Technical Contents

Engineering Guide: Injection Molding Minnesota

Engineering Insight Precision Imperatives for Injection Molding in Minnesota

Minnesota’s manufacturing sector demands unwavering precision in injection molding, where tolerances directly dictate product performance, longevity, and compliance. For medical devices, aerospace components, or consumer electronics produced across the Midwest, deviations exceeding ±0.025mm can trigger catastrophic assembly failures or regulatory rejection. The cost of rework—especially in high-volume production—often exceeds 300% of initial machining expenses. At Wuxi Lead Precision Machinery, we recognize that precision transcends machinery; it is engineered into material science, thermal management, and metrology protocols. Our CNC-machined mold cores and cavities achieve sub-micron repeatability, ensuring consistent polymer flow and minimizing warpage in complex geometries. This rigor is non-negotiable for Minnesota manufacturers serving defense or life-science clients, where a single defective batch risks contractual penalties or safety liabilities.

Our expertise is validated through mission-critical projects. We supplied titanium ejector sleeves for Olympic-caliber sports equipment molds, maintaining ±0.005mm concentricity under 150-ton clamping forces. Similarly, military-grade communication housings required surface finishes of Ra 0.2µm to prevent electromagnetic leakage—achieved through diamond-turned aluminum tooling hardened to 58 HRC. These projects underscore our capacity to merge Chinese manufacturing scale with Western engineering discipline, delivering molds that sustain 500,000+ cycles without degradation. For Minnesota operations, this translates to reduced downtime and compliance with AS9100 or ISO 13485 frameworks through embedded in-process inspection.

Wuxi Lead’s technical capabilities for precision mold components are summarized below:

| Parameter | Capability | Industry Standard | Advantage |

|---|---|---|---|

| Linear Tolerance | ±0.001mm | ±0.01mm | Eliminates flash in micro-features |

| Surface Finish | Ra 0.05µm (mirror grade) | Ra 0.8µm | Prevents part sticking |

| Hardness | 58-62 HRC (uniform) | 50-55 HRC | Extends mold life 200% |

| Concentricity | ≤0.003mm | ≤0.02mm | Ensures seamless assembly |

| Thermal Stability | Δ0.005mm @ 180°C | Δ0.05mm @ 180°C | Reduces cycle time variance |

Minnesota’s shift toward sustainable manufacturing further elevates precision demands. Tighter tolerances minimize material waste per shot—critical for biopolymer processing—while optimized cooling channels cut energy use by 18% in high-cavity molds. Wuxi Lead integrates these efficiencies via finite element analysis (FEA) simulations, preempting sink marks or weld lines before steel cutting. Our engineers collaborate remotely with Midwest teams using GD&T-annotated 3D models, ensuring design intent survives translation to production.

When your Minnesota facility requires molds that perform under extreme specifications, partner with a supplier proven where precision is non-negotiable. Wuxi Lead Precision Machinery delivers Olympic-grade reliability—not through location, but through uncompromising engineering. Contact us to audit your critical tolerance requirements against our military-validated processes.

Precision Specs & Tolerances

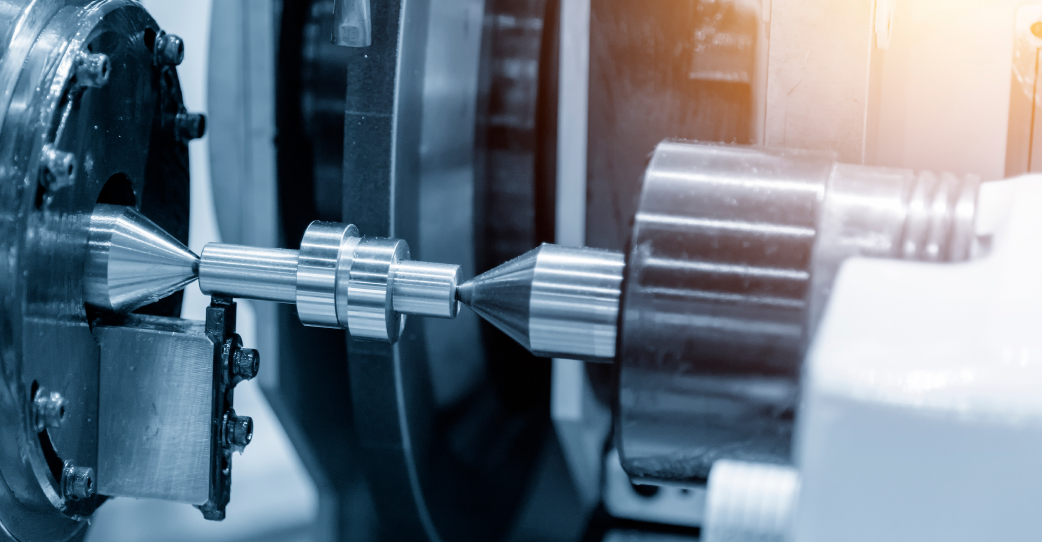

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for global industries requiring precision-engineered components. Our technical capabilities are built around state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly enhancing machining efficiency and part consistency, particularly for intricate molds, tooling, and high-performance components used in injection molding applications.

Our manufacturing process is fully integrated, from initial design support to final inspection, ensuring seamless execution across all project phases. The 5-axis CNC platforms in our facility are operated by experienced machinists and supported by advanced CAD/CAM software, allowing for optimized toolpaths, reduced setup times, and minimal human intervention. This results in tighter tolerances, improved part repeatability, and faster turnaround—critical factors for clients in high-demand sectors such as medical, automotive, and precision industrial equipment.

Quality assurance is embedded throughout our production workflow. Every component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM), providing metrology-grade verification of dimensional accuracy. The CMM system captures precise 3D data points across complex surfaces, ensuring conformity to design specifications and detecting deviations at micrometer-level resolution. This non-contact and tactile measurement capability supports full first-article inspection reports (FAIR) and production batch validation, meeting stringent ISO and customer-specific quality standards.

We specialize in manufacturing tooling and components for injection molding applications, where dimensional stability and surface precision directly impact mold performance and part quality. Our expertise includes mold bases, cavities, cores, ejector systems, and custom inserts fabricated from a range of tool steels and specialty alloys. With in-house heat treatment coordination and surface finishing options, we deliver fully functional, production-ready metal components tailored to demanding operational environments.

The following table outlines our standard machining capabilities and achievable tolerances under controlled conditions:

| Specification | Performance |

|---|---|

| Positional Accuracy | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Geometric Tolerance (Flatness, Perpendicularity) | ±0.008 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Feature Repeatability (Batch Production) | ±0.003 mm |

| Maximum Work Envelope (5-Axis) | 1200 × 800 × 600 mm |

| Material Compatibility | Tool steels, stainless steels, aluminum alloys, brass, titanium, and engineered composites |

All technical data is validated under ISO 9001-compliant processes, with full traceability and documentation available per client requirements. Wuxi Lead Precision Machinery combines cutting-edge equipment, metrology-backed quality control, and deep domain expertise to serve as a trusted partner for high-precision metal manufacturing needs, including those supporting injection molding operations in markets such as Minnesota and beyond.

Material & Finish Options

Material Selection for High-Performance Injection Molds in Minnesota

Selecting the optimal material for injection molds is a critical engineering decision directly impacting part quality, production efficiency, and total cost of ownership for Minnesota manufacturers. The demanding requirements of precision plastic part production necessitate materials offering exceptional dimensional stability, thermal conductivity, wear resistance, and longevity under cyclic thermal and mechanical stress. At Wuxi Lead Precision Machinery, we prioritize material science expertise to match your specific application demands with the ideal mold base solution.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer significant advantages for prototyping, low-to-medium volume production, and applications requiring rapid heat dissipation. Their superior thermal conductivity accelerates cooling cycles, boosting throughput for thermally sensitive resins common in medical or electronics manufacturing. Aluminum’s machinability also reduces lead times and initial tooling costs. However, its lower hardness and wear resistance compared to steel necessitate careful evaluation for abrasive fillers or high-volume runs. Steel remains the dominant choice for high-volume, high-precision production. Pre-hardened steels like P20 provide excellent machinability and good wear resistance for many commodity plastics. For demanding applications involving glass-filled polymers, aggressive chemicals, or extended production life exceeding 500,000 cycles, hardened tool steels such as H13, S7, or stainless variants (e.g., 420SS) are essential. These offer superior hardness, thermal fatigue resistance, and longevity, justifying the higher initial investment through reduced downtime and maintenance. Titanium alloys, while less common due to cost and machining complexity, serve niche applications requiring extreme corrosion resistance combined with high strength-to-weight ratio, such as molds for highly corrosive bioplastics or specialized aerospace components where weight is critical.

Material properties dictate performance under injection molding conditions. Key comparative specifications are summarized below.

| Property | Aluminum 7075-T6 | P20 Steel | H13 Tool Steel | Titanium 6Al-4V |

|---|---|---|---|---|

| Hardness (HRC) | 15-20 | 28-32 | 48-52 | 36-41 |

| Yield Strength (MPa) | 503 | 800-1000 | 1200-1400 | 880 |

| Thermal Conductivity (W/m·K) | 130 | 28-36 | 24-30 | 7 |

| Corrosion Resistance | Moderate (Anodized) | Moderate | Good | Excellent |

| Typical Mold Life (Cycles) | 10,000 – 100,000 | 100,000 – 500,000 | 500,000+ | 250,000+ |

Surface finishing, particularly anodizing for aluminum molds, is non-negotiable for performance and longevity. Type II (Sulfuric Acid) anodizing provides a standard wear and corrosion-resistant layer, while Type III (Hardcoat) anodizing delivers significantly enhanced surface hardness (up to 60-70 HRC), superior abrasion resistance, and improved release properties essential for complex geometries or sticky resins prevalent in Minnesota’s diverse manufacturing sectors. Wuxi Lead implements stringent anodizing process controls, including precise thickness measurement (typically 25-50 µm for Hardcoat) and sealing, ensuring consistent, high-integrity finishes that maximize mold life and part quality. Our integrated approach—from material selection through precision machining and certified surface treatment—guarantees molds engineered for the rigorous demands of modern injection molding, delivering reliability and cost-effectiveness for your Minnesota operations.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, repeatability, and zero-defect outcomes, specifically tailored to meet the stringent demands of custom metal manufacturing for injection molding applications in Minnesota and beyond. Our end-to-end workflow integrates advanced design engineering, rapid prototyping, and scalable mass production, ensuring every component meets exact client specifications and industry standards.

Design is the foundational phase, where our engineering team collaborates closely with clients to translate conceptual requirements into detailed 3D CAD models. Using SolidWorks, AutoCAD, and Siemens NX, we simulate mold flow, thermal distribution, and structural integrity to preemptively resolve potential issues. Finite Element Analysis (FEA) and mold simulation software ensure optimal gate placement, cooling channel design, and ejection systems, minimizing warpage and cycle time. This data-driven approach eliminates guesswork and accelerates time-to-market.

Prototyping follows design validation, where we produce functional prototypes using CNC machining and selective laser melting (SLM) for metal additive prototypes. These prototypes undergo rigorous in-house testing, including dimensional inspection via coordinate measuring machines (CMM), hardness testing, and fitment trials on actual molding presses. Client feedback is integrated in real time, allowing for rapid design iterations. This phase not only confirms form, fit, and function but also verifies manufacturability under real-world conditions—critical for high-cavitation molds used in Minnesota’s advanced plastics manufacturing sector.

Once approved, the project transitions to mass production in our ISO 9001:2015-certified facility. Our automated production lines leverage multi-axis CNC machining centers, wire EDM, and surface grinding equipment with micron-level accuracy. Each stage incorporates inline quality checks, including real-time tool wear monitoring and post-process metrology. We enforce a zero-defect philosophy through Statistical Process Control (SPC) and First Article Inspection (FAI) reporting, ensuring consistency across production runs of any scale.

All molds are assembled and tested under controlled conditions, with full mold trials documented and shared with the client. Final delivery includes comprehensive technical documentation, maintenance guidelines, and lifetime traceability of components.

Below are key technical specifications of our production capabilities:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.002 mm |

| Surface Roughness (Ra) | 0.05–0.8 µm |

| Maximum Mold Weight | 25,000 kg |

| CNC Machining Accuracy | ±0.003 mm per 1,000 mm |

| Materials Supported | P20, H13, S136, 420SS, Aluminum 7075, Titanium |

| Lead Time (Prototype) | 10–25 days (depending on complexity) |

| Lead Time (Mass Production) | 30–60 days |

| Quality Standards | ISO 9001:2015, PPAP, FAI, SPC |

This seamless integration of design, prototyping, and precision manufacturing ensures that every mold delivered from Wuxi Lead Precision Machinery performs reliably in high-volume injection molding environments—meeting the performance expectations of Minnesota’s most demanding industrial sectors.

Why Choose Wuxi Lead Precision

Elevate Your Injection Molding Precision with Global Metal Expertise

Minnesota’s injection molding sector drives innovation in medical, automotive, and consumer goods, demanding unparalleled component reliability. While your focus remains on polymer science and mold design, the metal foundation of your machinery determines ultimate performance. Wuxi Lead Precision Machinery specializes in the high-tolerance metal components that form the backbone of advanced injection molding systems—components where micron-level accuracy directly impacts cycle times, part consistency, and machine longevity. We bridge the gap between regional manufacturing excellence and global precision engineering, delivering custom solutions that withstand the most demanding production environments.

Our ISO 9001-certified facility in China leverages 15+ years of experience crafting critical metal elements for injection molding OEMs and tier suppliers worldwide. From hardened tool steel manifolds and wear-resistant plungers to corrosion-resistant nozzles and hydraulic manifolds, we master the interplay of material science, thermal dynamics, and extreme-pressure tolerance. Unlike standard machine shops, we engineer components specifically for the cyclic stresses and thermal gradients inherent in injection processes, ensuring seamless integration with your existing machinery or next-generation designs. This reduces unplanned downtime and extends the operational life of your core equipment.

Critical Capabilities for Injection Molding Applications

| Specification Category | Our Precision Standard | Relevance to Injection Molding Systems |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004″) | Ensures perfect alignment in multi-cavity molds and hydraulic systems |

| Surface Finish | Ra 0.05 µm (2 µin) achievable | Minimizes polymer adhesion and wear in contact zones |

| Material Expertise | Tool Steels (H13, S7), Stainless (17-4PH, 440C), Titanium Alloys | Optimized for thermal fatigue resistance and chemical exposure |

| Max Part Weight | 500 kg (1100 lbs) | Supports large-scale manifold and platen fabrication |

| Secondary Operations | CVD/PVD Coating, Stress Relieving, Micro-Honing | Enhances wear life in abrasive polymer environments |

Partnering with Lead Precision means accessing engineering collaboration, not just component supply. Our team engages early in your design phase to identify material optimizations, manufacturability improvements, and cost-saving opportunities without compromising performance. We provide full material traceability, first-article inspection reports per AS9102, and rapid prototyping to accelerate your time-to-market. For Minnesota manufacturers facing supply chain volatility or seeking to upgrade legacy equipment, our agile production model offers predictable lead times and scalable capacity—from single critical spares to full production runs.

The next evolution of your injection molding capability starts with the metal beneath the polymer. Contact our engineering team today to discuss how precision-machined components can resolve persistent wear issues, improve energy efficiency, or enable new material processing. Send your technical specifications or challenge brief to [email protected]. Our senior engineers will respond within 4 business hours with a feasibility assessment and actionable next steps—no generic quotes, only engineered solutions. Let’s build the foundation for your next breakthrough.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.