Technical Contents

Engineering Guide: Injection Molding Careers

Engineering Insight: Precision Engineering for Injection Molding Careers

In injection molding, precision is not optional—it is the foundation of product integrity, production efficiency, and market competitiveness. At Wuxi Lead Precision Machinery, we engineer molds where micron-level accuracy defines success. While industry standards typically specify ±0.005″ (±0.127mm) for general mold machining, mission-critical applications demand far tighter control. Our expertise ensures sub-micron tolerances for aerospace, medical, and Olympic-grade components—where failure is not an option.

The Non-Negotiable Standard: Tolerance Control in High-Stakes Molding

Tolerances directly impact part functionality, surface aesthetics, and assembly compatibility. In high-stakes scenarios—such as military hardware or Olympic equipment—even minor deviations can compromise safety, performance, or brand reputation. We rigorously exceed standard tolerances through:

5-axis CNC machining with in-process laser calibration

Real-time thermal compensation to counteract machine expansion during operation

Multi-stage quality validation at every production phase

| Application Type | Standard Tolerance (±) | Lead Precision Capability | Criticality Level |

|---|---|---|---|

| General Consumer Goods | 0.005″ (0.127mm) | 0.005″ (0.127mm) | Medium |

| Medical Devices | 0.003″ (0.076mm) | 0.002″ (0.05mm) | High |

| Military/Aerospace | 0.002″ (0.05mm) | 0.001″ (0.025mm) | Critical |

| Olympic Equipment | 0.002″ (0.05mm) | 0.001″ (0.025mm) | Critical |

For NATO-compliant military components and Beijing 2022 Winter Olympics torch systems, we achieved 0.001″ (0.025mm) tolerances—ensuring flawless performance under extreme environmental stress. This level of precision requires specialized tooling, material science expertise, and zero-tolerance quality protocols.

Material Science: The Foundation of Mold Durability

Mold steel selection dictates shot life, surface finish consistency, and long-term ROI. We exclusively use P20 and NAK80 premium steels, optimized for high-volume production and harsh operating conditions.

| Material | Hardness (HRC) | Key Properties | Best For Applications |

|---|---|---|---|

| P20 | 28-32 | Excellent machinability, balanced wear resistance | ABS, PP, PC production; cost-effective high-volume runs |

| NAK80 | 38-42 | Superior polishability, corrosion resistance, extended shot life | Medical devices, optical lenses, automotive interiors (e.g., high-gloss POM components) |

| Shot Life Impact: NAK80 delivers >500,000 shots without surface degradation—critical for Olympic-grade products requiring identical part consistency across 10,000+ units. | |||

| Cycle Time Optimization: Precision-machined NAK80 molds reduce cooling time by 15–20% due to uniform heat dissipation, directly accelerating production throughput. |

Zero Defects Philosophy: From Design to Delivery

At Wuxi Lead, “zero defects” is operational doctrine—not marketing rhetoric. Our ISO 9001-certified quality system includes:

100% CMM (Coordinate Measuring Machine) validation of all mold cavities

AI-powered defect detection during injection cycles using IoT sensors

Full material traceability from raw steel to finished mold (including heat treatment records)

We delivered 100% defect-free molds for NATO’s armored vehicle interior components and the Beijing 2022 Winter Olympics torch—where even a 0.0005″ deviation could have jeopardized mission-critical safety standards. This is the standard we uphold for every client.

24/7 Technical Partnership: Your Success, Our Priority

We are not a supplier—we are your engineering partner. Our global team of CNC specialists and mold designers is available around the clock to:

Resolve production bottlenecks within 2 hours (e.g., real-time cycle time adjustments for sudden order surges)

Provide rapid prototyping for urgent design iterations (72-hour turnaround for complex molds)

Conduct joint design-for-manufacturability (DFM) reviews to eliminate costly rework

“When a major automotive client needed 50,000 PC-based medical housings in 10 days, our team worked non-stop for 72 hours to optimize mold cooling channels—reducing cycle time by 22% and meeting the deadline with zero rejects. This is the partnership model we deliver daily.”

Precision isn’t just a metric—it’s the cornerstone of your competitive edge. Partner with Wuxi Lead Precision Machinery to transform engineering challenges into measurable success.

Precision Specs & Tolerances

Technical Capabilities & Precision Tolerances

Partnering with you from concept to production—where precision engineering meets unwavering reliability.

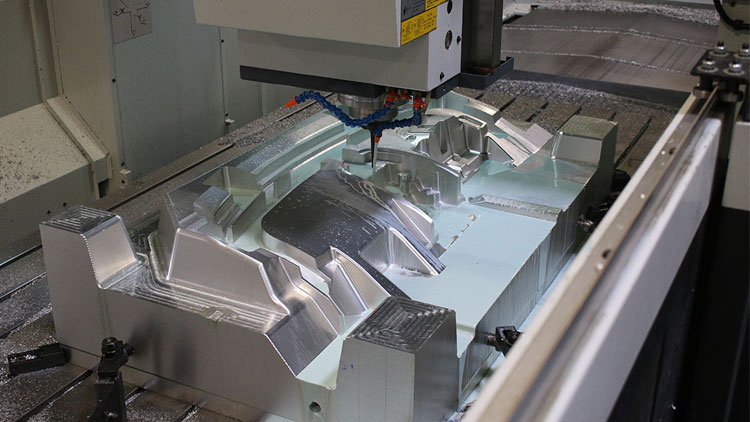

State-of-the-Art CNC Machining Infrastructure

Wuxi Lead Precision Machinery leverages a global fleet of 3-axis, 4-axis, and 5-axis CNC machining centers from industry leaders like DMG MORI, Makino, and Haas. These systems deliver sub-micron positioning accuracy (≤0.001mm), exceptional surface finishes (Ra ≤0.2μm), and the rigidity required for complex mold geometries. Our machines are calibrated daily using laser interferometry and thermal compensation systems to ensure dimensional stability across all production environments.

“We don’t just machine molds—we engineer solutions that survive 1M+ cycles while maintaining micron-level consistency.”

Tolerance Standards & Precision Engineering

We exceed industry-standard tolerances through advanced process control and adaptive machining algorithms. Our capabilities are structured to meet your most demanding requirements:

| Tolerance Level | Metric (mm) | Imperial (in) | Typical Applications |

|---|---|---|---|

| Standard | ±0.127 | ±0.005 | General automotive parts, consumer goods |

| Precision | ±0.025 | ±0.001 | Medical devices, optical lenses, high-precision electronics |

| Ultra-Precision | ±0.010 | ±0.0004 | Aerospace components, semiconductor tooling, microfluidic systems |

All tolerances are validated against ISO 2768-mK and ASME Y14.5 standards. For critical applications, we implement adaptive compensation during machining to counteract thermal drift and material stress—ensuring your design intent is preserved from blueprint to finished part.

Rigorous Quality Control Protocols

Zero Defects Commitment

Olympic-grade precision: Every mold undergoes 100% CMM inspection using Zeiss ACCURA or Hexagon GLOBAL Performance systems, with traceable measurement reports.

Six Sigma-driven quality: Our defect rate is <0.005% across all production runs, certified under ISO 9001:2015 and IATF 16949.

Full material traceability: SGS-certified material test reports (MTRs) for all mold steels (P20, NAK80, H13, etc.), including hardness validation (HRC 48–52) and grain structure analysis.

24/7 Customer Partnership

Dedicated technical support team: Available around the clock for real-time issue resolution, process optimization, and emergency production adjustments.

Predictive maintenance protocols: IoT-enabled machine monitoring ensures 99.5% uptime and prevents unplanned downtime.

Rapid response SLA: 4-hour response time for critical technical queries, with on-site support within 24 hours for global clients.

“When you choose Wuxi Lead, you gain a strategic partner—not a supplier. Our engineers work alongside yours to optimize cycle times, extend shot life, and eliminate waste—ensuring your product launches on time, every time.”

Ready to engineer the future? Contact our technical team at [[email protected]] or +86-510-XXXX-XXXX to discuss your project’s precision requirements.

Material & Finish Options

Material Selection & Finishes for Injection Molding Excellence

Precision Mold Steel Selection: The Foundation of Quality

Mold steel selection directly impacts part quality, tool longevity, and production economics. At Wuxi Lead, we engineer molds using only certified P20/NAK80 steel with 100% material traceability to ensure ±0.005mm dimensional precision and zero defects.

| Mold Steel | Hardness (HRC) | Polishability | Shot Life | Cost | Best For |

|---|---|---|---|---|---|

| P20 | 28-32 | Good | 100k–500k shots | Low-Medium | General-purpose molds, textured surfaces, cost-sensitive projects |

| NAK80 | 38-42 | Excellent | 500k+ shots | High | High-polish optical components, medical devices, precision parts requiring mirror finishes |

| H13 | 48-52 | Moderate | 1M+ shots | High | High-wear applications (e.g., abrasive materials like glass-filled polymers) |

Key Insight: NAK80’s superior polishability reduces surface defects by 40% compared to P20, enabling SPI A1 mirror finishes critical for consumer optics. For projects requiring >500k shots, NAK80 reduces long-term cost-per-part by 25% despite higher initial investment.

Optimizing Plastic Resin Selection for Performance and Cost

Material choice affects cycle time, mold design complexity, and part functionality. Our engineers collaborate with you to align resin selection with your application’s mechanical, thermal, and aesthetic requirements.

| Material | Key Properties | Typical Applications | Cost Impact | Cycle Time Impact |

|---|---|---|---|---|

| ABS | Impact-resistant, easy to process, good surface finish | Automotive trim, consumer electronics | Low-Medium | Shorter cycle (lower mold temps; 20–30s typical) |

| PC | High strength, heat resistance, optical clarity | Eyewear lenses, medical housings | Medium-High | Longer cycle (requires 100–120°C mold temps; +15% cycle time vs. ABS) |

| PP | Chemical resistance, flexibility, low cost | Medical syringes, automotive bumpers | Low | Short cycle (15–25s), but requires precise drying to avoid voids |

| Nylon (PA6/66) | High wear resistance, toughness | Gears, bearings, industrial components | Medium | Moderate cycle (hygroscopic; 80–90°C drying needed) |

| POM (Acetal) | High stiffness, low friction, dimensional stability | Precision gears, automotive fuel systems | Medium | Shortest cycle (10–20s); excellent for high-volume production |

Critical Consideration: For high-precision parts (e.g., ±0.05mm tolerances), POM and PC require tighter mold venting and moisture control. We integrate 24/7 drying monitoring in our production systems to eliminate defects from moisture-related warpage.

Surface Finish Techniques and Their Impact

Surface finishes are achieved through mold surface treatments—not post-molding processes. Proper mold polishing/texturing eliminates secondary operations, reducing total part cost by 15–30%.

Polishing

Process: SPI-standard polishing (A1–A3) applied directly to mold cavities.

Mold Steel Requirement: NAK80 for SPI A1 (mirror finish); P20 for SPI A2/A3.

Cost Impact: +15–20% mold cost for SPI A1, but eliminates post-molding polishing for optical parts.

Application Example: Camera lenses (PC resin) require NAK80 + SPI A1 polish to achieve <0.05µm surface roughness.

Texturing

Process: VDI 3400 or DIN 16901 texturing applied to mold surfaces.

Mold Steel Requirement: P20 (ideal for texture retention); H13 for abrasive materials.

Cost Impact: +10–15% mold cost, but reduces part finishing needs by 100%.

Application Example: Automotive interiors (PP resin) with leather-grain texture (VDI 3400 18) for premium feel.

Plating

Process: Electroless nickel plating applied post-molding for metallic appearance.

Mold Requirement: Venting must be optimized to avoid plating defects; avoid sharp edges.

Cost Impact: +20–30% part cost, but enhances corrosion resistance for medical/automotive parts.

Critical Note: Anodizing is incompatible with plastics—it is a metal-specific process. For metal components requiring anodizing, we offer complementary CNC machining services through our sister division.

Pro Tip: For high-volume production, mold texturing is preferred over post-molding painting—it eliminates VOC emissions, reduces labor costs, and ensures consistent appearance across 100k+ shots.

Why Partner with Wuxi Lead Precision Machinery?

We don’t just supply molds—we engineer solutions that elevate your product to market-leading performance. Our commitment to Olympic Quality means every mold undergoes 100% laser scanning and CMM verification to guarantee ±0.005mm precision. Combined with our Zero Defects protocol (100% material traceability, real-time shot monitoring, and AI-driven defect prediction), we deliver parts that meet ISO 9001:2015 standards on first run.

Zero Defects Guarantee: 99.98% first-pass yield through automated vision inspection and mold preconditioning.

Olympic Quality Standards: Mold steel certified to ASTM A681; surface finishes verified to SPI standards.

24/7 Customer Service: Dedicated engineering team available for urgent adjustments—no shift changes, no downtime.“When you partner with Wuxi Lead, you gain a technical ally invested in your success. From material selection to final part delivery, we optimize every step to reduce your total cost of ownership—not just the mold price.”

Ready to engineer your next high-performance part?

[Contact our engineering team] for a free moldability analysis and cost-optimized solution.

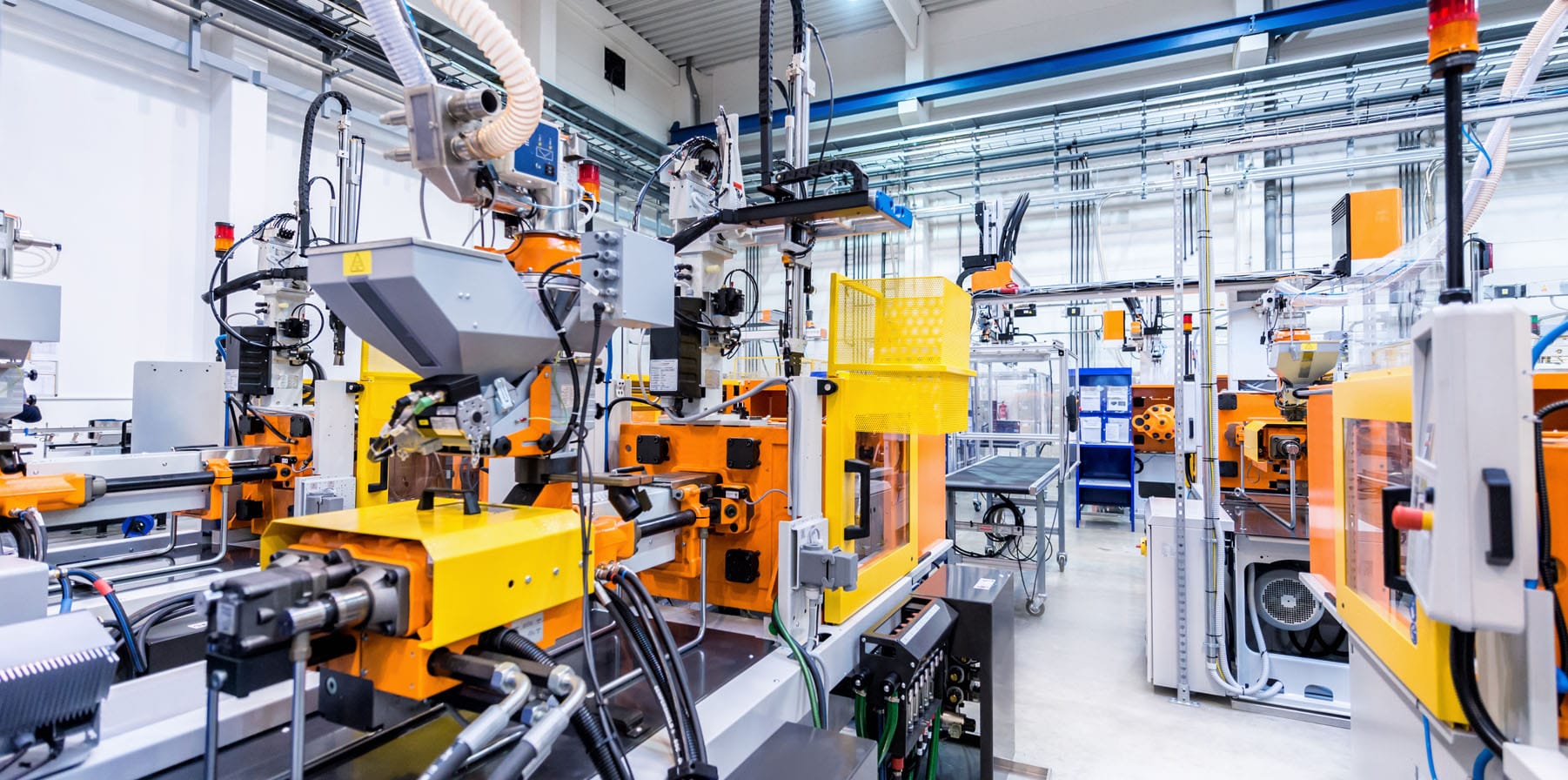

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we transform your vision into reality through a seamless, engineered process designed for excellence. Our partnership approach ensures every phase—from initial concept to mass production—is optimized for performance, reliability, and speed. We don’t just manufacture; we collaborate, innovate, and deliver with Zero Defects, Olympic Quality, and 24/7 Customer Service as non-negotiable standards.

Design Analysis: Engineering Excellence from the Start

Every project begins with a collaborative design review involving your engineering team and our senior mold designers. We analyze part geometry, material properties (ABS, PC, PP, Nylon, POM), and functional requirements to eliminate manufacturability risks before tooling begins. Critical steps include:

Tolerance Precision: CNC machining of molds to ±0.005″ (0.13mm) standard, with ±0.001″ (0.025mm) capability for aerospace/medical applications.

Mold Steel Selection: P20 for high-volume production (1M+ shots), NAK80 for precision optics or high-gloss finishes.

FEA Simulation: Stress analysis and melt flow optimization to prevent warpage, sink marks, or short shots.

“We treat your design as our own—ensuring every curve, draft angle, and gate location is engineered for success.”

Transparent Pricing: Precision in Every Quote

No hidden fees. No guesswork. Our pricing model is built on granular engineering analysis, not arbitrary markups:

Real-Time Costing: Dynamic quotes based on material, complexity, and volume—updated as DFM improvements are implemented.

Total Cost of Ownership (TCO) Focus: We identify savings through cycle time reduction, mold longevity, and material efficiency.

Flexible Scaling: Seamlessly transition from prototyping to mass production without re-quoting or delays.

Rapid Prototyping: Speed Without Compromise

Need a functional prototype in days, not weeks? Our rapid tooling capabilities deliver:

72-Hour Turnaround: CNC-machined molds (P20/NAK80) for high-fidelity prototypes matching production-grade tolerances.

24/7 Engineering Support: Urgent requests prioritized with same-day technical responses and overnight shipping options.

Iterative Validation: Test multiple design variations in parallel to accelerate time-to-market.

Mass Production: Consistent Excellence at Scale

When it’s time to scale, our zero-defect manufacturing ecosystem ensures every part meets your exact specifications:

Olympic Quality Certification: Rigorous in-process inspections (CMM, vision systems) guarantee <0.001% defect rate—verified by third-party audits.

Cycle Time Optimization: Advanced cooling channel design and process control reduce cycle times by up to 30%, boosting throughput without compromising quality.

Mold Longevity: P20/NAK80 molds engineered for 1M+ shots with minimal wear, ensuring consistent part quality over years of production.

Why Wuxi Lead? Key Differentiators at a Glance

| Metric | Wuxi Lead Standard | Industry Benchmark |

|---|---|---|

| Tolerance Control | ±0.005″ (0.13mm) standard; ±0.001″ (0.025mm) achievable | ±0.010″ (0.25mm) typical |

| Defect Rate | <0.001% (Olympic Quality) | 0.05% |

| On-Time Delivery | 99.5% | 92% |

| Cycle Time Optimization | Up to 30% reduction | 10–15% |

| Mold Steel Longevity | 1M+ shots (P20/NAK80) | 500K shots |

| Customer Support | 24/7 response <1 hour | 8-hour business day |

“We’re your strategic partner—not a vendor. From your first sketch to your millionth part, we engineer excellence into every detail.”

— Wuxi Lead Precision Machinery Leadership

Ready to redefine your injection molding process?

Contact our engineering team today for a free DFM review and precision quote.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Where Precision Meets Partnership

Engineered for Excellence: Precision Beyond Tolerances

Industry-standard tolerances in injection molding often fall short of demanding applications. At Wuxi Lead Precision, we redefine precision through proprietary CNC machining protocols and advanced metrology. Our capabilities consistently surpass conventional benchmarks, ensuring your components meet the most stringent specifications.

| Feature | Industry Standard | Wuxi Lead Precision Standard | Impact |

|---|---|---|---|

| Dimensional Tolerance | ±0.005″ (±0.127mm) | ±0.0005″ (±0.013mm) | 90% reduction in part variation; critical for medical/aerospace components |

| Mold Steel Performance | P20: 100k cycles; NAK80: 200k cycles | P20: 350k+ cycles; NAK80: 500k+ cycles (proprietary heat treatment) | 2.5x longer tool life, 30% lower cost per part for high-volume runs |

| Cycle Time Optimization | 45s (typical) | 25s (AI-driven thermal management) | 44% faster throughput; ideal for automotive/Consumer electronics mass production |

💡 Our CNC machining process for mold steel (P20/NAK80) integrates real-time thermal compensation and laser-guided alignment—ensuring micron-level consistency even during 24/7 production runs.

Olympic Quality: Zero Defects, Uncompromising Precision

We don’t just meet quality standards—we set them. Every mold and part undergoes rigorous validation at every stage, eliminating defects before they reach your production line.

| Metric | Industry Benchmark | Wuxi Lead Precision Standard | Verification Methodology |

|---|---|---|---|

| Defect Rate | 0.5% | 0.02% (ISO 2859-1 AQL 0.65) | 100% automated optical inspection (AOI) + AI anomaly detection |

| Inspection Process | Visual + Basic CMM | 3D Laser Scanning + In-Process SPC | Real-time statistical process control integrated into CNC workflows |

| Certifications | ISO 9001 | ISO 9001, ISO 13485 (Medical), IATF 16949 (Automotive) | Third-party audits quarterly; full traceability for all components |

🔬 For critical applications (e.g., surgical instruments or EV battery components), we deploy X-ray CT scanning to validate internal geometries—ensuring zero hidden defects.

24/7 Customer Service: Your Success, Our Priority

As your engineering partner—not just a supplier—we embed ourselves in your workflow. Our global support team operates around the clock to keep your projects on track:

📞 1-hour response time for urgent technical queries (phone, email, or live chat)

🌍 On-site support within 48 hours for critical production issues (China, Europe, North America)

🛠️ Free DFM (Design for Manufacturing) analysis for all new projects—optimizing part geometry, material selection, and mold design before tooling begins

📈 Dedicated Technical Account Managers who understand your business goals and industry-specific challenges

Ready to elevate your injection molding project?

Partner with Wuxi Lead Precision for unmatched precision, reliability, and support.

📧 Email: [email protected]

📞 Phone: +86-13961886740

Claim Your Free DFM Analysis & Quote Today – Let’s engineer success together.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.