Technical Contents

Engineering Guide: Injection Molding For Dummies

Engineering Insight Precision Is Non-Negotiable in Metal Injection Molding

In metal injection molding MIM achieving micron-level precision isn’t merely desirable it is the absolute foundation of functional reliability and performance especially for mission-critical components. Unlike plastic molding MIM deals with metal powders binders and complex thermal cycles where minute variations in material density wall thickness or cooling rates propagate into significant dimensional deviations. A tolerance shift of just 0.05mm can render a surgical instrument unsafe compromise the sealing integrity of an aerospace valve or cause catastrophic fatigue in a defense mechanism. At Wuxi Lead Precision Machinery we engineer for zero-failure scenarios because our clients operate where compromise is not an option. This demands more than advanced machinery it requires deep metallurgical understanding process physics mastery and relentless validation protocols embedded into every production phase.

Our facility has consistently delivered components meeting the most stringent global standards validated through projects supporting the Beijing 2022 Winter Olympics medical equipment supply chains and classified military subsystems. These engagements demanded not only adherence to AS9100 and ITAR but also demonstrable process capability indices Cpk >1.67 under third-party audit. Olympic-grade medical tools required biocompatible alloys with surface finishes under Ra 0.4µm to prevent tissue adhesion while military actuators demanded magnetic permeability control within 0.5% across 50,000 units. Such outcomes stem from our closed-loop manufacturing ecosystem where real-time cavity pressure monitoring feeds directly into adaptive control algorithms correcting for powder lot variations before they affect part geometry. We treat material science as equally critical as machine calibration understanding how particle size distribution in 17-4PH stainless steel affects sintering shrinkage vectors.

The table below outlines the precision thresholds we routinely achieve and validate which separate true high-integrity MIM from commodity production. These specs are not theoretical maximums but baseline commitments backed by 15 years of serial production data.

| Specification Category | Capability Range | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.02mm to ±0.05mm | CMM with 0.0001mm resolution GD&T analysis |

| Surface Roughness | Ra 0.2µm to Ra 1.6µm | Profilometry per ISO 4287 |

| Material Density | 98% to 99.5% theoretical | Archimedes testing metallography |

| Alloy Consistency | ±0.3% elemental composition | OES spectroscopy batch traceability |

| Production Volume Control | Cp/Cpk ≥1.33 at 100k+ units | SPC real-time SPC dashboards |

Precision in MIM transcends technical execution it is a commitment to your product’s operational lifespan and your brand’s reputation. When tolerances dictate whether a component survives arctic deployment or ensures patient safety during delicate procedures there is no room for approximation. Wuxi Lead Precision Machinery builds this certainty into every part through engineered processes not hopeful adjustments. Contact our engineering team to discuss how our validated precision framework can eliminate your risk in high-stakes applications.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision Metal Manufacturing

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the rigorous demands of high-performance industries including aerospace, medical, automotive, and industrial automation. Specializing in custom metal manufacturing, we integrate state-of-the-art 5-axis CNC machining with comprehensive quality control protocols to deliver components that adhere to the tightest tolerances and highest material integrity standards.

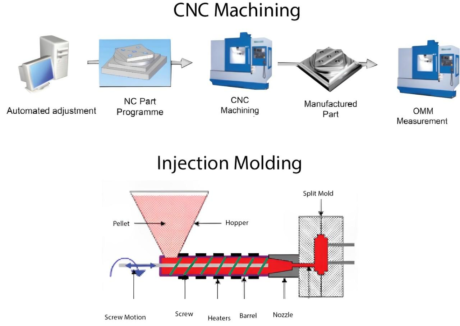

Our 5-axis CNC machining centers provide unparalleled precision and flexibility in complex part production. Unlike conventional 3-axis systems, 5-axis technology allows simultaneous movement across five planes, enabling the machining of intricate geometries in a single setup. This reduces cumulative error, improves surface finish, and significantly shortens lead times. We work with a wide range of metals including aluminum alloys, stainless steel, titanium, tool steel, and high-temperature superalloys, ensuring compatibility with demanding operational environments.

All machining operations are supported by in-house programming using advanced CAD/CAM software, allowing for optimized toolpaths, efficient material removal, and seamless transitions from prototype to full-scale production. Our skilled machinists oversee every stage of the process, ensuring that design intent is fully realized in the final component.

Quality assurance is central to our manufacturing philosophy. Each part undergoes rigorous inspection using a Coordinate Measuring Machine (CMM), providing metrology-grade verification of dimensional accuracy. The CMM system captures thousands of data points with micron-level precision, confirming compliance with geometric dimensioning and tolerancing (GD&T) requirements as defined in engineering drawings. This level of inspection ensures repeatability and traceability across production batches, critical for regulated industries.

Beyond dimensional verification, our quality process includes material certification, surface roughness analysis, and first-article inspection reporting. We maintain full documentation for every project, supporting audit readiness and customer compliance requirements.

The table below outlines the standard tolerance capabilities achievable through our 5-axis CNC and inspection systems. These values represent our typical production performance; tighter tolerances are attainable based on material, geometry, and customer specifications.

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (up to 200 mm) | ±0.01 mm | ±0.005 mm |

| Linear Dimensions (200–500 mm) | ±0.02 mm | ±0.01 mm |

| Hole Diameter | +0.015 / -0.005 mm | +0.005 / -0.002 mm |

| Positional Tolerance | ±0.02 mm | ±0.01 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm (polished) |

| Angular Tolerance | ±0.05° | ±0.02° |

Wuxi Lead Precision Machinery combines advanced equipment, expert craftsmanship, and metrology-backed quality control to deliver precision metal components that perform reliably in the most demanding applications. Our technical capabilities are not just about machinery—they reflect a commitment to engineering excellence and customer success.

Material & Finish Options

Material Selection for Injection Molding Tooling: Precision Foundations

Understanding material selection for injection molds is critical for production efficiency, part quality, and total cost of ownership. While the molded part itself is typically plastic, the mold tooling—the core component shaping that plastic—is manufactured from high-performance metals. Selecting the correct mold base material directly impacts cycle time, surface finish capability, maintenance frequency, and overall tool longevity. Wuxi Lead Precision Machinery emphasizes that this decision is foundational, not incidental, to successful high-volume manufacturing. Confusing mold materials with part materials is a common oversight; this guide focuses exclusively on the metals forming the mold cavity and core.

Aluminum alloys, specifically 7075-T6, offer significant advantages for prototyping and low-volume production (under 10,000 shots). Its superior thermal conductivity accelerates cooling cycles, reducing part cycle time by up to 30% compared to steel molds. Machining aluminum is faster and less expensive, enabling rapid tool iteration. However, its lower hardness limits resistance to abrasive engineering resins and wear in high-volume scenarios. Steel remains the dominant choice for production molds. Pre-hardened steels like P20 (28-32 HRC) provide an optimal balance of machinability, moderate cost, and durability for medium runs (100,000 shots). For demanding applications involving abrasive fillers (glass fiber) or high-volume production exceeding 500,000 shots, hardened tool steels such as H13 (48-52 HRC) are essential. H13 offers exceptional wear resistance, thermal fatigue resistance, and longevity but requires slower, more precise CNC machining and heat treatment. Titanium alloys see niche use in highly corrosive environments or extreme weight-sensitive applications due to exceptional strength-to-weight ratio and corrosion resistance, though cost and machining complexity make them impractical for most standard molds.

Surface finishes, particularly anodizing for aluminum molds, are vital secondary processes. Hard anodizing (Type III) creates a dense, wear-resistant ceramic layer on aluminum tooling, significantly extending its usable life in medium-run applications and improving release properties. It is not applicable to steel molds, which utilize nitriding, chrome plating, or specialized PVD coatings for enhanced surface performance.

The following table summarizes key properties for common mold materials:

| Material | Typical Hardness | Relative Cost | Ideal Application Range (Shot Count) | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| Aluminum 7075 | 150 HB | 1.0x | < 10,000 | Fast machining, excellent thermal conductivity | Low wear resistance, soft surface |

| P20 Steel | 28-32 HRC | 2.0x | 100,000 – 500,000 | Good balance of cost, machinability, durability | Limited for highly abrasive resins |

| H13 Steel | 48-52 HRC | 3.0x | 500,000+ | Superior wear/thermal fatigue resistance | Higher machining cost, longer lead time |

Selecting the optimal material requires analyzing resin abrasiveness, required production volume, part geometry complexity, and surface finish demands. Partnering with an experienced precision manufacturer like Wuxi Lead ensures material and finish choices align precisely with your operational goals, maximizing tool investment and minimizing production downtime. We rigorously evaluate these factors during the quoting phase to deliver molds engineered for your specific success.

Manufacturing Process & QC

Design: The Foundation of Precision

The injection molding process begins with meticulous design engineering, where functionality, material behavior, and manufacturability converge. At Wuxi Lead Precision Machinery, our engineering team employs advanced CAD/CAM software and finite element analysis (FEA) to simulate mold flow, thermal distribution, and structural integrity before any physical work begins. This virtual prototyping ensures optimal gate placement, cooling channel layout, and ejection mechanisms, minimizing the risk of warpage, sink marks, or incomplete fills. Design for manufacturability (DFM) reviews are conducted collaboratively with clients to refine part geometry, wall thickness, and tolerance specifications—ensuring the final product meets exact performance and aesthetic standards. Every design is validated against international quality benchmarks, including ISO 9001 and IATF 16949, setting the stage for zero-defect production.

Prototyping: Validating Performance

Once the design is finalized, we move to rapid prototyping using high-precision CNC-machined molds or 3D-printed tooling, depending on complexity and volume requirements. These prototypes are not mock-ups—they are fully functional parts produced under near-production conditions, allowing for rigorous testing of fit, form, and function. We conduct dimensional inspections using coordinate measuring machines (CMM), surface finish analysis, and environmental stress testing to validate performance across temperature, load, and chemical exposure conditions. Feedback from this phase is integrated into mold adjustments, ensuring that any micro-deflection or shrinkage is compensated before mass production. This iterative validation process is critical to achieving zero defects and reducing time-to-market.

Mass Production: Consistency at Scale

With design and prototype approval, production transitions to high-speed, automated injection molding cells. Our facility in Wuxi operates state-of-the-art electric and hybrid molding machines with real-time process monitoring systems. Each cycle is tracked for injection pressure, melt temperature, cooling time, and clamp force, with data logged for full traceability. In-line vision systems and automated metrology check every part for dimensional accuracy, rejecting outliers before they proceed downstream. Cleanroom environments are maintained for medical and electronics-grade components, ensuring particulate-free production. All molds are maintained under a preventive schedule, with cavity hardness and surface coating integrity regularly inspected to extend tool life and maintain consistency.

Process Specifications

| Parameter | Specification Range |

|---|---|

| Clamping Force | 50–2,500 Tons |

| Shot Weight Accuracy | ±0.1% |

| Dimensional Tolerance | ±0.02 mm (standard), ±0.005 mm (precision) |

| Surface Roughness (Ra) | 0.05–1.6 µm |

| Material Compatibility | Engineering plastics, liquid silicone, PEEK, PPS, PC, PBT |

| Cycle Time Monitoring | Real-time, IoT-enabled SCADA |

| Quality Control Standard | ISO 9001, IATF 16949, 100% inspection for critical features |

This disciplined progression—from intelligent design to validated prototyping and tightly controlled mass production—ensures every component meets the uncompromising standards of zero-defect manufacturing.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Molding Excellence

Injection molding success hinges on precision metal components. Substandard molds cause part warpage, production delays, and costly scrap—risks no manufacturer can afford. Wuxi Lead Precision Machinery eliminates these vulnerabilities through engineered excellence in custom mold bases, cavities, cores, and critical wear components. We are not merely a supplier; we are your precision engineering partner, integrating decades of CNC mastery with deep injection molding process knowledge to deliver molds that perform flawlessly from first shot to high-volume production.

Our ISO 9001 and ISO 14001 certified facility in Wuxi, China, operates at the pinnacle of metal manufacturing capability. We deploy advanced 5-axis milling, grinding, and EDM technologies alongside rigorous metrology protocols to achieve tolerances down to ±0.001mm. Every component undergoes stringent material verification and process validation, ensuring dimensional stability under thermal cycling and mechanical stress. This commitment translates to longer mold life, reduced downtime, and consistent part quality for your production line. Partnering with Lead Precision means accessing engineering collaboration from initial design review through final validation, optimizing your mold for manufacturability, cost efficiency, and peak performance.

Technical Capabilities at a Glance

| Specification Category | Lead Precision Standard | Industry Typical |

|---|---|---|

| Positional Accuracy | ±0.001 mm | ±0.005 mm |

| Surface Finish (Cavity) | Ra 0.05 µm | Ra 0.2 µm |

| Material Verification | 100% PMI + Hardness Test | Spot Checks |

| DFM Analysis | Integrated Engineering Review | Optional Add-on |

| Lead Time (Complex Mold Base) | 18-22 Days | 25-35 Days |

We understand the critical link between mold precision and your bottom line. Our engineering team proactively identifies potential molding defects during the design phase—addressing sink marks, knit lines, or ejection issues before metal is cut. This preventive approach minimizes costly iterations and accelerates time-to-market. Global brands trust us for mission-critical applications in automotive, medical devices, and consumer electronics because we deliver repeatability where it matters most: in the consistency of your final product.

Do not compromise on the foundation of your injection molding process. Contact our engineering team today to discuss your specific requirements. Send your RFQ or 3D model to [email protected] for a detailed technical proposal within 24 hours. Include your target cycle time, material, and part complexity for a tailored capability assessment. Let us demonstrate how precision metal manufacturing elevates your molding outcomes—reducing total cost of ownership while exceeding quality expectations. Schedule your technical consultation now and transform your injection molding challenges into competitive advantages.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.