) reviews are conducted to refine tolerances, surface finish, and ejection mechanisms, ensuring seamless transition to physical production.

Prototyping follows, utilizing rapid tooling techniques with hardened steel or aluminum molds. Low-volume runs with production-grade polyurethane resins validate the design under real process conditions. We monitor key parameters including temperature profiles, injection pressure, and cure time, adjusting within narrow bands to achieve dimensional stability and mechanical consistency. Prototype parts undergo full metrology inspection using CMM (Coordinate Measuring Machines), optical scanning, and physical testing for hardness, tensile strength, and elongation. Any deviations trigger immediate design or process correction, ensuring fidelity before scale-up.

Mass Production leverages fully automated injection molding cells equipped with real-time process monitoring. Each cycle is logged for traceability, with sensors detecting anomalies in pressure or temperature that could affect part integrity. Our cleanroom-class production environment controls humidity and particulate levels, critical for maintaining polyurethane’s chemical consistency. In-line vision systems and automated dimensional checks ensure 100% inspection capability, while statistical process control (SPC) maintains CpK values above 1.67 across batches. All molds are maintained under preventive schedules, with cavity surface finishes inspected to ensure replication accuracy down to ±0.02 mm.

Throughout the production lifecycle, Wuxi Lead enforces a Zero Defects philosophy grounded in ISO 13485 and IATF 16949 standards. Non-conforming material is quarantined immediately, and root cause analysis is conducted using 8D methodology. Continuous feedback loops between production and engineering ensure sustained process optimization.

Key process specifications are maintained as follows:

| Parameter | Specification Range |

|---|---|

| Material Types | Aliphatic & Aromatic Polyurethane |

| Hardness Range (Shore A/D) | 30A to 85D |

| Tolerance (Standard) | ±0.05 mm |

| Tolerance (Precision) | ±0.02 mm |

| Surface Finish (Ra) | 0.1 – 1.6 μm |

| Production Volume Capacity | 1,000 – 500,000 pcs/month |

| Cycle Time Range | 30 seconds – 5 minutes |

| Cleanroom Class | ISO 8 (Optional ISO 7) |

Wuxi Lead Precision Machinery combines deep material expertise with closed-loop manufacturing to deliver injection molded polyurethane components that meet the highest standards of performance and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Engineered Solution for Polyurethane Injection Molding Excellence

Achieving consistent, high-performance polyurethane (PU) components demands more than standard molding processes. It requires precision-engineered metal tooling capable of withstanding urethane chemistry, managing exothermic reactions, and delivering micron-level dimensional integrity across every cycle. At Wuxi Lead Precision Machinery, we bridge the critical gap between advanced polymer science and uncompromising metal fabrication. Our CNC-machined molds and dies are not merely tools—they are the foundation of your production stability, part longevity, and cost efficiency. We engineer for the unique thermal expansion, chemical resistance, and surface finish requirements inherent to polyurethane, eliminating common pitfalls like flash, incomplete fills, or premature wear that plague generic tooling solutions.

Our integrated approach combines decades of metallurgical expertise with state-of-the-art 5-axis milling and grinding capabilities. Every mold plate, cavity, and core undergoes rigorous thermal treatment and surface hardening processes tailored to your specific PU formulation and production volume. This ensures optimal heat transfer control during curing, minimizes internal stresses in the final part, and extends tool life significantly beyond industry averages. The result is reduced scrap rates, lower per-part costs, and accelerated time-to-market for demanding applications in automotive sealing, medical devices, industrial rollers, and high-resilience consumer goods.

Critical Specifications Delivered by Lead Precision Machinery

| Specification | Capability Range | Relevance to Polyurethane Molding |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (±0.00008″) | Ensures consistent wall thickness & sealing integrity |

| Surface Finish (Cavity) | Ra 0.05 µm (2 µin) to mirror polish | Critical for demolding & aesthetic requirements |

| Material Options | H13, S7, Stainless 420, Custom Alloys | Optimized for urethane chemistry compatibility |

| Max. Mold Base Size | 1200 x 1000 x 800 mm | Supports complex multi-cavity production tools |

| Hardness Range | 48-54 HRC (post-heat treatment) | Balances wear resistance & thermal conductivity |

| Lead Time (Prototype) | 15-25 working days | Accelerates validation of new PU formulations |

Do not compromise your polyurethane component quality with tooling that lacks the metallurgical sophistication required for this demanding process. Wuxi Lead Precision Machinery operates at the intersection of materials science and precision manufacturing, providing the technical partnership essential for scaling from prototype to high-volume production. Our engineering team collaborates directly with your R&D and production staff to analyze flow dynamics, optimize gate design, and select the ideal steel grade—transforming material challenges into competitive advantages.

Your pursuit of flawless polyurethane injection molding outcomes begins with the integrity of the metal foundation. Contact our application engineers today to discuss how our custom tooling solutions can resolve your specific production hurdles. Email [email protected] with your project specifications and material requirements. We will provide a detailed capability assessment and timeline within 24 business hours. Partner with a manufacturer that treats your precision as non-negotiable—engineer reliability with Wuxi Lead Precision Machinery. Let us build the foundation for your next generation of high-performance polyurethane components.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.