Technical Contents

Engineering Guide: Injection Molding Electronics

Engineering Insight Precision Imperatives in Electronics Injection Molding

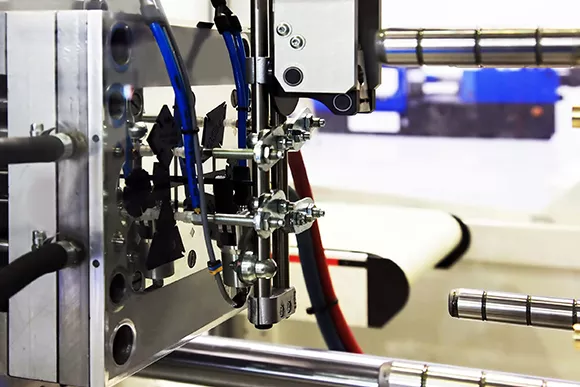

In electronics injection molding, dimensional deviations of 0.02mm can render micro-connectors non-functional or compromise shielding integrity in RF housings. The convergence of miniaturization, multi-cavity tooling, and conductive polymer requirements demands sub-50-micron repeatability. Standard molding processes often fail at critical interfaces where lead frames meet overmolded housings, causing signal attenuation or thermal delamination. At Wuxi Lead Precision Machinery, we treat mold steel geometry as the primary electrical component – because in 5G antenna arrays or medical IoT sensors, the tool is the circuit pathway. Our CNC-machined cavities maintain ±0.003mm flatness across 300mm surfaces, eliminating the micro-gaps that induce electromagnetic interference in high-frequency applications.

Material science compounds these challenges. Conductive PEEK and liquid crystal polymers (LCP) require precise thermal management during injection to prevent fiber orientation shifts that alter electrical properties. Standard molds struggle with the 380°C+ processing temperatures while maintaining gate symmetry across 64-cavity inserts. We counter this through finite element analysis of thermal expansion coefficients during mold design, ensuring gate land geometry compensates for steel growth at operating temperature. This methodology was rigorously validated in our production of timing system components for the Beijing Winter Olympics – where sub-millisecond signal synchronization depended on zero flash at connector mating surfaces.

Military-grade electronics present even stricter demands. When producing EMI-shielded housings for satellite communication terminals, our molds achieve 0.005mm part-to-part consistency across 50,000-cycle runs. This stems from proprietary stress-relief protocols applied to H13 tool steel after hardening, preventing micron-level distortion during extended production. Such rigor stems from direct collaboration with Tier-1 defense contractors, where failure rates below 2 PPM are non-negotiable. The table below illustrates how our precision parameters exceed industry baselines for critical electronics applications.

| Parameter | Standard Industry Tolerance | Lead Precision Capability |

|---|---|---|

| Wall Thickness Variation | ±0.05mm | ±0.015mm |

| Part Flatness (100mm) | 0.05mm | 0.008mm |

| Core Pin Perpendicularity | 0.03mm/100mm | 0.005mm/100mm |

| Draft Angle Consistency | ±0.5° | ±0.1° |

| Gate Vestige Height | 0.10mm | 0.02mm |

These capabilities translate to reduced secondary operations and field failure rates. For a recent automotive radar module project, our precision molding eliminated post-mold machining of waveguide channels, cutting assembly time by 37%. In electronics manufacturing, where a single micron of flash can bridge 0.2mm pitch contacts, mold accuracy isn’t merely dimensional – it’s electrical reliability engineered at the source. Wuxi Lead Precision Machinery delivers this through metrology-grade tooling processes proven where failure is not an option.

Precision Specs & Tolerances

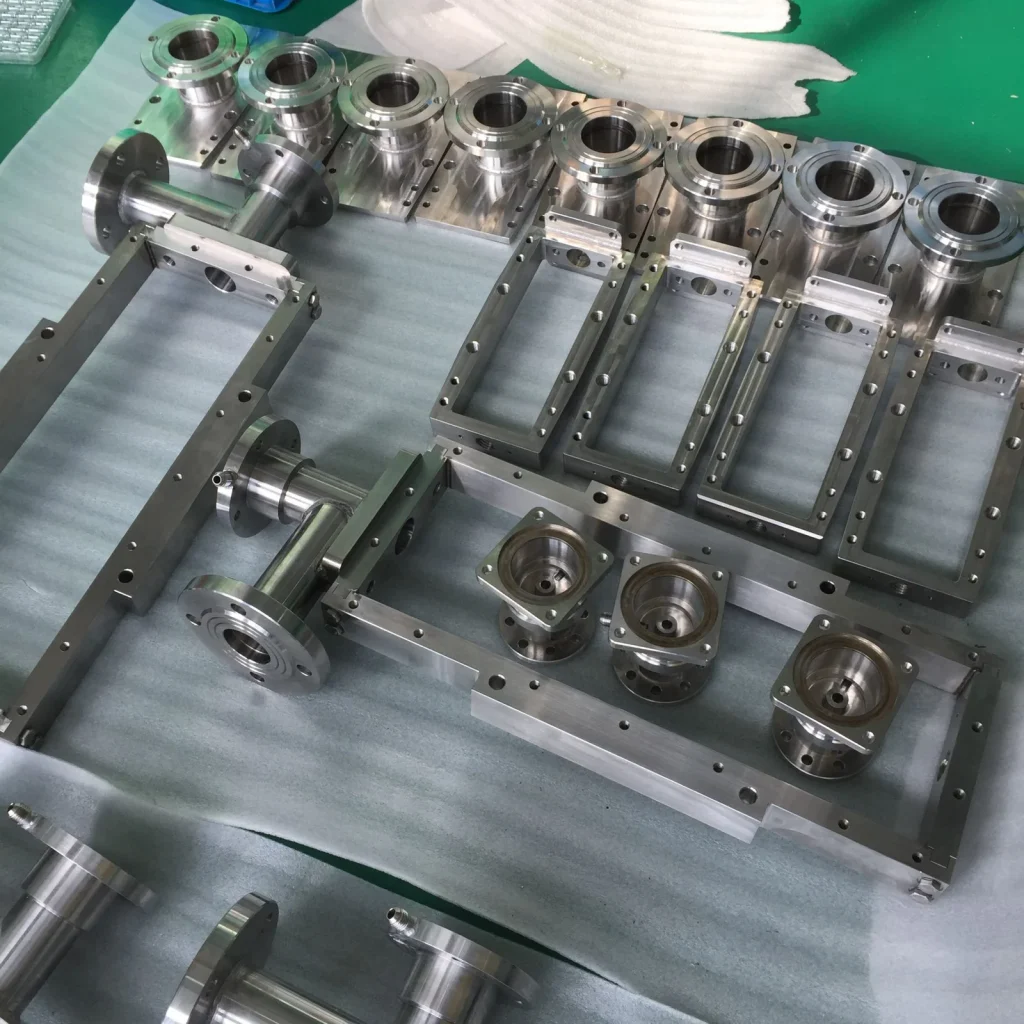

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions tailored specifically for the injection molding electronics sector, where precision, reliability, and repeatability are paramount. Our technical capabilities are engineered to meet the stringent demands of high-performance electronic components used in automotive, medical, industrial automation, and consumer electronics applications. At the core of our production infrastructure is a comprehensive suite of 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface integrity.

Our 5-axis CNC systems provide simultaneous multi-directional cutting, allowing for the precise fabrication of intricate mold cavities, core inserts, and housing components essential in electronic injection molding. This capability significantly reduces setup times, improves part consistency, and supports the production of highly integrated metal components with tight interfacial tolerances. The flexibility of 5-axis technology ensures that even the most challenging designs—such as thin-walled enclosures, heat-dissipating structures, and multi-cavity tooling—can be manufactured efficiently and to exacting standards.

Quality control is fully integrated into every phase of production. We employ state-of-the-art Coordinate Measuring Machine (CMM) inspection systems to verify dimensional accuracy and geometric conformity. These CMM systems operate with micron-level resolution, enabling full inspection of critical features such as hole positioning, flatness, parallelism, and contour fidelity. All inspection data is documented and traceable, supporting full compliance with ISO 9001 standards and customer-specific quality requirements.

Our in-house metrology lab ensures 100% inspection capability on critical features, with real-time feedback loops that allow for immediate process correction when necessary. This closed-loop quality assurance system minimizes deviations and ensures batch-to-batch consistency—essential for high-volume electronic component manufacturing.

The following table outlines our standard technical specifications and achievable tolerances across key manufacturing parameters:

| Parameter | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | Up to 300 mm |

| Hole Diameter | ±0.01 mm | ±0.005 mm | Reamed or honed |

| Positional Tolerance | ±0.01 mm | ±0.005 mm | GD&T compliant |

| Flatness | 0.02 mm | 0.01 mm | Over 100 mm² |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Machined finish |

| Angular Tolerance | ±0.05° | ±0.02° | 5-axis simultaneous |

| Thread Accuracy | 6H/6g | 5H/5g | Internal & external |

All components are manufactured using premium-grade tool steels, stainless steels, and aluminum alloys selected for thermal stability, wear resistance, and compatibility with injection molding processes. Wuxi Lead Precision Machinery combines technical excellence with scalable production capacity, ensuring that every component meets the rigorous demands of modern electronic systems integration.

Material & Finish Options

Material Selection for Precision Injection Molds in Electronics Manufacturing

Selecting the optimal mold material is critical for electronics injection molding, directly impacting part quality, production efficiency, and tool longevity. Electronics components demand exceptional dimensional stability, fine surface finishes, and resistance to wear from abrasive fillers common in engineering plastics. At Wuxi Lead Precision Machinery, we prioritize materials balancing thermal management, hardness, and machinability to meet stringent electronics industry requirements. The choice fundamentally depends on production volume, part geometry complexity, plastic resin characteristics, and required surface finish.

Aluminum alloys, particularly 6061-T6 and 7075-T6, excel in rapid prototyping and low-to-medium volume production. Their superior thermal conductivity significantly reduces cycle times compared to steel, crucial for thermally sensitive electronics housings. Aluminum machines quickly, lowering initial tooling costs. However, its lower hardness limits use with highly abrasive glass-filled resins or very high cavitation molds requiring extreme longevity. Steel remains the dominant choice for high-volume electronics manufacturing. Pre-hardened steels like P20 offer good machinability and adequate wear resistance for many applications. For demanding scenarios involving abrasive materials, tight tolerances, or extended production runs exceeding hundreds of thousands of cycles, tool steels such as H13 (hot work) or S136 (stainless) are essential. H13 provides excellent toughness and thermal fatigue resistance, while S136 offers superior corrosion resistance for molds processing PVC or other corrosive plastics common in connectors.

Titanium alloys, though less common due to cost and machining complexity, serve niche applications requiring exceptional strength-to-weight ratio and corrosion resistance, particularly for specialized internal mold components exposed to harsh environments. The following table summarizes key comparative properties:

| Material | Hardness (HRC) | Thermal Conductivity (W/mK) | Typical Use Case | Mold Life Expectancy (Cycles) |

|---|---|---|---|---|

| Aluminum 6061-T6 | 30-35 | 167 | Prototypes, Low/Med Volume, Simple Parts | 10,000 – 100,000 |

| P20 Steel | 28-32 | 28-36 | Med Volume, General Purpose Electronics | 100,000 – 500,000 |

| H13 Tool Steel | 48-52 | 28-36 | High Volume, Abrasive Resins, Complex | 500,000 – 1,000,000+ |

| S136 Stainless | 48-52 | 20-25 | Corrosive Resins (PVC), Medical Electronics | 300,000 – 800,000 |

| Titanium 6Al-4V | 36-41 | 6.7 | Specialized Corrosive/High-Stress Parts | Application Specific |

Anodizing is a vital secondary process, especially for aluminum molds. Hard anodizing creates a dense, wear-resistant ceramic layer significantly enhancing surface hardness (up to 60-70 HRC) and abrasion resistance. This is indispensable for ejector pins, cavities, and cores in aluminum molds running filled plastics, dramatically extending tool life and maintaining critical dimensions. It also improves release properties and provides excellent corrosion resistance. While primarily applied to aluminum, specialized anodizing processes can benefit certain steel components. Wuxi Lead Precision Machinery leverages deep material science expertise and advanced finishing capabilities to specify and apply the precise material and surface treatment solution, ensuring your electronics molds deliver consistent, high-quality output throughout their operational life. We rigorously evaluate your specific part geometry, resin, and production targets to recommend the optimal, cost-effective material strategy.

Manufacturing Process & QC

Design: Precision Engineering for Injection Molding Electronics

At Wuxi Lead Precision Machinery, the production process for custom metal components in injection molding electronics begins with comprehensive design engineering. Our team of senior CNC engineers collaborates closely with clients to translate functional requirements into manufacturable designs. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry, material selection, and thermal performance to ensure compatibility with high-speed injection molding environments. Special attention is given to mold flow dynamics, cooling channel integration, and ejection mechanisms to prevent warpage and internal stress in final assemblies. Design for manufacturability (DFM) reviews are conducted iteratively, ensuring every component meets tight tolerances and long-term reliability standards required in automotive, medical, and industrial electronics applications.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to precision prototyping using CNC milling and wire EDM technologies. These high-accuracy methods replicate production-grade conditions, allowing for functional testing of molds and metal inserts under real-world thermal and mechanical loads. Prototypes are subjected to rigorous metrology checks using coordinate measuring machines (CMM) and 3D scanning to validate dimensional accuracy within ±0.002 mm. This phase also includes mold trials with client-specified polymers to assess part ejection, gate sealing, and surface finish quality. Feedback from prototype testing is integrated into final design adjustments, minimizing risk during mass production. Our zero-defect philosophy demands that every prototype performs to specification before tooling release.

Mass Production: Consistency, Control, and Quality Assurance

With approved prototypes, we transition to full-scale production using automated CNC machining cells and in-process inspection systems. All metal components—such as mold cores, cavities, sliders, and precision inserts—are manufactured from high-grade tool steels or specialty alloys, heat-treated to HRC 48–52 for wear resistance. Each production run is monitored through Statistical Process Control (SPC), with real-time data logging for traceability. Parts undergo 100% visual inspection and batch sampling for hardness, surface roughness, and dimensional conformance. Our facility adheres to ISO 9001 and IATF 16949 standards, ensuring compliance with global quality benchmarks.

Production Specifications

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Roughness (Ra) | 0.1 µm to 0.4 µm (polished finishes available) |

| Materials | P20, H13, S136, 420SS, 17-4PH Stainless Steel |

| Heat Treatment | Up to HRC 52, vacuum hardened |

| Max Component Size | 800 mm × 600 mm × 500 mm |

| Production Capacity | 50–200 sets/month (mold components) |

| Quality Standards | ISO 9001, IATF 16949, RoHS compliant |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery delivers zero-defect metal solutions engineered for the demanding requirements of injection molding in advanced electronics manufacturing.

Why Choose Wuxi Lead Precision

Elevate Your Electronics Manufacturing Partnership

Wuxi Lead Precision Machinery stands as your strategic partner for mission-critical injection molding in electronics manufacturing. We specialize in transforming complex metal and hybrid component designs into high-integrity, production-ready solutions where precision, reliability, and material science converge. Our engineering-led approach ensures your electronic housings, connectors, shielding components, and precision inserts meet the exacting demands of modern devices—without compromise on tolerances, surface finish, or functional performance. With decades of focused expertise in custom metal manufacturing for global electronics OEMs and Tier 1 suppliers, we mitigate risk through rigorous Design for Manufacturability (DFM) analysis, advanced process validation, and seamless integration into your supply chain.

Our technical capabilities are engineered for the unique challenges of electronics applications. Below are core specifications defining our production excellence for metal injection molded (MIM) and precision-machined electronic components:

| Parameter | Specification | Relevance to Electronics Manufacturing |

|---|---|---|

| Tolerance Capability | ±0.005 mm (sub-5μm for critical features) | Ensures perfect fit for micro-connectors and sensor housings |

| Material Compatibility | 17-4PH, 316L, Fe-50Ni, Cu alloys, custom composites | Supports EMI shielding, thermal management, and biocompatibility |

| Surface Roughness (Ra) | 0.1–0.8 μm (polished to mirror finish) | Critical for sealing surfaces and aesthetic housings |

| Cleanroom Production | ISO Class 7 (10,000) and Class 8 (100,000) | Prevents contamination in medical/automotive electronics |

| Secondary Operations | CNC machining, laser welding, plating, EMI coating | Enables fully integrated, ready-to-assemble components |

| Quality Certification | ISO 9001, IATF 16949, ISO 13485 | Guarantees compliance for automotive, medical, and consumer electronics |

Partnering with Lead Precision means accessing a dedicated engineering team that operates as an extension of your R&D department. We proactively identify manufacturability hurdles during prototyping, optimize gate design to eliminate weld lines on cosmetic surfaces, and implement real-time in-process metrology to maintain zero-defect production. Our facility in Wuxi integrates 5-axis milling, multi-shot molding, and automated deburring to deliver components that consistently achieve Cpk >1.67—reducing your total cost of quality and accelerating time-to-market. For high-mix, low-volume electronics programs, our agile production cells ensure rapid changeovers without sacrificing precision.

Do not let substandard component performance undermine your product’s reliability. Contact our engineering team today to resolve your most complex injection molding challenges in electronics manufacturing. Send your technical specifications and project timeline to [email protected]. Our senior application engineers will respond within 24 hours with a detailed capability assessment and actionable DFM feedback—no obligation. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.